The Marriott Hotel at Penn Square and Lancaster County Convention Center

advertisement

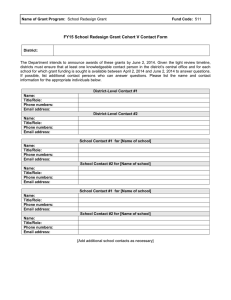

The Marriott Hotel at Penn Square and Lancaster County Convention Center Trevor Sullivan Penn State University 5th Year AE – CM Option The Marriott Hotel at Penn Square and Lancaster County Convention Center Trevor Sullivan Project Introduction The Pennsylvania State University Problem Statement Architectural Engineering Proposal Construction Management Option Laser Scanning Research Fifth Year Thesis Presentation Plumbing Redesign April 15th 2008 Minipile Research Structural Breadth Retaining Wall Design Floor System Redesign Construction Sequencing Conclusions and Acknowledgments Images courtesy of: http://www.lancasterconventioncenter.com/ Structural: Project Information: 200 caissons : 36”-90” diameter Location: Penn Square – Lancaster, PA Cast-in-place concrete structure (post-tensioned Total Cost: $170 million for hotel tower) Construction Cost: $105 million 153’ bow string metal trusses span the large Total Area: 412,079 SF, 19 Stories exhibit level floor Convention Center: 220,000 SF Mechanical: Marriott Hotel : 300 rooms Combination air and water system Construction: (8) large boilers, (2) cooling towers, (2) water Phase 1: Site Prep: May 2006 – Oct. 2006 cooled chillers Electrical: ( 6 Months) Phase 2: Construction: Oct. 2006 – Dec. 2008 2 main service points, each 4000 amp, 480Y/277 ( 26 Months) volts, 3PH., 4W. Historical: 2000 HP backup generator with Façade stabilization and restoration of the 109 a 2000 gallon diesel storage tank year old Watt & Shand façade 4 surrounding historical structures to be incorporated into the project as museums. Delivery Method Organization Chart Owners RACL / LCCCA WBE / MBE Liaison J. Allen Taylor Facility Manager Interstate Hotel Developer High Associates, Ltd Historical Preservation Trust 17 Prime Contractors Architect Cooper Carry, Inc. Construction Manager RCM Testing Lab Schoor Depalma Architect CHP Electrical Eng. Rosser International Structural Eng. Uzun & Case Geotech. Eng. McClymont & Rak Structural Eng. Baker Ingram Façade Consultant Tradjer Cohen Mech/Plumbing Eng. Jordan & Skala Other Consultants Site Architect Hammel Associates Problem Statement The Marriott Hotel at Penn Square and Lancaster County Convention Center Project Introduction Problem Statement Proposal Plumbing Redesign Minipile Research Structural Breadth Retaining Wall Design Floor System Redesign Construction Sequencing Conclusions and Acknowledgments Proposed Solutions Natural Spring Encountered: An underground spring was encountered during excavation in the museum level. This directly effected the abiliblty to place the museum level SOG and thus proceed with the construction of the concrete structure. Trevor Sullivan Penn State University 5th Year AE – CM Option Laser Scanning Research Convention Entry Construction Exhibit Level Convention Entry Level Museum Level Façade Issues: During construction the existing Watt & Shand façade was discovered to not be straight nor plumb – The caissons could not be drilled where needed and thus changed the column locations and edge of slab locations for the entire tower. 3 months of redesign/revision work to drawings to completely rectify the problem. Implement Laser Scanning Technology: Use Laser Scanning to survey the Watt & Shand façade (not traditional methods). Foundation Redesign: Implement a combination caisson and minipile foundation system. Excavation Process Plumbing Redesign: Increase the capacity of the groundwater lift station to handle the additional flow requirements. Structural Redesigns: Foundation Wall Redesign Convention Center Structural System Redesign Construction Re-Sequencing Analysis: to implement the proposed changes. The Goal: Decrease Construction Schedule! Composite Joist Detail Façade Issues: The Marriott Hotel at Penn Square and Lancaster County Convention Center Laser Scan Survey Comparison Limited surveying data points obtained Initial Cost Additional Costs due to Redesign Delays due to Redesign Savings Traditional $500 $40,000 3 months - Laser Scan $27,500 - - $13,000 Façade not straight or plumb Trevor Sullivan Penn State University 5th Year AE – CM Option Caissons near the façade could not be drilled due to conflicts. The result: The columns needed to be moved Project Introduction The edge of slab locations changed Problem Statement Changes needed to be reflected on Proposal all the drawings – took 3 months to Laser Scanning Research complete. Typical Laser Scanning Equipment Plumbing Redesign Minipile Research Existing Watt & Shand Façade: Structural Breadth To be stabilized, restored, and integrated into the new Retaining Wall Design Floor System Redesign building Parts of the façade are 109 years old Laser Scanning Computer Output for a Facade Construction Sequencing Conclusions and Acknowledgments Photos courtesy of: http://www.arctron.com/pix/vermessung/3scanner Groundwater Piping Design Estimate The Marriott Hotel at Penn Square and Lancaster County Convention Center Trevor Sullivan Penn State University 5th Year AE – CM Option Pump Calculation Summary Total Discharge Head TDH Plumbing Redesign Summary Project Introduction Problem Statement Proposal Laser Scanning Research Plumbing Redesign Minipile Research Structural Breadth Retaining Wall Design Floor System Redesign Construction Sequencing Conclusions and Acknowledgments Item Existing Proposed Pump Sizes 1 HP 15 HP Pump Capacity 60 GPM 340 GPM Pump Arrangement Duplex Triplex Total Capacity 120 GPM 1020 GPM Underslab Drainage 4" PVC 6" PVC Ontop of Footing Drainage 6" PVC 10" PVC Item = 18.95 ft Gallons per Minute GPM = 340 gal/min Total Head Developed H = 58.0 ft Brake Horsepower BHP = 13.7 HPpump Description Size Quantity Unit Cost $85.00 $30.00 $10.00 $15.00 Pipe* Carbon Steel Carbon Steel PVC PVC Plain Sch. 40 Plain Sch. 40 Sch 40 Perforated Sch 40 Perforated 8" 4" 6" 8" LF 80 175 825 250 Equipment Pre-cast Basin Submersible Pumps 96" diameter 340 GPM 1 1 1 3 $5,000.00 $15,000.00 Total * includes an allowance in the unit price for fittings. Under-slab drainage installation (above) Pre-cast basin installation: Sanitary on left, Ground water on right (left) Additional Plumbing Costs Total $74,050 Cost $6,800 $5,250 $8,250 $3,750 $5,000 $45,000 $74,050 The Marriott Hotel at Penn Square and Lancaster County Convention Center Trevor Sullivan Penn State University 5th Year AE – CM Option Project Introduction Problem Statement Minipile Foundation Design Summary 2) 3) Proposal 4) Laser Scanning Research Plumbing Redesign Minipile Research 5) 6) Structural Breadth 7) Retaining Wall Design Floor System Redesign Construction Sequencing Conclusions and Acknowledgments Description Design Input 1) Grout Strength f'c = 3 Grout Factor Safety FSg = 3 Cross Sectional Area of Grout Ag = Steel Yield Strength Fy-steel Steel Factor of Safety FSy-steel Bar Diameter Ab 38.48 ksi 2) Axial Compression Pc-allowable All caissons (existing system) $1,084,140 --- 26 --- 36" caissons converted to minipiles $1,466,160 $382,020 10 -16 36" and 42" caissons converted to minipiles $1,783,980 $699,840 16 -10 Minipile and Caisson Schedule Analysis = 60 ksi Caisson casing shafts creating site congestion (above) Weeks 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 Karst topography map of PA (upper left) = Karst topography section (lower left) 0.47 Caissons Only Minipile to caisson load comparison Chart (below) = 1.25 Cross Sectional Area of Casing Acasing = 11.82 Allowable Axial Stress Fa Schedule Difference in2 2 in Caisson to Minipile Load Comparison Caisson Diameter 2 in = = 128 300 Min. Required 8" Minipile Load # of Minipiles Capacity Capacity per Group 36" 42" 54" 60" 66" 72" 84" 90" Design Output 1) Minipile and Caisson Analysis Summary Cost Schedule Cost Difference (weeks) ksi k Images courtesy of: www.delminsociety.net fwie.fw.vt.edu 565K 770K 1200K 1500K 1900K 2260K 3080K 3535K 300K 300K 300K 300K 300K 300K 300K 300K 2 3 4 5 7 8 11 12 Minipile and Caisson (36" and 42" to minipile) 204 375 37 Minipile and Caisson (36" caissons to minipile 244 78 Legend Caisson Duration (with quantity) Minipile Duration (with quantity) Schedule Savings Ivany Block: The Marriott Hotel at Penn Square and Lancaster County Convention Center Trevor Sullivan Penn State University 5th Year AE – CM Option Project Introduction Problem Statement Proposal Location of Retaining Walls Reduces Formwork Fast Rebar Installation Structural Redesigns: Cantilevered Design: Foundation Wall RedeUtilize an Allows for full height backfilling Ivany block cantilevered retaining saving time wall over the current cast-in-place more room on site concrete pinned foundation wall design to save time and increase Laser Scanning Research space on site. Plumbing Redesign Convention Center Structural Minipile Research System Redesign: Utilize a steel Structural Breadth system over the current cast-in- Retaining Wall Design Floor System Redesign Construction Sequencing Potential space gain. place concrete system to save time. Specifically a composite joist floor system. Conclusions and Acknowledgments Ivany Block Detail Photo of construction for the existing retaining wall design Proposed Wall Detailing Cantilever Condition Existing Design Detail Retaining Wall Estimate Summary Utilized Cast-in-Place Concrete Wall System Foundation wall, cast in place, pumped, 14' high, 12" thick Quantity (LF) 2250 Pinned Condition $/LF Total 650 $1,462,500 Proposed Ivany Block Wall System Ivany Block Wall, 14' high, 16" thick, filled solid, pumped. Quantity (LF) 2250 Height (ft) 14 Area (SF) 31500 Cost per SF 37.25 $1,173,375 Ivany Block System Saves: $289,125 (-20%) Note: Estimate excludes excavation difference. Major Differences: 14” concrete to 16” block Footing increase Total Exhibit Hall Level Floor System Typical Bay 20 x 40 18CJ 2771/2368/130 Convention Entry Level Floor System 350 PSF Live Load (693 PSF Total Factored Load) Typical Bay 20 x 40 Less Site Congestion Structural System Estimate Summary 100 PSF Live Load (293 PSF Total Factored Load) Convention Entry Construction Steel System Column Total: Base Plate Total: Beam Total: Joist Total: Metal Decking w/ Slab: Spray Fire Proofing: Total: 18CJ 1171/768/130 Composite Joist Detail $34,816 $708 $127,204 $579,720 $385,250 $77,050 $1,204,748 Concrete System Concrete: Formwork: Shoring: Reshoring: Rebar: Finishing: Total: $363,214 $535,515 $14,694 $53,600 $121,111 $14,254 $1,102,388 Steel Cost an Additional: $102,360 (+9%) The congestion from shoring and re-shoring of a concrete structure makes it difficult to work around No Change in Ceiling Height 14’-0” - 5” - 18” - 16” - 6” 10’-3” Floor to floor height Decking and slab on deck Joists (and girders) Duct (deepest used on the floor) Ceiling (drywall with high-hat light fixtures) Ceiling height = No Change Existing 30x30 column grid: Proposed 40x20 column grid: Provides more open space with the same floor plan. Only minor conflicts requiring changes to the floor plan; i.e.. door relocation. Proposed Steel Erection Sequencing Photo from tower crane of crane erecting convention center steel. The Marriott Hotel at Penn Square and Lancaster County Convention Center Trevor Sullivan Penn State University 5th Year AE – CM Option Key points for schedule reduction: Problem Statement Proposal Laser Scanning Research Plumbing Redesign Minipile Research Structural Breadth Retaining Wall Design Floor System Redesign Construction Sequencing Conclusions and Acknowledgments For concrete construction the museum level SOG A portion of the SOG left out to allow for the crane path during steel erection. Project Introduction needs to be placed first. Utilized Date: 5/14/07 Proposed Utilized Date: 6/22/07 Proposed Utilized Date: 7/24/07 Proposed Utilized Date: 9/21/07 Proposed Utilized Date: 11/8/07 Proposed Utilized Date: 12/12/07 Proposed Date: 11/8/07 24 Work Days Saved 5 Weeks 169 Days 193 Days Acknowledgments A special thanks to the following people for their help and support throughout the AE Senior Thesis process: The Marriott Hotel at Penn Square and Lancaster County Convention Center Summary Table Trevor Sullivan Penn State University 5th Year AE – CM Option Item Was the goal met? Project Introduction Problem Statement Proposal The Goal: Decrease Construction Schedule! Yes – Save 5 weeks! Laser Scanning Research Plumbing Redesign Retaining Wall Design Floor System Redesign Construction Sequencing Conclusions and Acknowledgments Structural Redesign C.I.P. Concrete to Steel Joists C.I.P. Concrete to Block Retaining Walls QUESTIONS? Schedule $102,361 -$289,125 Plumbing (Groundwater Lift Station) Redesign Duplex 120GPM to Triplex 1020 GPM Capacity Research Laser Scanning Technology Minipile and Caisson Foundation System -$17,500 $382,020 Total $251,806 Laser Scanning Research Rettew Quantapoint Urweiler & Walter Minipile Foundation Research Shelly Foundations Clark Foundations Hayward Baker $74,050 CM Study Resequencing Minipile Research Structural Breadth Cost - 5 Weeks - 5 Weeks Additional Cost of $251,806 (+0.15% to Total Project Cost) Saves 5 Weeks Project Use and Information High Realty/Associates Reynolds Construction Management Lancaster County Convention Center Authority Senior Thesis Mentors Penn State AE Faculty Family and Friends Mom and Dad Amy, Nate, Cory