Process Flow Analysis

Goldratt: Balance flow not capacity

8/24/04

Paul A. Jensen

Operations Research Models and Methods

Copyright 2004 - All rights reserved

Our Goal: For a single

product

Given: the process design

Given: operation time and scrap rates at

each operation

Given: product demand

Find: The flow in each operation and

the total time required for each

operation

2

To construct a model you must

know the process

The process is described by its

operations

R1

R1

R2

R2

R3

5

6

R3

3

1

2

7

4

8

A

3

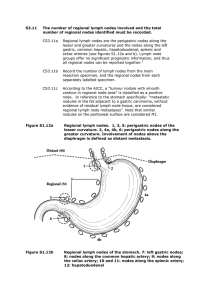

The process model admits

greater detail

R1

R3

R2

11

5

1

12

6

2

Raw Materials Inventory

Processing Operation

3

13

4

Inspection

14

8

Delay

15

9

16

10

7

17

18

19

20

Finished Goods Inventory

4

What happens to product

flows at junctions?

Do they assemble?

Do they combine?

Do they mix?

Do they disassemble?

Do they separate?

Do they split?

R3

R2

R1

5

6

3

1

2

7

4

8

5

“And” nodes model flows that

assemble

The flows are equal on all entering and

leaving arcs

Assembly

Disassembly

General Case

fi

A

fk

A

A

fh

fj

fh = fi = fj = fk

6

“Or” nodes model flows that

combine

The total flow in equals the total flow out

Combining Flows

Separating Flows

General Case

fi

O

O

fk

O

fh

fj

fi + fk = fh + fj

7

“Proportionality” nodes model

arbitrary combinations

Input and output proportions are given

Mixing

Splitting

1

0.4

pi

0.6

P

General Case

fi

0.5

fk

P

P

1

pk

0.5

ph f h

p

j

fj

f i = xp i , f k = xp k

f h = xp h , f j = xp j

8

All junction nodes must be

specified in a process chart

R3

R2

R1

5

6

3

1

2

A

7

4

O

8

9