Professor Blake Spring 2010

advertisement

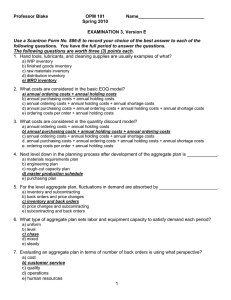

Professor Blake OPM 101 Spring 2010 Name__________________________ EXAMINATION 3, Version A Use a Scantron Form No. 886-E to record your choice of the best answer to each of the following questions. You have the full period to answer the questions. The following questions are worth three (3) points each. 1. What are purchased items or extracted materials that will be transformed into components or products called? a) work-in-process inventory b) finished goods inventory c) raw materials inventory d) distribution inventory e) MRO inventory 2. Hand tools, lubricants, and cleaning supplies are usually examples of what? a) WIP inventory b) finished goods inventory c) raw materials inventory d) distribution inventory e) MRO inventory 3. What costs are considered in the quantity discount model? a) annual ordering costs + annual holding costs b) annual purchasing costs + annual holding costs + annual ordering costs c) annual ordering costs + annual holding costs + annual shortage costs d. annual purchasing costs + annual ordering costs + annual holding costs + annual shortage costs e. ordering costs per order + annual holding costs 4. The ranking in ABC inventory analysis is based on what? a) annual dollar usage b) annual demand in units c) alphabetical order d) unit price e) item number 5. The next level down in the planning process after development of the aggregate plan is the _____________. a) materials requirements plan b) engineering plan c) rough-cut capacity plan d) master production schedule e) purchasing plan 6. What type of aggregate plan maintains a constant workforce and produces the same amount of product in each time period? a) uniform b) level c) chase d) mixed e) steady 1 Professor Blake OPM 101 Spring 2010 Name__________________________ 7. What type of aggregate plan sets labor and equipment capacity to satisfy demand each period? a) uniform b) level c) chase d) mixed e) steady 8. A proactive marketing approach in aggregate planning involves ___________________________. a) varying inventory levels b) modifying work force size c) back orders d) shifting the demand patterns to level demand fluctuations e) varying overtime rate 9. What information system enables companies to have the right material in the right amounts available at the right time? a) manufacturing resources planning b) multifunctional requirements planning c) material requirements planning d) material relationships planning e) manufacturing requirements planning 10. The file lists the materials needed to build a product. a) master production schedule b) bill of material c) inventory records d) material needs e) build structure 11. The details the company’s planned products, quantity, and the schedule used by marketing when promising deliveries. a) master production schedule b) bill of material c) inventory records d) material product sales e) promised deliveries 12. What is a technique for improving inventory record accuracy? a) cycle counting b) drum, buffer, rope c) Kanban d) tracking signal e) statistical process control 13. Which of the following techniques determines when the job must begin in order to be completed by the due date? a) infinite loading b) finite loading c) forward scheduling d) backward scheduling e) input/output control 2 Professor Blake OPM 101 Spring 2010 Name__________________________ 14. What does makespan measure? a) WIP inventory b) due-date performance c) the amount of time it takes to finish a batch of jobs d) job tardiness e) job lateness 15. Which of the following scheduling rules minimizes the average number of jobs in the system? a) first come, first served b) last come, first served c) earliest due date d) shortest processing time e) longest processing time 16. What is a unique, one-time event that is intended to achieve an objective in a given time period? a) a project b) a job c) a task d) an activity e) an event 17. The critical path is the sequential path of interrelated activities which has the ________________. a) most activities b) longest time c) most nodes d) most events e) most arrows 18. An activity in a network diagram has an optimistic time estimate of five days, a most likely time estimate of seven days, and a pessimistic time estimate of 15 days. Its expected time is _______. a) 5 days b) 7 days c) 8 days d) 10 days e) 15 days 19. Inventory record accuracy is especially critical for master production schedule users. a) True b) False 20. A primary objective of the master production schedule is to achieve the desired customer service level. a) True b) False 21. A product structure tree is a visual depiction of the subassemblies and components that are needed to produce a finished product. a) True b) False 3 Professor Blake OPM 101 Spring 2010 Name__________________________ 22. A Gantt chart is a basic scheduling tool for low-volume systems. a) True b) False 23. A local priority rule sets priority based only on the jobs waiting at that individual work center. a) True b) False 24. In network diagramming, arrows represent precedence relationships. a) True b) False The following problems are worth ten (10) points each. 1. Jefferson Products offers the following all-units quantity discount schedule for its 4 feet by 8 feet sheets of quality plywood. Order Size Price 1-9 sheets $25 10-49 sheets $23 50-99 sheets $21 100 sheets or more $18 Washington Home Furnishings orders plywood from Jefferson Products. The firm has an ordering cost of $50, an annual inventory holding cost percentage of 20%, and an annual demand of 250 sheets. What should the order size be every time that an order is placed? Q=√2𝐷𝑆/𝐻 =√2 ∗ 250 ∗ 50/.20 ∗ 18 = √25000/3.6 = 83.33 infeasible Q=√2𝐷𝑆/𝐻 =√2 ∗ 250 ∗ 50/.20 ∗ 21 = √25000/4.2 = 77.15 feasible TC=PD*D/Q*s+Q/2*H Q=77 TC = 250(21) + 250/77*50 + 77/2*(.20(21) = 5250 + 162.34 + 161.70 = $5,574.04 Q=100 TC = 250(18) + 250/100*50 + 100/2(,20)(18) = 4500 + 125 + 180 = $4,805 The order size should be 100 units. 2. Given the following data: Usage per Lead Time Gross Item Parent (weeks) Requirements J 1 10 K 4 3 40 L 2 2 20 M 4 3 160 N 1 1 40 O 2 2 80 The end product J is made from components K, and L. K is made from M, N, and O. (a) What is the replenishment lead time for J, assuming there are no inventories? JL =1+2=3 JKM=1+3+3=7 JKN=1+3+1=5 JKO = 1+3+2=6 The replenishment lead time is 7 weeks. (b) Calculate the gross requirements for each of the components if the company plans to build 10 of its J model. Assume that there are no beginning inventories. See above. 4 Professor Blake OPM 101 Spring 2010 Name__________________________ 3. The following jobs are waiting to be processed at J. J. Rupper’s work center. Job Production Days Needed Due Date A 20 35 B 30 90 C 16 40 D 10 25 E 18 50 Customers usually do not pick up orders before the due date. Today is day 0. Using the SPT priority rule, calculate the (a) mean flow time, (b) average number of jobs in the system, and (c) average job tardiness. Sequence: D, C, E, A, B Jobs D C E A B Production Days 10 16 18 20 30 94 Flow Time 10 26 44 64 94 238 Due Date 25 40 50 35 90 a) Mean flow time: 238/5 = 47.6 days b) Avg. jobs in system: 238/94 = 2.53 jobs c) Avg. job tardiness: 33/5 = 6.6 days 5 Tardiness 0 0 0 29 4 33