Supporting Information Facile Synthesis of Core-Shell, Multiple-Compartment Anisotropic Particles

advertisement

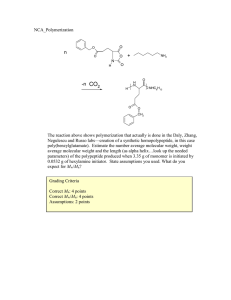

Supporting Information Facile Synthesis of Core-Shell, Multiple-Compartment Anisotropic Particles via Control of Cross-linking and Continuous Phase Separations in One-Pot Dispersion Polymerization Yanan Liu, Qing Yang, Jinmei Zhu, Lianying Liu1, 2*, Wantai Yang1, 2* 1. Key Laboratory of Carbon Fiber and Functional Polymers, Ministry of Education 2. State Key Laboratory of Chemical Resource Engineering College of Materials Science and Engineering, Beijing University of Chemical Technology, Beijing 100029 Preparation of Polystyrene (PSt) Spherical Particles by Dispersion Polymerization St (2.5 ml), AIBN (0.0453 g), NaSS (0.0453 g), EG (15 ml) and deionized water (10 ml) were added to a 100 ml three-neck round-bottom flask equipped with a reflux condenser and a mechanical stirrer. The mixture was heated up to 80°C in a water bath while stirred at 200 rpm to get a homogeneous solution (Fig. S1). Then, reaction was allowed to run for 8 h and samples (0.5-1 ml, m0) were taken at intervals to check monomer conversion, molecular weight and distribution of polymer produced. Before checking, samples were rinsed extensively with methanol, dried in a vacuum oven to a constant weigh (m1). Monomer conversion was calculated from the expression: Conversion (%)= m1 100 m0 0.08 Average molecular weights (Mw) and distributions (PDI) of polymers were determined by a Waters 515-2410 gel-permeation chromatography (GPC) instrument using THF as eluent. The result was calibrated using linear polystyrene with narrow molecular weight distribution as standard. 1 Fig. S1 Digital photos of samples taken in the process of dispersion polymerization of St in a medium of EG and water (EG/H2O=6/4, vol.). Fig. S2 Monomer conversion, particle size vs. polymerization time curves obtained in dispersion polymerization of St using a mixture of EG and water as medium (EG/H2O=6/4, vol.) Table S1 Molecular weight (Mw) and its distribution (PDI) of PSt in microspheres produced by dispersion polymerization of St in a medium of EG and water Time (min) 40 60 90 120 150 180 240 300 480 Mw103 15.2 17.5 28.1 28.4 29.4 29.6 24.3 26.5 28.1 PDI 1.81 1.71 2.56 2.56 2.47 2.64 2.87 2.59 2.63 2 Fig. S3 SEM and TEM image (the upper right inserted) of particles synthesized by adding DVB (66.4 %) to polymerization of St in EG and water at reaction time of 60 min. The lower right inserted is TEM image of particles subjected to immersing in THF. Scale bar of the SEM image is 500 nm, and scale bar of the insert TEM image is 250 nm. 3 Table S2 Gel contents of particles synthesized by AIBN or APS (0.02g) as initiator in the second step of dispersion polymerization. Sample Gel Contents % Sample Gel Contents % Figure 5a 65 Figure 1d1 72 Figure 5b 51 Figure 1c2 63 Figure 5c 40 Figure 1a3 61 Samples of Figure 5a and Figure 1d1 were prepared by adding 44.3% of DVB at 60 min. Samples of Figure 5b and Figure 1c2 were prepared by adding 33.2% of DVB at 180 min. Samples of Figure 5c and Figure 1a3 were prepared by adding 16.1% of DVB at 360 min. 4