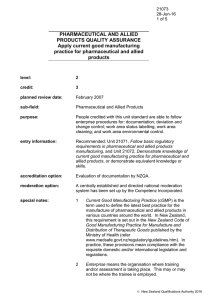

PHARMACEUTICAL AND ALLIED PRODUCTS MANUFACTURING Demonstrate basic knowledge of engineering for pharmaceutical and

advertisement

21943 28-Jun-16 1 of 4 PHARMACEUTICAL AND ALLIED PRODUCTS MANUFACTURING Demonstrate basic knowledge of engineering for pharmaceutical and allied products manufacturing level: 2 credit: 4 planned review date: August 2007 sub-field: Pharmaceutical and Allied Products purpose: People credited with this unit standard are able to demonstrate basic knowledge of engineering for pharmaceutical and allied products manufacturing. entry information: Recommended: Unit 21071, Follow basic regulatory requirements in pharmaceutical and allied products manufacturing, and Unit 21072, Demonstrate knowledge of current good manufacturing practice for pharmaceutical and allied products, or demonstrate equivalent knowledge and skills. accreditation option: Evaluation of documentation by NZQA. moderation option: A centrally established and directed national moderation system has been set up by the Competenz Incorporated. special notes: 1 Current Good Manufacturing Practice (cGMP) is the term used to define the latest best practice for the manufacture of pharmaceutical and allied products in various countries around the world. In New Zealand, this requirement is set out in the New Zealand Code of Good Manufacturing Practice for Manufacture and Distribution of Therapeutic Goods published by the Ministry of Health (refer www.medsafe.govt.nz/regulatory/guidelines.htm). In practice, these provisions mean compliance with the requisite domestic and/or international legislation and regulations. 2 Enterprise means the organisation where training and/or assessment is taking place. This may or may not be where the trainee is employed. New Zealand Qualifications Authority 2016 21943 28-Jun-16 2 of 4 PHARMACEUTICAL AND ALLIED PRODUCTS MANUFACTURING Demonstrate basic knowledge of engineering for pharmaceutical and allied products manufacturing 3 Competenz unit designation is PAME2.1. Elements and Performance Criteria element 1 Demonstrate basic knowledge of engineering for pharmaceutical and allied products manufacturing. performance criteria 1.1 Common utilities and plant services used in pharmaceutical and allied products manufacturing are named, and an example of a common use for each is described. Range: 1.2 The primary equipment required to produce plant services are named. Range: 1.3 plant services – air conditioning and ventilation, compressed air, process water, water for product manufacture, lighting, dust extraction, vacuum, steam, hot water, refrigeration. The plant services used in the enterprise are identified, and their function is explained. Range: 1.4 utilities – electricity, potable water, gas, effluent disposal; plant services – air conditioning and ventilation, compressed air, process water, water for product manufacture, lighting, dust extraction, vacuum, steam, hot water, refrigeration; evidence is required for eight plant services. plant services may include – air conditioning and ventilation, compressed air, process water, water for product manufacture, lighting, dust extraction, vacuum, steam, hot water, refrigeration. An example of the influence each of the enterprise plant services can have on product quality is described. New Zealand Qualifications Authority 2016 21943 28-Jun-16 3 of 4 PHARMACEUTICAL AND ALLIED PRODUCTS MANUFACTURING Demonstrate basic knowledge of engineering for pharmaceutical and allied products manufacturing Range: 1.5 The routine operating, testing, calibration, and maintenance of enterprise plant services are outlined. Range: 1.6 construction of manufacturing facilities includes – structure and materials, weatherproofing, pest proofing, security, cleanability, surface finishes, sealants; maintenance of manufacturing facilities includes – access control, contractor control, activity control, emergency procedure control, signage, lighting, damage repair, cleaning; evidence is required for five examples of construction and five examples of maintenance. The impact of cGMP requirements on the maintenance of manufacturing equipment is outlined. Range: 1.8 plant services may include – air conditioning and ventilation, compressed air, process water, water for product manufacture, lighting, dust extraction, vacuum, steam, hot water, refrigeration. The impact of cGMP requirements on the construction and maintenance of manufacturing facilities is outlined. Range: 1.7 plant services may include – air conditioning and ventilation, compressed air, process water, water for product manufacture, lighting, dust extraction, vacuum, steam, hot water, refrigeration. maintenance – surface finishes, cleanability, cleaning, lighting, signage, contractor control, activity control, emergency procedures, damage repair, parts, equipment failure; evidence is required for seven examples of maintenance. The impact of cGMP requirements on engineering practice is explained. Range: engineering practice includes – dedicated tools, change control, approved lubricants and additives, documented work practices, approved materials, approved tools, documented maintenance records, reporting of deviations, status labelling, configuration changes; evidence is required for six examples of engineering practice. New Zealand Qualifications Authority 2016 21943 28-Jun-16 4 of 4 PHARMACEUTICAL AND ALLIED PRODUCTS MANUFACTURING Demonstrate basic knowledge of engineering for pharmaceutical and allied products manufacturing Comments on this unit standard Please contact Competenz info@competenz.org.nz if you wish to suggest changes to the content of this unit standard. Please Note Providers must be accredited by the Qualifications Authority or a delegated interinstitutional body before they can register credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by the Qualifications Authority before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for providers wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. This unit standard is covered by AMAP 0134 which can be accessed at http://www.nzqa.govt.nz/site/framework/search.html. New Zealand Qualifications Authority 2016