Course TEN-702 Industrial waste management unit-2 • Lecture -10

advertisement

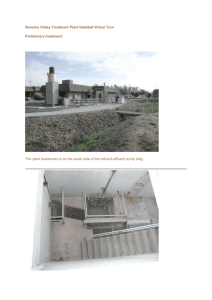

Course TEN-702 Industrial waste management unit-2 • Lecture -10 Pretreatment – Grit Removal • Grit is typically removed during pretreatment at larger plants – Grit can cause premature wear of equipment – Becomes cleaning issue if not removed • Aerated grit tanks and vortex systems are common grit removal processes • Grit removal systems typically employ a classifier/washer Pretreatment – Grit Removal • Vortex grit unit • Unit rotates to suspend light organics • Heavy, dense grit settles to bottom Pretreatment – Grit Removal • Grit removal requires “hardened” pump • Classifier and washer • Washed material into dumpster Pretreatment – Grit Removal • Aerated grit tank • Diffused air suspends light weight organics • Heavy, dense grit settles to bottom of tank • Submersible pump in tank Pretreatment – Grit Removal • Aerated grit tank also has classifier and washer • Note that washed grit is deposited to screw conveyor Pretreatment - Equalization • Some sanitary collection systems have high levels of infiltration and inflow (I/I) that result in excessive peak flows – I/I is storm water and ground water that enters sanitary system – Present in all systems, but can be excessive • Removing I/I is difficult, and best solution may be to build Equalization tank Pretreatment - Equalization • Influent EQ Basin Pretreatment – Odor Control • Raw wastewater is often odorous, usually due to the lack of dissolved oxygen • Covered channels and tanks often control odor sufficiently • Pretreatment Buildings are ventilated and can be source of odor. • Odor control equipment is used to limit odors from the Pretreatment Building, and from tanks Pretreatment – Odor Control • Activated carbon systems are common • Biofilters can be used • Chemical addition sometimes used reduce odor potential from downstream additions Pretreatment – Odor Control • Activated carbon odor control equipment • Odorous compounds adsorb to the activated carbon Pretreatment – Chem. Addition • Chemical addition for pH control • Nutrient addition for industrial wastewaters Assignment-3 • Why is equilization necessary in a wastewater treatment plant.? With appropriate diagrams describe the difference between on-line and off-line equilization. On line/off line equalization QU QU Equilization Tank QS QS Equilization Tank On-Line Equalization: Variable flow, QU is influent to the equalization tank.? However, a steady flow QS is effluent from this tank.? When QU>QS, excess wastewater is stored in the tank.? When QU<QS, the deficit is made up from the wastewater stored in the tank. Off-line Equalization When QU > QS, the difference, i.e., QU-QS is stored in the equalization tank.? When QU < QS, the difference, i.e., QS-QU is supplied from the equalization tank. In next lecture we will primary clarifier in detail thanks!