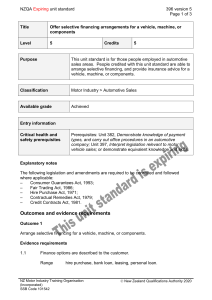

NZQA unit standard 969 version 5

advertisement

NZQA Expiring unit standard 969 version 5 Page 1 of 3 Title Retrofit a turbocharger to a petrol engine Level 5 Credits 4 Purpose This unit standard is for people in the automotive repair industry. People credited with this unit standard are able to: demonstrate knowledge of turbocharging a non-turbo engine; test an engine prior to installing a turbocharger system; and install a suitable turbocharger kit. Classification Motor Industry > Automotive Fuel Systems and Exhaust Available grade Achieved Entry information Critical health and safety prerequisites Unit 898, Identify an automotive wiring diagram and translate information to a motor vehicle circuit; Unit 923, Carry out general repairs to a cylinder head; and Unit 967, Measure and interpret engine performance; or demonstrate equivalent knowledge and skills. Explanatory notes 1 The following legislation, regulations, and their amendments are to be consulted and followed where applicable: – Health and Safety in Employment Act, 1992 – Transport (Vehicle Standards) Regulations, 1990. 2 Reference to suitable tools and equipment means industry approved tools and equipment that are recognised within the industry as being the most suited to complete the task to a professional and competent manner with due regard to safe working practices. Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of turbocharging a non-turbo engine. Evidence requirements 1.1 The reason for turbocharging an engine is explained in terms of improved power output. NZ Motor Industry Training Organisation (Incorporated) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 1.2 Costs associated with turbocharging an engine are identified. Range 1.3 969 version 5 Page 2 of 3 cost of kit, conversion cost, economic viability, other external modifications. Engine modifications necessary as a result of retrofitting are described according to manufacturer’s installation instructions. Range compression ratio, valves and cylinder head, reciprocating components, oil pump and oil cooler, cooling system, fuel system, knock sensor. Outcome 2 Test the engine prior to installing a turbocharger system. Evidence requirements 2.1 Safe working practices are observed throughout the task. Range personal safety, safety of others, equipment and vehicle safety. 2.2 Technical information on the engine is consulted to ensure that the modifications carried out are according to the turbocharger kit specifications. 2.3 The engine condition and performance is checked to ensure that it is capable of successful modification. Range mechanical inspection; state of engine tune; existing cooling, induction, and exhaust system condition. Outcome 3 Install a suitable turbocharger kit. Evidence requirements 3.1 Safe working practices are observed throughout the task. Range personal safety, safety of others, equipment and vehicle safety. 3.2 Suitable tools and equipment are selected and used to enable the kit to be installed. 3.3 The turbocharger kit selected matches the engine specifications. 3.4 The modifications required are completed according to the kit manufacturer's instructions. NZ Motor Industry Training Organisation (Incorporated) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 969 version 5 Page 3 of 3 3.5 The turbocharger unit is installed according to kit manufacturer's instructions, to ensure accessibility for maintenance. 3.6 Associated engine systems function as intended by the kit manufacturer. Range fuel system, air induction system, exhaust system, cooling system. 3.7 The completed unit operates and performs to kit manufacturer's specifications. 3.8 The performance results are recorded for employer and customer information. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 9 November 1993 31 December 2016 Review 2 4 October 1996 31 December 2016 Review 3 26 February 1999 31 December 2016 Review 4 25 January 2008 31 December 2016 Rollover 5 19 November 2010 31 December 2016 Accreditation and Moderation Action Plan (AMAP) reference 0014 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Consent requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. NZ Motor Industry Training Organisation (Incorporated) SSB Code 101542 New Zealand Qualifications Authority 2016