Inventory Levels

advertisement

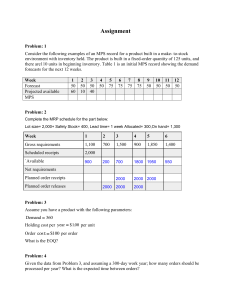

Inventory Levels Better inventory management is possible by setting inventory levels, like maximum level, reorder level and minimum level. Maximum stock level represents the quantity of inventory beyond which the stock should never move up. Reorder level refers to the level of stock at which an order for replenishing the inventory has to be placed. Minimum level or safety level is the stock level below which the size of inventory should not normally fall. Lead time, lead time consumption and the economic order quantity (EOQ) determine these inventory levels. Lead time refers to the time lapse between order placement and receipt of goods. Lead time consumption refers to the requirement/demand during the lead time. Lead time is not a constant factor, neither lead time consumption is. So, minimum, average and maximum lead times and minimum, average and maximum lead time usage rates (per period) are found from experience. EOQ is a fixed quantity which the square root of twice the period (say a year) requirement of material times ordering cost per order divided by carrying cost of a unit of material per period (a year). The different inventory levels are given by: 1. Reorder stock level = Maximum lead time x maximum usage rate or Minimum stock + (Average lead time X average usage rate) 2. Maximum stock level = Reorder level + EOQ – (Minimum lead time X Minimum Usage rate) 3. Minimum stock level = Reorder level – (Average lead time X Average Usage rate) 4. Average stock level = Minimum level + ½ of EOQ or (Minimum level + Maximum level)/2 5. Danger stock level = Minimum usage rate X Emergency lead time. MBA- Knowledge Base