Version de autor_Int J Food Microbiol 139 9-14 (2010).doc

advertisement

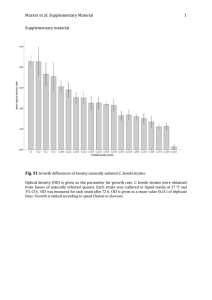

1 1 A new methodology to obtain wine yeast strains overproducing mannoproteins 2 3 MANUEL QUIRÓS 1*, DANIEL GONZALEZ-RAMOS 2, LAURA TABERA2, RAMON 4 GONZALEZ 1,2 5 6 1 7 Tecnológico, C/ Madre de Dios, 51. 26006 Logroño (La Rioja), Spain Instituto de Ciencias de la Vid y del Vino (CSIC-UR-CAR), Complejo Científico 8 9 10 2 Instituto de Fermentaciones Industriales (CSIC), C/ Juan de la Cierva, 3. 28006 Madrid, Spain 11 12 * To whom correspondence should be addressed: 13 Instituto de Ciencias de la Vid y del Vino (CSIC-UR-CAR), Complejo Científico 14 Tecnológico 15 C/ Madre de Dios, 51 16 26006 Logroño (La Rioja) 17 Spain 18 Tel: +34 941 299691 19 Fax: +34 941 299608 20 E-mail address: mquiros@icvv.es 21 22 23 24 25 Short running title: Mannoprotein overproducing yeasts 2 26 ABSTRACT 27 Yeast mannoproteins are highly glycosylated proteins that are covalently bound to the β-1,3- 28 glucan present in the yeast cell wall. Among their outstanding enological properties, yeast 29 mannoproteins contribute to several aspects of wine quality by protecting against protein 30 haze, reducing astringency, retaining aroma compounds and stimulating growth of lactic-acid 31 bacteria. The development of a non-recombinant method to obtain enological yeast strains 32 overproducing mannoproteins would therefore be very useful. Our previous experience on the 33 genetic determinants of the release of these molecules by Saccharomyces cerevisiae has 34 allowed us to propose a new methodology to isolate and characterize wine yeast that 35 overproduce mannoproteins. The described methodology is based on the resistance of the 36 killer 9 toxin produced by Williopsis saturnus, a feature linked to an altered biogenesis of the 37 yeast cell wall. 38 39 40 41 42 Keywords: wine yeast, mannoproteins, UV mutagenesis, Williopsis saturnus, killer 9 toxin 43 resistance 44 45 46 47 48 3 49 INTRODUCTION 50 Yeast mannoproteins are highly glycosylated proteins containing over 90% sugars, mainly 51 mannose, that are located in the outermost layer of the yeast cell wall, representing between 52 35 to 40% of its dry weight. Most of them act as structural components, giving the cell wall 53 its active properties and being partially responsible for its permeability (Cid et al., 1995; Klis 54 et al., 2002). Due to their high sugar content, mannoproteins behave like polysaccharides 55 rather than like proteins. In Saccharomyces cerevisiae, the glycan portion of mannoproteins is 56 mainly composed of mannose, with some neutral oligosaccharides that contain N- 57 acetylglucosamine and acidic sugars containing mannosylphosphate (Jigami and Odani 1999). 58 Over the past decades, yeast mannoproteins have gained ground as one of the most interesting 59 molecules involved in the improvement of both the technological processes during wine 60 making and the sensorial properties of the resulting product. Several authors have emphasized 61 the key role played by these molecules on the chemical stabilization of wine by protecting 62 against protein haze (Dupin et al., 2000a, b; Gonzalez-Ramos and Gonzalez 2006; Schmidt et 63 al., 2009; Waters et al., 1994, 2005) and tartaric instability (Feuillat et al., 1998). Though it is 64 well known that physicochemical procedures for the stabilization of wines are satisfactorily 65 employed (e.g. bentonite fining against protein haze, Blade and Boulton 1988; cold 66 stabilisation to avoid tartaric instability, Boulton et al., 1998), several studies support that 67 these can also negatively affect the quality of the fined wine as some texture, flavour and 68 aroma compounds will also be lost (Høj et al., 2000; Voilley et al., 1990). Additionally, the 69 use of bentonite will cause a significant loss in the volume of treated wine, estimated to range 70 between 3 to 10%. Brown et al. (2007) cloned and overexpressed YOL155c and YDR055w in 71 S. cerevisiae laboratory strains, respectively encoding Hpf1p and Hpf2p (from Haze 72 protecting factors), and showed that turbidity was reduced up to 40% when Hpf2p was added 73 to the wine, which would clearly allow to minimize these procedures. 4 74 Other appreciated enological features of mannoproteins are their ability to absorb ochratoxin 75 A and thus reduce its concentration in the final product (Ringot et al., 2005), stimulate the 76 growth of lactic-acid bacteria (Guilloux-Benattier et al., 1995) due to the adsorption of 77 medium chain fatty acids released by yeast strains present in the medium and contribute to 78 several organoleptic features by retaining aroma compounds (Lubbers et al., 1994), reducing 79 astringency, improving the foaming properties of sparkling wines (Núñez et al., 2006) and 80 increasing the sweetness, body, roundness and mouthfeel of the wine (Guadalupe et al., 2007; 81 Vidal et al., 2004, for a review of mannoprotein properties see Caridi 2006). 82 For all these positive contributions it would be desirable to obtain new yeast strains that 83 would naturally overproduce mannoproteins. Previous works have allowed the identification 84 of some genetic determinants of the release of mannoproteins in wine yeasts (Gonzalez- 85 Ramos and Gonzalez 2006; Gonzalez-Ramos et al., 2008) and proven that wines fermented 86 with recombinant mannoprotein overproducing strains presented a higher stability against 87 protein haze compared to those obtained after fermentation with the native strain. Among the 88 different recombinant genotypes constructed and studied, strains deleted for KNR4 (from 89 Killer Nine Resistant, also known as SMI1), a gene involved in β-1,3-glucan biosynthesis 90 identified by Hong et al. (1994), yielded optimal results (Gonzalez-Ramos et al., 2008). Two 91 additional gene targets were later identified to improve mannoprotein release and bentonite 92 responsiveness (Gonzalez-Ramos et al., 2009). In the present paper, a new methodology for 93 the selection of non-recombinant mannoprotein overproducing yeast strains based on their 94 phenotypic properties is developed. 95 96 MATERIALS AND METHODS 97 Strains and culture conditions 5 98 Twelve different S. cerevisiae strains were used in this work. EC1118 is a wine yeast strain 99 commercialised by Lallemand Inc. (Ontario, Canada). T73-4 is a uridine auxotroph derived 100 from the winemaking strain T73 (Puig et al., 1998) EFD-31, EGD-13 and EKD-13 are double 101 deletion mutants derived from EC1118 lacking FKS1, GPI7 and KNR4 genes, respectively 102 (González-Ramos et al., 2008, 2009). TGD-13, TGASD-31 and TKD-123 are knockout 103 strains derived from T73-4 lacking GPI7, GAS1 and KNR4 genes, respectively (González- 104 Ramos et al., 2008, 2009). Finally, BY4741 strain (MATa; his3Δ1; leu2Δ0; met15Δ0; 105 ura3Δ0) was obtained from the EUROSCARF consortium while IFI475 and IFI87, both 106 industrial winemaking strains, were obtained from the Instituto de Fermentaciones 107 Industriales culture collection (CSIC). Strains were routinely maintained on YPD plates, 108 containing 2% glucose, 2% peptone, 1% yeast extract and 2% agar. GCY medium, containing 109 2% glucose, 2% BactoTM Casamino Acids (BD, Sparks, USA) and 0.67% DifcoTM Yeast 110 Nitrogen Base (BD) was the medium used to assay the release of mannoproteins and 111 polysaccharides. When fermentations were performed with BY4741 and its derived strains, 112 the medium was supplemented with leucine and uridine (24,9 and 83,0 mg/L, respectively) so 113 that the auxotrophies of the strains were complemented. 114 Production of killer 9 toxin 115 In order to produce the killer 9 toxin, Williopsis saturnus var. mrakii CECT 11031 strain was 116 grown in YPD broth buffered with 50 mM sodium citrate (pH 4.3) during 3 days at 19 ºC and 117 150 rpm in an orbital shaker according to the conditions described by Hong et al. (1994). This 118 culture was subsequently centrifuged and the supernatant filtered through 0.22 μm pore size 119 membranes and stored at 4 ºC until used. For the preparation of the k9-containing YPD plates, 120 sodium citrate buffered YPD agar plates were overlayed with 5 mL of the filtered supernatant 121 containing the killer 9 toxin and left open in a laminar air flow bench until its complete 122 absorption. 6 123 UV mutagenesis 124 S. cerevisiae strains were grown in 10 mL YPD broth at 28 ºC and 150 rpm o/n. Cells were 125 washed twice and resuspended in 1 mL sterile distilled water. The number of cells in the 126 suspensions was determined by serial dilution and counting on a BlauBrand Thoma counting 127 chamber (Brand GMBH + CO KG, Wertheim, Germany). A 20 mL cell suspension 128 containing 107 cells/mL was then prepared, placed in a Petri dish and irradiated under a UV 129 lamp (Camag, Muttenz, Switzerland) at 254 nm. 1 mL aliquots of the cell suspension were 130 taken after 20, 40 and 60 seconds of exposure, placed in Eppendorf tubes and kept in darkness 131 for 30 minutes. Serial 10-fold dilutions of each of these aliquots (up to 10-5) were then 132 prepared in saline solution and 100 μL were plated in YPD agar plates and k9 toxin- 133 containing YPD plates. These were incubated for 48-72 h at 28 ºC and survival and resistance 134 rates for each of the exposure times were then determined. k9 toxin-resistant mutants were 135 picked and transferred to fresh YPD plates. 136 In order to check the k9 toxin resistant phenotype, cells were grown o/n in YPD, washed with 137 sterile water and resuspended to a final concentration of 107 cells/mL. Four 10-fold serial 138 dilutions were performed and 5 µL of each spotted on selective YPD plates, containing k9 139 toxin, as well as non-selective YPD plates as control. 140 Quantification of total mannoproteins and polysaccharides 141 Yeasts were inoculated in 5 mL of GCY medium, grown at 30 ºC o/n and used to inoculate 142 100 mL shakeflasks containing 50 mL of GCY broth to a final O.D. of 0.1. Growth was 143 monitored by O.D.600 nm measurement. After 24 hours of incubation at 30 ºC and 150 rpm, 144 cultures were centrifuged and the supernatant transferred to clean Falcon tubes. 145 Macromolecules in these supernatants were separated from monosaccharides by gel filtration 146 using 147 manufacturer’s Econo-Pac columns (Bio-Rad recommendations. The Laboratories, concentration Hercules, of total CA) following the mannoproteins and 7 148 polysaccharides in the eluted fraction was determined by the phenol-sulfuric acid method 149 described by Segarra et al. (1995) using a standard curve of commercial mannan from S. 150 cerevisiae (Sigma-Aldrich, St. Louis, MO). Furthermore, glucose and mannose content of the 151 macromolecular fraction was estimated performing acid hydrolysis as described by François 152 (2006) followed by HPLC determination of the released polysaccharides. Four replicates for 153 each sample were performed and data were analysed by one-way ANOVA and the Dunnett 154 test for comparison of means. Bivariate correlation between the final biomass values of the 155 strains used and their corresponding polysaccharide production values was studied using 156 Pearson’s correlation coefficient. In all cases, SPSS 15.0 software (SPSS Inc., Chicago, USA) 157 was used. 158 Fermentation of synthetic must 159 Industrial strains showing an improved release of mannoproteins in GCY medium were tested 160 in a synthetic must (pH 3.5) containing 10% glucose, 10% fructose, 0.6% citric acid, 0.6% 161 malic acid, 0.17% YNB without aminoacids and ammonium sulphate (Difco), 306 mg/L 162 NH4Cl and 2/3 of the amount of aminoacids used in a control synthetic grape must (CNC) by 163 Beltran et al. (2004). Fermentations were performed in duplicate at 20 ºC using 100 mL 164 bottles capped with Müller valves containing 40 mL of must. Yeast strains were grown o/n in 165 YPD broth, washed twice in sterile distilled water and finally inoculated at a final 166 concentration of 106 cells/mL. Fermentation time course was monitored by determining the 167 production of CO2 expressed as weight loss until weight was constant. 168 HPLC analysis of musts and wines 169 Fermentation samples were analysed by HPLC in order to determine the concentration of 170 glucose, fructose, ethanol and glycerol. Prior to injection in duplicate, samples were 171 centrifuged at 10000 rpm for 5 minutes, supernatants filtered through 0.45 μm pore size nylon 172 filters (Symta, Madrid, Spain) and diluted 5 or 10-fold. A Surveyor Plus chromatograph 8 173 (Thermo Fisher Scientific, Waltham, MA) equipped with a refraction index detector 174 (Surveyor RI Plus Detector) was used. The column employed was a HyperREZTM XP 175 Carbohydrate H+ 8μm (Thermo Fisher Scientific) assembled to its correspondent guard. 1.5 176 mM H2SO4 was used as the mobile phase with a flux of 0.6 mL/min and a column 177 temperature of 50 ºC. 178 Stress tolerance assays 179 To confirm the suitability of the selected overproducing strains for industrial purposes, 180 tolerance to three different stress factors, i.e. pH, osmolarity and temperature, was assayed. 181 Serial 10-fold dilutions of cell suspensions containing 107 cells/mL were prepared for all the 182 strains and 3 µL of each plated in YPD medium with a pH of 2.8, 3.0 and 3.2 (pH stress), 183 YPD containing 200, 250 and 300 g/L of glucose (osmotic stress) and YPD plates that were 184 incubated at 13, 20, 28 and 32 °C. 185 186 RESULTS 187 Common phenotype for yeasts overproducing mannoproteins 188 Previous studies carried out in our group have identified four genes whose deletion resulted in 189 an increased mannoprotein release. In order to find a common phenotype suitable for the 190 positive selection of mannoprotein overproducing mutants, we turned our sight to the primary 191 description of yeast mutations affecting these four genes. Hong et al. (1994) observed that 192 yeast mutants deficient in the KNR4 gene activity, encoding a regulatory protein required for 193 the correct targeting of the Stl2p MAP kinase, showed resistance to the k9 toxin from 194 Hansenula mrakii coupled to a reduced level of both (1.3)-β-glucan synthase activity and 195 (1,3)-β-glucan content in the cell wall. Taking this into account, a k9 toxin sensitivity assay 196 was performed using the knockout strains previously constructed, using their wild type 197 counterparts as control (Fig. 1). As expected (Hong et al., 1994), deletion of KNR4 resulted in 9 198 an improved resistance to the killer 9 toxin in the two genetic backgrounds studied (see EKD- 199 13 and TKD-123 strains in Fig.1). Similar results were obtained for the deletion of FKS1, a 200 gene encoding a subunit of the β-1,3-glucan synthase, in EC1118 background (EFD-31 strain) 201 and for the deletion of GAS1, encoding a glycoprotein of the plasma membrane, in T73-4 202 background (TGASD-31 strain). In contrast, deletion of GPI7, encoding an enzyme required 203 for the synthesis of the GPI anchor, a structure mediating the linkage of some proteins to the 204 plasma membrane or to the cell wall, resulted in an increased sensitivity to the toxin in both 205 genetic backgrounds (EGD-13 and TGD-13 strains). 206 Considering that the modification of three out of the four genetic targets analysed that had 207 been previously shown to improve mannoprotein release also conferred yeast cells an 208 increased resistance to k9 toxin, we decided to test this feature as an enrichment criterion for 209 mannoprotein overproducing mutants in mutagenesis experiments. 210 Preliminary k9 toxin selection of UV mutants 211 As a proof of concept, two different mutagenesis experiments followed by k9 resistance 212 selection were performed on the haploid strain BY4741. Survival rates after the different 213 irradiation times were calculated by colony counting on YPD plates and results ranged from 214 33 to 12% for a 20 seconds exposure, from 1.1 to 2.1% for 40 seconds and from 0.25 to 215 0.18% for a UV exposure of 60 seconds. Ten colonies were randomly picked both from the 216 control YPD plates and the selective YPD plates containing k9 toxin in order to compare 217 polysaccharide and mannoprotein release with the original strain after fermentation in GCY 218 medium. In general, final O.D. values of k9-resistant strains were significantly lower than 219 those obtained for the strains picked from non-selective YPD plates and from the control 220 strain. So, while BY4741 presented a final O.D. value of 9.42 ± 0.7, the average O.D. 221 obtained for the k9-resistant mutants was 6.3 ± 1.5 while that obtained for the ten strains 222 picked from non-selective YPD was 9.2 ± 1.4. 10 223 The release of total polysaccharides and mannoproteins in all the k9-resistant strains tested is 224 shown in Fig. 2. Production values in mg/L are shown in panel A while values normalized by 225 the final biomass are depicted in panel B. As can be observed for the non-normalized values, 226 7 out of the 10 mutants selected in YPD+k9 plates significantly produced higher amounts of 227 total polysaccharides and mannoproteins than the control strain, BY4741 (p<0.01). The 228 increase in the production of polysaccharides and mannoproteins for the k9 resistant mutants 229 ranged from 30% for mutant Mut3 to 238% for Mut6. When the normalized values are 230 considered, 8 out of the 10 mutants significantly produced more polysaccharides than the 231 control strain. On the contrary, none of the colonies isolated from the non-selective medium 232 after the UV treatment overproduced mannoproteins and total polysaccharides (p<0.01, data 233 not shown). 234 Mannoprotein overproducing mutants from industrial wine yeast strains 235 These encouraging results made us test the described enrichment procedure for the genetic 236 improvement of three different wine making strains: IFI87, IFI475 and T73. The survival 237 rates observed in this case significantly differed between strains. So, for IFI87, IFI475 and 238 T73 the rates obtained were 29.6, 46.7 and 51,4% after 20 seconds of UV exposure, 2.7, 43.6 239 and 24.9% for 40 s and 0.6, 7.0 and 1.4% for 60 s, respectively. It is noteworthy to mention 240 that the percentage of k9 resistant cells, calculated as (no. of colonies on YPD+k9 / no. of 241 colonies on YPD) x 100 varied for every strain and UV treatment but ranged between 0.18% 242 and 0.09%. 243 Ten colonies were randomly picked for each of the strains from YPD+k9 plates 244 corresponding to different survival rates and fermentations in GCY performed as in the 245 previous cases. As no overproducing mutants were identified for strain IFI475, the screening 246 was extended in this case with 40 additional strains. 11 247 In the case of strain IFI87, the most relevant overproducing mutant was Mut10, releasing 248 126.5 ± 2.8 mg/L of polysaccharides. This value represents a 3.5 times increase in the release 249 of mannoproteins, as the wild type strain produced an average of 35.8 ± 2 mg/L. More 250 discrete improvements were observed for strains Mut 24 and 47 derived from IFI475, which 251 increased the release of mannoproteins 19% and 25% respectively when compared to their 252 control and for T73 Mut1, with an increase of 14%. Increased production values were also 253 confirmed after normalization with the final biomass values. 254 Fermentation of synthetic must 255 In order to prove that the selected strains would increase the release of mannoproteins during 256 winemaking, fermentations using a synthetic must were carried out in duplicates. 257 Fermentation profiles did not differ significantly from the wild type strain in the case of the 258 two mutants obtained from IFI475 while some differences were observed in the case of IFI87 259 Mut10 and T73 Mut1 (Fig. 3). However, final concentration of the metabolites analysed by 260 HPLC (i.e. glucose, fructose, glycerol and ethanol) did not significantly differ from those 261 obtained for the wild type strains. Values obtained for the release of total polysaccharides are 262 shown in Fig. 4. It is relevant to mention that, while the differences found in the values 263 between IFI87 Mut10 and IFI475 Mut24 and 47 compared to their wild type strains were very 264 similar to the ones obtained after fermentation in GCY, a 94% increase in the production of 265 total polysaccharides was observed for strain T73 Mut1 when compared to the original strain 266 while fermentation on GCY had just shown a slight increase of 14%. 267 Even these results demonstrated the suitability of the selected strains we decided to perform 268 stress tolerance assays, so that they were exposed to different winemaking related stresses 269 (pH, osmotic and temperature stress). After monitoring growth for three days, no significant 270 differences were observed between the overproducing mutant strains and their wild type 271 counterparts (see Supplementary data). 12 272 273 DISCUSSION 274 During the last decades, several studies have demonstrated the positive contribution of yeast 275 mannoproteins to the sensorial quality and chemical stability of wines (Waters et al., 1993, 276 1994; Moine-Ledoux and Dubourdieu 1999; Dupin et al., 2000a, b). Different studies 277 performed in our group have identified several genetic targets for the improved release of 278 mannoproteins by S. cerevisiae during wine fermentations (Gonzalez-Ramos and Gonzalez 279 2006, Gonzalez-Ramos et al., 2009) However, the use of GMOs in food applications is 280 strictly regulated in most countries, including the USA and those belonging to the EU. As 281 genetic engineering of microorganisms does not therefore represent a viable option, genetic 282 improvement of yeast has normally been achieved either by parasexual hybridization by 283 means of protoplast fusion or by consecutive cycles of random mutagenesis and selection, 284 using both chemical or physical agents. 285 The method for the selection of yeast strains overproducing mannoproteins described in the 286 current paper consists in a random mutagenesis using a physical agent such as 254 nm UV 287 light, followed by a direct selection on YPD plates containing killer 9 toxin from Williopsis 288 saturnus var. mrakii. When mutagenesis was applied to the haploid strain BY4741, optimal 289 results were obtained, as 70% of the resistant strains assayed overproduced polysaccharides. 290 On the contrary, as mentioned in the Results section, none of the strains isolated from non- 291 selective YPD plates after UV exposure showed an increased production of polysaccharides. 292 This fact proves that selection with Williopsis saturnus killer 9 toxin results in a clear 293 enrichment in polysaccharide overproducing mutants and that, as clearly observed in our 294 results, the number of strains needed to be screened drastically decreases. 295 It is necessary to indicate that, in most cases, strains isolated from the k9 containing YPD 296 plates yielded lower biomass values when grown on GCY than the native strain, BY4741. 13 297 Indeed we found a negative correlation between the amount of total polysaccharides released 298 and the final biomass values of the cultures performed in GCY medium (Pearson’s correlation 299 coefficient = -0.661, p<0.05). By using killer 9 toxin on the YPD plates, we are in some way 300 selecting for strains presenting an impaired cell wall biosynthesis. Such a defective cell wall 301 could make these strains more sensitive to external factors such as pH or osmotic stress and 302 could explain the differences found in the biomass values observed. This fact sets a clear limit 303 on the degree of overproduction that could be reached when this methodology is applied. So, 304 strains severely affected in the biogenesis of their cell wall would release a much higher 305 amount of polysaccharides but would certainly not resist the different stresses present in a 306 grape must and would therefore not represent an industrial viable option. 307 Once the methodology showed its usefulness using a haploid laboratory strain, our next goal 308 was to prove its utility with industrial strains. Results obtained in this case were not as 309 dazzling as the observed for the haploid strain as, in the case of IFI87 and T73, one out of the 310 ten mutants analysed overproduced polysaccharides while this proportion dropped to two out 311 of forty in the case of IFI475 mutants. This finding might be due to the fact that, as previously 312 observed for the deletion of FKS1, GAS1, GPI7 and KNR4 (Gonzalez-Ramos and Gonzalez 313 2006, Gonzalez-Ramos et al., 2009), mutations of genes that can influence mannoprotein 314 release have a recessive phenotype. The probability of obtaining a recessive homozygous 315 strain by random mutagenesis is very low compared to the probabilities of getting loss-of- 316 function mutants using haploid strains, as only one point mutation could be enough. It should 317 always be kept in mind that, though not analysed in this paper, there is a clear effect of the 318 genetic background of the strain on the results obtained after deletion or interruption of these 319 genes (Gonzalez-Ramos and Gonzalez 2006, Gonzalez-Ramos et al., 2008, 2009). Indeed, 320 one of the reasons that might explain the differences in the proportion of overproducing 321 mutants observed for the three strains used in this work could be their ploidy. So, strains with 14 322 a higher ploidy would hamper the process of obtaining mutants overproducing 323 mannoproteins, as probabilities of getting homozygous strains for a certain mutation would 324 considerably decrease. In fact, when the proposed methodology was applied to the BY4743 325 strain, a diploid yeast strain presenting the same genetic background as BY4741, the 326 percentage of mutants overproducing mannoproteins drastically decreased, as none out of the 327 30 mutants studied overproduced these compounds (data not shown). 328 Considering the limitations pointed out for the experiment performed with the lab strain 329 BY4741, we decided to test the behaviour of the industrial strains selected in a synthetic must 330 and to study their resistance to different stresses. In general, fermentations performed in this 331 medium confirmed the results observed for fermentations in GCY in terms of improvement of 332 the release of mannoproteins. Besides, none of the selected strains presented a significantly 333 sensitive phenotype to any of the different stresses tested with regards to their wild type 334 counterparts (Supplementary data). 335 Considering the results presented, the proposed methodology represents a fast and 336 straightforward 337 mannoproteins, which can clearly contribute to the chemical stabilization of wine and to the 338 improvement of its organoleptic properties. An increased number of interesting 339 overproducing mutants could also be obtained applying the described methodology to spores 340 isolated from the desired industrial strains. approach to obtain non-recombinant yeast strains overproducing 341 342 ACKNOWLEDGEMENTS 343 This work was supported by the Spanish Ministerio de Ciencia e Innovación (grants 344 AGL2006-02558, and Consolider CSD2007-00063). D.G.-R was supported by a pre-doctoral 345 fellowship from the Government of The Basque Country (Gobierno Vasco-Eusko Jaurlaritza). 346 The authors are grateful to José María Barcenilla and Laura López Berges for their excellent 15 347 technical assistance and to Jytte Laursen for kindly reviewing the English expression in this 348 manuscript. 349 350 REFERENCES 351 - Beltran, G., Novo, M., Rozès. N., Mas, A., Guillamón, J.M., 2004. Nitrogen catabolite 352 repression in Saccharomyces cerevisiae during wine fermentations. FEMS Yeast Research 4, 353 625-632. 354 - Blade, W.H., Boulton, R., 1988. Adsorption of protein by bentonite in a model wine 355 solution. American Journal of Enology and Viticulture 39, 193-199. 356 - Boulton, R.B., Singleton, V.L., Bisson, L.F., Kunkee, R.E. 1998. Heating and cooling 357 applications. In: Principles and practices of winemaking. Kluwer Academic/Plenum 358 Publishers, New York, pp. 492-520. 359 - Brown S.L., Stockdale V.J., Pettolino F., Pocock K.F., de Barros Lopes M., Williams P.J., 360 Bacic A., Fincher G.B., Hoj P.B., Waters E.J., 2007. Reducing haziness in white wine by 361 overexpression of Saccharomyces cerevisiae genes YOL155c and YDR055w Applied 362 Microbiology and Biotechnology 73, 1363-1376. 363 - Caridi, A., 2006. Enological function of parietal yeast mannoproteins. Antonie van 364 Leeuwenhoek 89, 417-422. 365 - Cebollero, E., Gonzalez-Ramos, D., Tabera, L., Gonzalez, R., 2007. Transgenic wine yeast 366 technology comes of age: is it time for transgenic wine? Biotechnology Letters 29, 191-200. 367 - Cid, V.J., Duran, A., del Rey, F., Snyder, M.P., Nombela, C., Sanchez, M., 1995. Molecular 368 basis of cell integrity and morphogenesis in Saccharomyces cerevisiae. Microbiological 369 Reviews 59, 345-386. 370 - Dupin, I.V.S., McKinnon B.M., Ryan, C., Boulay, M., Markides, A.J., Jones, G.P., 371 Williams, P.J., Waters, E.J., 2000a. Saccharomyces cerevisiae mannoproteins that protect 16 372 wine from protein haze: their release during fermentation and lees contact and a proposal for 373 their mechanism of action. Journal of Agricultural and Food Chemistry 48, 3098-3105. 374 - Dupin, I.V.S., Stockdale, V.J., Williams, P.J., Jones, G.P., Markides, A.J., Waters, E.J., 375 2000b. Saccharomyces cerevisiae mannoproteins that protect wine from protein haze: 376 evaluation of extraction methods and inmunolocalization. Journal of Agricultural and Food 377 Chemistry 48, 1086-1095. 378 - François, J.M., 2006. A simple method for quantitative determination of polysaccharides in 379 fungal cell walls. Nature Protocols 1, 2995-3000. 380 - Feuillat, M., Charpentier, C., Nguyen van Long, T., 1998. Yeast's mannoproteins: a new 381 possible enological adjuvant. Bulletin de l’OIV. 71, 944-967. 382 - Gonzalez-Ramos, D., Cebollero, E., Gonzalez, R., 2008. A recombinant Saccharomyces 383 cerevisiae strain overproducing mannoproteins stabilizes wine against protein haze. Applied 384 and Environmental Microbiology 74, 5533-5540. 385 - Gonzalez-Ramos, D., Gonzalez, R., 2006. Genetic determinants of the release of 386 mannoproteins of enological interest by Saccharomyces cerevisiae. Journal of Agricultural 387 Food Chemistry 54, 9411-9416. 388 - Gonzalez-Ramos, D., Quirós, M., Gonzalez, R., 2009. Three different targets for the genetic 389 modification of wine yeast strains resulting in improved effectiveness of bentonite fining. 390 Journal of Agricultural Food Chemistry 57, 8373-8378. 391 - Guadalupe, Z., Palacios, A., Ayestarán, B., 2007. Maceration enzymes and mannoproteins: a 392 possible strategy to increase colloidal stability and color extraction in red wines. Journal of 393 Agricultural and Food Chemistry 55, 4854-4862. 394 - Guilloux-Benattier, M., Guerreau, J., Feuillat, M., 1995. Influence of initial colloid content 395 on yeast macromolecule production and on the metabolism of wine microorganisms. 396 American Journal of Enology and Viticulture 46, 486-492. 17 397 - Hong, Z., Mann, P., Brown, N.H., Tran, L.E., Shaw, K.J., Hare, R.S., Didomenico, B., 1994. 398 Cloning and characterization of KNR4, a yeast gene involved in (1,3)-β-glucan synthesis. 399 Molecular and Cellular Biology 14, 1017-1025. 400 - Høj, P.B., Tattersall, D.B., Adams, K., Pocock, K.F., Hayasaka, Y., van Heeswijck, R. and 401 Waters, E., 2000. The ‘haze proteins’ of wine – a summary of properties, factors affecting 402 their accumulation in grapes, and the amount of bentonite required for their removal from 403 wine. Proceedings of the American Society of Enology and Viticulture (ASEV) 50th 404 Anniversary Meeting, Seattle, Washington, pp. 149-154. 405 - Jigami, Y, Odani, T., 1999. Mannosylphosphate transfer to yeast mannan. Biochimica et 406 Biophysica Acta 1426, 335-345. 407 - Klis, F.M., Mol, P., Hellingwerf, K., Brul, S., 2002. Dynamics of cell wall structure in 408 Saccharomyces cerevisiae. FEMS Microbiology Reviews 26, 239-256. 409 - Lubbers, S., Voilley, A., Feuillat, M. and Charpentier, C., 1994. Influence of mannoproteins 410 from yeast on the aroma intensity of a model wine. Lebensmittel-Wissenschaft & 411 Technologie 27, 108-114. 412 - Moine-Ledoux, V., Dubourdieu, D., 1999. An invertase fragment responsible for improving 413 the protein stability of dry white wines. Journal of the Science of Food and Agriculture 79, 414 537-543. 415 - Núñez, Y.P., Carrascosa, A.V., Gonzalez, R., Polo, M.C., Martínez-Rodríguez, A., 2006. 416 Isolation and characterization of a thermally extracted yeast cell wall fraction potentially 417 useful for improving the foaming properties of sparkling wine. Journal of Agricultural and 418 Food Chemistry 54, 7898-7903. 419 - Puig, S., Ramón, D., Pérez-Ortín, J.E., 1998. Optimized method to obtain stable food-safe 420 recombinant wine yeast strains. Journal of Agricultural and Food Chemistry 46, 1689-1693. 18 421 - Ringot, D., Lerzy, B., Bonhoure, J.P., Auclair, E., Oriol, E., Larondelle, Y., 2005. Effect of 422 temperature on in vitro ochratoxin A biosorption onto yeast cell wall derivatives. Process 423 Biochemistry 40, 3008-3016. 424 - Segarra, I., Lao, C., López-Tamames, E., de la Torre-Boronat, M.C., 1995. 425 Spectrophotometric methods for the analysis of the polysaccharide levels in winemaking 426 products. American Journal of Enology and Viticulture 46, 564-570. 427 - Schmidt, S.A., Tan E.L., Brown, S., Nasution, U.L., Pettolino, F., MacIntyre, O.J., de Barros 428 Lopes, M., Waters, E.J., Anderson, P.A., 2009. Hpf2 glycan structure is critical for protection 429 against protein haze formation in white wine. Journal of Agricultural and Food Chemistry 57, 430 3308-3315. 431 - Vidal, S., Francis, L., Williams, P., Kwiatkwoski, M., Gawel, R., Cheynier, V., Waters, E., 432 2004. The mouth-feel properties of polysaccharides and anthocyaneins in a wine like medium. 433 Food Chemistry 85, 519-525. 434 - Voilley, A., Lamer, C., Dubois, P., Feuillat, M., 1990. Influence of macromolecules and 435 treatments on the behaviour of aroma compounds in a model wine. Journal of Agricultural 436 and Food Chemistry 38, 248-251. 437 - Waters, E.J. Alexander, G., Muhlack, R., Pocock, K.F., Colby, C., O’Neill, B.K., Høj, P.B., 438 Jones, P., 2005. Preventing protein haze in bottled white wine. Australian Journal of Grape 439 and Wine Research 11, 215-225. 440 - Waters, E.J., Pellerin, P., Brillouet, J.M., 1994. A Saccharomyces mannoprotein that 441 protects wine from protein haze. Carbohydrate Polymers 23, 185-191. 442 - Waters, E.J., Wallace, W., Tate, M.E., Williams, P.J., 1993. Isolation and partial 443 characterization of a natural haze protective factor from wine. Journal of Agricultural and 444 Food Chemistry 41, 724-730. 19 445 Captions for Figures 446 447 Fig. 1. Williopsis saturnus k9 toxin sensitivity assay performed with EC1118 and T73-4 448 knockout strains. Images on the left-hand side represent growth of the strains in non-selective 449 buffered YPD plates. Images on the right-hand side depict growth on k9-containing buffered 450 YPD plates. 451 452 Fig. 2. A) Production of polysaccharides (mg/L) obtained for ten BY4741 mutant strains after 453 UV mutagenesis, selection on YPD+k9 plates and fermentation in GCY medium. 454 B) Production values of the same strains normalized using the final biomass. In both cases 455 strains releasing a significantly higher amount of mannoproteins than the wild type strain are 456 marked with an asterisk (p<0.01). 457 458 Fig. 3. Time course of fermentations of industrial wild type and mutant strains in synthetic 459 must. 460 461 Fig. 4. Total polysaccharides (mg/L) released in synthetic must by the industrial mutant 462 strains selected in this work and their wild type counterparts. 463 464 Supplementary data 465 Growth of the mutant industrial strains selected and their wild type counterparts in YPD- 466 based media representing three different stress factor (pH, high osmolarity and temperature) 467 after 72 h. of incubation. 468 469 20 470 471 472 473 474 475 476 477 478 479 480 481 482 483 484 485 486 487 488 489 490 491 492 493 494 Buf EC1 EFD-31 118 EGD-13 (ΔFKS1) EKD-13 (ΔGPI7) T7 (ΔKNR4) TGD-13 3-4 TGASD-13 (ΔGPI7) TKD-123 (ΔGAS1) (ΔKNR4) Fig. 1. Manuel Quirós fered YP D Buffe red YPD + k9 120 A * 100 80 60 * 40 20 0 Fig. 2. Manuel Quirós * * * * * [Polysaccharides]/Biomass (mg/LxOD) 495 496 497 498 499 500 501 502 503 504 505 506 507 508 509 510 511 512 [Polysaccharides] (mg/L) 21 25 * B 20 15 10 5 0 * * * * * * * 22 CO2 produced (g) 513 514 515 516 517 518 519 520 521 522 523 524 525 526 527 528 529 530 531 5 5 5 4 4 4 3 3 3 2 2 2 IFI475 1 IFI87 1 IFI475 Mut 24 IFI87 Mut10 0 0 0 5 10 Time (days) Fig. 3. Manuel Quirós 15 20 1 T73 IFI475 Mut 47 T73 Mut1 0 0 5 10 Time (days) 15 20 0 5 10 Time (days) 15 20 23 200 Total polysaccharides (mg/L) 160 120 80 40 Fig. 4. Manuel Quirós M ut 1 3 3 T7 T7 M ut 47 M ut 24 47 5 IF I 47 5 47 5 IF I IF I M ut 10 87 IF I 87 0 IF I 532 533 534 535 536 537 538 539 540 541 542 543 544 545 546 547 548 549 550 551 552 553 554 555 24 556 557 Supplementary material