Structural Analysis of Load Distribution within Single Cell Fuel Cell

advertisement

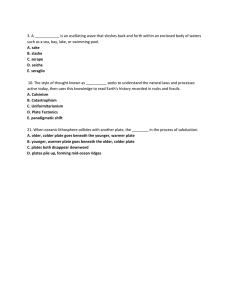

Structural Analysis of Load Distribution within Single Cell Fuel Cell by Eric J. O’Brien An Engineering Project Submitted to the Graduate Faculty of Rensselaer Polytechnic Institute in Partial Fulfillment of the Requirements for the degree of MASTER OF ENGINEERING IN MECHANICAL ENGINEERING Approved: _________________________________________ Ernesto Gutierrez-Miravete, Thesis Adviser Rensselaer Polytechnic Institute Hartford, Connecticut December, 2011 ii CONTENTS LIST OF SYMBOLS ........................................................................................................ iv LIST OF TABLES ............................................................................................................. v LIST OF FIGURES .......................................................................................................... vi ABSTRACT .................................................................................................................... vii 1. INTRODUCTION/BACKGROUND .................................................................... viii 2. THEORY/METHODOLOGY .................................................................................. x Stress Theory ............................................................................................................... x DOE methodology ...................................................................................................... xi Geometry ................................................................................................................... xii Materials ................................................................................................................... xiii 4. DISCUSSION .......................................................................................................... xxi 5. CONCLUSIONS .................................................................................................... xxii 1. Bibliography ........................................................................................................... xxiii APPENDICES ............................................................................................................. xxiv iii LIST OF SYMBOLS E = Modulus of Elasticity (GPa) ν = Poisson’s Ratio (-) ε = Strain (-) ω = Displacement (mm) σ = Normal Stress (GPa) τ = Shear Stress (GPa) G = Shear Modulus (GPa) p = Applied Load (N) M = Applied Moment (N*m) ρ = Density (kg/m^3) iv LIST OF TABLES Table 1: DOE factorial variables for analysis................................................................... xi Table 2: Material Properties........................................................................................ xiv v LIST OF FIGURES Figure 1 - How a fuel cell works .................................................................................... viii Figure 2: Geometry of the single cell ............................................................................. xiii Figure 3: Highlighted surfaces represent symmetry boundary conditions ...................... xv Figure 4 - Boundary load location on the pressure plate ................................................ xvi Figure 5: Mesh containing tetrahedrals and triangular prisms. ..................................... xvii Figure 6 - Side view of cell mesh .................................................................................. xvii Figure 8 - Stress plot of a cross section of the separator plate. .................................... xviii Figure 7 – Von Mises stress plot of the pressure plate ................................................... xix Figure 10: Case 1 ............................................................................................................. xx vi ABSTRACT A PEM fuel cell consists of the electrode assembly, separator plates to deliver the reactant gases, and pressure plates to load the system for sealing and conduction. Distribution of pressure on a fuel cell is crucial for maximum performance and durability. In general, low loads on a cell increases resistance and therefore reduces performance. High loads can create excessive stress on the cell membrane decreasing lifetime of the cell. This study evaluates the factors which affect the pressure on the cell assembly, within a single cell fuel cell. Using design of experiments 2 factorial methods, the factors will be optimized for minimum pressure distribution. vii 1. INTRODUCTION/BACKGROUND Fuel Cells utilize an electrochemical reaction between a fuel, usually hydrogen, and oxygen, typically from air to generate electricity. There are multiple types of fuel cells which have different benefits for different applications. These include Direct Methanol, Alkaline, Phosphoric Acid, Molten Carbonate, Solid Oxide and PEM fuel cells. The fuel cell type which will be evaluated in this paper is a Proton Exchange Membrane (PEM) fuel cell. Multiple cells can be stacked together into a Cell Stack Assembly. The area of each cell and the number of cells in the stack can be varied to meet specific operating conditions. Figure 1 - How a fuel cell works For a PEM fuel cell to function it needs to have an anode plate, a cathode plate, and an electrolyte. In addition to conducting electricity the anode and cathode plates, also known as separator plates, all have channels machined into them for the fuel and air to flow though. These flow channels allow for fuel and air to pass by the electrode assembly, which contains the electrolyte as well as gas diffusion layers (GDLs) which are located on either side of the electrode. viii Electricity is generated in the fuel cell when a fuel, pure hydrogen in the case of PEM fuel cells, flows over the anode side of the electrode assembly and air flows over the cathode side of the electrode assembly. When this occurs the hydrogen reacts with a catalyst in the electrode which causes positive ions to pass through the electrode membrane, while the negative ions create an electrical current to whatever it is powering. The positive ions then react with the oxygen in the air on the cathode side of cell to produce water. In between them is a membrane which has a GDL on each side. The performance of the fuel cell is dependent on the load of the GDL (1). Proper load distribution of the fuel cell is important for performance and durability. Fuel cell stacks with dozens of cells end up with relatively even distribution due to the ability for the pressures to equilibrate through the thickness of the cell stack. Single cell assemblies, as well as low power assemblies which have only a few cells, can have poor load distribution across the cell. The pressure within a given single cell has been proven to vary as much as 4x from the lowest pressure to the highest pressure even with different loads (1). The question ot be answered in this study is what variable of the design affect this ratio from the highest load to the lowest load. To apply load to the stack, there are stainless steel pressure plates on the either end of the assembly. Threaded tie rods are used to connect the two end plates and apply a compressive load to the cell stack. The manifolds for the stack design evaluated in this study are assumed to be external to the cells. Therefore there are no ports on the pressure plate. ix 2. THEORY/METHODOLOGY To ensure proper loading, optimization of the pressure plate and bipolar plate design is needed. The objective of this task is to evaluate the change in load distribution when changing the pressure plate structure, including the thickness, tie rod location, and aspect ratio. Using a constant pressure plate configuration, the pressure on the electrode assembly will be evaluated. The channel/rib ratio will be varied to analyze the effect on the electrode assembly. (Karvonen, Hottinen, Ihonen, & Uusalo, 2008) The model was analyzed in Comsol using the solid mechanics module. The geometry was originally modeled in Pro/Engineer and was then refined within Comsol such that the parametric features could be used within Comsol. Some simplifications will be made in order to keep the mesh of reasonable size, such as the number of channels in the bipolar plate. Minitab was used to develop a Design of Experiment series of runs each with 2 factors each. The results were evaluated for each of the cases required for the DOE analysis. The thru plane stress will be the main data point compared for each case. The overall deflection plot as well as other stresses will be examined when appropriate. The target goal will be to have the smallest range of stresses on the electrode assembly. Stress Theory Since the pressure plate holds most of the structure due to its material properties as well as its thickness relative to the separator plate. Therefore an estimation of the load within the cell can be calculated using plate theory with the pressure plate. It is assumed that there are no initial stresses on the materials from machining or material processing and all materials are assumed to be isotropic. Due to the relatively low temperature of a PEM fuel cell, which is usually less than 100C, the material properties are assumed to be the same as room temperature. There is also assumed to be no thermal stress in the system. The stress within the material is represented with the following equation: x x xy xz ij xy y yz zx zy z Since the system is in equilibrium the following equation applies: * 0 The stress-stain relationship: x E x Because there are simple and symmetric boundary conditions for this problem in Cartesian coordinates, the strip theory for plates can be applied to this problem. DOE methodology To generate the cases 4 parameters were changed. The Minitab software will be used to randomly generate a set of tests based on a 2 factorial DOE analysis. These cases will then be analyzed and the results entered back into Minitab. Minitab can then generate an optimized solution. Table 1: DOE factorial variables for analysis Run # 1 2 3 4 5 6 7 Pressure Plate Thickness (mm) 10 16 10 16 10 16 10 Load (kPa) 200 200 350 350 200 200 350 xi Aspect Ratio 2:1 2:1 2:1 2:1 3:1 3:1 3:1 Tie Rod Distance (mm) 0 30 30 0 30 0 0 8 16 350 3:1 30 The table above has the 8 runs which were analyzed. The pressure plate thickness is the thought thickness of the plate which was varied from 10mm to 16mm. The load is the pressure on the active area of the cell ranging from 200 kPa to 350 kPa. The aspect ratio of the cell varied from 2:1 to 3:1. The tie rod distance is the location of the tie rod from the edge of the active area of the cell. Geometry The geometry is a simplified representation of a fuel cell containing pressure plates, a fuel flow field plate, a fuel flow field plate and an electrode assembly. To reduce the number of elements needed to run the model was made as ¼ of the actual assembly. This is possible because the cell is symmetrical in both directions. Symmetry boundary conditions were used on the symmetrical interfaces. The gaskets within the flow field plates were ignored as they are only on the very edge of the plate and this study is focused on the lack of pressure within the center of the assembly. The cell stack is assumed to have external manifolds for the reactants and coolant flows. Therefore, there are no features on the pressure plates other than the holes for the tie rods. xii Figure 2: Geometry of the single cell The corner which transitions between the main part of the pressure plate and the flange had a large radius to account for the high local stresses in the part. Instead of removing the radius completely it was changed to a small block of material. This way it was able to be meshed with the rest of the structure. The hole for the tie rods were removed to create a simpler mesh and not create unrealistic stresses on the hole due to the coarse mesh in that area. Since that area was not of concern for this analysis the simplification of it was appropriate. Materials xiii Three different materials are included in the fuel cell. The pressure plate is made of stainless steel. For the purposes of this analysis the pressure plate is made from Type 316 stainless steel. The flow field plate is made from graphite. The UEA is also made from a fibrous graphite. The material properties are listed in table X. Table 2: Material Properties Material Density (g/cc) Young’s Modulus (Gpa) Poisson's Ratio Source 316 SS 7.92 193 .28 Efunda 1.5 10 .27 .9 10 .27 Graftech Graphite Plate UEA Graftech & NASA Graftech Boundary Conditions In order to simulate the entire cell while still maintaining a manageable model, the symmetry boundary condition was used on two sides of the cell. xiv Figure 3: Highlighted surfaces represent symmetry boundary conditions The load on the fuel cell is created by 4 tie rods that run between the pressure plates. The load from the tie rod is distributed onto the pressure plate through a washer. The load from this washer is added to circular surfaces on the pressure plate flanges. This load was scaled to a pressure such that the load on the circular area under the washer was equal to the load on the cell represented in the DOE table. xv Figure 4 - Boundary load location on the pressure plate Mesh The mesh is made up of triangular prism and quadrilateral elements. In order to mesh the separator plate with channels, a surface mesh of triangles was first created on the side of the plate. The triangular prisms were then swept through the plate. xvi Figure 5: Mesh containing tetrahedrals and triangular prisms. The same process of sweeping triangles was used for the all of the pressure plate, except for the pressure plate flanges. The flanges were made of quadrilateral elements which meshed properly with the triangular elements at the flanged end of the pressure plate. Figure 6 - Side view of cell mesh xvii 3. RESULTS The results below show how the pressure within the cell for each case of the DOE table. The main focus of results is the load distribution across the separator plate. Since the exact stresses on the UEA show some unrealistically high stresses due to the thinness of the geometry. Therefore a plane through the center of the separator plate was used to review the stress distribution across the cell. The place is showed in the plot below. The remaining plots of this plane will be 2D contour plots of this cross section. Figure 7 - Stress plot of a cross section of the separator plate. Since the cell is loaded by the tie rods in the majority of the stress is transferred through the corners of the pressure plate which is represented by the von mises stress plot below for case 1. Although only case 1 is shown below, the stress plot looks very similar for all cases although the values may scale up or down depending on the variables. xviii Figure 8 – Von Mises stress plot of the pressure plate Below are the cross sections of the separator plate detailed in the beginning of the results section. These results are of the Z component of stress which is through plane of the separator plate. Based on the plots below most of the load goes into the top corner of the cell in all cases, which is to be expected because the load is cantilevered off the end of the cell. xix Figure 9: Case 1 xx DISCUSSION xxi 4. CONCLUSIONS Due to the fact that the load in the middle of the cell is much less than the edge of the cell, the tie rod load should be moved as close to the active are of the fuel cell as possible. Also, the thicker the pressure plate is, the less deflection it will have and will therefore better distribute the load of the fuel cell. A fuel cell which has an aspect ratio closest to 1:1 will also have the best distribution of load for a given area size because it will have a maximized area for a given distance from tie rod load to the center of the cell. xxii 1. Bibliography 1. The effects of compression and gas diffusion layers on the performance of a PEM fuel cell. Woo-kum Lee, chien-Hsien Ho, J.W. Van Zee, Mahesh Murthy. 1999, Journal of Power Sources 84, pp. 45-51. 2. Modeling of Polymer Electrolyte Membrane Fuel Cell Stack End Plates. Karvonen, Suvi, et al., et al. 2008, Journal of Fuel Cell Science and Technology, pp. 041009-1 to 04009-9. 3. Analyses of the fuel cell stack assembly pressure. Lee, Shuo-Jen, Hsu, Chen-De and Huang, Ching-Han. 145, TaoYuan : Journal of Power Sources, 2005. 4. Stainless Steel AISI Type 316. efunda.com. [Online] http://www.efunda.com/Materials/alloys/stainless_steels/show_stainless.cfm?ID=AISI_ Type_316&prop=all&Page_Title=AISI%20Type%20316. (1) xxiii APPENDICES xxiv