Formal Design Review

advertisement

Eelectric

Energy Harvesting

Through Piezoelectric Polymers

Formal Design Review

Don Jenket, II

Kathy Li

Peter Stone

Presentation Overview

Project Goals

Choice of Materials

Choice of Processing Techniques

Device Architecture

Future Tests

Revised Timeline

March 11, 2004

Eelectric

Formal Design Review

Objective

DARPA Objective: Convert mechanical energy

from a fluid medium into electrical energy.

Fluid flow creates oscillations in an eel body

Creates strain energy that is converted to AC

electrical output by piezoelectric polymers

AC output is stored and/or utilized

3.082 Objective: Harness enough power from

air flow to operate a L.E.D.

March 11, 2004

Eelectric

Formal Design Review

PVDFPoly(vinylidene

fluoride)

F

H

C

C

F

H

n

Properties

Chemically

Inert

Flexible

High

Mechanical Strength

Production

React

HF and methylchloroform in a refrigerant gas

Polymerization from emulsion or suspension by free radical

vinyl polymerization

References: http://www.psrc.usm.edu/macrog/pvdf.htm, Accessed on: 3-9-04; Piezoelectric SOLEF PVDF Films. K-Tech Corp., 1993.

March 11, 2004

Eelectric

Formal Design Review

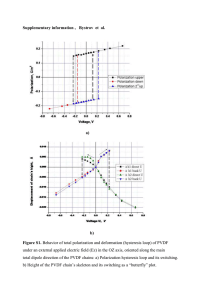

Piezoelectric PVDF

Molecular Origin

Fluorine atoms draw electronic density away from carbon

and towards themselves

Leads to strong dipoles in C-F bonds

Piezoelectric Model of PVDF (Davis 1978)

Piezoelectric activity based upon dipole orientation within

crystalline phase of polymer

Need a polar crystal form for permanent polarization

a-phase (antiparallel dipoles)

b-phase

(piezoelectric)

Reference: Davis, G.T., Mckinney, J.E., Broadhurst, M.G., Roth, S.C. Electric-filed-induced phase changes in poly(vinylidene fluoride). Journal of Applied Physics

49(10), October, 1978.

March 11, 2004

Eelectric

Formal Design Review

Piezoelectric PVDF

Poled by the Bauer Process

Biaxially stretch film: Orients some crystallites with their

polar axis normal to the film

Application of a strong electric field across the thickness of

the film coordinates polarity

Produces high volume fractions of b-phase crystallites

uniformly throughout the poled material

Selected Properties of 40 mm thick bioriented PVDF

Electromechanic coupling factor

0.11

Young’s Modulus

~2,500 MPa

Melting Point

175º C

Depoling Temperature

90º C

Table courtesy of K-Tech Corporation

Reference: Piezoelectric SOLEF PVDF Films. K-Tech Corp., 1993.

March 11, 2004

Eelectric

Formal Design Review

Tensile Testing of PVDF

Clamp

Rubber

PVDF

Cross-sectional Area of the

Film Tested: 1 cm X 40

microns = 4 X 10-7 m2

Measured strain: .063

Force at .063 strain: 3.95

lbs.

E = s e-1

Elastic Modulus Calculated:

2.56 GPa

March 11, 2004

Eelectric

Formal Design Review

Electrodes and Wires

Desired Properties

Electrodes

High Conductivity

Flexibility

Won’t oxidize

Wires

Ease of Attachment

Flexibility

The Process

Attach Electrodes using RF Magnetron Sputtering

Sputter 40 nm thick Gold electrodes on sample

Attach 3 mil copper wire with silver paste

March 11, 2004

Eelectric

Formal Design Review

Schematic of Sputtering

Sample Holder

Rotates

Sample Holder;

Sample faces down

Vacuum Pump

Load-Lock Chamber

Load-Lock Arm

Vacuum Pump

Main

Chamber

Sputter Guns

Adapted From: Twisselmann, Douglas J. The Origins of Substrate-Topography-Induced Magnetic Anisotropy in Sputered Cobalt Alloy Films. MIT Doctoral Thesis, February, 2001

March 11, 2004

Eelectric

Formal Design Review

Sputtering Apparatus

Sample Holder

Load-Lock

Chamber

Vacuum Pump

March 11, 2004

Main Chamber

Eelectric

Formal Design Review

Sputtering Target

March 11, 2004

Eelectric

Formal Design Review

“Eel Tail” Schematic

6-10 cm

2 cm

Top View

Cu Wire

Gold Electrode

Cu Wire

0.04 mm

Silver paste

6-10 cm

2 cm

Side View

March 11, 2004

Front View

Eelectric

Formal Design Review

Air Flow Testing of Eel Tail

For cost purposes, used unpoled PVDF

Thickness of PVDF film: 74 mm.

Can visually inspect eel oscillations

Wave forms

Estimate flexure and strain

Tested 2 cm by {5,6,7,8,9,10} cm tails

Copper “Fin”

Fan

PVDF

2 cm

Length= 5-10 cm

March 11, 2004

Eelectric

Formal Design Review

Air Flow Testing of Eel Tail

2cm x 6cm PVDF

March 11, 2004

Eelectric

Formal Design Review

Air Flow Testing of Eel Tail

2cm x 10cm PVDF

March 11, 2004

Eelectric

Formal Design Review

Piezoelectric Response

in Air Flow

2cm x 6cm Piezoelectric PVDF

March 11, 2004

Eelectric

Formal Design Review

Estimation of

Piezoelectric Response

If we model the tail as a cantilever:

V = 3/8 * (t/L)2 * h31 * dz,

t= thickness; L = Length; dz = bending radius and

h31 = g31*(c11 + c12)+ g33*c13

g31 = 6*10-12/11eo [V*m/N] c11 = 3.7 GN*m-2

g33 = -0.14 [V*m/N]

c12 = 1.47 GN*m-2

dz = 3 cm

c13 = 1.23 GN*m-2

L = 6 cm

t = 40 mm

Equation taken from: Herbert, J.M., Moulson, A.J. Electroceramics: Materials, Properties, Applications. Chapman and Hall: London, 1990.

Piezoelectric Constants taken from: Roh, Y. et al. Characterization of All the Electic, Dielectric and Piezoelectric Constants of uniaxially oriented poled PVDF films. IEEE

Transactions on Ultrasonics, Ferroelectics and Frequency Control. 49(6) June 2002.

March 11, 2004

Eelectric

Formal Design Review

Estimation of

Piezoelectric Response

Estimated voltage: 0.7322 V

Voltage Measured in Air Field: 0.207 V

Voltage required to bias Ge-doped

diode: 0.2 V

Sources of Error in Estimation

Cantilever does not account for oscillation

Wave form of eel is not a cantilever; looks

more like a sinusoid.

March 11, 2004

Eelectric

Formal Design Review

Rectifier Design

ACin

Reference: http://www.mcitransformer.com/i_notes.html

March 11, 2004

Eelectric

Formal Design Review

Proposed Integrated

Design

Fan

Rectifier

Storage

Circuit

Electronics Housing

March 11, 2004

Eelectric

Formal Design Review

Future Research

Dynamic Mechanical Testing (DMA) - ?

Oscilloscope

Quantified wave forms (peak amplitude)

Frequency

Continued Air Stream Testing

Possible water system (time permitting)

Environmental Protection stiffens the eel

Understanding vortex shedding

March 11, 2004

Eelectric

Formal Design Review

Project Timeline

2/10

2/17

2/24

3/2

3/9

3/16

4/1

4/6

4/13

4/20

4/27

5/4

5/11

Electroded piezoelectronic sample

Obtain PVDF

Investigate electrode technology

Attach electrodes to PVDF

Preliminary measurements

Build Prototype

Electronic Circuitry

Environmental Protection

Construct Housing/Barrier

Test Prototype

Air testing

Output measurement

Optimizing Prototype

Build Prototype II

Optimizing Circuitry

Test protoype II

Investigate water (time permitting)

Prepare Demo

Final Presentation

March 11, 2004

Eelectric

Formal Design Review