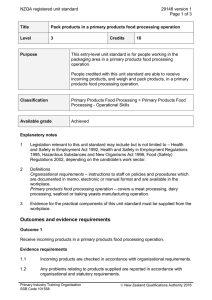

NZQA registered unit standard 21136 version 3 Page 1 of 3

advertisement

NZQA registered unit standard 21136 version 3 Page 1 of 3 Title Operate a process control interface in a dairy processing operation Level 4 Purpose Credits 5 This unit standard is for people carrying out milk processing functions in a dairy processing operation. People credited with this unit standard are able to: navigate the process control interface; use process control interface to operate and maintain a process within required parameters; and analyse data to predict and control performance, in a dairy processing operation. Classification Dairy Processing > Milk Processing Available grade Achieved Explanatory notes 1 Legislation Legislation relevant to this unit standard includes but is not limited to Animal Products Act 1999, Animal Products (Dairy) Regulations 2005, Health and Safety in Employment Act 1992, Health and Safety in Employment Regulations 1995. 2 Definitions Organisational requirements – refer to instructions to staff on policies and procedures which are documented in memo, electronic and/or manual format and are available in the workplace. These include but are not limited to – site-specific and company standard operating procedures (SOPs), occupational health and safety, food safety and quality management requirements. Process control interfaces include but are not limited to – computer based operating programmes, touch screens, programmable large circuits with laptop interface, inventory set fuse operating a data defence, computers. 3 This unit standard assumes an operator has a working knowledge of automation systems, diagnostics, and fault finding. 4 This unit standard must be assessed in a realistic workplace environment. The candidate must be under realistic time pressures and use relevant commercial equipment. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA registered unit standard 21136 version 3 Page 2 of 3 Outcomes and evidence requirements Outcome 1 Navigate the process control interface in a dairy processing operation. Evidence requirements 1.1 Interface and related components are confirmed as ready for operation in accordance with organisational requirements. 1.2 Hardware is used to operate the interface in accordance with organisational requirements. 1.3 Page links are used to move between screens in accordance with organisational requirements. 1.4 Messages and alarms are acknowledged in accordance with organisational requirements. 1.5 Information is accessed from screen displays in accordance with organisational requirements. 1.6 Interface system malfunctions are reported and recorded in accordance with organisational requirements. Outcome 2 Use the process control interface to operate and maintain a process within required parameters in a dairy processing operation. Evidence requirements 2.1 Items of equipment and/or processes are started up, monitored and shutdown using the control interface in accordance with organisational requirements. 2.2 Equipment is selected and status altered by fixing settings to meet operating and organisational requirements. 2.3 Sequences are activated to initiate process operation in accordance with organisational requirements. 2.4 Equipment indicating malfunction is recognised and action is taken to identify and correct faults in accordance with organisational requirements. Outcome 3 Analyse data to predict and control performance in a dairy processing operation. Evidence requirements Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016 NZQA registered unit standard 21136 version 3 Page 3 of 3 3.1 Data is selected and analysed to identify performance patterns in accordance with organisational requirements. 3.2 Causes of abnormal or unacceptable performance are identified and corrective action taken in accordance with organisational requirements. 3.3 Information is recorded in accordance with organisational requirements. Planned review date 31 December 2020 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 27 October 2005 31 December 2014 Rollover and Revision 2 17 July 2009 31 December 2016 Review 3 18 June 2015 N/A Consent and Moderation Requirements (CMR) reference 0022 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMRs). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Primary Industry Training Organisation standards@primaryito.ac.nz if you wish to suggest changes to the content of this unit standard. Primary Industry Training Organisation SSB Code 101558 New Zealand Qualifications Authority 2016