Presentation from April 24, 2003

advertisement

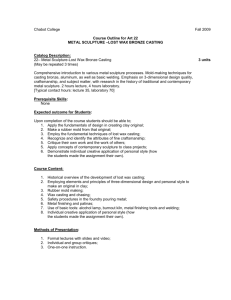

Project Update April 24, 2003 Massachusetts Institute of Technology 3.082 Rachel Sharp Corinne Packard Isaac Feitler Hao Hu This Week’s News Die fabrication Troubleshooting the Magneform machine New, thinner workpieces Contingency plans Review of Goals Conduct electrohydraulic forming of sheet metal. Form sheet metal ‘part’ Revised Gantt Chart Week 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Vessel design and parts acquisition Break Capacitor bank acquisition CAD Pressure Vessel assembly Die printing Casting of mold Electrohydraulic test Funnel formation Final part formation Presentation preparation Pressure Vessel Capacitor Bank Mold Electrohydraulic forming Final Presentation Creating the Dies CAD files of dies created with Solidworks Dies are printed 3D printer From MIT & Z-corp Prints composed of starch Creation of Plaster Mold Casting with Bronze LOST WAX CASTING 3D print infiltrated with liquid wax in ZW4 Remaining crevices in print sealed by hand with scrap wax and smear on sealant wax Pegs and blocks of Hex wax and bees wax are mounted on top of the the 3D print with sticky wax to form funnels and air holes All edges are smoothed and all gaps remaining are sealed to prevent ceramic mix from entering Lost Wax Casting, cont’ Preparing ceramic mold mix Ceramic powder – 6 liters – ceramic C-5, bauxite and fused silica Binder Mix – 25 % weight total of powder – R25 ethyl silicate, 60% weight total – Straight alcohol, 40% weight total – Ammonium Carbonate catalyst, 6% weight total * over 100% weight, ammonium carbonate acts to catalyze reactions, doesn’t affect the composition of final product, amount present miniscule Lost Wax Casting, cont’ Burn out starch and wax at Boxford, MA Pour in liquid bronze Post Processing – smooth out all edges with milling tools – Face off the top and bottom sides of the die in a lathe to ensure proper clamping Recent Magneform History Wednesday (last week): Small capacitor bank option abandoned Broken safety interlock on Magneform discovered and replaced with a jumper. Magneform fired on empty soda cans. Magneform works, but not perfectly. Thursday (last week): Examination of Magneform continues, safety concerns raised and discussed. New plan: run the electrohydraulic forming in Parallel with the Magneform to help prevent malfunction. Monitor current to electrohydraulic system with special current monitor. Recent Magneform History, continued. Friday (last week): Magneform behaves strangely in further tests, charging but failing to discharge as expected. Different discharging events produced disturbingly loud noises. No major components appear damaged. Tuesday: Friday’s problems traced to burnt out resistor. Replacing the resistor restores the Magneform to it’s previous state of working imperfectly. Wednesday: Further probing and tracing. Options for using and repairing Magneform considered. Notes on Troubleshooting Dave Bono’s experience helps. Circuit schematics are essential to understanding the machine and knowing which components to test. Voltages and resistances measured with multimeter to check proper function and identify malfunctions Troubleshooting Precautions Care must be observed when probing the machine: Machine only plugged in when necessary Use probes, clips to touch machine, avoid contact with skin. Avoid dropping small parts into the machine, be prepared to catch screws that you remove. When possible, use only one hand to reach inside machine, to avoid a conducting path across your heart. Current Magneform Status Our understanding of the Magneform is becoming more sophisticated. Magneform is partially malfunctioning, but can be made to work safely (at least for the operators, if not the machine) Inspections continue, to figure out the best way to make the machine work. The Magneform may break permanently at some point, so we will minimize any firing of the Magneform that isn’t intended to perform electrohydraulic forming. New Workpieces The portion of energy that will flow through our system, in parallel with the Magneform work coil, is currently unknown. We’ve purchased thinner workpiece materials to increase the likelihood of significant results: 5052 Aluminum in thicknesses of 0.032, 0.040, and 0.050” (old workpieces 0.0625” thick) Also, 110 Copper Alloy in thicknesses of 0.021 and 0.032” What’s next? Electrohydraulic tests with the Magneform, free expansion without a die. Workpieces marked with spraypainted grids, so that we can measure strains. Casting and processing dies. Final part formation. Contingencies One option was to ship our pressure vessel to Prof. Daehn at Ohio State University, but we’ve run out of time for that. Although the Magneform is not working perfectly, the major, high-power compenents all seem fine, so we’ll be able to use it. If most of the energy goes into the work coil, instead of our system, we may be able to build our own coil with greater impedance. Acknowledgements Dave Bono for help troubleshooting the Magneform Chris Schuh, Joe Parse, and Yet-Ming Chiang for general advice. Toby Bashaw for all the help making the parts of our system. Yin-Lin Xie and Maria Nargi for help purchasing parts and materials. Print3 and especially Flex for putting up with our sometimes disruptive work.