Perform basic saw doctoring calculations

advertisement

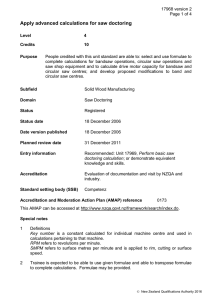

17969 version 2 Page 1 of 3 Perform basic saw doctoring calculations Level 2 Credits 5 Purpose People credited with this unit standard are able to perform basic calculations: used in saw sharpener operations and stretcher roller operations; and for a machine centre. Subfield Solid Wood Manufacturing Domain Saw Doctoring Status Registered Status date 18 December 2006 Date version published 18 December 2006 Planned review date 31 December 2011 Entry information Recommended: Unit 668, Demonstrate knowledge of the principles of saw doctoring; or demonstrate equivalent knowledge and skills. Accreditation Evaluation of documentation by NZQA and industry. Standard setting body (SSB) Competenz Accreditation and Moderation Action Plan (AMAP) reference 0173 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Definitions RPM refers to revolutions per minute. SMPM refers to surface metres per minute and is applied to rim, cutting or surface speed. 2 Trainee is expected to be able to use given formulae and able to transpose formulae to complete calculations. All formulae will be provided. 3 All performance criteria must be demonstrated and assessed in accordance with the reference text: Perform basic and apply advanced saw doctoring calculations (Auckland: Competenz, 2001) and available from Competenz, PO Box 9005, Newmarket, Auckland 1149. New Zealand Qualifications Authority 2016 17969 version 2 Page 2 of 3 Elements and performance criteria Element 1 Perform basic calculations used in saw sharpener operations. Range calculations for – SMPM, RPM, pulley size. Performance criteria 1.1 Formulae are transposed in accordance with mathematical principles. 1.2 Saw sharpener data are interpreted and entered into the formulae correctly. 1.3 Calculations are completed accurately to provide the required values. 1.4 Accuracy of the calculated values is verified against industry standards published in the reference text. Element 2 Perform basic calculations used in stretcher roller operations. Range calculations for – SMPM, gearbox ratio. Performance criteria 2.1 Formulae are transposed in accordance with mathematical principles. 2.2 Stretcher roller machine data are interpreted and entered into the formulae correctly. 2.3 Calculations are completed accurately to provide the required values. 2.4 Accuracy of the calculated values is verified against industry standards published in the reference text. Element 3 Perform basic calculations for a machine centre. Range calculations for – SMPM, RPM, tooth bite, feed speed, tooth pitch, feed per revolution. Performance criteria 3.1 Formulae are transposed in accordance with mathematical principles. 3.2 Machine centre data are interpreted and entered into the formulae correctly. 3.3 Calculations are completed accurately to provide the required values. New Zealand Qualifications Authority 2016 17969 version 2 Page 3 of 3 3.4 Accuracy of the calculated values is verified against industry standards published in the reference text. Please note Providers must be accredited by the Qualifications Authority, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by the Qualifications Authority before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Competenz at info@competenz.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016