Perioperative Enterprise: Re-Designing Ambulatory Surgery Center Supplies Replenishment

advertisement

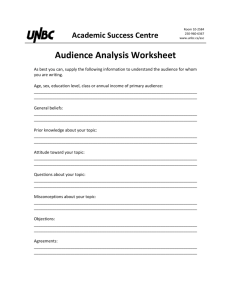

Perioperative Enterprise: Re-Designing Ambulatory Surgery Center Supplies Replenishment Presenter: David Bivens Team Members Materials: Lisa McMillian, Lauren Smoke, Patrice Jordan, Brodrick Thompson, Mary Murray Supply Chain: Jim Ishikawa IT: Wade Altman, Craig Owen, Keith Shook, Irvin Serra Institution The University of Texas MD Anderson Cancer Center So What Kind of Project is This? • Focus: OR Supplies Management • Involves: – Physical setup of supplies storage – Path Supplies take to arrive in the OR – Supplies ordering process Geographical Proximity of the Main and Ambulatory ORs Main OR & Supplies Storage Ambulatory Surgery Center & Supplies Overview of Baseline Condition • 2 Locations Performing Surgical Functions – Main OR • Supporting 29 OR Rooms plus the Ambulatory Surgery Center – Ambulatory Surgery Center (ASC) • 6 OR Rooms • 1 stock location – Supplier Ordering and Receiving in Main Only • Automated, receipts daily – Ambulatory Surgery Center orders from Main OR Stock • Manual ordering requisitions to Main OR daily Geographical Proximity of the Main and Ambulatory ORs Main OR & Supplies Storage Ambulatory Surgery Center & Supplies Catalyst For Starting the Project • Why did we start this project? – Logical 2nd Step of a project that separated the two electronic stock locations in our OR Management Software – Large quantities being returned to Main OR Stockroom – Some Items getting close to expiration – Backup staff from Main stockroom struggling with workflow demands unique to the ASC Baseline Conditions: ASC Workflow • Only Generalized Work Processes • No Standard Way to Perform a Task – What is the effect? • Inconsistent service to the Operating Rooms • No documentation for consistent training • No “Best Method” from a quality and performance standpoint • No clearly defined pars – Result: Too Much and Too Little • $’s tied up, expired material, lots of expediting Baseline VSM Suppliers Email to Main Warehouse & Finance Lawson I 1 hrs Main Whse Receipt I 12 hrs 2 Pick for ASC Re-Supply 3 I 2 hrs C/T=60min Delivery to ASC 1 I ASC Whse Receipt 8 hrs 1 C/T=180min C/T=60min C/T=40min Re-Supply Order Generation & IDT 1 Processing 1 C/T=85min I 4 hrs Pick for ASC Sched. Cases 3 C/T=75min Non Value Added Lead Time (waiting) 720 min 120 min 480 min 26 Hrs 240 min Processing Lead Time (activity) 40 min 60 min 60 min 180 min 85 min 7.1 Hrs Total Lead Time 33.1 Hrs Baseline Data • Inventory Level – Total Inventory on hand $ 322,500 – This equates to a days on hand of…. >30 days = 620 SKUs, >60 days = 546 SKUs, >90 days = 504 SKUs ... out of 1210 total items – In Terms of Dollars $ > 10 days = $186,830 $ >15 days = $118,979 $ >20 days = $51,128 • The Opportunity? – Set a goal of 30% reduction in On-Hand Inventory Aim Statement “To reduce the amount of supplies transferred from the main POE materials center to the ASC materials location by 50% by August 31, 2011” Secondary Aim “To reduce the inventory on hand in the ASC materials location by 30% by August 31,2011 through improved par management” ASC Ishikawa Exercise Personnel Physical Space Item used once, never again Can’t find item when needed Items not logically organized Space crowded with supplies Item in wrong location In wrong qty Not enough Nothing to help determine how many to order Too much Item stocked and seldom or never used Main uses handheld, ACB doesn’t Nothing to show what’s already been ordered Tools Staff perform tasks differently Staff Training Communication with main Scheduling AddOns Non-typical procedure Pars not set for the majority of items Have to ask Main what to order Excessive searching Multiple items in same bin or location Methods Not always as timely as necessary Sub-Optimal ASC Supply Management Re-Ordering is completely manual No Standard Work Processes Locations not in Picis OR Manager so can’t “look-up” where item is in storage area ASC Ishikawa Exercise Physical Space Can’t find item when needed Items not logically organized Item used once, never again In wrong qty Nothing to help determine how many to order Too much Main uses handheld, ACB doesn’t Communication with main Scheduling Item stocked and seldom or never used Nothing to show what’s already been ordered Tools Staff Training Space crowded with supplies Item in wrong location Not enough Personnel Staff perform tasks differently AddOns Non-typical procedure Pars not set for the majority of items Have to ask Main what to order Excessive searching Multiple items in same bin or location Methods Not always as timely as necessary Sub-Optimal ASC Supply Management Re-Ordering is completely manual No Standard Work Processes Locations not in Picis OR Manager so can’t “look-up” where item is in storage area VSM Idea Sheet Suppliers Email to Main Warehouse & Finance Lawson I 1 hrs Main Whse Receipt 2 C/T=40min I 12 hrs Pick for ASC Re-Supply 3 Delivery to ASC I 2 hrs 1 Double Handling of ASC C/T=60min Supplies I ASC Whse Receipt 8 hrs 1 C/T=180min C/T=60min Re-Supply Order Generation & IDT 1 Processing Manual Re-Ordering -can we use barcode scanner? 1 C/T=85min I 4 hrs Pick for ASC Sched. Cases Manual IDT Process 3 C/T=75min Non Value Added Lead Time (waiting) 720 min 120 min 480 min 26 Hrs 240 min Processing Lead Time (activity) 40 min 60 min 60 min 180 min 85 min 7.1 Hrs Total Lead Time 33.1 Hrs VSM: Future State Plan Suppliers Utilize Barcode scanner for ordering JIT items Email to Main Warehouse & Finance Lawson I 1 hrs Main Whse Receipt I 12 hrs 2 Pick for ASC Re-Supply 3 I 2 hrs C/T=60min Delivery to ASC 1 I ASC Whse Receipt 8 hrs 1 C/T=180min C/T=60min C/T=40min Re-Supply Order Generation & IDT 1 Processing 1 C/T=85min I 4 hrs Pick for ASC Sched. Cases 3 C/T=75min Non Value Added Lead Time (waiting) 720 min 120 min 480 min 26 Hrs 240 min Processing Lead Time (activity) 40 min 60 min 60 min 180 min 85 min 7.1 Hrs Total Lead Time 33.1 Hrs Project Timeline 2010 Milestone Baseline Phy. Inventory Project Initiation Testing PAR Analysis & Decisions Phy. Inventory Setup Begin Ordering from ASC Begin deliveries JIT Barcode ordering Post Implementation Phy. Inv. 2011 Mar. ---> Jul. Aug. Sep. Oct. Nov. Dec. Jan. Feb. Mar. ---> Aug. PAR Analysis • Based on a combination of actual usage documented in the OR Case Record and staff review for validation. • PAR calculations: – If JIT: PAR = (Avg. Day) + (Highest Day) – Non-JIT: PAR = (5) x (Avg. Day) Both were rounded up to next Order Unit, either each, box or case Sample of PAR Analysis Cat # 8881-220100 DYNJ05132 31142527 1808060 26006M-D/10 7541 006775-901 1600 138659 FCS9 1706060 29410 Desc. QOH 12 mo. Usage (ORMgr) NEEDLE Spinal 22g x 3 1/2" 77 ACE Wrap 6" Sterile 34 ENDO Fog Prevention Dr. Fog 10 POWER PORT isp M.R.I. 8Fr Chronoflex Single 15Lumen CABLE HI-FI W/8MM PLUG 300CM 13 COVERLET 4 x 8 50 ACMI Dolphin Collection Kit 24 Catheter Plug 30 CAUTERY PENCIL FOOT CONTROL 10ft. 43 HARMONIC FOCUS Shears Curved,Torque/Grip 30 9mm PORT Power isp 6Fr 10 SHEET Laparotomy Disposable 20 31 14 46 70 61 235 116 186 267 196 463 1022 Highest Avg/ Day's Usage Days on Day (in OU's) Hand 0.12 0.06 0.18 0.28 0.24 0.94 0.46 0.74 1.06 0.78 1.84 4.07 2.0 0.2 0.1 2.0 0.4 7.0 1.0 6.0 0.2 0.8 5.0 0.6 623 610 55 54 53 53 52 40 40 38 5 5 New Stockroom Setup Barcode Scanning Replenishment • No more scrolling through each item or typing items and quantities • Just scan locations needing re-supply and type in quantity remaining Job Guidance Sheet: New Process • Posted in the Work Area • Training Aid • As-Needed Quick Reference Data Over Time: Revisiting the Aim Statement “To reduce the amount of supplies transferred from the main POE materials center to the ASC materials location by 50% by August 31, 2011” So, using QI Analyst software an Individuals and Moving Range chart was created to monitor the progress. IDT History Prior to Intervention Total: 19 Rows: All Std Dev :79.211 CpM : N/A CpK: N/A Est % out SL (Cap) : N/A Act % out SL: N/A Dist:Normal X-Bar298.478 : Est Sigma:44.308 Sigma Type: N/A MR-Bar :49.996 Supply IDT's to ASC (per case adjusted): Baseline Process Baseline 500.0 Nov. 10’: PAR Analysis 450.0 UCL=431.402 Mar. 10’: Baseline Physical Inventory 400.0 Individual Values Process Statistics 350.0 July 09’: First Data Available 300.0 CL=298.478 250.0 Jan. 10’: Physical Inventory Setup 200.0 LCL=165.554 150.0 Label: 200.0 Moving Range Chart Point UCL=163.314 150.0 X: X UCL: X CL: X LCL: MR: 100.0 50.0 CL=49.996 0.0 LCL=0.000 1 2 3 4 5 6 7 8 9 10 11 Point Number 12 13 14 15 16 17 18 19 Intervention Timeline Monthly IDTs to ASC (per case adjusted): Baseline & Post Implementation Baseline 500.0 450.0 July 09’: First Data Available 400.0 Individual Values 350.0 New Process Nov. 10’: PAR Analysis 300.0 250.0 200.0 UCL=181.477 Mar. 10’: Baseline Physical Inventory 150.0 100.0 CL=85.009 Jan. 10’: Physical Inventory Setup 50.0 0.0 LCL=-11.460 -50.0 Moving Range 250.0 200.0 150.0 UCL=118.524 100.0 50.0 CL=36.284 LCL=0.000 0.0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 Point Number Intervention Timeline Monthly IDTs to ASC (per case adjusted): Baseline & Post Implementation Baseline 500.0 450.0 July 09’: First Data Available 400.0 Individual Values 350.0 New Process Nov. 10’: PAR Analysis 300.0 Mar.11’: Start JIT handheld Ordering 250.0 200.0 Mar. 10’: Baseline Physical Inventory 150.0 100.0 0.0 UCL=181.477 CL=85.009 Jan. 10’: Physical Inventory Setup 50.0 -50.0 LCL=-11.460 Aug. 11’: FollowUp Physical Inventory 250.0 Moving Range Feb.11’: Begin Direct Ordering/ Receiving at ASC 200.0 150.0 UCL=118.524 100.0 50.0 CL=36.284 LCL=0.000 0.0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 Point Number VSM: New Current State Suppliers EDI to Vendor Replenishment Order Lawson Email IDT to Finance I 1 hrs Re-Supply Order Generation & IDT 1 Processing 1 ASC Whse Receipt C/T=61min 1 Lead Time Reduction of 24.8 hrs & Labor Reduction of 3.1 Hrs per Day C/T=180min I 4 hrs Pick for ASC Sched. Cases 3 C/T=75min Non Value Added Lead Time (waiting) 720 min 120 min 480 min 4 Hrs 240 min Processing Lead Time (activity) 40 min 60 min 60 min 180 min 75 min 4.3 Hrs Total Lead Time 8.3 Hrs Results – Primary Aim • 71.5% Reduction in transfers from Main to ASC ($298/case to $85/case) through 8 Months of post implementation data available – (Feb. ‘11 through Sept. ’11). • Looking at the last 6 months to get beyond the learning curve, transfers have reduced by 79.9%, exceeding goal by 59.7%. – This translates to a labor savings of $47,376 annually Chart of Total Transferred by Month Go Live Results – Secondary Aim • 48% Reduction in on hand inventory. • This is a reduction from the baseline physical inventory of $322,534 to $169,220 recorded in the first post implementation annual inventory (Aug. 31, 2011). • The goal of a 30% reduction in on-hand inventory has been exceeded by 58% Next Steps? Explore Implementing bar code scanning replenishment in the main POE Materials location proved out at ASC. Re-Allocate some of the staff hours gained by the project to case cart picking of instruments. This would free Sterile Processing staff to focus on improving instrument set turnaround time and quality.