Demonstrate knowledge of advanced manufacturing processes and equipment

advertisement

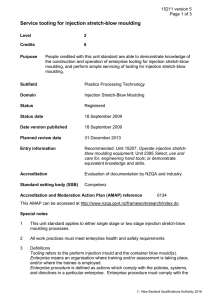

22922 version 2 Page 1 of 4 Demonstrate knowledge of advanced manufacturing processes and equipment Level 6 Credits 15 Purpose This unit standard is intended primarily for use in diploma courses in mechanical engineering. It covers knowledge of advanced processes and equipment in the context of modern manufacturing plants. People credited with this unit standard are able to: investigate advanced manufacturing processes; investigate computer-integrated manufacturing strategies; demonstrate knowledge of tooling for manufacturing; and demonstrate knowledge of metrology and its application in manufacturing. Subfield Mechanical Engineering Domain Applied Principles of Mechanical Engineering Status Registered Status date 26 November 2007 Date version published 19 March 2010 Planned review date 31 December 2015 Entry information Recommended: Unit 21788, Demonstrate and apply knowledge of manufacturing processes and equipment for mechanical engineering, or demonstrate equivalent knowledge and skills. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Competenz Accreditation and Moderation Action Plan (AMAP) reference 0013 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 References BS EN 20286-1:1993, ISO system of limits and fits. Bases of tolerances, deviations and fits. BS EN 20286-2:1993, ISO system of limits and fits. Tables of standard tolerance grades and limit deviations for holes and shafts. New Zealand Qualifications Authority 2016 22922 version 2 Page 2 of 4 ISO/IEC Guide 98-1:2009, Uncertainty of measurement -- Part 1: Introduction to the expression of uncertainty in measurement. 2 Definitions AGV – Automatic Guided Vehicle. CAM – Computer Aided Manufacturing. CIM – Computer Integrated Manufacturing. CMM – Coordinate Measuring Machine. CNC – Computer Numerical Control. DNC – Distributed Numerical Control. EDM – Electric Discharge Machining. HERF – High Energy Rate Forming (of powdered metals). Elements and performance criteria Element 1 Investigate advanced manufacturing processes. Performance criteria 1.1 Advanced manufacturing processes for metals are analysed in terms of purpose and application. Range 1.2 Advanced manufacturing processes for non-metals are analysed in terms of purpose and application. Range 1.3 processes may include but are not limited to – squeeze casting, semi-solid forming, powder metallurgy, EDM, HERF, electrochemical, laser, ultrasonic, water jet, chemical etching; evidence of six processes is required. non-metals – polymers, ceramics, composites, timber. Advanced manufacturing processes are selected for an application involving a combination of both advanced metal and non-metal processing. Element 2 Investigate computer-integrated manufacturing strategies. Performance criteria 2.1 Equipment and techniques are analysed in terms of purpose and application. Range CNC, CIM, CAM, DNC. New Zealand Qualifications Authority 2016 22922 version 2 Page 3 of 4 2.2 Automated equipment and processes are analysed in terms of purpose and application. Range equipment – materials handling, robotics, AGV; processes may include but are not limited to – production lines, total automated systems, ‘lights-out’ factories; evidence of two processes is required. Element 3 Demonstrate knowledge of tooling for manufacturing. Performance criteria 3.1 Principles of tooling are described in terms of manufacturing applications. Range 3.2 Cutting and forming tools for metals are analysed and matched to a range of applications. Range 3.3 materials may include but are not limited to – timber, paper and/or board, textiles, plastics, ceramics, composites; evidence of four materials is required. Jigs and fixtures are described in terms of benefits for manufacturing. Range 3.5 tools for – drilling, trepanning, broaching, pressing, forming. Tools for non-metals are analysed and matched to a range of materials. Range 3.4 principles – degrees of freedom, ergonomics, productivity, tool and work holding, safety. benefits – reliability, repeatability, accuracy. Types of jigs and fixtures used in typical manufacturing operations are described in terms of design considerations, standardisation of parts, and production volume. Element 4 Demonstrate knowledge of metrology and its application in manufacturing. Performance criteria 4.1 The principles of conventional engineering measuring instruments are explained, and instruments selected for dimensional measurement applications. Range measurements – diameter, radius, length, height, depth, angle; instruments may include but are not limited to – micrometers, height gauges, depth gauges, vernier callipers, radius gauges, slip gauges, sine bars, comparators, dial test indicators; evidence of six instruments is required. New Zealand Qualifications Authority 2016 22922 version 2 Page 4 of 4 4.2 Fits and limits, geometric dimensions and tolerances, and levels of acceptable uncertainty are specified for three engineering components in accordance with the ISO system and guidelines. 4.3 CMM technology is compared to traditional instruments in terms of use, accuracy, training, and cost. 4.4 The roles of metrology and standards in the achievement and enforcement of predefined standards of accuracy, precision, reliability, and traceability in manufacturing processes are discussed. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact Competenz info@competenz.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016