The Multiplicative Impact Of Total Quality Management On The Bottom Line

advertisement

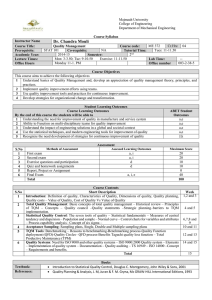

2007 Oxford Business & Economics Conference ISBN : 978-0-9742114-7-3 The Multiplicative Impact of Total Quality Management on the Bottom Line Dr. Jordi Fortuny-Santos, Universitat Politècnica de Catalunya, Manresa, Spain Dr. Jorge Olivella-Nadal, Universitat Politècnica de Catalunya, Castelldefels, Spain Dr. Josep Comajuncosa-Casabella, Universitat Politècnica de Catalunya, Manresa, Spain Dr. Lluís Cuatrecasas-Arbós, Universitat Politècnica de Catalunya, Barcelona, Spain ABSTRACT This paper aims to address the question whether or not Total Quality Management (TQM) has an impact on the performance of a company, especially in its profitability. To do so, literature has been reviewed to discover different approaches that lead to contradictory conclusions, due to the many exogenous elements that obscure economic results and the lack of commitment from top management, related to a lack of in-depth knowledge of quality management, that usually leads to failure. Therefore, companies considering taking the TQM way to improve their competitiveness through quality at low cost might feel confused and doubt about TQM’s effectiveness and impact on the bottom line. In spite of these previous studies, we are of the opinion that much more research into this area is needed before it is fully conceptualized. Our theoretical approach is based on Microeconomics and its results show the effects of TQM on the profit of a company: the unit cost decreases (and the price might also increase) and the total amount of units sold increases leading to a multiplicative combination that causes an improvement in gross margin. A case study shows how a company, on the basis of the costs of quality can prepare a strategic plan to improve quality, in accordance with the European EFQM quality scheme, involve employees and officers through a Hoshin Kanri deployment, and by means of small improvements -considered realistic by managers that were surveyed-, achieve an important increase in gross margin. INTRODUCTION One of the keys of competitiveness for current companies is to produce quality goods and services in an efficient way. Companies providing parts for the motor vehicle industry have been certified according to a quality assurance system, like ISO 9001:2000 and other specific standards to fulfill the clients’ requirements about the quality of manufactured parts. Years ago, and maybe even today in certain industries, there was an option between quality and cost: companies could bring to the market superior quality goods or services based on a higher production cost and a higher sales price or they could sell low quality goods or services, at a lower price (or not so low, for monopolies). Under current competition, companies only can sell perfect parts to the car manufacturers. Besides, vendors are liable for all damages that faulty parts can cause to the car assembler and even to the car buyer. Furthermore, car manufacturers usually ask their suppliers for a progressive reduction in the price of their parts from year to year. If part manufacturers are positively assessed by the car manufacturers (on quality, price, reliability and other aspects about the goodness of their organizations), they can reach the status of “preferred supplier” being eligible for new projects (which means an increase in sales). According to the rules above, to be competitive in this market, a company needs to be a leader in both quality and cost (Forker et al, 1996). It is to say, to achieve quality at a low cost, although it sounds paradoxical. Many studies (see Martinez-Lorente et al. (2000) and Heras et al. (2004) for thorough reviews) have reported that product quality is related to increased sales and profits (we consider the model developed by Bergman and Klefsjö (1994)). We are going to prove that these statements are truthful when we consider the costs of quality, developed by Crosby (1987), within the framework of Total Quality Management (TQM), from a microeconomic point of view in order to avoid the many interferences that empirical works have to face (and that are reviewed in this paper). Finally, a case study will show the possibilities of the model. June 24-26, 2007 Oxford University, UK 1 2007 Oxford Business & Economics Conference ISBN : 978-0-9742114-7-3 THE COSTS OF POOR QUALITY Juran (1951) was probably the first one to talk about the costs of quality around 1950. He provided the move from statistical Quality Control to Total Quality Control by raising the level of quality management from the shop floor to the whole organization and stressing the importance of holistic thinking, beginning with product design. Crosby (1987) classifies the costs of poor quality in prevention costs (cost incurred to prevent failures through activities like suppliers’ assessment, training, marketing research, maintenance, quality staff, consultancy fees and external audit fees, research and development…), appraisal costs (based on inspections, training, maintenance costs, research and development…) and failure costs (reworks, scrap). According to Campanella (1999), failure costs can be internal (cost of time and materials to correct mistakes before products are shipped, research cost, manufacturing cost of faulty products, low activity due to bad scheduling, lack of motivation that leads to mistakes, accidents and absenteeism) or external (costs to process complaints, returns, indemnities, due to the lack of quality that customers have found in the product and intangible costs due to the company’s image and the lost of current or future customers). These costs can be grouped in costs of quality (prevention and appraisal), related to the maintenance and improvement of the quality system, and costs of non-quality (failure cost). Most experts on the costs of poor quality estimate losses in the range of 20 to 30 percent of gross sales for defective or unsatisfactory products (Krajewsky and Ritzman, 1999). Camaleño (2006) quantifies them as a 13 to 18 percent of the total cost of the product. Once these costs are measured, a company can try to control and reduce them. By cutting the costs of poor quality, a company can increase its profit selling the same quantities, to the same customers and at the same price. Many times, senior management does not consider these costs, but the costs of poor quality are a powerful tool to detect where the problems hide and to measure the effect of the solutions implemented (Crosby, 1987). The aim of this research is to find how ISO 9001:2000-certified companies, that intend to implement a Total Quality management (TQM) system according to the EFQM model, can use the costs of poor quality to improve the quality of their products but also to improve the quality of their management. We also analyze the consequences of these activities on cost reduction (Flynn et al. 1994) and on sales figures (number of units sold and its price) as a proof that TQM entails two kinds of improvements on profits: an increase in the difference between price and cost due to an improvement in the costs of poor quality (Rust et al, 1995) and an increase in the amount of units sold (due to the attraction of new clients and the fall of complaints (Lee, 1998)) which are combined in a multiplicative way so the resulting improvement is much bigger than any of the factors by itself. We term it “the multiplicative effect of TQM”. TOTAL QUALITY MANAGEMENT Many companies ignore their quality costs maybe because they just hold an ISO 9001:2000 certificate to improve the company’s image or because their customers require this standard (Gotzamani and Tsiotras, 2002). Nevertheless, many others try to go beyond the simple certificate and then they, among many other activities, start measuring the costs of poor quality. The thousands of brochures requested to the European Foundation for Quality Management (EFQM) prove that also many companies use the nine criteria in the EFQM business excellence scheme as a system for self-assessment to establish a continuous improvement program. The EFQM scheme is a well renowned Total Quality Management model and its European Quality Award is similar to the Malcolm Baldrige National Quality Award (USA) or the Deming Award (Japan). EFQM’s nine criteria (enablers and results) -Leadership; People; Policy and strategy; Partnerships and resources; Processes; People results; Customer results; Society results; Key performance results- underpin main dimensions of TQM: Leadership and constancy of purpose; Customer orientation; Corporate social responsibility; People development and involvement (participation of everybody); Results orientation; Management by processes and facts; Continuous learning, innovation and improvement; Partnership development. June 24-26, 2007 Oxford University, UK 2 2007 Oxford Business & Economics Conference ISBN : 978-0-9742114-7-3 According to Feigenbaum (1961) and Ishikawa (1985), Total Quality Management (TQM) is the highest level of quality management. TQM is a concept made fashionable by Japanese companies in the last quarter of the Twentieth century. It could be described as an approach of eliminating errors that increase costs and reduce customer satisfaction (Hendricks and Singhal, 1999). Total Quality Management is a framework (a set of values, techniques and tools) that includes a quality assurance system but also the management of all processes and resources, with a strong top management commitment and the involvement of all the people in the company in continuous improvement activities (preventing mistakes and waste of time) striving after the clients’ satisfaction and strengthening brand image (Membrado, 1999). A comprehensive review on the critical dimensions and elements of TQM can be found in Lloréns et al. (2002). Many newspapers and magazines in the United States have considered that TQM was a management fad and now is dead (Hendricks and Singhal, 1999). Others contend that TQM is alive and kicking (Heras et al, 2004). Miller (1994) considers TQM a démodé term but points out that many companies benefit from continuous process improvement practices and techniques based on the TQM concept. Former ISO 9002:1994 certificate helped to improve the procedures, but it did not guarantee that the result was a satisfied customer (Singels et al, 2001). Current ISO 9001:2000 norm is considered a first approach to TQM because it refers to the concepts of customer satisfaction (based on measurable compromises), continuous improvement and a focus not on products but on processes. Therefore, it seems a good opportunity to start the TQM journey. More over, if the EFQM scheme brings guidelines for good management practices, they must lead to excellent results. It seems a good way to achieve quality at a low cost by cutting the hidden costs of non-quality and to increase the number of units sold by winning the clients’ loyalty, based on the company’s reliability. Nevertheless, does it work? The aim of this paper is to provide encouragement to companies that might be contemplating about adopting TQM but were discouraged by the controversy about its payoff. Deming (1986) stated that an improvement in quality leads to a reduction in costs and the consequent improvement in profits. According to many practitioner papers, companies are benefiting from TQM and the effects of a TQM framework on quality (number of defects) or manufacturing performance (by means of indicators like productivity or cycle time). Young (1985) reports the improvements achieved in Hewlett Packard over 5 years: Reduction in manufacturing costs (42 per cent), defects (60 per cent) inventories (64 per cent) and increase in productivity (91 per cent), profits (177 per cent) and market share (214 per cent). Dukes (2004) reports a 5 per cent reduction in the cost of quality over four years and a decrease of 66 per cent in the number of customer complaints in 2 to 3 years. However, many of these papers include self-reported data and, therefore, might be biased or they simply do not prove a cause-effect relation. In these studies, when an association between business performance improvement and best practice (TQM) is found, authors tend to infer causality to best practice but this may be unsound and bi-directional causation should be considered (Dick, 2004) (i.e. TQM does not mean higher profits but companies with higher profits tend to apply TQM). While many papers describe success stories about the benefits of quality management, ISO 9000 certification and TQM, others relate complete disasters. A survey (Miller, 1994) showed that 85 per cent of American managers thought that TQM had failed at their companies. A more recent survey (Dukes, 2004) showed that 82 per cent of manufacturing executives were skeptical about TQM’s benefits. Heras et al. (2004), in a rigorous empiric academic paper, could not demonstrate the relation between ISO 9000 and economic performance in Spanish companies (at first sight, certified companies were more profitable than the rest but, before certification, they already were!). The same happed in Denmark (Häversjö, 2000). Terziovski et al. (1999) also found, in Australia, that ISO 9000-certified firms did not perform significantly better than firms that were not certified. Bad results and disillusion can be due the lack of understanding of the concepts and principles of quality management (Terziovski et al, 1999); the impatience, asking for short-term payoffs and specially a fast bottom-line payback; the belief that gaining a certificate is synonymous with becoming a quality organization; the fact that many companies view TQM as a quick fix when it really is an attitude and they fail when they adapt TQM to their particular needs (Harari, 1997); and the fact that many companies started TQM as something they thought they could do but without being really committed to it - a nonnegotiable condition June 24-26, 2007 Oxford University, UK 3 2007 Oxford Business & Economics Conference ISBN : 978-0-9742114-7-3 according to W. Edwards Deming, one of the fathers of TQM, because it’s impossible to lead others without the right mindset- leaving the key principles of TQM (focus on customer satisfaction, employee involvement, continuous improvement) insincerely accepted and falsely practiced within the company. Of course, before one can attempt to measure the effects of TQM on a company, it is necessary to measure if TQM has really been implemented (Hackman and Wageman, 1995; McAdam and Bannister, 2001). A review of the literature about the critical factors of TQM that must be considered for an effective implementation can be found in Conca et al. (2004). Prior to quantify the impact of TQM on economic performance in a specific company, it is necessary to assess the goodness of TQM’s implementation in that company. Some researchers like Zhang (2000) or Fuentes and Hurtado (2002) have developed and validated scales to measure the outcome of TQM (including growth in profit, growth in sales, growth in market share, customer satisfaction, defect ratio, employee satisfaction, absenteeism, and so on) but it is always difficult to quantify the impact of TQM on the bottom-line because many organizational characteristics, that managers cannot always control, moderate the benefits of TQM: the bottom-line in the company’s accounting statement reflects a variety of components (Häversjö, 2000) such as success or failure of new products, production efficiency, marketing, logistics and overhead functions like accounting and administration that don’t seem affected by quality management policies. In addition, when a performance measure is two different companies is assigned the same name, the elements measuring the performance measure in the two companies may differ. Quality doesn’t directly affect directly the bottom-line, but by means of intermediate factors like client satisfaction, productivity or brand image, that, in turn, are affected by other factors (Fuentes and Hurtado, 2002). Moreover, a lot of other internal and external events coincide and coexist with TQM practices (Hackman and Wageman, 1995): if sales fall, is it because of a (bad) quality system or just a drop in clients’ sales?) Furthermore, when a company is preparing for an ISO certification or is starting a TQM experience, it will try to improve all the sources of inefficiency that may arise, so efficiency is expected to improve but not as a result of quality management. If we measure TQM performance over a short period of time in order to avoid disturbing interferences, it may not have developed its benefits –for example, Singels et al. (2001) state that an improvement in performance can only be experienced over a certain time after ISO certification and, according to our experience, TQM benefits they may take possibly 3 to 5 years to develop-; and the longer we wait, the more likely exogenous disturbances obscure TQM outcome. Prior studies (Helton, 1995; Power, 1995; Hendricks and Singhal, 1996 and 1997) show positive relationship between quality improvement programs and financial performance. Hendricks and Singhal (2001) identify changes in operating income associated with effective implementation of TQM in a sample of quality award winners. Hendricks and Singhal (2002) found, in a sample of 3000 quality award winning companies, that, in a five year post-award period (starting one year before and ending four years after the award), operating income for award winners increased by an average of 91 per cent compared to 43 per cent for similar firms (that had shown similar results in the pre-award period). Winners improved sales by 69 per cent (compared to 32 per cent for the control group). The return on sales improved by 8 per cent compared to no improvement for the benchmarks, and the return on assets improved by 9 per cent compared to 6 per cent for other companies. In Spain, Casadesús et al. (2001), Escanciano et al. (2001) and Casadesús and Karapetrovic (2005) found that ISO-certification led to benefits related to clients, staff, suppliers, environment, efficiency and profits, on condition that companies are really interested in quality management and willing to improve their quality. Tarí and Molina (2002) concluded (from a sample of 106 Spanish companies) that those companies that had a good quality management system had improved their profitability, and had improved the satisfaction of their clients and employees. Sila and Ebrahimpour (2005), using structural equations modeling as a strong method to test 23 hypotheses about the effects of leadership, strategic planning, customer focus, information and analysis, human resource management, process management and supplier management, just found 13 significant hypotheses and only leadership and process management had positive, direct effects on business results, while customer focus had no effect. June 24-26, 2007 Oxford University, UK 4 2007 Oxford Business & Economics Conference ISBN : 978-0-9742114-7-3 MICROECONOMIC APPROACH As there are many empirical difficulties to show the impact of TQM on the bottom line, we can analyze it from the point of view of Microeconomics, where the “ceteris paribus” condition applies (It means that the many factors that in real life affect the results, here remain unchanged so we can see the effect of the main variables that we are analyzing) (Wonnacott and Wonnacott, 1986). Let us assume that the U-shaped curve of the short-run average variable cost (AVC) of a factory can be represented by a parabolic function (Equation 1), where q is the number of units produced and sold and a is a positive constant. Then, Equation 2 represents total variable cost (TVC), and Equation 3 the short-run total cost (TC), being k the total fixed cost. Dividing Equation 3 by q, we get (Equation 4) the total average cost (AC). The derivative of Equation 3 with respect to q is the marginal cost (MC) (Equation 5). AVC a q 2 b q c VC q cv a q 3 b q 2 c q (1) TC a q b q c q k AC TC a q 2 b q c k q q MC dTC 3 a q 2 2 b q c dq (3) 3 (2) 2 (4) (5) Let us now consider that the company has a demand curve like Equation 6 where p is the net sale price. Then, total revenue (TR) will be expressed by Equation 7 and its derivative with respect to q, Equation 8, shows the marginal revenue (MR). v q q w w v TR p q v q q v q w 2v MR v q w pv w p v v 2 q w (6) (7) (8) If the company operates in its profit-maximizing quantity, then marginal revenue is equal to marginal cost (Equation 9) we get a quadratic equation, which can be solved, yielding the optimal number of units (q*) that the company has to manufacture (Equation 10). v 2 v q 3 a q2 2 b q c w (9) 2 v v q* b b 3 a c v 3a w w (10) Average profit (AP) (Equation 11) is the difference between average income (Equation 6) and average cost (Equation 4). If the company is operating in its profit-maximizing point, q can be substituted by its optimal value (Equation 10). If we multiply Equation 11 by q*, we get the total profit (P) (Equation 12) AP a q* 2 b v P a q* b v 3 q v c k q * (11) v c q* k (12) * w q *2 w Alternatively, if we do not consider the fixed cost k, then we get the average margin (AM) (Equation 13) and the total margin (TM) (Equation 14). Equations 11 to 14 can be expressed either as functions of the June 24-26, 2007 Oxford University, UK 5 2007 Oxford Business & Economics Conference ISBN : 978-0-9742114-7-3 quantity q* or functions of the market price p* because they are linked by Equation 6 (the demand curve). As, an example, Equation 15 is the total margin (TM) in terms of p. It can be seen that total margin is a certain proportion m(p) of the sales price (Equation 16). 2 w w AM p a q bq c p a w p* b w p* c v v 3 v 2 TM a q* b q* v c q* w * * 2 * * 3 (13) (14) 2 w v w w TM a w p* b w p* v c w p* v w v v * TM m p* p (15) (16) If the company is able to reduce the costs of non-quality, this shifts the cost curves down and Equations 1 to 5 become Equations 17, 18, 19, 20 and 21 (prime marks have been used). AVC a q 2 b q c (17) VC a q b q c q (18) 3 2 TC a q b q c q k k ATC a q 2 b q c q 3 2 MC 3 a q 2 2 b q c (19) (20) (21) Many times, real competition is termed imperfect competition, between the extreme models of perfect competition and monopoly. Companies are able to influence the price and cause a shift in their demand curves (and thus the quantity demanded may increase), by differentiating their products (in our example, this differentiation would be on the basis of a better quality and a better reliability) (Porter, 1985). Equations 6 to 8 would become 22, 23 and 24. v q w v TR v q q 2 w 2 v MR v q w p v (22) (23) (24) Equation 25 shows the new equilibrium point. v v b b 3 a c v w w q* 3 a 2 (25) Of course, the value of q’ can be viewed as a certain proportion (f) (greater that 1) of the current quantity q (Equation 26). q* f q* June 24-26, 2007 Oxford University, UK 6 (26) 2007 Oxford Business & Economics Conference ISBN : 978-0-9742114-7-3 The new expressions of profit and margin would be calculated as in Equations 11 to 16, always using a prime mark. The new total revenue (TR’), as in Equation 16, would be given as a proportion m’(p) of the current price p (not the expected price p’). If the company keeps producing q* and the demand remains stable, m’(p) would be larger that m costs decrease while the price remains the same. If the company shifts to the new equilibrium point and demand schedule remains stable, m’(p) would be smaller due to the positive slope of the average cost curve (the law of marginal diminishing returns) combined with the negative slope of the demand curve (related to its elasticity). If demand eventually increases and the company moves to the new equilibrium point, the value of m’(p) will depend on the elasticity of demand and on the magnitude of the shifts in cost and demand. Equation 27 shows the change in profits. 3 2 3 v v 2 a q* b q* v c q* k a q* b q* v c q* k TP TP w w P 3 2 v TP a q* b q* v c q* k w (27) Although Equation 27 is the exact effect of TQM on profits, the expression is not very clear because it depends on 12 parameters (a, b, c, k, v, w, a’, b’, c’, k’, v’ and w’) that shape the total cost curve and the demand curve and that can be found empirically. For an easier understanding, we could put the growth in margin (or in profit) as in Equation 28. Then we see that this growth relies on two factors. The first one (m’/m) is the improvement in margin over the current price due to cost reduction and shift in the demand curve. The second one (f) is the increase in quantity due to a shift in the demand curve. ATM TM TM AM q AM q m p f q m p q m f 1 TM AM q m pq m (28) Figure 1 shows the multiplicative effect on profits (dotted area) of a shift in cost and a shift in demand: as average cost is lower and demand is higher (meaning higher margins), the equilibrium point shifts to the right so the number of units sold increases. A higher amount of automotive parts is sold at a higher price. EFFECT OF A SHIFT IN DEMAND AND COST Cost and Revenue (Euro) Average Variable Cost Marginal Cost Marginal Revenue Total profit Average Revenue Average Variable Cost' Marginal Cost' Marginal Revenue' Average Revenue' Increase in profit Quantity (parts) Figure 1. Effect of a change in the equilibrium point and consequent total profit when cost curves (average cost and marginal cost) and demand curves (average revenue and marginal revenue) shift. June 24-26, 2007 Oxford University, UK 7 2007 Oxford Business & Economics Conference ISBN : 978-0-9742114-7-3 A CASE STUDY Now we can apply Equation 28 to a real company. This company, in the motor vehicle parts and accessories industry, has its major plant near Barcelona (Catalonia-Spain) producing parts for the nearby SEAT (Volkswagen) and Nissan car assembly plants. Its income and expenditure account shows that its revenue (for year 0) is 42.85 million euros. Variable costs are 35,91 million euros and fixed costs are 5,20 million euros, giving a profit before interests (0,33 million euros) and taxes of 1,74 million euros. This company has determined that the variable costs of non-quality are 0,81 million euros so the variable cost could be 35,10 million euros. Many times, the costs due to the lack of quality are evident: Clients charge our company the expensed and the losses that they experienced due to bad quality parts. As an example, once the company supplied a product without the necessary staples. The client had to check for a solution and find the necessary parts in its own warehouse. They charged our company 88,35 Euro (cost of Engineering) plus 88,35 Euro (warehouse labor) plus 75,13 Euro (administrative cost). Lets assume that this company has sold 720,050 homogeneous parts at an average price of 59,51 euros each. Therefore, the company needs a strategy based on quality management in order to reduce the costs of manufactured goods. This plant is certified pursuant to ISO 9001:2000 standard, which is very common in Spain (ISO, 2004), as well as other standards requested by clients in the automotive industry (VDA 6.1, QS9000 and ISO TS 16949:1999) and even according to standards like ISO 14001:1996 about environmental compliance to respond to the expectations of the society and OHSAS 18001:1999 about occupational health and safety. The quality system states that the long-term mission of the company is to consolidate its growth, measured through financial performance indicators like return on investment (ROI) and net profit. The way to reach this aim is by means of new product development, satisfying customer needs and expectations based on quality, ensuring the customer’s loyalty. Guidelines for the European Excellence Award are used as a system for self-assessment to establish a continuous improvement program, although the company does not compete for the award. The relations between strategic planning, including its activities and performance indicators, and the nine EFQM criteria are depicted in Figure 2. The nine boxes in the picture are the nine EFQM criteria (enablers and results) and the contents of each box refers to the values, tools and techniques that this company uses to measure, preserve and improve every facet of its quality system. People * Training * Empowerment * Involvement Leadership * Commitment to quality * Communication * Training Policy and strategy * Updated plans Partnerships and resources * Early manufacturing Processes * Designed according to quality standards (ISO 9001:2000) * Number defective parts People results * Absenteeism * Kaizen activities/group * Turnover * Satisfaction surveys Customer results * SPC/FMEA/QFD Key performance results * R+D * Clients' requirements * Continuous improvement * The tools of quality * Complaints * Returns * Loyalty * Logistic indicators (distribution) * ROI * Net profit * Gross margin * Costs of poor quality * Sales (in physical units and in €) * Unit margin * Environmental compliance *Safety and health indicators * Satisfaction surveys * Sales Society results involvement with clients and suppliers * Environmental compliance *Safety and health indicators Figure 2. EFQM criteria and activities / indicators used in our research to develop a plan to increase profit as a combination of sales and margin. Source: Fortuny and Comajuncosa (2004). In this company, TQM, more than a set of organizational practices, is the heart of the company culture (Prajoso and McDermott, 2005). As Barney (1986) states “organizational culture is a source of sustained competitive advantage” and consequently TQM implementation is aligned with strategy, competitive environment and goals. TQM helps in developing strategic plans and it is used as a basis to implement the strategic plans. Therefore, to improve quality by means of the TQM tools (Hackman and Wageman, 1995), the June 24-26, 2007 Oxford University, UK 8 2007 Oxford Business & Economics Conference ISBN : 978-0-9742114-7-3 company develops annual policies, according to the long-term mission, reaching everyone in the company. Change management is based on the Hoshin Kanri (Policy Deployment) approach which clearly defines the organization purpose and establishes realistic goals and objectives in accordance with the mission in a defined time frame within the organization’s capacity for implementation; communicates those goals and objectives to the organization’s constituents in search of total involvement; focuses on key priorities and provides a base to measure progress (Akao, 1991). In order to cut the costs of poor quality (Rust et al, 1995), senior management announces the following measures, that intend to preserve the mission of the company and state specific goals for every area in the company: To quantify the following targets, and make them be as likely-looking as possible to make sure they wouldn’t be rejected as untruthful by managers and employees, we conducted a small survey and a Delphi study on 18 ISO-certified companies in the same industry in central Catalonia (Fortuny and Cuatrecasas (2003), some of them using the EFQM framework and even competing for the award (Revista de Qualitat, 1999), to measure the effect of Total Quality on defects, costs and expected improvements. The questions in the survey tried to find how much would a company save improving each one of the items. Gathering empirical data, a conservative credible model was created. (i) Improvement in external quality: The company strives to be considered a preferred supplier by their customers. On average, surveyed companies agree that it is possible to reduce complaints and product returns in a 50% in three years (from an initial 2% to a final 1% of total sales in this company). To fulfill this objective, the quality department will analyze all complaints (according to ISO 9001:2000). In this ongoing improvement, different tools can be used like histograms, Pareto Charts or Fishbone diagrams. They help to determine what are the sources of poor quality and what are the possible solutions (these three are the most used in surveyed companies). Half the problems are due to mistakes in packaging and distribution. The other half is due to lack of product quality. These returns account for 1% of total cost, which would be saved. (ii) Improvement in internal quality: It is necessary to decrease the number of defective parts by 50% (from current 2% to targeted 1%) in three years. Processes must be analyzed in search for the sources of variation following the Deming Wheel (Plan-Do-Check-Act). Different techniques can be used, from statistic process control (SPC) to potential failure mode and effect analyzes (FMEA), benchmarking or quality function deployment (QFD). Employee involvement is vital to guarantee the continuous improvement through small group improvement activities or individual suggestions (kaizen). That can save around 1% of total costs (including the introduction of new prevention and appraisal costs). (iii) Improvement in people development (work-force management): The top-down approach of TQM begins with the top management commitment to quality. Their constancy and leadership must transmit the idea that quality is not a fashion but a permanent culture. Department managers, foremen and blue collar employees must get involved in this culture. Kaizen programs must help to improve quality. A better motivation can be measured through a decrease in absenteeism. Surveyed managers agree that absenteeism figures can drop from 4% to 3% (that means a 25% reduction). (iv) Improvement in sales: As auto parts show an elastic demand (absolute price elasticity is around 1.5), the sales department agrees that an increase in product quality, along with the development of new products, can bring an annual increase in sales figures of around 5%. (15% in a three year horizon). The announced improvement in people development cannot skip the sales force because high-motivated people are necessary to raise sales (sales force must be motivated to reach the 5 % annual increase). Discounts based on poor quality (discounts on price given to force to accept poor quality or bad service) will not be so necessary due to the better quality so they are supposed to be reduced and that means an increase of 1% on the net sales price. (v) Results: The prior analysis of quality costs shows that unit profit margin on sales price can raise from 15% to 18% in three years (that means an annual increase of 20%). Working with motivated people and improving quality day by day, productivity will increase and it will be possible to increase annual production around 15%. The percentage increase in total margin (TM) over the three-year period is calculated, using Equation 28, in Equation 29. It means that in three years, if nothing else changes, the profit of the plant will be a 38 per cent higher. June 24-26, 2007 Oxford University, UK 9 2007 Oxford Business & Economics Conference TM ISBN : 978-0-9742114-7-3 0,18 1,15 q p 0,15 q p 0.18 1.15 1 0.38 0,15 q p 0.15 (29) These results are fully compatible with those achieved in real experiences. A 1988 McKinsey survey (De Meyer and Wittenberg-Cox, 1994) on 230 European companies showed that, if TQM principles are well applied, unit margins can rise by 17 per cent and variable costs can drop a 35 per cent. CONCLUSIONS There is a vast literature about TQM and its expected effects. Beyond potentially biased studies and empirical works unable to prove a cause-effect relations, it is always difficult to confirm statistically whether company results are due to TQM programs or not because there are a lot of environmental exogenous disturbances and organizational characteristics that affect the bottom line. Besides, bad results attributed to TQM seem to be caused by impatience (TQM needs some years to pay off) or ignorance. Sometimes, so-called TQM programs might not be TQM at all because of the lack of all the TQM values. Nevertheless, the effects of quality policies, if any, lead to continuous improvement in products and processes and that brings a reduction in the number of customer complaints and a decrease in costs of poor quality. And nowadays, that is a vital strategy for companies in many industries. It may be difficult to measure the effect of TQM on profit and to estimate what would be the profit without TQM but it’s possible to know how much does a company save in hidden costs -that affect the final results- as a result of quality management. Unfortunately, only few companies control their quality costs and it is necessary to measure them in order to make plans to reduce them. However, in some industries the costs of poor quality (or at least some of them) are evident because the customer bills the supplier for all the expenses (and even lost sales) that faulty parts cause. As the empirical effects of TQM on the bottom line are difficult to measure, we propose a theoretical approach based on Microeconomics. Using real empirical data, the average cost curve and the demand schedule of a company can be drawn. If we subtract the costs of poor quality and we consider the magnitude of a possible shift in demand that better quality can bring, we get the effect on profits caused by better quality, under the ceteris paribus assumption. It means that this result is what the company can expect and must strive for, although real results might be different due to many other variables. A brief case study showed how a company, when it realizes that the cost of poor quality must be reduced, can use our microeconomic model to prepare an improvement plan on the basis of TQM, namely the EFQM excellence model and the Hoshin Kanri (Policy Deployment) approach, in order to involve everyone in the company. Enablers and results show where to improve, using what techniques and how to measure it. Besides the focus on customer satisfaction (which leads to loyalty), TQM pays great attention to people in the company. TQM does not consider quality the responsibility for quality department but a matter of everyone in the organization. TQM models like EFQM and accountancy of poor quality costs allow managers to prepare improvement plans that reach everyone in the company and their effects on financial indicators can be estimated. All managers interviewed in this research agree with the idea that TQM improves the company performance even though ratios as decrease in defective parts or decrease in absenteeism strongly vary from one company to another and even it their names are the same, they might be calculated in a different way from company to company. In these circumstances, a Delphi study is the best solution to reach a conservative consensus about the intensity that improvements can be possible. Proposed values in internal quality, external quality, absenteeism, production and sales can be seen as small but they are considered realistic because some companies consider it difficult to achieve greater goals. The consequences of quality on sales have been considered: the unit cost tend to decrease as poor quality costs are cut while that the total amount of units sold tends to increases due to customer preferences on reliable companies. As a final consequence, the net effect of TQM on gross margin (or profit) increase is June 24-26, 2007 Oxford University, UK 10 2007 Oxford Business & Economics Conference ISBN : 978-0-9742114-7-3 important even though it is based on small improvements because their effects (increase in market share and return on sales) are combined in a multiplicative way. REFERENCES Akao, Y. (1991). Hoshin Kanri: Policy deployment for successful TQM. Cambridge: Productivity Press. Barney, J.B. (196). Organisational culture: Can it be a source of sustained competitive advantage?. Academy of management review, 11 (3), 656-665. Bergman, B., and Klefsjö, B. (1994). Quality: From customer needs to customer satisfaction. London: McGraw Hill. Page 38. Camaleño Simón, M. C. (2006). Los costes de calidad y de no calidad. Compras y existencias, 145(July-August), 14-24. Campanella, J. (1999). Principios de los costes de la calidad. Madrid: Ediciones Díaz de Santos. Casadesús, M. and Karapetrovic, S. (2005). Has ISO 9000 lost some of its lustre? A longitudinal impact study. International journal of operations & production management, 25 (6), 580-596. Casadesús, M., Gimenez, G and Heras, I. (2001). Benefits of ISO 9000 implementation in Spanish industry. European Business Review, 13, 327-336. Conca, F. J., Llopis, J., and Tarí, J. J. (2004). Development of a mesure to assess quality management in certified firms. European Journal of Operational Research, 156, 683-697. Crosby, P. B. (1987). Quality is free. The art of making quality certain. New York: McGraw-Hill. Deming, W. E. (1986). Out of the crisis. Cambridge: MIT Press. De Meyer, A., and Wittenberg-Cox, A. (1994). Nuevo enfoque de la función de producción. Calidad y flexibilidad. Barcelona: Editorial Folio. Page 37. Dick, G. (2004). Best practice and performance improvement: towards a bi-directional theory of causation. In: Operations management as a change agent. Proceedings of the 11th EurOMA Annual Conference, Vol.II. INSEAD (France), 153-162. Dukes, R. (2004). Go ask Alice: Entering TQM Wonderland. The Illinois Manufacturer Magazine. Fall, accessed November, 10, 2006, [available at http://www.ima-net.org/publications/curpubs/fall03/cover.html]. Escanciano, C., Fernandez, E., and Vazquez, C. (2001). ISO 9000 certification and quality management in Spain: results of a national survey. The TQM Magazine, 13(3), 192-200. Feigenbaum, A. V. (1961). Total Quality Control. New York: McGraw-Hill. Flynn, B. B., Schroeder, R.G., and Sakakibara, S. (1994). A framework for quality management research and an associated measurement instrument. Journal of Operations Management, 11 (4), 339-366. Forker, L. B., Vickery, S. K., and Dröge, C. L. M. (1996). The contribution of quality to business performance. International Journal of Quality Science, 16(8), 44-62. Fortuny-Santos, J and Cuatrecasas, L (2003). How to increase machine efficiency in a TQM company under new ISO 9000:2000. In: Proceedings of the 7th International Research/Expert Conference ”Trends in the Development of Machinery and Associated Technology”. Neum (Bosnia & Herzegovina), 631-634. Fortuny-Santos, J., and Comajuncosa-Casabella, J. (2004). The multiplicative effect of TQM. In: Proceedings of the 8th International Research/Expert Conference ”Trends in the Development of Machinery and Associated Technology”. Lloret de Mar (Spain). Fuentes Fuentes, M. M. and Hurtado Torres, N. E. (2002). Variables críticas en la medición del desempeño en empresas con implantación de la gestión de la calidad total. Investigaciones europeas de dirección y economía de la empresa, 8 (2), 87-102. Gotzamani, K. D., and Tsiotras, G. D. (2002). The true motives behind ISO 9000 certification. Their effect on the overall certification benefits and long term contribution towards TQM. International Journal of Quality & Reliability Management , 19 (2), 151-169. Hackman, J. R., and Wageman, R. (1995). Total quality management: Empirical, conceptual and practical issues. Administrative Science Quarterly, 40 (2), 309-343. Harari, O. (1997). Ten Reasons TQM Doesn’t Work. Management Review, 86 (1), 38-44. Häversjö, T. (2000). The financial effect of ISO 9000 registration for Danish companies. Managerial audition journal, 15 (1-2), 47-52. Helton, R. B.(1995). The Baldie play. Quality progress, 28 (2), 43-45. Hendricks, K.B., and Singhal, V. R. (1996). Quality Award and the Market Value of the Firm: An Empirical Investigation. Management Science, 42 (3), 415-436. Hendricks, K. B., Singhal, V. R. (1997). Does Implementing an Effective TQM Program Actually Improve Operating Performance? Empirical Evidence From Firms that Have Won Quality Awards. Management Science, 43 (9), 1258-1274. Hendricks, K. B., and Singhal, V. R. (1999). Don’t count TQM out. Quality progress, 32 (4), 35-42. Hendricks, K. B., Singhal, V. R. (2001). Firm characteristics, total quality management, and financial performance. Journal of Operations Management, 19 (3), 269-286. Hendricks, K. B., Singhal, V. R. (2002). TQM Significantly boost bottom line. EFQM Excellence One Magazine, May 10. Heras Saizarbitoria, I., Casadesús Fa, M., and Marimon Viadiu, F. (2004). Incidencia de la certificación ISO 9000 en el rendimiento económico empresarial, Cuadernos de Economia y Dirección de la Empresa, 18, 173-190. Ishikawa, K. (1985). What is total quality control. The Japanese Way. New York: Prentice Hall. ISO (2004) The ISO survey of ISO 9001:2000 and ISO 14001 certificates - 2003. Geneve: ISO Central Secretariat. Page 15. accessed November, 10, 2006,[available at http://www.iso.org]. Juran, J.M. (1951). Quality Control Handbook. New York: McGraw-Hill. Krajewsky, L.J., and Ritzman, L.P. (1999). Operations management. Strategy and analysis. Reading: Addison Wesley Longman. Lee, T.Y. (1998). The development of ISO 9000 certification and the future of quality management. International journal of quality & reliability management, 15 (2), 162-177. Lloréns Montes, F.J., Molina Fernández, L.M., and Fuentes Fuentes, M.M. (2002). Calidad Total: Una investigación comparativa atendiendo a la dimension empresarial, Investigaciones europeas de dirección y economía de la empresa, 8 (2), 118-131. McAdam, R., and Bannister, A. (2001). Business performance measuring and change management within a TQM framework, International Journal of Operations & Production Management, 21(1-2), 88-107. Martínez-Lorente, A R., Dewhurst, F. W. and Gallego-Rodríguez, A. (2000) Relating TQM, marketing and business performance: an exploratory study, International Journal of Production Research, 38 (14), 3227-3246. Membrado, J. (1999). La gestión empresarial a través del modelo europeo de excelencia empresarial. Madrid: Ediciones Diaz de Santos. Miller, C. (1994). TQM out; “Continuous process improvement” in, Marketing news 28 (10), 5 –7, September 9. Porter, M. E. (1985). Competitive Advantage. Creating and Sustaining Superior Performance. New York: The Free Press (McMillan, Inc.). Power, T.C. (1995). Total quality management as competitive advantage: A review and empirical study, Strategic Management Journal, 16(1),15-37. June 24-26, 2007 Oxford University, UK 11 2007 Oxford Business & Economics Conference ISBN : 978-0-9742114-7-3 Prajoso, D.I. and McDermott, C.M. (2005). The relationship between total quality management practices and organizational culture. International journal of operations and production management, 25 (11), 1101-1122. Revista de Qualitat (1999). Experiència. Fundería Condals, una empresa amb deu “propietaris” responsables de la producció, Revista de Qualitat, 33, 15-17. Rust, R.T., Zahorik, A.J. and Keiningham, T.L. (1995). Return on quality (ROQ): Making service quality financially accountable. Journal of marketing, 59, 58-70. Sila, I. and Ebrahimpour, M (2005). Critical linkages among TQM factors and business results. International journal of operations & production management, 25 (11), 1123-1155. Singels, J., Ruel, G. and Van de Water, H. (2001). ISO 9000 series: certification and performance, International Journal of Quality & Reliability Management, 18(1), 62-75. Tarí, J.J. and Molina, J.F. (2002). Quality management results in ISO 9000 certified Spanish firms. The TQM Magazine, 14 (4), 232-239. Terziovski, M., Sohal, A., and Moss, S. (1999). Longitudinal analysis of quality management practices in Australian Organizations, Total Quality Management, August 1, 10 (6), 915-926. Wonnacott, P., and Wonnacott, R. (1986). Economics. New York: McGraw-Hill. Page 58. Young, J.A. (1985). The quality focus at Hewlett-Packard, The journal of business strategy, 5 (3), 6-9. Zhang, Z. (2000). Developing a model of quality management methods and evaluating their effects on business performance. Total Quality Management, 11 (1), 129-137. June 24-26, 2007 Oxford University, UK 12