Maintain track circuit equipment in position in a rail environment

advertisement

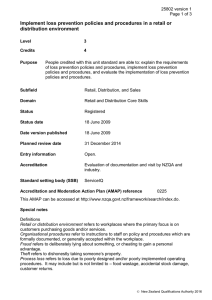

24035 version 1 Page 1 of 4 Maintain track circuit equipment in position in a rail environment Level 4 Credits 4 Purpose People credited with this unit standard are able to, in a rail environment: prepare for the maintenance of track circuit equipment; fault find and repair track circuit equipment; and test and adjust track circuit equipment. Subfield Rail Transport Domain Rail Infrastructure Status Registered Status date 21 May 2008 Date version published 21 May 2008 Planned review date 31 December 2013 Entry information Open. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Competenz Accreditation and Moderation Action Plan (AMAP) reference 0013 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Assessment against this unit standard is to be carried out within the context of an organisation operating under a current, valid Rail Licence issued in accordance with the provisions of the Railways Act 2005. The organisation’s operating rules, codes, and instructions, referred to in this unit standard, are those the organisation has in place to meet the requirements of the Rail Licence. 2 Candidates must first hold the appropriate licence, qualification, and/or certification for any electrical work undertaken in the course of assessment for this unit standard. This condition will be in accordance with organisational procedures and/or regulatory requirements that govern live electrical work. Examples include: electrical service technician (A, B), registered electrician. New Zealand Qualifications Authority 2016 24035 version 1 Page 2 of 4 3 Legislation relevant to this unit standard includes the Health and Safety in Employment Act 1992, Railways Act 2005, Resource Management Act 1991, Electricity Act 1992, Electricity Regulations 1997. 4 The following Code of Practice applies to this unit standard: NZECP 60:1997, New Zealand Electrical Code of Practice for Inspection, Testing and Certification of Low Voltage A.C. Railway Signalling Control Circuits, Ministry of Commerce, Wellington. 5 Track circuit equipment refers to both electronic and non-electronic systems and their various components which may include but is not limited to: conduits, track leads, cables, track bonds, relays, transformers, rectifiers. 6 Maintenance is to be undertaken on at least three occasions, using one or more item of track circuit equipment, with at least one being electronic. 7 Tools and equipment for maintenance purposes may include but are not limited to: hand and power tools; flood lighting; portable two way radios; air compressors; measuring rules; gauges. 8 Operations may: be conducted by day or night in all relevant weather conditions; be conducted in restricted spaces or exposed conditions or controlled or open environments; involve exposure to chemicals, dangerous or hazardous substances and movements of equipment, materials and vehicles. 9 Competenz acknowledges the assistance provided by the Transport and Logistics Industry Skills Council in permitting unit of competency TDTB5401A, Install and Maintain Track Circuit Equipment to be used as the basis for this unit standard. 10 Definitions In position refers to equipment located in its usual place within the rail network, as opposed to being temporarily off-site in, for example, an engineering workshop or other maintenance facility. Organisational procedures refer to documents that include: worksite rules, codes, and practices; equipment operating instructions; routine maintenance schedules; technical specifications; documented quality management systems; maintenance schedules; and health and safety requirements. Elements and performance criteria Element 1 Prepare for the maintenance of track circuit equipment. Performance criteria 1.1 Relevant instructions and information are accessed in accordance with job requirements and organisational procedures. New Zealand Qualifications Authority 2016 24035 version 1 Page 3 of 4 1.2 Work is planned to ensure safe maintenance activities and minimum disruption to train operations. Range 1.3 may include but is not limited to – rail permissions, track protection, Train Control bulletins, local work schedules, train movements, special circumstances. Personal protective equipment (PPE) is used in accordance with organisational requirements. Range may include but is not limited to – high visibility clothing, hearing protection, gloves, sunscreen, sunglasses, safety glasses, insect repellent, safety headwear, safety footwear, portable radios, hand lamps, flags. Element 2 Fault find and repair track circuit equipment. Performance criteria 2.1 Equipment is checked in terms of integrity, position, and security. 2.2 Normal function and operating parameters are confirmed in accordance with organisational procedures. 2.3 Fault finding and diagnostic techniques are completed in accordance with organisational procedures to verify system/faults. 2.4 Faulty, damaged, or insecure components are replaced, repaired or secured in accordance with organisational procedures. 2.5 Equipment is tested in accordance with organisational procedures to meet required technical parameters. 2.6 Maintenance records are completed in accordance with organisational procedures. Element 3 Test and adjust track circuit equipment. Range test instruments may include but are not limited to – voltmeters, ammeters, decade resistances, ohmmeters, track circuit short finders, peak voltage meters, rail induction meters, integrators, frequency selective meters, multimeters, dummy amplifiers (REED), code generators, shunt boxes. Performance criteria 3.1 Correct calibration of test instruments is verified in accordance with organisational procedures. New Zealand Qualifications Authority 2016 24035 version 1 Page 4 of 4 3.2 Appropriate readings are measured and recorded using relevant test instruments. 3.3 Equipment is adjusted in accordance with organisational procedures. 3.4 Equipment operational tests are completed in accordance with organisational procedures. 3.5 Circuits are monitored in accordance with organisational procedures. Range 3.6 monitoring equipment may include but is not limited to – stop watches, data loggers, indicator lamps, LED and graphic displays. Equipment is confirmed as fulfilling functional tests in accordance with organisational procedures. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Competenz qualifications@competenz.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016