DIVING - OCCUPATIONAL Complete non destructive testing (NDT) inspections of dive sites

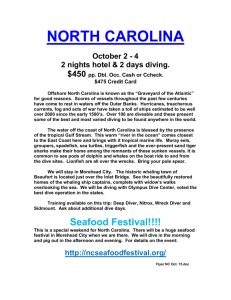

advertisement

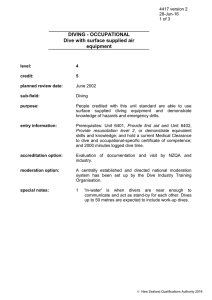

8593 version 2 11-Dec-96 1 of 6 DIVING - OCCUPATIONAL Complete non destructive testing (NDT) inspections of dive sites level: 5 credit: 10 planned review date: June 2002 sub-field: Diving purpose: People credited with this unit standard are able to: demonstrate: knowledge of NDT methods; complete magnetic particle inspections; record findings of magnetic particle inspections; and use ultrasonic testing equipment. entry information: Prerequisite: Unit 4417, Dive with surface supplied air equipment, or demonstrate equivalent knowledge and skills. accreditation option: Evaluation of documentation and visit by NZQA and industry. moderation option: A centrally established and directed national moderation system has been set up by the Dive Industry Training Organisation. special notes: 1 Industry technical and safety criteria refer to the training manuals and/or codes of practice of the training agencies approved by the Dive Industry Training Organisation. New Zealand Qualifications Authority 2016 8593 version 2 11-Dec-96 2 of 6 DIVING - OCCUPATIONAL Complete non destructive testing (NDT) inspections of dive sites 2 All workplace diving practice must comply with the requirements of the Health and Safety in Employment Act, 1992 (HSE) and subsequent regulations relating to Occupational Diving. All practice must also comply with Accident Rehabilitation and Compensation Insurance Act, 1992 (ARCI) and Occupational Safety and Health (OSH) guidelines. Elements and Performance Criteria element 1 Demonstrate knowledge of NDT methods. performance criteria 1.1 Description of magnetism meets industry criteria. Range: 1.2 principles, magnetic materials, electrically induced magnetic fields, hysteresis loops, methods of magnetisation. Explanation of ultrasonic waves meets industry technical and safety criteria. Range: compressional waves, pulsed system, Snell’s Law, attenuation, scattering, acoustic impedance, production of waves, piezoelectric effect, generation of waves. New Zealand Qualifications Authority 2016 8593 version 2 11-Dec-96 3 of 6 DIVING - OCCUPATIONAL Complete non destructive testing (NDT) inspections of dive sites 1.3 Explanation of radiography identifies the principles and safety precautions required. element 2 Complete magnetic particle inspection. performance criteria 2.1 Description of equipment used in magnetic particle inspection meets industry criteria. Range: fixed, portable, and transportable installations (DC battery, AC mains, DC rectified full current), inspection lighting, viewing aids, marking devices, demagnitisers, contrast aids. 2.2 Pre dive procedures match operation and meet industry technical and safety criteria. 2.3 Use of equipment is to manufacturer’s specification and meets industry technical and safety criteria. Range: calibration, checks, deployment. 2.4 Use of magnetic detection inks, concentrates, and powders facilitates magnetic particle inspection. 2.5 Magnetic particle inspection determines solid content. New Zealand Qualifications Authority 2016 8593 version 2 11-Dec-96 4 of 6 DIVING - OCCUPATIONAL Complete non destructive testing (NDT) inspections of dive sites 2.6 Demagnetising and post dive procedures match operation and meet industry technical and safety criteria. element 3 Record findings of magnetic particle inspection. performance criteria 3.1 Reporting of indications meets industry technical and safety criteria. 3.2 Surface and sub surface indications identify the type of discontinuity. 3.3 Surface grinding confirms indications. 3.4 Grinding of weld toes and/or parent plate meets required profile 3.5 Reporting and recording of findings meet industry technical and safety criteria. Range: transparent tape transfer, lacquer transfer, photographic, narrative commentary. New Zealand Qualifications Authority 2016 8593 version 2 11-Dec-96 5 of 6 DIVING - OCCUPATIONAL Complete non destructive testing (NDT) inspections of dive sites element 4 Use ultrasonic testing equipment. performance criteria 4.1 Use of ultrasonic testing equipment is to manufacturer’s specification and meets industry technical and safety criteria. Range: transducers, flaw detector, digital thickness meters, wave probes. 4.2 Calibration of equipment prior to testing meets industry technical and safety criteria. 4.3 Selection of probe, frequency, and scanning technique matches operation. 4.4 Use of ultrasonic equipment identifies condition of scanned material. Range: 4.5 surface condition, thickness, internal corrosion. Reporting and recording of findings meet industry technical and safety criteria. Range: written recording, narrative commentary. New Zealand Qualifications Authority 2016 8593 version 2 11-Dec-96 6 of 6 DIVING - OCCUPATIONAL Complete non destructive testing (NDT) inspections of dive sites Comments to: Dive Industry Training Organisation Unit Standard Revision PO Box 160 WELLINGTON by June 2002. Please Note: Providers must be accredited by the Qualifications Authority before they can offer programmes of education and training assessed against unit standards. Accredited providers assessing against unit standards must engage with the moderation system that applies to those unit standards. [Please refer to relevant Plan ref: 0180] New Zealand Qualifications Authority 2016