NZQA registered unit standard 17759 version 3 Page 1 of 4

advertisement

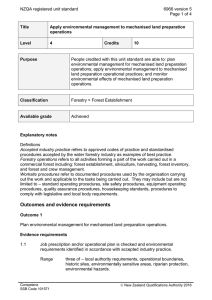

NZQA registered unit standard 17759 version 3 Page 1 of 4 Title Audit value recovery from stems using computer aided log-making systems Level 5 Purpose Credits 20 This unit standard is intended for people employed in a computerised log making role in a forestry operation. People credited with this unit standard are able to: demonstrate knowledge of the auditing of computer aided and manual logmaking systems; prepare the computer database to meet the requirements of a selected company’s log grades; gather and process data to enable comparison of computer generated log making decisions with company log-maker decisions; and produce audit comparisons and communicate results. Classification Forestry > Forest Landing Operations Available grade Achieved Explanatory notes Definitions Accepted industry practice – approved codes of practice and standardised procedures accepted by the wider forestry industry as examples of best practice. Worksite procedures – documented procedures used by the organisation carrying out the work and applicable to the tasks being carried out. They may include but are not limited to – standard operating procedures, site safety procedures, equipment operating procedures, quality assurance procedures, housekeeping standards, procedures to comply with legislative and local body requirements. Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of the auditing of computer aided and manual log-making systems. Evidence requirements 1.1 The purposes of auditing log-making systems are described in terms of optimising the value of the forest resource, meeting customer requirements, and assisting log-maker. 1.2 Computer aided log-making systems are described in terms of optimising the value of tree stems. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA registered unit standard Range 1.3 17759 version 3 Page 2 of 4 cutting decisions, auditing cutting decisions. Information requirements of a log making system are identified in accordance with worksite procedures. Outcome 2 Prepare the computer database to meet the requirements of a selected company’s log grades. Evidence requirements 2.1 Log type details are entered into the computer program in accordance with worksite procedures. Range 2.2 A coding system is produced which converts company log grade details into a format compatible with the computer program. Range 2.3 log type diameters, quality codes, minimum and maximum constraints, sweep codes, relative values. Details are entered into the computer program in accordance with worksite procedures. Range 2.4 dimensions, values, quality characteristics, codes, minimum and maximum tolerances. log types include – veneer, large saw, industrial, pulp. A minimum of one log for each type is required. Files from the master database are extracted in a format suitable for use on the remote computer. Outcome 3 Gather and process data to enable comparison of computer generated log making decisions with company log-maker decisions. Evidence requirements 3.1 Computer is operated to generate an optimal solution over a minimum of six stems in accordance with worksite procedures. 3.2 Computer generated optimal logs are checked using measuring methods in accordance with accepted industry practice. 3.3 Log-maker options are collected and entered into the computer program in accordance with manufacturer's recommendations. 3.4 Logs produced using the log-maker are checked using selected measuring methods in accordance with accepted industry practice. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA registered unit standard 3.5 17759 version 3 Page 3 of 4 Computer program is edited to accommodate data entry errors in accordance with manufacturer's recommendations. Outcome 4 Produce audit comparisons and communicate results. Evidence requirements 4.1 Computer generated optimal results and log-maker results are used to produce a comparison of value recovery. Range 4.2 value recovery percentages, defect error rate percentages, defect types. Audit comparisons are explained to the log-maker being audited. Range analysis of performance, training needs. Planned review date 31 December 2020 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 5 December 2000 31 December 2017 Review 2 22 May 2008 31 December 2017 Review 3 10 December 2015 N/A Consent and Moderation Requirements (CMR) reference 0173 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA registered unit standard 17759 version 3 Page 4 of 4 to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact Competenz at qualifications@competenz.org.nz if you wish to suggest changes to the content of this unit standard. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016