CAN MAKING Control can making processes and trial product variations

advertisement

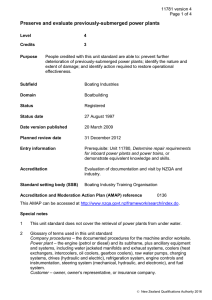

4812 version 4 28-Jun-16 1 of 3 CAN MAKING Control can making processes and trial product variations level: 4 credit: 40 planned review date: July 2009 sub-field: Manufacturing Skills purpose: People credited with this unit standard are able to control can making processes, and trial product variations on an existing can making process. entry information: Open. accreditation option: Evaluation of documentation and visit by NZQA. moderation option: A national moderation system of regional panels and assessor networks has been established by Competenz. special notes: 1 All work practices must meet recognised codes of practice and documented worksite safety procedures (where these exceed code) for personal, product, and worksite safety, and must meet the obligations required under current legislation. 2 Legislation relevant to this unit standard includes but is not limited to the: Health and Safety in Employment Act 1992; Resource Management Act 1991; Hazardous Substances and New Organisms Act 1996. 3 Definitions Worksite procedures refers to documents that include: worksite rules, codes, and practices; equipment operating instructions; documented quality management systems; and health and safety requirements. Optimise refers to achieving the balance of variables to maintain or improve a can making operation to meet worksite requirements. New Zealand Qualifications Authority 2016 4812 version 4 28-Jun-16 2 of 3 CAN MAKING Control can making processes and trial product variations Elements and Performance Criteria element 1 Control can making processes. Range: evidence is required for controlling three can making processes. performance criteria 1.1 Machine safety devices and personal protective equipment are used in accordance with job requirements and worksite procedures. 1.2 The stages in the can production process are identified and described in accordance with worksite procedures. 1.3 Can making machine and line controls are set, monitored, and adjusted as necessary to optimise worksite production and quality requirements in accordance with worksite procedures. Range: 1.4 Machine malfunctions are identified, corrected, and reported in accordance with worksite procedures. Range 1.5 speed, feed, pressure, temperature, timing. causes of malfunctions may include but are not limited to – mechanical, electrical, operator error, materials problems. Human and material resources are deployed to fulfil production capability. element 2 Trial product variations on an existing can making process. Range: evidence is required for trialling three product variations. performance criteria 2.1 Machine safety devices and personal protective equipment are used in accordance with job requirements and worksite procedures. New Zealand Qualifications Authority 2016 4812 version 4 28-Jun-16 3 of 3 CAN MAKING Control can making processes and trial product variations 2.2 Requirements of varied product are interpreted from technical data. Range: requirements may include but are not limited to – materials, machines, human resources, operating procedures, engineering drawings, technical support, product specifications. 2.3 Process equipment and tooling are prepared for trial in accordance with worksite procedures. 2.4 Trial procedures are carried out and results evaluated in accordance with worksite procedures. 2.5 Adjustments are made to optimise product quality, productivity, and safety in accordance with worksite procedures. 2.6 Procedure is documented in accordance with worksite procedures. Range: may include but is not limited to – hard copy and/or electronic documentation. Comments on this unit standard Please contact Competenz qualifications@competenz.org.nz if you wish to suggest changes to the content of this unit standard. Please Note Providers must be accredited by the Qualifications Authority or a delegated interinstitutional body before they can register credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by the Qualifications Authority before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for providers wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. This unit standard is covered by AMAP 0013 which can be accessed at http://www.nzqa.govt.nz/site/framework/search.html. New Zealand Qualifications Authority 2016