Montgomery College New Science Center Energy Efficient System Design: Geothermal System Coupled with

advertisement

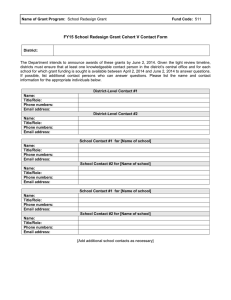

Montgomery College New Science Center Energy Efficient System Design: Geothermal System Coupled with Chilled Beams and DOAS AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Presentation Material: Building Overview Redesign Goals Current Mechanical System Mechanical System Redesign Lighting Redesign Acoustic Impact Energy Savings Cost Analysis Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 •Located on Montgomery College Rockville Maryland Campus Presentation Material: Building Overview •Four Stories •140,700 Square Feet Redesign Goals •Direct Addition to Science East Current Mechanical System •Bridge Connected to Science West Mechanical System Redesign Lighting Redesign •Consists of Laboratories, Classrooms, and Offices Acoustic Impact • Four Story Atrium Energy Savings •Roof Observatory with power switch sliding roof Cost Analysis •Exterior Amphitheatre Conclusions •Water Retention Pond AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 System Redesign Goals: Presentation Material: Building Overview Redesign Goals Current Mechanical System Mechanical System Redesign Lighting Redesign Acoustic Impact Energy Savings Cost Analysis •Energy Efficiency •Environmental Impact Original Design Goals: •Energy Efficiency •Control Laboratory Contaminants •Anticipated Expansion Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Current Central Chilled Water System: Presentation Material: System in Place: Building Overview •225 Ton Chillers with VFD Redesign Goals •Cooling Tower Current Mechanical System •Two Condenser Pumps Mechanical System Redesign Lighting Redesign Original New Design: •Two 305 Ton Centrifugal Chillers Acoustic Impact Energy Savings •Two induced draft-cross flow Cooling Towers arranged to share a basin with VFDs Cost Analysis Conclusions •Two Primary & Secondary Pumps with VFDs AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Current Central Hot Water System: Presentation Material: •Two 3 Million BTU 87% operating efficiency Boilers Building Overview Redesign Goals •Two Distribution & Campus Distribution Pumps Current Mechanical System •No Boiler Pumps Mechanical System Redesign Lighting Redesign Acoustic Impact Energy Savings Cost Analysis Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Current Central Air Handling System: •Two VAV Rooftop Units manifolded together by a common discharge plenum Presentation Material: Building Overview Redesign Goals •Dual Supply Fans •Isolation Dampers to isolate one unit from the rest of the system Current Mechanical System •No Return Fan Mechanical System Redesign •Return Air Damper maintains building pressure Lighting Redesign •Heating and Cooling Coils Acoustic Impact Energy Savings Cost Analysis •Heat Recovery Coil •Local Reheat Coils at Rooms Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Current Central Exhaust System: Presentation Material: Building Overview Redesign Goals Current Mechanical System Mechanical System Redesign Lighting Redesign Acoustic Impact Energy Savings •Four high plume Exhaust Fans connected by common plenum •Maintain Negative pressure in the Exhaust Plenum and Laboratories •Constant Volume/fan; Variable Volume for the building •Make-up Air Damper in Exhaust Plenum to maintain a constant exhaust flow rate •Dampers within plenum normally open that maintains remote duct static pressure Cost Analysis Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Geothermal Systems: Presentation Material: Building Overview Redesign Goals •Earth’s solar energy is absorbed into the ground in the form of heat energy •Moves Heat Energy •Open loop systems use a water source as the heat sink •Utilizes a heat sink to take or expel heat energy •Closed loop systems use the constant ground temperature as a heat sink •Open and closed loop system types Current Mechanical System Mechanical System Redesign Lighting Redesign Acoustic Impact Energy Savings Cost Analysis Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Geothermal Systems: Presentation Material: •Transfers energy between the heat sink and the building Building Overview •Works in place of a the cooling tower & boiler in a typical HVAC system Redesign Goals •Variable flow is ideal to decrease the pumping power Current Mechanical System Mechanical System Redesign •Reduces the amount of electricity & fossil fuel needed Lighting Redesign Acoustic Impact Energy Savings Cost Analysis Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 •Passive chilled beams induce current through natural convection Chilled Beams: Presentation Material: Building Overview Redesign Goals Current Mechanical System Mechanical System Redesign Lighting Redesign Acoustic Impact Energy Savings Cost Analysis Conclusions •Low investment costs •Air passes over cooled coils and drops into the room •High Cooling Capacities •Available as passive or active •Coupled with a geothermal system: become a water- to – water system , increasing the energy efficiency •Warm air rises into the beam to be cooled and then redistributed into the room •Active chilled beams provide ventilation air through small air jets in addition to the induced air flow •Recessed in or hung from the ceiling in place of a diffuser •Water pumped to the chilled beam in the room to cool the air locally •Natural convection and ventilation air induce airflow over the coils •Allows the HVAC system to decouple the ventilation and the humidity requirements from the sensible heating and cooling requirements •Air is then cooled and diffused into the room •Possible noise problems AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Laboratory and Classroom Mechanical System Redesign: Presentation Material: Building Overview Redesign Goals Current Mechanical System Mechanical System Redesign •Replaces the original boilers, chillers, and cooling towers, with water to water heat pumps and water to air heat pumps. •Four water to water heat pumps are provided for the laboratories and classrooms •One additional water to water heat pump for redundancy and simultaneous heating and cooling conditions Lighting Redesign •The water is supplied to and from the pond to a heat exchanger Acoustic Impact •The geothermal system acts like a closed loop system taking water to and from the heat exchanger to the water to water heat pump Energy Savings Cost Analysis Conclusions •The water to water heat pump water is distributed to the variable flow active chilled beams AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Labs/CB WW Heat Pumps Heating Cooling MBH 1,399 1,071 TONS 117 89 UNIT MBH 350 393 # OF UNITS 4 3 COP 4.08 5.22 EER 13.92 17.80 GPM 84 84 Laboratory and Classroom Mechanical System Redesign: Presentation Material: Building Overview Redesign Goals •The heat exchanger that transfers the heat energy from the water retention pond, supplies the water to the DOAS heat pump •Ventilation air is supplied to the laboratory and classroom active chilled beams by the DOAS heat pump Current Mechanical System •The DOAS heat pump provides any necessary dehumidification Mechanical System Redesign •The water is condensed out of the air until 55% RH is reached and then reheated Lighting Redesign Acoustic Impact •All air from the laboratories is exhausted from the building after passing over the enthalpy wheel Energy Savings Cost Analysis Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Lab/CB DOAS HP Heating Cooling MBH 1,203 8,154 TONS 100 680 CFM 101,255 101,255 UNIT MBH 406 916 # OF UNITS 3 9 UNIT CFM 12,400 12,400 # OF UNITS 9 9 COP 4.30 5.33 EER 14.67 18.20 Office Mechanical System Redesign: Presentation Material: Building Overview Redesign Goals Current Mechanical System Mechanical System Redesign Lighting Redesign Acoustic Impact Energy Savings Cost Analysis Conclusions Office Rooftop HP Heating •Water is supplied from the heat exchanger to the rooftop heat pump where the heat energy is transferred to the air that is then supplied to the offices Cooling •The rooftop heat pump supplies air to the offices at 52⁰F through a VAV box and reheat coil •The water for the reheat coils is provided by the water-to-water heat pumps •Air is returned from the offices to the rooftop heat pump decrease the amount of air conditioning •Dehumidification is completed in the rooftop heat pump similar to the DOAS heat pump but without the help of the enthalpy wheel AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 BTUH 196,52 1 405,64 0 TON S 16 34 CFM 15,62 7 15,62 7 UNIT MBH 181 # OF UNITS 2 UNIT CFM 8,000 # OF UNITS 2 COP EER 3.40 11.60 237 2 8,000 2 4.25 14.50 Energy Efficient Replacement Fixtures: Presentation Material: Lighting Redesign Original Lighting Heating (boilers etc.) Cooling (chillers etc.) Fans, pumps and controls Lights Equip. 8445.139 8406.94 13749.672 13885.029 310949.906 310998.094 1247.095 1432.732 4773.785 4773.785 Building Overview Redesign Goals Earth Friendly Troffers • Up to 88% efficiency Current Mechanical System • Recessed 2’x4’ Mechanical System Redesign Lighting Redesign • Power Density: 0.7 W/ft2 Acoustic Impact • Highly reflective matte white power coating Energy Savings • Engineered louvers Cost Analysis • 3” Baffle element that illuminates while reducing glare Conclusions • Occupancy Sensors AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Lightings Schedules within IES Model: Presentation Material: •Occupancy Type Building Overview •Anticipated Typical Weekday Usage Redesign Goals •Anticipated Typical Weekend Usage Current Mechanical System Mechanical System Redesign Lighting Redesign Acoustic Impact Energy Savings Cost Analysis Office Weekday Lighting Schedule Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Lighting Redesign Energy Savings: Presentation Material: Lighting Redesign Energy Comparison Savings in: 339,600 Redesign Goals 339,500 Current Mechanical System 339,400 •Cooling Energy and Load 339,300 •HVAC Equipment Energy and Load MMBTU Building Overview Mechanical System Redesign Lighting Redesign •Illuminance Energy 339,200 Acoustic Impact 339,100 Energy Savings 339,000 Cost Analysis Lighting Redesign Original Lighting Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Room Reverberation Time: Presentation Material: Original Acoustical Design Classrooms, Laboratories, and Offices should have a reverberation time between 0.7 and 1.1 seconds Building Overview Redesign Goals Current Mechanical System Mechanical System Redesign Lighting Redesign Acoustic Impact T60 at 500 HZ T60 at 1000 HZ Classroom Laboratory Office 0.66 seconds 0.66 seconds 0.46 seconds 0.65seconds 0.65 seconds 0.34 seconds Recommendations: •Some of the walls changed from the single layer of gypsum board to a double layer Recommended Acoustical Design •Acoustical Ceiling Tile replaced with Armstrong Suspended Ceiling •Carpet in Offices changed to Epoxy Terrazzo Energy Savings Cost Analysis ROOM •Light decorative Velour added to Large Offices Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 ROOM T60 at 500 HZ T60 at 1000 HZ Classroom Laboratory Office 0.77 seconds 0.78 seconds 0.73 seconds 0.70 seconds 0.70 seconds 0.71 seconds Classrooms Laboratories Private Offices Presentation Material: Building Overview Redesign Goals Chilled Beam Acoustics: NC Rating 25-30 35-40 30-35 •Static Pressure should never exceed 0.4” w.c. •Classrooms and offices need less ventilation air than the laboratories and therefore have smaller flow rates Current Mechanical System Mechanical System Redesign Lighting Redesign Acoustic Impact Energy Savings Cost Analysis Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Energy Savings: Presentation Material: Building Overview Redesign Goals Current Mechanical System Mechanical System Redesign Lighting Redesign Acoustic Impact Energy Savings Cost Analysis Redesign System Component MMBTU Nat gas 88 Electricity 5,404 Chilled Beam HP 507 (heating) Office Reheat 488 Chilled Beam HP (cooling) 953 DOAS HP 2,037 Office Heat Pump 546 Pumps 9,548 Lights 1,248 Total energy 20,817 •27.75% Energy Savings over the original design kwh 25,674 1,583,702 148,496 142,947 279,242 596,999 159,962 2,798,240 365,797 6,101,060 MMBTU 5,726 Original Design kwh System Component Fans, Controls, Plug, 1,678,087 Misc. 9,239 2,707,802 Direct Acting Heater 7,273 2,131,514 Boilers and Chillers 5,142 1432 28,811 1,506,947 419,695 8,444,045 Pumps Lights Total Original Energy Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Energy Comparison 28,811 M M B T U •energy required for the heat pumps is about half the energy needed for the boilers and chillers 20,817 •Needed Reheat was reduced almost 90% Total Redesign Energy Total Original Energy •Lighting energy was reduced by the lighting redesign •Saves 2,342,986 kilowatts a year Energy Savings: Presentation Material: Building Overview Redesign Goals Current Mechanical System Mechanical System Redesign Lighting Redesign Acoustic Impact Original System Design MMBTU therms boilers 2,949 29,493 Total Natural Gas 2,949 29,493 Energy Rates: •$1.54 per therm •$0.1321 per kilowatt hour Comparison: •Original design: $1,406,706/yr •Majority of cost is attributed to direct acting heaters due to local reheat •Redesign: $805,257/yr •Majority of cost is attributed to the pumps since the system is predominately hydronic Energy Savings Cost Analysis •Resultant Savings: $601,449/yr from original design $1,148,501/ yr from the Baseline Conclusions THE PENNSYLVANIA STATE UNIVERSITY Total Energy Cost MMBTU 4,324 9,239 3,617 5,142 2,108 1,433 25,863 kwh 1,267,280 2,707,690 1,060,092 1,506,884 617,925 419,896 7,579,767 $1.54/therm $1,349.33 MMBTU 5,404 507 488 953 2,037 546 9,548 1,248 20,817 $0.1321/kwh $209,207.06 $19,616.27 $18,883.34 $36,887.90 $78,863.56 $21,131.01 $369,647.55 $48,321.81 $803,907.83 $0.1321/kwh $167,407.66 $357,685.87 $140,038.12 $199,059.40 $81,627.95 $55,468.24 $1,001,287.24 $1,046,706.36 Total Energy Cost Energy Costs/year System Redesign $1,200,000.00 $1,000,000.00 $800,000.00 $600,000.00 $400,000.00 $0.00 APRIL 15TH 2009 System Redesign MMBTU therms Nat gas 88 876 Electricity Chilled Beam HP (heating) Office Reheat Chilled Beam HP (cooling) DOAS HP Office Heat Pump Pumps Lights Total energy $200,000.00 •Redesign saves 42.76% over the original design AMY LEVENTRY chillers direct acting heaters fan pump equipment Lights Total Electric $1.54/therm $45,419.11 $45,419.11 Original Design $805,257 $1,046,706 kwh 1,583,702 148,496 142,947 279,242 596,999 159,962 2,798,240 365,797 6,076,262 $805,257.16 LEED Assessment: Category •Increased the Energy and Atmosphere Category by 2 point Presentation Material: Building Overview •Gained the 2 points in the Optimize Energy Performance Credit Redesign Goals •Increase the credit from 8/10 points to 10/10 points available Current Mechanical System •The Original Design was an estimated 28% energy cost savings over the ASHRAE 90.1 Baseline Building Mechanical System Redesign Lighting Redesign •35% Energy Savings must be reached to receive 10 out of 10 of the Optimize Energy Performance Credit Acoustic Impact Energy Savings •The Redesign is an estimated 58.78% energy cost savings over the ASHRAE 90.1 Baseline Building Cost Analysis •This would most likely qualify for an additional Innovation and Design Credit Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Sustainable Site Water Efficiency Energy and Atmosphere Materials and Resources Indoor Environmental Quality Innovation and Design Total Category Sustainable Site Water Efficiency Energy and Atmosphere Materials and Resources Indoor Environmental Quality Innovation and Design Total Points Anticipated 8 3 12 4 13 2 42 Possible Points 14 5 17 13 15 5 69 Points Anticipated 8 3 14 4 13 2 44 Possible Points 14 5 17 13 15 5 69 Initial Cost Comparison: Presentation Material: •Original Design HVAC Initial Cost: •$73.43/ square foot $10,332,198 •Redesign HVAC Initial Cost: •$91.17/ square foot $12,828240 Mechanical System Redesign •Increased Cost: $2,496,042 Lighting Redesign •It would take 4.15 years for the energy savings to overcome the increased initial costs of the redesigned system over the original design Building Overview Redesign Goals Current Mechanical System Acoustic Impact Energy Savings Cost Analysis •Anticipated Payback Period: DOAS HP ROOFTOP HP WATER TO WATER HP CHILLED BEAMS HEAT EXCHANGER PIPING LOOP PIPING PUMPS DUCTWORK AIR VALVES VAV BOXES CONTROLS TESTING AND BALANCING HVAC COSTS: 11.17 years Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 $446,400.00 $64,000.00 $134,750.00 $267,300.00 $7,500.00 $1,909,880.00 $96,000.00 $55,200.00 $3,110,880.08 $4,563,000.00 $144,000.00 $1,441,300.00 $588,030.00 $12,828,240.08 Redesigned System Conclusions: Presentation Material: Building Overview Redesign Goals Current Mechanical System Mechanical System Redesign Lighting Redesign M M B T U •Payback period of 11.17 years THE PENNSYLVANIA STATE UNIVERSITY $600,000.00 Total Original Energy $200,000.00 $0.00 APRIL 15TH 2009 $1,046,706 $1,000,000.00 $800,000.00 Total Redesign Energy •The system redesign may not be a favorable alternative to the original design due to significant increase in the initial cost. AMY LEVENTRY 20,817 Original Design $1,200,000.00 $400,000.00 •The initial cost of the redesigned system was estimated to cost $2.5 million more. Energy Savings Conclusions 28,811 •This energy savings result in approximately $600,000 a year. Acoustic Impact Energy Costs/year System Redesign •Redesign was found to be over 27% more energy efficient than the original mechanical system design. •Therefore the payback for the new system compared to the original design would take slightly over four years. Cost Analysis Energy Comparison $805,257 Acknowledgements: Presentation Material: Building Overview Thesis Advisor Redesign Goals BurtHill Engineers Current Mechanical System Mechanical System Redesign Lighting Redesign Penn State Professors Acoustic Impact Energy Savings Parents Cost Analysis Conclusions AMY LEVENTRY THE PENNSYLVANIA STATE UNIVERSITY APRIL 15TH 2009 Dr. James Freihaut Jonathon Gridley Tom Hovan, PE Dustin Eplee Matt Rooke Kevin McCormick PE Dr. William Bahnfleth Dr. Moses Ling Atty. Tim Leventry Ruth Leventry