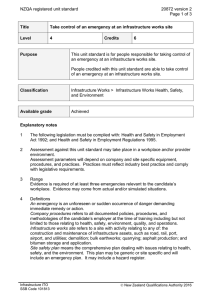

NZQA unit standard 17266 version 5

advertisement

NZQA Expiring unit standard 17266 version 5 Page 1 of 4 Title Strip and polish hard floors Level 4 Purpose Credits 5 This unit standard is for people in the cleaning industry. People credited with this standard are able to: prepare to scrub, strip and polish hard floors; scrub, strip and polish hard floors; and complete job-related tasks. Classification Cleaning and Caretaking > Cleaning Skills Available grade Achieved Entry information Recommended skills and knowledge Unit 1570, Buff hard floors, Unit 17270, Polish a hard floor with a high speed polisher, Unit 17265, Machine scrub hard floors, or demonstrate equivalent knowledge and skills. Explanatory notes 1 Competence demonstrated during assessment against this standard must comply with the requirements of: Employment Relations Act 2000; Health and Safety in Employment Act 1992. 2 Equipment and cleaning agents must be used in accordance with manufacturer’s recommendations. 3 Definitions Dustrol may also be called a static mop or dust mop. While the technical applications vary between each of these, the principles are the same. The purpose is to remove dust from the floor without creating dust showers. Flat mop is a type of microfibre mop and can be used in a wet or dry condition. Mop refers to either a string/cotton, sponge or microfibre type, or a flat mop. Industry best practice refers to any enterprise and/or establishment requirements, practices, policy, procedures, methods and protocols which are in accordance with applicable legislation, regulations and New Zealand Standards. Community Support Services ITO Limited SSB Code 101814 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 17266 version 5 Page 2 of 4 Outcomes and evidence requirements Outcome 1 Prepare to scrub, strip and polish hard floors. Evidence requirements 1.1 Selected equipment is clean and in working condition. Range scrubbing machine, scouring pad, scrubbing pad, polishing pad, wringer buckets, mops, dispensers, polisher, squeegee, wet vacuum cleaner, isolating transformer or residual current device (RCD). 1.2 Equipment is safety checked and non-operational and/or damaged equipment is reported in accordance with industry best practice. 1.3 Warning signs are displayed in accordance with industry best practice. Range at least one of – signs, barriers, cordons. 1.4 Floor is checked and made ready for stripping, scrubbing and polishing by the removal of loose soil and dust in accordance with industry best practice. 1.5 Provision of ventilation ensures comfort and safety of cleaner and public in accordance with industry best practice. 1.6 Dangers of working with electrical equipment in wet conditions are identified, and precautions are taken at all times. Range 1.7 dry hands during equipment operation, use of isolating transformer or RCD. Cleaning solution is prepared in accordance with manufacturer’s recommendations. Outcome 2 Scrub, strip and polish hard floors. Evidence requirements 2.1 Polished floor is stripped and dried in accordance with industry best practice. Range stripping solutions are applied, floor is machine stripped of all polish build-up, rinsing of floor removes all signs of stripping solution and polish residue, floor is dried removing stripping solution and polish residue. Community Support Services ITO Limited SSB Code 101814 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 2.2 Floor is sealed using appropriate polymer sealer in accordance with industry best practice. Range 2.3 17266 version 5 Page 3 of 4 area to be sealed is polished and dustrolled, sealant is applied. Appropriate polish is applied to floor in accordance with industry best practice. Range prepared floor is sealed and soil free, polish is applied, application of polish over area is complete, floor is polished after polish has stabilised, repetition of polish application and polishing is continued to meet requirements. Outcome 3 Complete job-related tasks. Evidence requirements 3.1 Task is completed without damage or risk to cleaner, public, furniture, fixtures, or fittings. 3.2 Equipment is cleaned, checked and stored in accordance with industry best practice Replacement information This unit standard and unit standard 17265 were replaced by unit standard 29391. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 27 April 2000 31 December 2014 Revision 2 8 February 2001 31 December 2014 Review 3 27 February 2006 31 December 2014 Review 4 18 October 2012 31 December 2018 Review 5 21 April 2016 31 December 2018 Consent and Moderation Requirements (CMR) reference 0004 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Community Support Services ITO Limited SSB Code 101814 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 17266 version 5 Page 4 of 4 Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Community Support Services ITO Limited SSB Code 101814 New Zealand Qualifications Authority 2016