FOOTWEAR Demonstrate knowledge of footwear manufacture and construction

advertisement

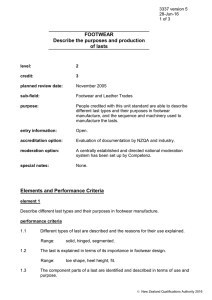

3348 version 5 28-Jun-16 1 of 3 FOOTWEAR Demonstrate knowledge of footwear manufacture and construction level: 3 credit: 6 planned review date: November 2005 sub-field: Footwear and Leather Trades purpose: People credited with this unit standard will be able to: describe the main manufacturing procedures; describe the processes to produce uppers, last, sole attach and finish footwear; and explain footwear constructions. This unit standard is for those in footwear retail, manufacturing and ancillary trades. entry information: Open. accreditation option: Evaluation of documentation and visit by NZQA and industry. moderation option: A centrally established and directed national moderation system has been set up by Competenz. special notes: None. Elements and Performance Criteria element 1 Identify and describe the main footwear manufacturing procedures. Range: design and/or pattern cutting, clicking, closing, bottom stock, lasting, sole attaching and finishing and/or boxing. performance criteria 1.1 Departments of footwear factory are identified. 1.2 The main processes carried out in each department are described. New Zealand Qualifications Authority 2016 3348 version 5 28-Jun-16 2 of 3 FOOTWEAR Demonstrate knowledge of footwear manufacture and construction element 2 Describe the processes to produce uppers. Range: cutting, lining assembly, skiving, splitting, reinforcing, stitching, folding, binding, closed seaming, lap seaming, post trimming, decorative stitching. performance criteria 2.1 Cutting and closing machinery is identified and its purpose explained. 2.2 Operations carried out on each machine are described. element 3 Describe the processes to last, sole attach and finish and/or box footwear. Range: upper conditioning, forepart lasting, seat and/or side lasting, heat setting, bottom preparation, sole laying, moulding, rough rounding, sole stitching, finishing and/or boxing operations. performance criteria 3.1 Lasting, bottom preparation and sole attachment machinery is identified and its purpose explained. 3.2 Operations carried out on each machine are described. 3.3 Hand operations carried out are described. element 4 Explain the different footwear constructions. Range: cemented, stitchdown, welted, force lasted, moulded. performance criteria 4.1 Construction methods are described. 4.2 The features of each lasting method are described. New Zealand Qualifications Authority 2016 3348 version 5 28-Jun-16 3 of 3 FOOTWEAR Demonstrate knowledge of footwear manufacture and construction Range: 4.3 inlasted, outlasted, force lasted, string lasted. The main features, purposes and benefits of footwear produced by different construction methods are described. Comments on this unit standard Please contact Competenz info@competenz.org.nz if you wish to suggest changes to the content of this unit standard. Please Note Providers must be accredited by the Qualifications Authority or a delegated interinstitutional body before they can register credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by the Qualifications Authority before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for providers wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. This unit standard is covered by AMAP 0030 which can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. New Zealand Qualifications Authority 2016