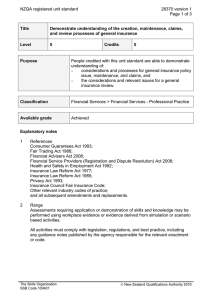

NZQA registered unit standard 14297 version 4 Page 1 of 6

advertisement

NZQA registered unit standard 14297 version 4 Page 1 of 6 Title Carry out commissioning and maintenance tests on single and multiple input protection systems Level 5 Credits 6 Purpose People credited with this unit standard are able to: prepare to test single and multiple input protection systems; set up test equipment; carry out commissioning and maintenance tests on single and multiple input protection systems; interpret test results and complete compliance documentation; and return the equipment to service. Classification Electricity Supply > Electricity Supply - Testing Available grade Achieved Entry information Critical health and safety prerequisites Unit 14287, Use and maintain test instruments used within the high voltage electrical industry, or demonstrate equivalent knowledge or skills. Explanatory notes 1 This unit standard is intended for, but not restricted to, workplace assessment. The range statements across the unit standard can be applied according to industry-specific equipment, procedures, and processes. 2 Safety of personnel and plant must be prioritised during assessment against this unit standard. If the client safety requirements are not met assessment must stop. 3 Performance of the evidence requirements must comply with all current legislation, especially the Electricity Act 1992, and any regulations and codes of practice recognised under that statute; the Health and Safety in Employment Act 1992; and the Resource Management Act 1991. Electricity supply industry codes of practice and documented industry procedures include the current version of the Safety Manual – Electricity Industry (SM-EI) (Wellington: Electricity Engineers’ Association). A full list of current legislation and industry codes is available from the Electricity Supply Industry Training Organisation, PO Box 1245, Hamilton 3240. Electricity Supply Industry Training Organisation SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 14297 version 4 Page 2 of 6 4 The phrase in accordance with industry requirements applies to all of the evidence requirements in this unit standard. 5 Industry requirements include all asset owner requirements; manufacturers’ specifications; and enterprise requirements. Enterprise requirements may include the documented workplace policies, procedures, specifications, business, and quality management requirements relevant to the workplace in which assessment is carried out. 6 Practical exercises should be used for assessment wherever possible. 7 This unit standard covers carrying out commissioning and maintenance tests on single and multiple input protection relays. Testing is normally initially applied in a test laboratory situation and maintenance normally takes place at electricity supply substations. Please note that this unit standard does not cover distance protection. 8 Definition CT = Current Transformer. Outcomes and evidence requirements Outcome 1 Prepare to test single and multiple input protection systems. Evidence requirements 1.1 The relevant technical specifications and logic schematic diagrams for single and multiple input protection systems are selected and interpreted in terms of client requirements. Range 1.2 The test specifications and performance standards for protection system relays are selected. Range 1.3 may include but is not limited to – differential, power, phase displacements, synchronising, directional earth faults, inverse, definite time, electronic and electro-mechanical relays. may include but is not limited to – performance characteristics, pick-up, drop-off, polar plots. The selected test circuit, inspection, and data acquisition monitoring requirements are identified in terms of client testing requirements. Range may include but is not limited to – differential, power, phase displacements, synchronising, directional earth faults, inverse, definite time, electronic and electro-mechanical relays, performance characteristics, pick-up, drop-off, polar plots. Electricity Supply Industry Training Organisation SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 1.4 The commissioning, or test plan, is prepared and provides for a comprehensive test of the whole protection system. Range 1.5 14297 version 4 Page 3 of 6 may include but is not limited to – correct function at prescribed signal levels, input signals are confirmed as being at the correct polarity and value, correct and accurate calibration of indications, alarms valid, component tests, subsystem tests, system tests. The extent of main equipment to be released from service is identified and an equipment release is requested for work access. Range includes but is not limited to – completing all requests in a timely and correct manner. Outcome 2 Set up test equipment. Evidence requirements 2.1 The selected monitoring equipment is correctly assembled to be ready for testing. Range 2.2 The prepared commissioning, or test plan, and selected test, inspection, and monitoring procedures are made available for reference during testing. Range 2.3 may include but is not limited to – design specifications, previous test results, history cards, manufacturer’s information and manuals, client’s performance requirements. The status of the test instrument calibration is verified as required by the test procedures. Range 2.4 may include but is not limited to – manufacturer’s guidelines, client operating and maintenance standards and test procedures, inspection of test leads for damage. includes but is not limited to – calibration certificates are valid, accuracy of settings. Any hazards associated with the testing are identified, and safety measures are prepared and implemented, to comply with industry safety rules. Range hazards may include but are not limited to – charged capacitors, auxiliary services, risk of trip for other equipment and alarms, control circuits; safety measures include but are not limited to – discharged capacitors, isolated auxiliary services, identified risk of trip for other equipment and alarms, earthed open circuit CT. Electricity Supply Industry Training Organisation SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 14297 version 4 Page 4 of 6 Outcome 3 Carry out commissioning and maintenance tests on single and multiple input protection systems. Evidence requirements 3.1 The tests are carried out using the selected procedures and commissioning plans. Range 3.2 may include but is not limited to – differential, power, phase displacements, synchronising, directional earth faults, inverse, definite time, electronic and electro-mechanical relays, performance characteristics, pick-up, drop-off, polar plots. The results of the tests and inspections are recorded as required by standard documentation or as specified by the client. Range may include but is not limited to – client requirements, values and signal functional relationships captured for analysis and interpretation. Outcome 4 Interpret test results and complete compliance documentation. Evidence requirements 4.1 The documented test results are interpreted for compliance with the standard required. Range 4.2 may include but is not limited to – reference design specification and schematic diagrams consistent with manufacturer’s requirements, enterprise standards, previous test results, ensure the results of tests are within given specifications. The acceptable results are noted on the test sheet. Range may include but is not limited to – actual values measured, functional compliance against the prescribed values in the test plan. 4.3 Tests with unacceptable results are repeated for confirmation. 4.4 Where necessary, adjustments are made to the protection system settings and the system is retested. Range may include but is not limited to – recording setting changes and the reason for changes. Electricity Supply Industry Training Organisation SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 4.5 14297 version 4 Page 5 of 6 Compliance or non-compliance documentation is completed for each unit tested. may include but is not limited to – manufacturer’s requirements, client documentation requirements, recommendations for remedial work, record of adjustments made, recommendations for design modifications. Range Outcome 5 Return the equipment to service. Evidence requirements 5.1 All temporary testing and monitoring equipment circuitry is removed from the equipment. 5.2 All protection relays are left correctly set. may include but is not limited to – recording final settings for future reference. Range 5.3 The test team report of ‘all clear’ for the protection system, and the return to work control system authorisation, are verified in accordance with client requirements. 5.4 The network protection system is switched into service without incident. includes but is not limited to – main equipment is checked and secure, all equipment is left in a state ready for service, the equipment is returned to service without incident. Range Planned review date 31 December 2015 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 27 April 1998 31 December 2012 Revision 2 11 February 2004 31 December 2012 Review 3 19 May 2006 31 December 2012 Review 4 8 December 2011 N/A Consent and Moderation Requirements (CMR) reference 0120 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Electricity Supply Industry Training Organisation SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 14297 version 4 Page 6 of 6 Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Electricity Supply Industry Training Organisation info@esito.org.nz if you wish to suggest changes to the content of this unit standard. Electricity Supply Industry Training Organisation SSB Code 101813 New Zealand Qualifications Authority 2016