NZQA registered unit standard 15764 version 3 Page 1 of 5

advertisement

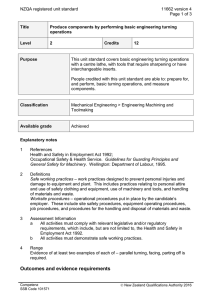

NZQA registered unit standard 15764 version 3 Page 1 of 5 Title Demonstrate knowledge of sawmill operations Level 3 Credits 15 Purpose People credited with this unit standard are able to: describe sawmill equipment and its operation; describe sawmill products and processes; describe cutting patterns and schedules; and describe legislative requirements relating to sawmill operations. Classification Solid Wood Manufacturing > Sawmilling Available grade Achieved Entry information Recommended skills and knowledge Unit 160, Demonstrate knowledge of the principles of sawmilling; Unit 5847, Demonstrate knowledge of timber yard operations; and Unit 166, Confirm log grades and scale logs; or demonstrate equivalent knowledge and skills. Explanatory notes 1 Legislation relevant to this unit standard includes, but is not limited to, the: Health and Safety in Employment Act 1992, and the Resource Management Act 1991, and their subsequent amendments. 2 Definition Worksite policies and procedures refer to documented policies and to documented or other directions provided to staff. These include, but are not limited to, ways of managing health and safety, environmental considerations, quality, and production, and must conform to legislation. Examples include standard operating procedures, company health and safety plans, on-site briefings, and supervisor’s instructions. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA registered unit standard 15764 version 3 Page 2 of 5 Outcomes and evidence requirements Outcome 1 Describe sawmill equipment and its operation. Evidence requirements 1.1 Saw centre specifications are described. Range saw centre – circular, band; specifications – maximum and minimum input sizes, kerf, and feed speeds. 1.2 Specification requirements for saw orientation are described in accordance with worksite policies and procedures. 1.3 Debarker specifications are described. Range 1.4 Types of log transport system are described. Range 1.5 advantages, and types – twin frame, quad, single circular, horizontal, line bar band resaw, centre line band resaw, edger, gang edger, breast bench, docking; description – operating principles, roles, and limitations; evidence is required for five types. The role and benefits of types of computerised equipment are described. Range 1.7 types – carriage, sharp chain, end dogging; description – operating principles, disadvantages. Types of secondary saw centre are described. Range 1.6 specifications – allowable bark in chip, issues relating to chip quality, and maximum and minimum input sizes. computerised equipment – scanners, board trimmers, cameras, setworks, slabbers, bin sorters, docking systems, log positioning/turning equipment. Chipper specifications are described. Range Competenz SSB Code 101571 chip size and quality, maximum and minimum input sizes. New Zealand Qualifications Authority 2016 NZQA registered unit standard 15764 version 3 Page 3 of 5 Outcome 2 Describe sawmill products and processes. Evidence requirements 2.1 Grade, finish and value of timber products are described. Range examples of timber products are – finger jointed timber, structural timber, clears; evidence is required for five. 2.2 Differences in nominal and target sizes of timber are identified. 2.3 Monitoring requirements and aims are outlined in accordance with worksite policies and procedures. Range 2.4 Data collection and its application to size control in sawmilling are described. Range 2.5 methods – dip, spray. The impacts of kerf in sawmilling operations are explained. Range 2.7 data collection – manual, computerised. Application methods for antisapstain are identified and described in accordance with worksite policies and procedures. Range 2.6 monitoring – operator and downstream. impacts may include – recovery, conversion, production, saw life, maintenance. Packet build and packaging requirements are interpreted from Occupational Safety and Health (OSH), customer, and/or worksite policies and procedures. Range requirements – fillet placement, number of boards across, height. Outcome 3 Describe cutting patterns and schedules used in sawmill operations. Evidence requirements 3.1 The use of cutting patterns and cutting schedules to maximise grade recovery or volume, and production value are described. 3.2 Log types are matched with cutting schedules. Range Competenz SSB Code 101571 pruned butt logs, unpruned sawlogs. New Zealand Qualifications Authority 2016 NZQA registered unit standard 15764 version 3 Page 4 of 5 3.3 The effects of alterations to cutting patterns on product quality and mill flow are described. 3.4 Options for use of defect cores are identified in accordance with worksite policies and procedures. 3.5 The concept of best opening face is described. description includes reference to – best sellable size, best face first, and best face last. Range Outcome 4 Describe legislative requirements relating to sawmill operations. Evidence requirements 4.1 Occupational health and safety matters relating to sawmill operations are explained in accordance with legislative requirements and worksite policies and procedures. Range 4.2 induction and training requirements, maximum work hours, accident and incident requirements, hazard identification, emergency procedures, safety committee operation, safety representatives. Environmental matters relating to sawmill operations are explained in accordance with legislative requirements and worksite policies and procedures. Range disposal and use of log and wood residues, restrictions on site operations, storage and disposal of chemicals and chemically treated product, chemical spillage procedures. Planned review date 31 December 2013 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 10 February 1999 31 December 2012 Review 2 18 December 2006 31 December 2012 Rollover and Revision 3 15 April 2011 N/A Consent and Moderation Requirements (CMR) reference 0173 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA registered unit standard 15764 version 3 Page 5 of 5 Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMRs). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Competenz at info@competenz.org.nz if you wish to suggest changes to the content of this unit standard. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016