Qualification details

advertisement

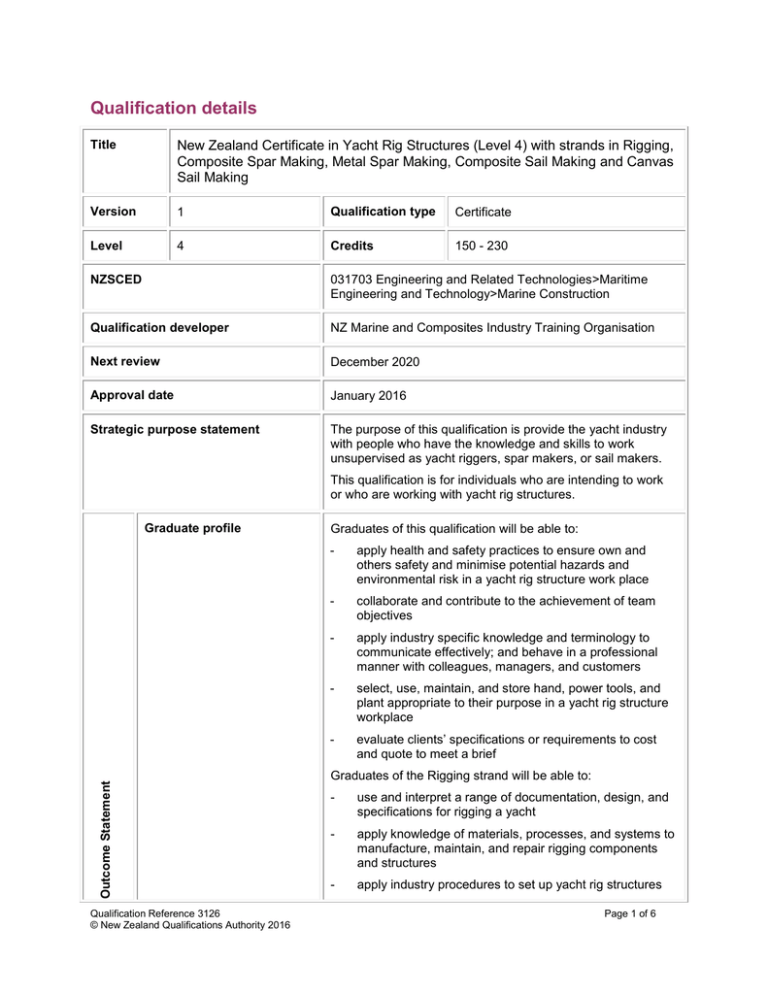

Qualification details Title New Zealand Certificate in Yacht Rig Structures (Level 4) with strands in Rigging, Composite Spar Making, Metal Spar Making, Composite Sail Making and Canvas Sail Making Version 1 Qualification type Certificate Level 4 Credits 150 - 230 NZSCED 031703 Engineering and Related Technologies>Maritime Engineering and Technology>Marine Construction Qualification developer NZ Marine and Composites Industry Training Organisation Next review December 2020 Approval date January 2016 Strategic purpose statement The purpose of this qualification is provide the yacht industry with people who have the knowledge and skills to work unsupervised as yacht riggers, spar makers, or sail makers. This qualification is for individuals who are intending to work or who are working with yacht rig structures. Outcome Statement Graduate profile Qualification Reference 3126 © New Zealand Qualifications Authority 2016 Graduates of this qualification will be able to: - apply health and safety practices to ensure own and others safety and minimise potential hazards and environmental risk in a yacht rig structure work place - collaborate and contribute to the achievement of team objectives - apply industry specific knowledge and terminology to communicate effectively; and behave in a professional manner with colleagues, managers, and customers - select, use, maintain, and store hand, power tools, and plant appropriate to their purpose in a yacht rig structure workplace - evaluate clients’ specifications or requirements to cost and quote to meet a brief Graduates of the Rigging strand will be able to: - use and interpret a range of documentation, design, and specifications for rigging a yacht - apply knowledge of materials, processes, and systems to manufacture, maintain, and repair rigging components and structures - apply industry procedures to set up yacht rig structures Page 1 of 6 Graduates of the Composite Spar Making strand will be able to: - use and interpret a range of documentation, design, and specifications for composite yacht spar making - apply knowledge of materials, processes, and systems to manufacture, maintain, and repair composite yacht spars - apply industry procedures to assemble a range of components for composite yacht spars Graduates of the Metal Spar Making strand will be able to: - use and interpret a range of documentation, design, and specifications for metal yacht spar making - apply knowledge of materials, processes, and systems to manufacture, maintain, and repair metal yacht spars - apply industry procedures to assemble a range of components for metal yacht spars Graduates of the Composite Sail Making strand will be able to: - use and interpret a range of documentation, design, and specifications for composite sail making - apply knowledge of materials, processes, and systems to manufacture, maintain and repair composite yacht sails - apply industry procedures to assemble or construct a range of components for composite yacht sails - test composite sails to ensure they are fit for purpose and they meet design and specification requirements Graduates of the Canvas Sail Making strand will be able to: Education pathway - use and interpret a range of documentation, design, and specifications for canvas sail making - apply knowledge of materials, processes, and systems to manufacture, maintain and repair canvas yacht sails - apply industry procedures to assemble or construct a range of components for canvas yacht sails - test canvas sails to ensure they are fit for purpose and they meet design and specification requirements This qualification may build on from the National Certificate of Educational Achievement (NCEA) Level 1, 2, or 3 or - New Zealand Certificate in Composites (Level 3) [Ref: 3055] Graduates of this qualification may progress to: Qualification Reference 3126 © New Zealand Qualifications Authority 2016 - New Zealand Diploma in Composites (Level 6) [Ref: 3059] - New Zealand Marine Diploma in Marine Design and Draughting (Level 6) [Ref: 3128] Page 2 of 6 Employment pathway Graduates will have the skills and knowledge to work in a range of unsupervised roles in the yacht rig structure industry. These include: - composite spar maker - metal spar maker - composite rigger - metal rigger - yacht sail maker. Qualification specifications Qualification award This qualification may be awarded by any organisation with an approved programme of study or industry training programme. Evidence requirements for assuring consistency Evidence for programme providers may include: - assessment information leading to the achievement of the graduate outcomes - a portfolio of learner work relating to the qualification and the annual review focus requirements - graduate and/or stakeholder/end-user feedback on outcome achievement - relevant excerpts from External Evaluation and Review reports Minimum standard of achievement and standards for grade endorsements Achieved. Other requirements for the qualification (including regulatory body or legislative requirements) None. General conditions for the programme leading to the qualification General conditions for programme Programmes will typically be a New Zealand Apprenticeship. The current version of the following documents must be complied with: Health and Safety in Employment Act 1992 Health and Safety in Employment Regulations 1995 Hazardous Substances & New Organisms (HSNO) Act 2001. Training and programmes must reflect current practice and maintain currency with amendments to, and replacements of relevant legislation, regulations and Australia/New Zealand Standards (AS/NZS). Qualification Reference 3126 © New Zealand Qualifications Authority 2016 Page 3 of 6 Further guidance related to programme development and training is available from the NZ Marine and Composites ITO. www.nzmarine.com or email training@bia.org.nz Conditions relating to the Graduate profile Qualification outcomes 1 Conditions Apply health and safety practices to ensure own and others safety and minimise potential hazards and environmental risk in a yacht rig structure work place. Credits 20 2 Collaborate and contribute to the achievement of team objectives. Credits 10 3 Apply industry specific knowledge and terminology to communicate effectively; and behave in a professional manner with colleagues, managers, and customers. Credits 10 4 Select, use, maintain, and store hand, power tools, and plant appropriate to their purpose in a yacht rig structure workplace. Credits 20 5 Evaluate clients’ specifications or requirements to cost and quote to meet a brief. Credits 10 Rigging strand 6 Use and interpret design, documentation, design and specifications for rigging a yacht. Credits 30 7 Apply knowledge of materials, processes, and systems to manufacture, maintain, and repair rigging components and structures. Credits 30 8 Apply industry procedures to set up yacht rig structures. Credits 30 Composite Spar Making strand Qualification Reference 3126 © New Zealand Qualifications Authority 2016 Page 4 of 6 9 Use and interpret a range of documentation, design, and specifications for composite yacht spar making. Credits 20 10 Apply knowledge of materials, processes, and systems to manufacture, maintain, and repair composite yacht spars. Credits 60 11 Apply industry procedures to assemble a range of components for composite yacht spars. Credits 60 Metal Spar Making strand 12 Use and interpret a range of documentation, design, and specifications for metal spar making. Credits 20 13 Apply knowledge of materials, processes and systems to manufacture, maintain, and repair of metal yacht spars. Credits 80 14 Apply industry procedures to assemble a range of components for metal yacht spars. Credits 60 Composite Sail Making strand 15 Use and interpret a range of documentation, design, and specifications for composite sail making. Credits 20 16 Apply knowledge of materials, processes, and systems to manufacture, maintain and repair composite yacht sails. Credits 20 17 Apply industry procedures to assemble or construct a range of components for composite yacht sails. Credits 20 18 Test composite sails to ensure they are fit for purpose and they meet design and specification requirements. Credits 20 Canvas Sail Making strand Qualification Reference 3126 © New Zealand Qualifications Authority 2016 Page 5 of 6 19 Use and interpret a range of documentation, design, and specifications for canvas sail making. Credits 20 20 Apply knowledge of materials, processes, and systems to manufacture, maintain and repair canvas yacht sails. Credits 20 21 Apply industry procedures to assemble or construct a range of components for canvas yacht sails. Credits 20 22 Test canvas sails to ensure they are fit for purpose and they meet design and specification requirements. Credits 20 Qualification Reference 3126 © New Zealand Qualifications Authority 2016 Page 6 of 6