GM_CH06_CIA.ppt

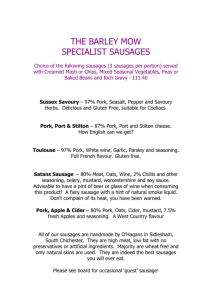

advertisement

Chapter 6 Sausage Chapter 6 Objectives Understand the role of sausages in culinary history Identify necessary ingredients for sausages Explain the importance of proper equipment selection, care and use in making sausages Classify various types of sausage Discuss fermented sausages and their manufacture Describe the process of making basic grind sausages Contrast the basic process with the procedure for emulsion sausages Recognize the value of testing Distinguish suitable garnishes for sausages Clarify the various types of sausage shaping options and preparation methods for each type The History of Sausage The word sausage comes from the Latin word “salsus” meaning “salted.” The earliest sausages were created in ancient Rome and Greece. Roman soldiers traveled with sausages and introduced sausages to other parts of Europe. By the Middle Ages, regional forms of sausage began to evolve into definite and unique forms all over Europe. Sausage Ingredients Sausages are made by grinding raw meats with salt and spices. This mixture is then stuffed into natural or synthetic casings. The first casings were made from intestines, stomachs and other animal parts. Main Ingredient Generally, sausage is made from tougher cuts of meat from the leg or the shoulder. The more exercised the muscle, the more highly developed the flavor. Meats for sausage should be trimmed and cut into dice or strips. When pork liver is called for in a sausage recipe, cut it into cubes before grinding. The seasonings or cure mix are tossed together with the meat before grinding. Main Ingredient Sausages in this chapter are made from: Pork Veal Lamb Beef Venison Pheasant Chicken Turkey Certified Pork Certified pork is pork that has been treated in a way that destroys the pathogens responsible for trichinosis. Pork sausages that undergo lengthy smoking or drying procedures but aren’t cooked must be made with certified pork. Preparing Certified Pork Minimum Temperature 5°F/10ºC Minimum Freezing and Holding Time 20 days -10°F/-23ºC 12 days -20°F/-29ºC 6 days Pack pork in containers to a depth of 6 inches. Fat 25 – 30% fat is preferred average in a sausage. Fat used in contemporary forcemeats: Pork jowl fat Pork fatback Heavy cream Seasonings and Cure Mixes Salt (ordinary table, kosher or sea salt) Sausages that will be cold or dry smoke must have nitrate or a nitrite-nitrate combination (like Prague Powder II). Hot-smoked and fresh sausages do not require nitrite. Sweeteners are added to mellow the sausage’s flavor and make the finished product moister. Spices Spices are added as whole toasted seeds, ground or in special blends like: Quatre épices Pâté spice Herbs Sausage formulas often call for dried herbs. Fresh herbs may be substituted for dry herbs. As a general rule, you will need about two to three times more fresh herbs compared to dried herbs. Aromatics Many aromatic ingredients may be added to sausage recipes including: Vegetables (usually cooked, added when cooled) Wines Citrus zest Prepared sauces (Tabasco and Worcestershire) Powdered onions and garlic Stock Vinegars (too much acid can give finished sausage a grainy texture) Equipment Selection, Care and Use Equipment: Electric meat grinders Food processors Choppers Mixers Sausage stuffers Equipment Selection, Care and Use 1) 2) 3) 4) 5) Use the following guidelines: Make sure equipment is in excellent condition. Make sure equipment is scrupulously clean before setting to work. Chill any part of the machine that comes into direct contact with the sausage ingredients. Choose the right tool for the job. Assemble the grinder correctly. Progressive Grinding The meat and/or fat is ground through a succession of increasingly smaller plates. Progressive grinding gives a fine, even texture to the forcemeat. Makes it easier for the grinder to process the meat down to a fine grind. The meat and/or fat should be near 28° to 30°F so that the meat grinds properly. Basic Grind Sausage Sausages have a medium to coarse texture. When left loose they are referred to as bulk sausages. These sausages are made with the basic grind method: Fresh sausages Cooked sausages Smoked and dried sausages that are later air-dried Basic Grind Sausage 1) 2) 3) Method: Grind chilled and diced meats, as well as other ingredients as required by recipe, to the desired texture (meats should be 28°F to 30°F). Mix the ground sausage meat(s) on speed 1 for 1 minute, then on second speed for 15 to 30 seconds, or until it becomes homogenous. The sausage mixture is now ready to test, garnish, and shape. Dry and Semi-Dry Fermented Sausages Fermented sausages have a tangy flavor because of the lactic acid that is produced during fermentation. Examples of semi-dry sausages are summer sausages, Lebanon bologna, and cervalats. One of the most well-known dry sausages is salami. Typically made of: Beef or pork Water (60 to 70% of the weight of the meat) Salt Curing agents such as nitrate and nitrite Sugars such as dextrose and sucrose Dry and Semi-Dry Fermented Sausages It is vital to inhibit or eliminate the growth of bacteria that can cause spoilage. When grinding, it is essential to keep the meat cold: 28°F – 30°F and the fat 5°F – 10°F. After grinding, the only step left is to stuff and smoke the sausage if desired. While they age, keep the sausages in an environment that is climate controlled. It is crucial to maintain a proper humidity level. Dry and Semi-Dry Fermented Sausages The fermentation during the drying process produces lactic and acetic acid which lower the pH level to between 4.6 and 5.2 for semidry sausages and to a pH level between 5.0 and 5.3 for dry sausages. Semi-dry sausages may lose 15% of their original weight as they age. Dry sausage could lose up to 30%. The finished product should be brightly colored, have a slight yeast flavor, and a smooth, slightly chewy texture Emulsion Sausages Made from a basic mixture referred to as 5-4-3 forcemeat, which reflects the ratio of ingredients: 5 parts trimmed raw meat to 4 parts fat (pork jowl fat) to 3 parts water (in the form of ice) by weight. Emulsion Sausages 1) 2) 3) 4) 5) Method: Cure the meat and then grind through the fine die. Grind the chilled fatback through the fine grinder die. Chop together the ground meat and crushed ice and process until the temperature drops to below 30°F / -1°C. Add the ground fat to the meat when the temperature reaches 40°F. Add the nonfat dry milk (and any remaining seasonings) when the temperature reaches between 45°F/7ºC and 50°F/10ºC. Continue to process the forcemeat until it reaches 58°F / 14°C. Emulsion Sausages Testing the emulsion forcemeat: Wrap a 1-ounce portion of the forcemeat in plastic wrap and poach it to the appropriate internal temperature (145°F/63°C for fish, 150°F/66°C for pork, beef, veal, lamb, and game, and 165°F/74°C for any item including poultry and poultry liver). Taste and check for flavor, seasoning, and consistency. Garnishing Garnish items are diced and added to the forcemeat after it has been tested and adjusted. Examples of garnishes are: Cheeses Vegetables Cured or smoked meats Nuts Dried fruits Sausage Shaping Loose or bulk: solid log in plastic wrap Made into patties Sausages in casings: Natural: are made from the intestines and stomach of sheep, hogs, and cattle Synthetic: made from a variety of food-grade materials (including collagen, plastic, paper, and wood pulp), some edible and some not See casing charts on page xxx of book for natural casing sizes, lengths and capacities. Preparing Natural Casings 1) 2) 3) Method: Rewind the casings and store covered in salt. Lay out the casings and remove any knots. Form into bundles of the required length. Before using the casings, rinse them thoroughly in tepid water, forcing the water through the casing to flush out the salt. Cut the casing into lengths if necessary (consult specific recipes) and tie a bubble knot in one end of the casing. Stuffing the Casing 1) 2) 3) Method using a sausage stuffing machine: Assemble and fill the sausage stuffer properly. Be sure that all parts of the sausage stuffer that will come in contact with the forcemeat are clean and chilled. Fill the stuffer with the sausage meat, tamping it down well to remove any air pockets. Press the sausage into the prepared casing. Gather the open end of the casing over the nozzle of the sausage stuffer. Press the sausage into the casing. Twist or tie the sausage into the appropriate shape.