23 Feb 2005 Raghav Sreenivasan Stanford University

advertisement

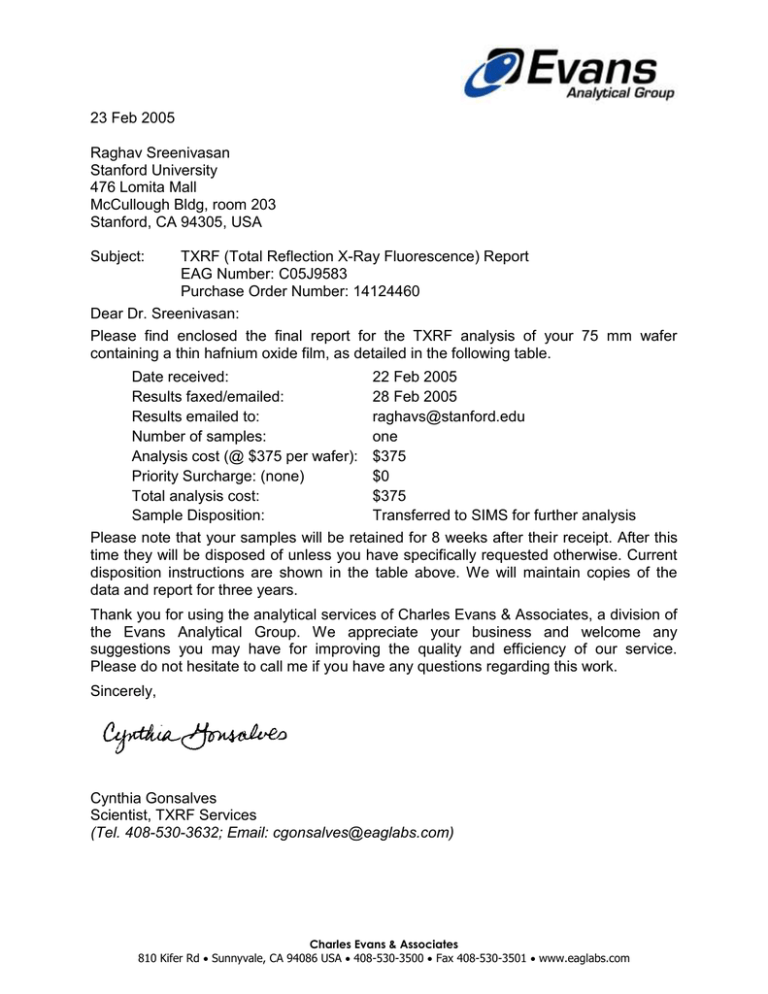

23 Feb 2005 Raghav Sreenivasan Stanford University 476 Lomita Mall McCullough Bldg, room 203 Stanford, CA 94305, USA Subject: TXRF (Total Reflection X-Ray Fluorescence) Report EAG Number: C05J9583 Purchase Order Number: 14124460 Dear Dr. Sreenivasan: Please find enclosed the final report for the TXRF analysis of your 75 mm wafer containing a thin hafnium oxide film, as detailed in the following table. Date received: 22 Feb 2005 Results faxed/emailed: 28 Feb 2005 Results emailed to: raghavs@stanford.edu Number of samples: one Analysis cost (@ $375 per wafer): $375 Priority Surcharge: (none) $0 Total analysis cost: $375 Sample Disposition: Transferred to SIMS for further analysis Please note that your samples will be retained for 8 weeks after their receipt. After this time they will be disposed of unless you have specifically requested otherwise. Current disposition instructions are shown in the table above. We will maintain copies of the data and report for three years. Thank you for using the analytical services of Charles Evans & Associates, a division of the Evans Analytical Group. We appreciate your business and welcome any suggestions you may have for improving the quality and efficiency of our service. Please do not hesitate to call me if you have any questions regarding this work. Sincerely, Cynthia Gonsalves Scientist, TXRF Services (Tel. 408-530-3632; Email: cgonsalves@eaglabs.com) Charles Evans & Associates 810 Kifer Rd Sunnyvale, CA 94086 USA 408-530-3500 Fax 408-530-3501 www.eaglabs.com TOTAL REFLECTION X-RAY FLUORESCENCE (TXRF) SURFACE ANALYSIS REPORT 23 Feb 2005 EAG NUMBER C05J9583 PO NUMBER 14124460 for Raghav Sreenivasan Stanford University 476 Lomita Mall McCullough Bldg, room 203 Stanford, CA 94305, USA Prepared by: ____________________________ Cynthia Gonsalves Scientist, TXRF Services (Tel. 408-530-3632; cgonsalves@eaglabs.com) Reviewed by: ____________________________ Lori Bisaha Scientist, TXRF, XRF, and SEM Services (Tel. 408-530-3614; lbisaha@cea.com) Charles Evans & Associates 810 Kifer Rd Sunnyvale, CA 94086 USA TEL 408-530-3500 FAX 408-530-3501 Charles Evans & Associates 810 Kifer Rd Sunnyvale, CA 94086 USA 408-530-3500 Fax 408-530-3501 www.eaglabs.com TOTAL REFLECTION X-RAY FLUORESCENCE (TXRF) SURFACE ANALYSIS REPORT Requester: EAG Number: Analysis Date: Raghav Sreenivasan C05J9583 23 Feb 2005 Purpose: The purpose of this analysis was to measure metal contamination on the surface of one 75 mm diameter wafer. This wafer has a 50Å hafnium oxide film on top of 20Å SiO2 on top of Si. The sample is identified by the description on the individual sample container. Summary: All results are shown in Table 1. Ca, Ti, and Fe are observed at all three locations; Cr is present at two out of three locations. Results will include contamination in the HfOx film and may also include some contamination at the SiO2 interface. Experimental: TXRF measurements were made using a TREX 610-T TXRF instrument. The following measurement conditions were used: Source: W rotating anode Beam Energy: 30 kV Beam Current: 50 mA Incident angle: 0.037 Integration time: 1000 seconds Measurements were made on the polished side of each wafer, at locations shown graphically on the data printouts and in the diagram below. Flat or Notch The analysis area is 10 mm in diameter, and analysis depth is ~50Å for polished silicon surfaces (using W primary beam). Analysis depth for this HfOx/SiO2/Si sample is not known. Analyses were performed with the sample in a nitrogen ambient at ~1 Torr. Charles Evans & Associates 810 Kifer Rd Sunnyvale, CA 94086 USA 408-530-3500 Fax 408-530-3501 www.eaglabs.com TXRF Analysis Report CEA Number C05J9583 Raghav Sreenivasan Stanford University Page 2 23 Feb 2005 Results and Discussion: Results are summarized in Table 1. Ca, Ti, and Fe are observed at all three locations; Cr is present at two out of three locations. At these levels in the spectra, identification and quantification of Ti is more uncertain due to possible diffraction artifacts that can occur at similar intensities in this region of the spectra. Identification and quantification of Cr and Mn are complicated by the high background/rising slope in this region and software subtraction of a Hf L escape peak near the Mn peak. Signal from the Hf in the film also interferes with measurement of several other species that are measured by TXRF on Si surfaces, as discussed below. The intense Hf peaks from Hf L-lines interfere with detection of Co, Ni and Cu due to overlap between the Hf L-peaks and the K-peaks for these elements. It is possible that Co may be present in these spectra. The software fitting of the Hf Ll line is improved if Co is included. However, unambiguous identification of Co is impossible due to the interference from the overlap of the Hf Ll peak with the Co K peak and the overlap of the Hf L peak with the Co K peak. Overlap of the Fe K and Hf Ll peak makes the quantification accuracy of Fe uncertain. The intense Hf M-lines interfere with measurement of S. The detection limits for other elements on this film are also higher than typically observed for a polished Si surface due to the higher background observed from the HfOx film and the reduced power of TXRF analysis necessary due to the intensity of the Hf fluorescence. The presence of the Hf M sum peak also increases the detection limits for K. The film thickness was given as 50 Å. The analysis depth for a polished Si surface using a W primary beam is ~50Å under normal power and angle conditions. The analysis depth for a Hafnium Oxide film under these reduced power and angle conditions is not known, but should be similar to or less than this (50Å). The analysis results here include the HfO x film, but may include contamination on the SiO2 interface below. It is not possible to sort out Si intensity in this data (in Si K-peaks) due to overlap of the Si K and the Hf M-peaks and the instrument software difficulties in fitting M-peaks. Quantification of TXRF data depends on the index of refraction at the surface of the sample. If the results include significant amount of the SiO2 interface, the quantification factors will be in error and the results overestimated. Other techniques might be useful in evaluation of thin hafnium oxide films. A wet chemical or vapor method may be useful for dissolving the film or leaching contamination from the surface. Jim Norberg (operations coordinator) would be the contact person to discuss analysis of this type. TOF-SIMS may also be used to look at this surface. The contact person to discuss this technique is Dr. Thomas Fister (manager, TOF-SIMS Analytical Services). Charles Evans & Associates 810 Kifer Rd Sunnyvale, CA 94086 USA 408-530-3500 Fax 408-530-3501 www.eaglabs.com Page 3 23 Feb 2005 TXRF Analysis Report EAG Number C05J9583 Raghav Sreenivasan Stanford University Table 1. TXRF Results for W source measurements (units of 1010 atoms/cm2). C05J9583 2/21/05 Hf 134 60 cyl Center 14,-14 -14,14 S Cl K Ca Ti Cr Mn Fe Ni Co Cu Zn Ar <2600 <1940 <6500 <380* <300* <860* <30 <30 <100* 140 76 160 30 33 63 34 18 <44 <21* <18* <43* 120 86 180 Int Int Int Int Int Int Int Int Int <7 <6 <11 <50 <40 <80 *may be present near detection limit Uncertainty values (±) reported are 1 standard deviations calculated from instrumental reproducibility and background signal-to-noise ratios. These numbers do not include uncertainties from interferences, if any. Practical detection limits (indicated by ‘<’) are calculated for each spectrum and may vary between analyses. Elements in the ranges S-Zn and Mo-Hf can be detected by W-source TXRF. If an element in this range is not reported in the table, it was not detected. X-ray lines for elements in the range Mo-Hf overlap X-ray lines for elements in the range S-Zn, making identification and/or quantification difficult if they are present at high levels. For example, it is not possible to distinguish S and Mo; what is reported as sulfur may be in part molybdenum. Correction factors: Corrections have been applied to Fe and Cu to compensate for detector background. Measurement locations: Locations are given in mm from the center of the wafer, assuming that the wafer is oriented with the notch at the bottom. Positive values are to the right and up, and negative values are left and/or down from the wafer center. ‘Int’ indicates interference. Charles Evans & Associates 810 Kifer Rd Sunnyvale, CA 94086 USA 408-530-3500 Fax 408-530-3501 www.eaglabs.com Page 4 23 Feb 2005 TXRF Analysis Report EAG Number C05J9583 Raghav Sreenivasan Stanford University Appendix A Brief Explanation of the Total Reflection X-Ray Fluorescence (TXRF) Technique Total Reflection X-Ray Fluorescence (TXRF) is a nondestructive method of analyzing flat, smooth samples. It is a survey technique, measuring a range of elements in a single analysis. primary beam detector wafer X-rays from a primary beam impinging on the surface of a flat, smooth sample at a low angle (less than the angle of total external reflection) excite impurity atoms on or near the surface of the sample. The excited atoms emit X-ray photons of characteristic energies which are detected and recorded by a large-area Si(Li) detector and the associated electronics. The photon energies are used to identify the elements present. The intensity of the X-ray fluorescence for each element is used to quantify the areal density of that atomic species. Reflection of the primary x-ray beam from the sample surface is maximized by use of mirror polished samples. Less penetration of the primary beam into the sample results in fewer excited matrix atoms and a proportionally larger number of photons from surface impurity atoms, leading in turn to enhanced detection capability. Analysis of rough surfaces such as wafer backsides, unpolished wafers, and patterned wafers, is possible however. Degradation of detection limits, accuracy, and precision of the analysis depend on the roughness of the sample. TXRF analysis is performed on unbroken full wafers from 100 to 300 mm in diameter. Smaller samples and partial wafers can be analyzed by mounting on carrier wafers. At Evans Analytical Group (EAG) laboratories, TXRF samples are handled and analyzed in a Class 10 environment to minimize chances of accidental contamination. The range of elements that can be analyzed in a single analysis depends on energy of the primary beam. TXRF instruments within the Evans Analytical Group use either a rotating W anode or a fine focus Mo X-ray tube, each with a monochromator, to produce and refine the primary X-ray beam. The two primary beams excite different ranges of elements: Tungsten source (W L) - sulfur through zinc, molybdenum through the lanthanide series Molybdenum source (Mo K) - gallium through bromine; tantalum through lead. Charles Evans & Associates 810 Kifer Rd Sunnyvale, CA 94086 USA 408-530-3500 Fax 408-530-3501 www.eaglabs.com Page 5 23 Feb 2005 TXRF Analysis Report EAG Number C05J9583 Raghav Sreenivasan Stanford University Appendix B Quantification, Detection Limits, Precision, and Accuracy QUANTIFICATION Quantification is based on the measurement of a reference sample with known areal density of impurity atoms on the surface. However, no universally accepted standards for TXRF quantification exist. Each laboratory must develop and provide its own reference wafers, which may lead to inter-laboratory discrepancies. Quantification for TXRF is based on measurement of one element (or several elements) present at a known areal density. Levels of all elements on the unknown sample are calculated using measured photon counts for each element on the unknown, photon counts for the standard element, and relative fluorescence yield factors for the different elements. Results can be quantified by extrapolation from measurement of a reference sample of known areal density, as long as the reference and the unknown are measured using the same instrument conditions. A separate reference sample for each element is not required because relative fluorescence yields are known. Signal response for a given element in TXRF analysis is sensitive to the way in which the element is distributed, as shown in Figure 1. As the glancing angle is changed, signal intensity varies by a factor of ~5 if the element is thinly plated on the surface, but remains constant within the range of angles normally used for analysis if the contamination is particulate or residue. If contamination is buried (e.g. an implanted layer), signal intensity will rise with increasing angle in a manner similar to the curve for plated contamination, but will not drop as sharply at higher angles. The matrix curve refers to signal response for the element(s) of the bulk material. Arbitrary Intensity Plated Residue Matrix 0 0.05 0.1 0.15 0.2 Glancing Angle (degrees) 0.25 0.3 0.35 Figure B-1. Schematic representation of signal intensity variation with glancing angle. Charles Evans & Associates 810 Kifer Rd Sunnyvale, CA 94086 USA 408-530-3500 Fax 408-530-3501 www.eaglabs.com Page 6 23 Feb 2005 TXRF Analysis Report EAG Number C05J9583 Raghav Sreenivasan Stanford University The EAG procedure is to assume that all contamination is present as a thin uniformly distributed plating on the sample surface unless otherwise stated in the Discussion section of the report. If contamination is present as particles greater than 0.1m diameter, as a thick residue, or as a buried layer, reported values will be high by an unspecified factor. DETECTION LIMITS Detection limits are variable, depending on element, sample surface, analysis conditions, and interferences. Interference free detection limits for first row transition metals (Fe, Ni, Cu) may be as low as 3E9 atoms/cm2. Sample roughness and interferences from other elements adversely affect detection limits. PRECISION AND ACCURACY Precision of TXRF measurement varies with the source, level of the element measured, and measurement conditions. Using EAG standard conditions, the precision on tungsten source TXRF measurements ranges from 1% at the 1X1015 atoms/cm2 level to ~100% at the levels near detection limit. Precision of repeat measurements on our SPC sample, which is vanadium at a level of 2x1013 atoms/cm2, is 16% over a period of more than six months. EAG TXRF instruments are calibrated to nickel contaminated wafers which have been verified by a Cr standard analyzed with HIBS. Uncertainty on the HIBS measurement is approximately 10%. Precision of molybdenum source repeat measurements on the SPC sample, vanadium at a level of 2X1013 atoms/cm2, is 17% over a period of more than six months. The molybdenum source is calibrated to a wafer with plated nickel contamination. The nickel level is taken from tungsten source TXRF measurement, and verified by measurement of a commercially available spin-coated reference wafer. Charles Evans & Associates 810 Kifer Rd Sunnyvale, CA 94086 USA 408-530-3500 Fax 408-530-3501 www.eaglabs.com Page 7 23 Feb 2005 TXRF Analysis Report EAG Number C05J9583 Raghav Sreenivasan Stanford University Appendix C The EAG TXRF Data Printout You will receive a data printout for each measurement made on your samples. Each printout consists of a listing of analysis identification and instrument conditions used for the measurement, graphical presentation of the data, and a data table. Analysis identification: file - name of data file stored on disk sample - sample name sub - substrate. Si Wafer or GaAs wafer memo 1 - company and name of client, EAG job identification number Analysis conditions: Slot - position in the special cassette into which samples are loaded for analysis M - measurement type (manual, programmed, angle scan, etc.) Size - wafer size in inches X: and Y: - analysis position measured in mm from wafer center Time - integration time for the analysis X-ray Voltage - anode operating voltage in kV X-ray Current - anode operating current in mA X-ray Target - anode material D.T.: - Dead time: percent of real time that detector does not accept new data Angle: - glancing angle at which measurement is made DP Cond: - Name of reference file used for data acquisition and processing Element Cond: - Name of reference file used for quantification Quant: - Name of reference file used for quantification Spectrum: The spectrum is a graph of fluorescence X-ray energy (from 1 to 10 keV for W primary beam or 1 to 18 keV for Mo primary beam) versus photon counts per second. For analysis of silicon wafers, the large peak at the low energy end of the spectrum is the silicon signal from the wafer substrate. High counts at the high energy end of the spectrum are due to scattered primary Xrays (W L or Mo K). Characteristic X-ray peaks of elements S through Zn (K) and Rb through Re (L) (W anode) or elements S through Br (K)and Rb through Bi (L) (Mo source) have energies between the silicon peak and the high-energy scatter. Quantitative Results: Spectrum: - symbol for the element and the name of the X-ray line used in calculation of areal density Energy keV - energy at which the line for that element appears on the spectrum Peak Int. cps - integrated counts per second for the identified peak Conc *E10 - uncorrected calculated areal density for the element, in units of 1010 atoms/cm2 Stand.Dev cps - standard deviation of counts per second in peak signal BG Int cps - background counts per second in peak region Charles Evans & Associates 810 Kifer Rd Sunnyvale, CA 94086 USA 408-530-3500 Fax 408-530-3501 www.eaglabs.com