PHARMACEUTICAL AND ALLIED PRODUCTS QUALITY ASSURANCE Perform routine testing for

advertisement

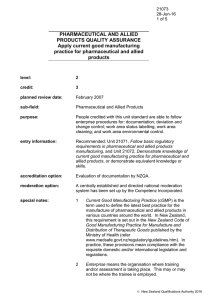

21363 28-Jun-16 1 of 5 PHARMACEUTICAL AND ALLIED PRODUCTS QUALITY ASSURANCE Perform routine testing for pharmaceutical and allied products manufacturing level: 2 credit: 4 planned review date: May 2007 sub-field: Pharmaceutical and Allied Products purpose: People credited with this unit standard are able to prepare to perform routine testing in accordance with enterprise procedure, and perform routine testing. entry information: Prerequisite: Unit 21071, Follow basic regulatory requirements in pharmaceutical and allied products manufacturing; and Unit 21072, Demonstrate knowledge of current good manufacturing practice for pharmaceutical and allied products; or demonstrate equivalent knowledge and skills. Recommended: Unit 21073, Apply current good manufacturing practice for pharmaceutical and allied products; and Unit 21361, Demonstrate knowledge of quality control for pharmaceutical and allied products manufacturing; or demonstrate equivalent knowledge and skills. accreditation option: Evaluation of documentation by NZQA. moderation option: A centrally established and directed national moderation system has been set up by Competenz New Zealand Qualifications Authority 2016 21363 28-Jun-16 2 of 5 PHARMACEUTICAL AND ALLIED PRODUCTS QUALITY ASSURANCE Perform routine testing for pharmaceutical and allied products manufacturing special notes: 1 Current Good Manufacturing Practice (cGMP) is the term used to define the latest best practice for the manufacture of pharmaceutical and allied products in various countries around the world. In New Zealand, this requirement is set out in the New Zealand Code of Good Manufacturing Practice for Manufacture and Distribution of Therapeutic Goods published by the Ministry of Health (refer www.medsafe.govt.nz/regulatory/guidelines.htm). In practice, these provisions mean compliance with the requisite domestic and/or international legislation and regulations. 2 Enterprise means the organisation where training and/or assessment is taking place. This may or may not be where the trainee is employed. 3 Enterprise procedure means actions that comply with the policies, systems, and directives in a particular enterprise. Enterprise procedures must comply with the requirements of the Health and Safety in Employment Act 1992, and subsequent amendments. They must also comply with the requisite Good Manufacturing Practice provisions for the enterprise such as the following New Zealand legislation and regulations: Medicines Act 1981; Medicines Regulations 1984; Dietary Supplement Regulations 1985; Agricultural Compounds and Veterinary Medicines Act 1997; and Agricultural Compounds and Veterinary Medicines Regulations 2001. 4 Routine testing may include tests for appearance, contaminants, uniformity of content, weight, moisture content, bulk density, particle size, specific gravity, thickness, hardness, dissolution, friability, disintegration, pH, viscosity, odour, conductivity, temperature, calibration, physical measurements, colour comparisons, and titration. 5 Evidence requirements for this unit standard must cover five different routine tests. New Zealand Qualifications Authority 2016 21363 28-Jun-16 3 of 5 PHARMACEUTICAL AND ALLIED PRODUCTS QUALITY ASSURANCE Perform routine testing for pharmaceutical and allied products manufacturing 6 Competenz unit designation is PAMT2.3. Elements and Performance Criteria element 1 Prepare to perform routine testing in accordance with enterprise procedure. performance criteria 1.1 The correct documentation and approved method for the test are identified. 1.2 Garmenting and personal hygiene procedures are followed. 1.3 Work area and equipment are checked to ensure they are clear of all previous materials, packaging, and documentation, and are appropriate for use. 1.4 Equipment, materials, and handling hazards are identified, and safety precautions are taken. 1.5 Personal protective equipment is identified and prepared. 1.6 Testing equipment is identified and prepared. 1.7 Test materials are located, checked, and positioned for testing. 1.8 Testing equipment checks are performed. Range: checks may include – calibration status, equipment challenge, suitability checks. New Zealand Qualifications Authority 2016 21363 28-Jun-16 4 of 5 PHARMACEUTICAL AND ALLIED PRODUCTS QUALITY ASSURANCE Perform routine testing for pharmaceutical and allied products manufacturing element 2 Perform routine testing. performance criteria 2.1 Special instructions for opening and handling test materials are identified and followed in accordance with enterprise procedure. 2.2 Unacceptable materials are identified, required action is taken, and documentation is completed, in accordance with enterprise procedure. Range: unacceptable may include – contaminated, untraceable, expired, non-conforming, insufficient quantity, incorrect. 2.3 Tests are performed in accordance with the approved method and enterprise procedure. 2.4 Test results are entered into test records and verified in accordance with enterprise procedure. 2.5 Enterprise procedures for notifying test failure and rectifying testing errors or incorrect conditions are explained. Range: enterprise procedures include – investigation of failed results, no immediate re-test of sample, re-sampling and re-test instructions. 2.6 Retention and unused materials are packed, labelled, and stored, and details are entered into test records, in accordance with enterprise procedure. 2.7 Waste materials are disposed of in accordance with enterprise procedure. 2.8 Testing records are delivered or filed in accordance with enterprise procedure. 2.9 Cleaning materials, cleaning equipment, and personal protective equipment required by the enterprise for cleaning work area and testing equipment are prepared. 2.10 Work area and testing equipment used are cleaned, status labels are applied, and records are completed, to meet enterprise requirements. New Zealand Qualifications Authority 2016 21363 28-Jun-16 5 of 5 PHARMACEUTICAL AND ALLIED PRODUCTS QUALITY ASSURANCE Perform routine testing for pharmaceutical and allied products manufacturing Comments on this unit standard Please contact Competenz info@competenz.org.nz if you wish to suggest changes to the content of this unit standard. Please Note Providers must be accredited by the Qualifications Authority or a delegated interinstitutional body before they can register credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by the Qualifications Authority before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for providers wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. This unit standard is covered by AMAP 0134 which can be accessed at http://www.nzqa.govt.nz/site/framework/search.html. New Zealand Qualifications Authority 2016