Document 15187982

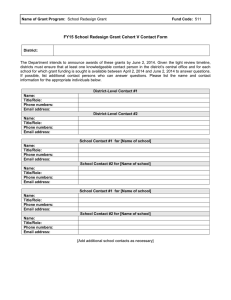

advertisement

STEM Building STEM Building Hagerstown Community College Hagerstown Community College Hagerstown, 21742 Hagerstown, Maryland Maryland 21742 Science Technology Engineering Mathematics Building Craig Owsiany Architectural Engineering – Construction Management Outline o Overview •5 Floors •Size: 62, 840 SF •Cost: $15.6 M •Duration: 18 Months o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Findings o Acknowledgments o Questions Southwest View South View Southeast View STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Science Technology Engineering Mathematics Building Craig Owsiany Architectural Engineering – Construction Management Outline o Overview o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Findings o Acknowledgments o Questions Typical Lab Typical Floor Plan Energy Lab STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Analysis I: Mat Slab Redesign Craig Owsiany Architectural Engineering – Construction Management Structural Breadth Outline Background o Overview •Blasting •Non Competent Rock Solutions Goal o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Findings o Acknowledgments o Questions •Reduce Cost Impact •Maintain Schedule •Ensure Structural Integrity STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Analysis I: Mat Slab Redesign Craig Owsiany Architectural Engineering – Construction Management Structural Breadth Outline o Overview o Analysis I: Mat Slab Redesign Structural Analysis • Sum Live and Deal Loads •Compare Against Design Load o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign Design>Actual=No Redesign o Conclusion/Findings Design<Actual=Redesign Required o Acknowledgments o Questions Structural Calculations Dead Loads Total (lbs) Compacted Soil (4') 496,100 Concrete-Normal Weight (5") 20,834 Concrete-Normal Weight (10") 728,625 Concrete-Normal Weight (12") 498,075 Concrete-Normal Weight (18") 56,306 Concrete-Normal Weight (20") 34,531 Concrete-Light Weight (4 1/4") 251,828 Beams 30,525 Stairs (20") 305,723 Curtain Wall & Metal Panels 23,460 Brick Veneer 92,576 Green Roof 132,688 Ceiling 28,604 Partitions 56,038 HVAC & Plumbing 57,208 Cistern 31,000 Total 2,844,119 Findings Live Loads Corridors 3rd Floor & Below Corridors Above 3rd Floor Classrooms Stairs Total Total (lbs) 80,990 97,188 105,240 122,289 405,706 Dead Loads Total Live Loads Total Extended Foundation Wall Loads Dead+Live Dead +Live+Extended Percentage Increase 2,844,119 405,706 139,750 3,249,826 3,389,576 4.12% • 10-15% load increase would require further investigation Total Load (P) Area (A) P/A (lbs/sf) 3,389,576 1,128 3,006 • Mat slab designed for 8000 psf •Actual Load = 38% of Design Load STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Craig Owsiany Architectural Engineering – Construction Management Analysis I: Mat Slab Redesign Structural Breadth Outline Cost Impact o Overview Triad Solution Cost $/Sq. Ft. CY o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Findings o Acknowledgments o Questions Materials Concrete Total Materials Formwork-Lumber Formwork-Plywood Lean Concrete Backfill Crew Total LF $/LF Sq. Ft. Savings $/CY 299.3 LF Materials LF Formwork-Lumber Formwork-Plywood Lean Concrete Normal Weight Concrete Backfill Crew Total $/LF 240 GC Solution $/Sq. Ft. CY Sq. Ft. Duration $/Crew 80 $/CY Duration $/Crew 0.3 755 1.41 208.8 80 1 $/LF 480 Proposed Solution $/Sq. Ft. CY Sq. Ft. $/CY Duration $/Crew 0.3 426 1.41 20.9 34.3 80 92 2 Total $ 23,944.00 $ 23,944.00 Total $ 72.00 $ 1,064.55 $ 16,704.00 $ 960 $ 960.00 $ 18,800.55 Total $ $ $ $ $ 960 $ $ 144.00 600.66 1,672.00 3,155.60 1,920.00 7,492.26 Totals Solution Triad GC Proposed $ $ $ Cost 23,944.00 18,800.55 7,492.26 Total Savings = $16k STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Analysis II: Green Roof Redesign Craig Owsiany Architectural Engineering – Construction Management Mechanical Breadth Outline Background Background Redesign o Overview o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Findings o Acknowledgments o Questions • Conventional Green Roof • 3” Low Profile •Architectural Facets • Negligible Thermal Value • Minimal Educational Value Green Roof Takeoffs SF Aggregate/Stone Gravel 308 Concrete Tile Pavers 542 Wood Panel Pavers 396 Indegenous Vegetation 776 Total SF 2022 % 15.2% 26.8% 19.6% 38.4% 100.0% • LiveRoof System • 6” High Profile • Added Thermal Value • Higher Educational Value STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Analysis II: Green Roof Redesign Craig Owsiany Architectural Engineering – Construction Management Mechanical Breadth Outline Conventional Green Roof LiveRoof System Benefits o Overview o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Findings o Acknowledgments o Questions • Faster Installation • Low Maintenance • Immediate Vegetation STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Analysis II: Green Roof Redesign Craig Owsiany Architectural Engineering – Construction Management Mechanical Breadth Outline Cost Impact Payback Period o Overview o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Findings o Acknowledgments o Questions Conventional Low-LiveRoof Low Conventional High-LiveRoof High Conventional Low-LiveRoof High Payback Period $ Markup $ Maintenance Savings Payback Period (years) 24264 $ 1,920.90 12.6 34374 $ 3,639.60 9.4 46506 $ 1,617.60 28.8 • Payback period is 28.8 years for maintenance cost alone. STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Analysis II: Green Roof Redesign Craig Owsiany Architectural Engineering – Construction Management Mechanical Breadth Outline o Overview o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Findings o Acknowledgments o Questions Thermal Calculations Thermal Calculations STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Analysis II: Green Roof Redesign Craig Owsiany Architectural Engineering – Construction Management Mechanical Breadth Outline Conventional Green Roof Heat Loss o Overview o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign Conventional Roof Materials Modified SBS Cap Sheet Modified SBS Base-Ply Sheet R-30 Insulation Decking/Concrete Conventional Roof Total (BTU/hr) Sq. Ft. R-Value Summer: Q=A(To-Ti)/R Winter: Q=A(Ti-To)/R 2022.00 0.70 2022.00 0.70 2022.00 30.00 2022.00 0.43 2022.00 31.83 101.66 2223.72 Current Green Roof Heat Loss Proposed Green Roof Heat Loss Current Green Roof Materials Sq. Ft. Lb./Sq. Ft. R-Value Conventional Roof R-Value Total R-Value Summer: Q=A(To-Ti)/R Winter: Q=A(Ti-To)/R Stone Aggregate 308.00 31.25 0.15 31.83 31.98 15.41 337.14 Wood Pavers 396.00 6.13 2.13 31.83 33.95 18.66 408.25 Concrete Pavers 542.00 23.00 0.65 31.83 32.48 26.70 584.14 3" Conventional Green Roof 776.00 23.44 1.43 31.83 33.25 37.34 816.84 Vegetation Soil Filter Fabric Drainage Channel Root Barrier Architectural Roof Total 98.12 2146.37 Proposed Green Roof System Materials 6" LiveRoof System Prevegetated Modules Root Barrier All Green Roof Total Sq. Ft. R-Value Conventional Roof R-Value 2022.00 2.85 31.83 Total R-Value Summer: Q=A(To-Ti)/R Winter: Q=A(Ti-To)/R 34.68 93.30 2040.95 93.30 • 100% LiveRoof System • High Profile o Conclusion/Findings o Acknowledgments o Questions • Low Profile Green Roof • Concrete Pavers • Wood Pavers • Stone Aggregate • 8.2% reduction from conventional roof • 5.0% reduction from current green roof 2040.95 STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Analysis II: Green Roof Redesign Craig Owsiany Architectural Engineering – Construction Management Mechanical Breadth Outline o Overview o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Findings o Acknowledgments o Questions Justification Educational Factor • Alternate Energy Program • Mechanical Engineering Educational Factor • Thermal Cameras • Heat Sensors STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Outline o Overview o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Findings o Acknowledgments o Questions Analysis III: Curtain Wall Redesign Background • • • • • • Stick Built Curtain Wall Approximately 1/3 of Building Envelope 9260 SF Lengthy Installation Time Site Congestion Short Lead Time Redesign • • • • • Unitized Curtain Wall System Short Installation Time Shakeout Not Required Higher Quality Seals Long Lead Time Craig Owsiany Architectural Engineering – Construction Management Goal • Reduce curtain wall installation time • Achieve earlier water tight date • Reduce over all schedule STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Analysis III: Curtain Wall Redesign Outline o Overview Craig Owsiany Architectural Engineering – Construction Management Schedule Schedule Acceleration • Original Duration: 40 Days • New Duration: 20 Days o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Findings o Acknowledgments o Questions 1. 2. 3. 4. 5. 6. Stick Built System Deliver Materials Shakeout Install Sills and Jambs Install Mullions Glaze Caulk Unitized System 1. Deliver Modules 2. Set Module 3. Caulk STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Analysis III: Curtain Wall Redesign Outline Lead Time o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Findings Week 1-6 o Questions Stick Built System Obtain materials • Stick Built: 8 Weeks • Unitized: 4 Weeks Unitized System Obtain materials Week Stick Built System Unitized System 1 Deliver/Frame Deliver/Install/Caulk 2 Deliver/Frame/Dimension Deliver/Install/Caulk 7 Fabricate/Deliver Fabricate/Deliver 3 Deliver/Frame/Dimension Deliver/Install/Caulk 8 Fabricate/Deliver Fabricate/Deliver 4 Deliver/Frame/Dimension/Glaze/Caulk Deliver/Install/Caulk 5 Deliver/Frame/Dimension/Glaze/Caulk 6 Deliver/Frame/Dimension/Glaze/Caulk 7 Glaze/Caulk 8 Glaze/Caulk 9-12 o Acknowledgments Installation Time • Stick Built: 8 Weeks • Unitized: 12 Weeks o Overview o Analysis I: Mat Slab Redesign Craig Owsiany Architectural Engineering – Construction Management Fabricate/Deliver STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Outline Analysis III: Curtain Wall Redesign Sequencing – Areas of Concern Craig Owsiany Architectural Engineering – Construction Management Resequencing o Overview o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign • Reduced Curtain Wall Installation • Begin MEP rough ins 1 week early. • Earlier Water Tight Date • Stack MEP rough ins and finishes on 3rd, 4th and 5th floors. • Finishes o Analysis III: Curtain Wall Redesign • MEP Rough Ins o Conclusion/Findings o Acknowledgments o Questions • Sync water tight date and completion of rough ins. STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Outline o Overview o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Findings o Acknowledgments o Questions Analysis III: Curtain Wall Redesign Accelerated Schedule • Overall schedule reduced by 44 days Craig Owsiany Architectural Engineering – Construction Management STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Outline Analysis III: Curtain Wall Redesign Analysis I Craig Owsiany Architectural Engineering – Construction Management Analysis II Analysis III o Overview o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Lessons Learned o Acknowledgments o Questions Mat Slab Redesign Green Roof Redesign Curtain Wall Redesign • Current mat slab will support additional load • Cannot place an R-Value on living organisms • 44 days saved • Redesign not required • Using an R-Value alone will not produce accurate heat transfer results • Higher quality product • Further attention given at a 10-15% load increase • Resequencing, not accelerating the schedule • Offers great value as an education tool • “We are sequencing trades in a manner to optimize productivity for all trades involved.” STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Outline Acknowledgements Analysis III: Curtain Wall Redesign Acknowledgements Craig Owsiany Architectural Engineering – Construction Management Acknowledgements o Overview o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Findings o Acknowledgments o Questions General Contractor • Greg Ramirez, Senior Project Manager • Eric Osborne, Senior Superintendent • Brett Robinson, Field Engineer Owner • Dawn Baker, Facilities Project Coordinator • Robert Spong, Facilities Management and Planning Director • Gerard Rath, Owner Rep. Architect • Mark Merolla, Architect Structural Engineer • Chris Johnson, Structural Engineer Penn State AE Faculty • Bob Holland • Rob Leicht STEM Building Hagerstown Community College Hagerstown, Maryland 21742 Outline Analysis III: Curtain Wall Redesign Questions o Overview o Analysis I: Mat Slab Redesign o Analysis II: Green Roof Redesign o Analysis III: Curtain Wall Redesign o Conclusion/Findings o Acknowledgments o Questions Questions? Craig Owsiany Architectural Engineering – Construction Management