PHARMACEUTICAL AND ALLIED PRODUCTS MANUFACTURING Demonstrate knowledge of air quality

advertisement

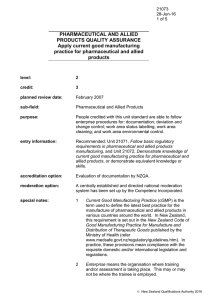

21944 28-Jun-16 1 of 4 PHARMACEUTICAL AND ALLIED PRODUCTS MANUFACTURING Demonstrate knowledge of air quality for pharmaceutical and allied products manufacturing level: 2 credit: 3 planned review date: August 2007 sub-field: Pharmaceutical and Allied Products purpose: People credited with this unit standard are able to demonstrate knowledge of air quality for pharmaceutical and allied products manufacturing. entry information: Recommended: Unit 21943, Demonstrate basic knowledge of engineering for pharmaceutical and allied products manufacturing, or demonstrate equivalent knowledge and skills. accreditation option: Evaluation of documentation by NZQA. moderation option: A centrally established and directed national moderation system has been set up by Competenz. special notes: 1 This unit standard applies to non-sterile manufacturing. 2 Current Good Manufacturing Practice (cGMP) is the term used to define the latest best practice for the manufacture of pharmaceutical and allied products in various countries around the world. In New Zealand, this requirement is set out in the New Zealand Code of Good Manufacturing Practice for Manufacture and Distribution of Therapeutic Goods published by the Ministry of Health (refer www.medsafe.govt.nz/regulatory/guidelines.htm). In practice, these provisions mean compliance with the requisite domestic and/or international legislation and regulations. 3 Enterprise means the organisation where training and/or assessment is taking place. This may or may not be where the trainee is employed. New Zealand Qualifications Authority 2016 21944 28-Jun-16 2 of 4 PHARMACEUTICAL AND ALLIED PRODUCTS MANUFACTURING Demonstrate knowledge of air quality for pharmaceutical and allied products manufacturing 4 The air filter classification systems that apply to performance criteria 1.4 are referred to in the following standards: Eurovent/Cecomaf Technical Secretariat, Eurovent 4/5 – 1992 Method Of Testing Air Filters Used In General Ventilation; Eurovent/Cecomaf Technical Secretariat, Eurovent 4/8 – 1985 In Situ Leak Test Of High Efficiency Filters In Clean Spaces (D.O.P. Aerosol Test); European Committee for Standardisation, BS EN 779:2002 Particulate Air Filters for General Ventilation – Determination of the Filtration Performance; European Committee for Standardisation, CEN EN 1822-1:1998 High efficiency air filters (HEPA and ULPA). Classification, Performance Testing, Marking. 5 References that apply to 1.1 are: International Organisation for Standardisation, ISO 14644:1999 Cleanrooms and Associated Controlled Environments – Part 1 Classification of Air Cleanliness; Standards Australia, AS 1386.1-1989 Cleanrooms and Clean Workstations – Principles of Clean Space Control. 6 Competenz unit designation is PAME2.2. New Zealand Qualifications Authority 2016 21944 28-Jun-16 3 of 4 PHARMACEUTICAL AND ALLIED PRODUCTS MANUFACTURING Demonstrate knowledge of air quality for pharmaceutical and allied products manufacturing Elements and Performance Criteria element 1 Demonstrate knowledge of air quality for pharmaceutical and allied products manufacturing. performance criteria 1.1 The class system is explained with reference to the applicable air classification standard for the enterprise, and the class of each zone within the enterprise manufacturing facility is identified. Range: classifications must comply with the requisite domestic and international standards such as – Annex 1 of the New Zealand Code of Good Manufacturing Practice for Manufacture and Distribution of Therapeutic Goods, ISO 14644:1999, AS 1386.11989. 1.2 The air pressure differentials and airflow directions within the enterprise manufacturing facility are identified, and their purpose is explained. 1.3 The applicable specifications for temperature and humidity within the enterprise manufacturing facility are identified, and their purpose is explained. 1.4 The basic concepts of the classification system for air filters are explained. Range: 1.5 classification system – coarse (EU3, EU4; G3, G4); medium (EU5EU7; F5-F7); fine (EU8-EU10; F8-F10); absolute (EU11 – EU14; H11- H14. The major components of an air distribution system that complies with cGMP are identified, and their purpose is explained. Range: major components – air plenum, pre-filters, supply and return fans, heating and cooling coils, humidifiers and dehumidifiers, condensate drains, air filters and housings, dampers, ducting, access hatches, grilles, registers, diffusers, silencers, control and monitoring instruments and equipment. New Zealand Qualifications Authority 2016 21944 28-Jun-16 4 of 4 PHARMACEUTICAL AND ALLIED PRODUCTS MANUFACTURING Demonstrate knowledge of air quality for pharmaceutical and allied products manufacturing 1.6 The routine monitoring and maintenance requirements for an air distribution system that complies with cGMP are identified and explained. Range: 1.7 requirements – pressure differentials (room, filter and system), particle counting, microbiological levels, temperature, humidity, airflow. The certification requirements and frequency for an air distribution system that complies with cGMP are explained. Range: certification requirements – air balancing, pressure differentials, air-change rates, particulate testing, filter integrity testing, calibration, temperature and humidity performance testing. Comments on this unit standard Please contact Competenz if you wish to suggest changes to the content of this unit standard. Please Note Providers must be accredited by the Qualifications Authority or a delegated interinstitutional body before they can register credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by the Qualifications Authority before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for providers wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. This unit standard is covered by AMAP 0134 which can be accessed at http://www.nzqa.govt.nz/site/framework/search.html. New Zealand Qualifications Authority 2016