Supporting Information capacitance of bulk sp

advertisement

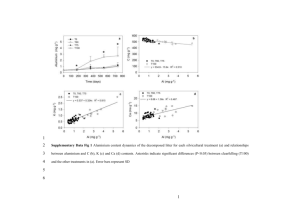

Supporting Information What are the practical limits for the specific surface area and capacitance of bulk sp2 carbon materials? Yanhong Lu1,2*, Guankui Long2, Long Zhang2, Tengfei Zhang2, Mingtao Zhang2, Fan Zhang2, Yang Yang2, Yanfeng Ma2 & Yongsheng Chen2,* 1 School of Chemistry & Material Science, Langfang Teachers University, Langfang, Hebei, 065000, China 2 Key Laboratory of Functional Polymer Materials and Center for Nanoscale Science and Technology, Institute of Polymer Chemistry, College of Chemistry, Nankai University, Tianjin, 300071, China Corresponding: yschen99@nankai.edu.cn;luyanhong_2003@126.com; 1 Synthesis of various bulk sp2 carbon materials Details for all the prepared materials are summarized in Table S1. An aqueous solution of the different carbon sources, including the phenol/formaldehyde mixture (PF, phenol/formaldehyde weight ratio of 0.7), polyvinyl alcohol (PVA), sucrose, cellulose and lignin was mixed with a GO aqueous suspension with different weight ratios of carbon source to GO. As a typical example, the preparation of S@24GA is as follows. An aqueous solution of sucrose (23 mL, 250 mg mL-1) and a GO aqueous suspension (47 mL, 5 mg mL-1) were homogeneously mixed and stirred for 4 h and then transferred to a sealed 100 mL Teflonlined autoclave, and heated to 180 °C for 12 h. After the autoclave was cooled to room temperature, the hydrothermal product was filtered, washed with distilled water and finally dried in vacuum at 120 °C for 24 h. The intermediate hydrothermal product was mixed with KOH activation agent at the weight ratio of 1:4, placed in a horizontal tube furnace and heated from room temperature to 900 °C for 1 h at 5 °C min-1 under Ar. After cooling to room temperature, the products were thoroughly washed with 0.1 M HCl to remove any inorganic salts, and then washed with distilled water until the pH value reached 7. The final products were obtained after drying in vacuum at 120 °C for 24 h. Calculations of the stack height (Lc) and lateral size (La) of graphene domains in the sp2 carbon materials The stack height Lc can be estimated from the XRD line broadening using the Scherrer equation: Lc = Kλ / (βc × cosθ), where K is the shape factor which is equal to 0.89, λ is the wave length of the X-ray radiation, βc is the full width at half height of the diffraction peaks and θ is the Bragg angle. With Raman spectra, Lorentzian fitting was carried out to obtain the positions and widths of the D and G bands. The size of graphene domains La (nm) can be estimated using the equation La = (2.4 × 10-10) λ4 (ID / IG)-1, where λ is the laser energy in nanometers, and ID and IG are the intensities of the D and G bands, respectively. 2 The estimated values of Lc and La of a series of sp2 carbon materials are shown in Table S2. As can be seen from Table S2, the average domain height Lc of the optimized activation products is found to be 0.7–0.8 nm, and the approximate dimensional size is around 5–6 nm depending on the carbon source. These results suggest that the basic structural units in the high SSA sp2 carbon materials are graphene sheets a few nanometers in size, most of which should be wrinkled single-layer sheets with some few-layer, as observed earlier [1, 2]. Theoretical modeling and calculations All DFT calculations were performed with the Gaussian 09 program package Full citation for Gaussian 09, Revision B.01, Gaussian, Inc., Wallingford CT, 2010. M. J. Frisch, G. W. Trucks, H. B. Schlegel, G. E. Scuseria, M. A. Robb, J. R. Cheeseman, G. Scalmani, V. Barone, B. Mennucci, G. A. Petersson, H. Nakatsuji, M. Caricato, X. Li, H. P. Hratchian, A. F. Izmaylov, J. Bloino, G. Zheng, J. L. Sonnenberg, M. Hada, M. Ehara, K. Toyota, R. Fukuda, J. Hasegawa, M. Ishida, T. Nakajima, Y. Honda, O. Kitao, H. Nakai, T. Vreven, J. A. Montgomery, Jr., J. E. Peralta, F. Ogliaro, M. Bearpark, J. J. Heyd, E. Brothers, K. N. Kudin, V. N. Staroverov, T. Keith, R. Kobayashi, J. Normand, K. Raghavachari, A. Rendell, J. C. Burant, S. S. Iyengar, J. Tomasi, M. Cossi, N. Rega, J. M. Millam, M. Klene, J. E. Knox, J. B. Cross, V. Bakken, C. Adamo, J. Jaramillo, R. Gomperts, R. E. Stratmann, O. Yazyev, A. J. Austin, R. Cammi, C. Pomelli, J. W. Ochterski, R. L. Martin, K. Morokuma, V. G. Zakrzewski, G. A. Voth, P. Salvador, J. J. Dannenberg, S. Dapprich, A. D. Daniels, O. Farkas, J. B. Foresman, J. V. Ortiz, J. Cioslowski, and D. J. Fox. 3 Construction of the effective ionic diameter (EID) model and calculation of effective specific surface (E-SSA) and theoretical capacitance (Cth) E-SSA, which is the accessible surface area for the electrolyte ions, was calculated according to the cumulative DFT SSA, the PSD of the carbon materials and the electrolyte ion size. In this work, the electrolyte ion sizes used to calculate the E-SSA in EMIMBF4, BMIMBF4 was obtained using DFT calculations (B3LYP/6-31G*) [3, 4] and the cation sizes of EMIM+, BMIM+ were found to be 0.752 and 1.107 nm, respectively, and the sizes of TEA+ in organic system and K+ in aqueous system are 0.684 and 0.266 nm, respectively, following the literature [5, 6]. Using the E-SSA, the theoretical capacitance was calculated. Before we could do that, EID, the actual size of the electrolyte ions absorbed on the active material surface, had to be known. For solvent free IL ions, the Cth could be obtained easily as there is no solvation issue. However, for aqueous and organic electrolyte systems, the ion size depends heavily on the solvation layer. With these provisos in mind, the bare electrolyte ion sizes could not be used. Thus, a more general model was proposed as shown in Figures 1 and S1, where the layers of solvent molecules around the ions were taken into account. Thus, the actual electrolyte ion size, EID, was obtained as the sum of the naked ion size (obtained from the van der Waals diameter) and the thickness of the shell of solvent molecules. With this model, the EIDs of 1.0 M TEA+ in organic solvent AN and 6 M K+ in water were taken as 1.320 and 0.662 nm, respectively, following the literature [5-7]. Based on the EID model and the method in our previous work [2], the corresponding Cth of representative materials in several of the most widely studied electrolyte systems was calculated. The calculation was based on equation (S1) [8]: Cp 0 A d (S1) 4 where ε0 is vacuum permittivity which is 8.85×10-12 F m-1, ε is the relative dielectric constant of the electrolyte, A is the E-SSA and d is the thickness of the electric double layer. In this work, room temperature ε was used because measurements were made at room temperature, and ε values are found to be 14.8, 12.9, 9.65 and 13.4 for EMIMBF4, BMIMBF4, 1 M TEABF4/AN and 6 M KOH electrolyte systems, respectively [5, 9]. Note that the capacitance contribution of pores with diameters smaller than the size of the solvated electrolyte ions but larger than that of the bare electrolyte ions was also included as suggested in the literature [10-12]. A series of representative E-SSA and cumulative specific capacitance values of GAC electrode materials in EMIMBF4, BMIMBF4, TEABF4/AN and KOH electrolyte systems are listed in Tables S3–S7. Note that we only used the cations for the estimation of Cth since all the corresponding anions are smaller than the cations. Similar to our previous report [2], the values of cumulative specific capacitance are quite different from Cex because the actual relative dielectric constant of the electrolyte could change due to many reasons such as the curvature of the pore surface, the temperature and frequency dependenc of the relative dielectric constant. Therefore, the cumulative specific capacitance of all the products in each electrolyte was normalized by the same degree to get the normalized cumulative specific capacitance. The normalized cumulative specific capacitances in EMIMBF4, BMIMBF4, TEABF4/AN and KOH electrolyte were divided by 2.3, 1.4, 1.15 and 2.5, respectively, to give what is defined as the theoretical specific capacitance Cth, and a systematic comparison with Cex was obtained, as shown in Figures 3 and S2. From the results, an excellent agreement between Cex and Cth for all the products in all electrolytes was observed, indicating that our model for the calculation of theoretical specific capacitance is appropriate for SCs based on the different carbon materials in all the studied electrolyte systems. 5 Calculation of the possible smallest stable graphene sheet size To theoretically obtain the possible smallest stable graphene sheet (fragment) size, geometrical optimization of all the graphene fragments with different sizes (different numbers of carbon atoms) was performed at the B3LYP levels of theory with the 3-21G basis set [3, 4]. Frequency analysis was used at the same level of theory to check whether the optimized geometrical structures were in stable states and to evaluate the zero-point vibration energy (ZPE). With these graphene fragments, a thermodynamic calculation was used. The smallest stable graphene fragment was then predicted under practical experimental conditions. To calculate the Gibbs free energy change of the reaction, the gas phase reaction enthalpy change ΔrH (g) at different temperatures is theoretically calculated. Assuming the gasification enthalpy of the reactants is equal to the solidification enthalpy of the products, ΔrH (g) could be used as the solid phase reaction enthalpy change ΔrH (s) of Equ. 1. In a similar way, the gas phase reaction entropy change ΔrS (g) of equation (2), dominantly provided by H2 with the value of 31.151 cal mol-1 K-1, could be used as the solid phase reaction entropy change ΔrS (s). Based on ΔrH (s) and ΔrS (s), the Gibbs free energy change ΔrG of the reaction in equation (2) at 900 °C could be obtained according to ΔrG = ΔrH - TΔrS. Calculation of theoretical SSA for a given size graphene sheet With a given graphene sheet size, the theoretical SSA of the sp2 carbon materials was calculated from a simple Monte Carlo integration technique where the probe molecule is “rolled” over the framework surface, and the probe radius is 1.82 Å (the kinetic radius of N2) [13, 14]. Based on this method, the corresponding theoretical SSA of the bulk carbon materials with 5 × 5–6 × 6 nm size graphene sheets would be ~ 3500–3700 m2 g-1. 6 Figure S1 Schematics of the packing mode of IL and solvated organic & aqueous electrolyte ions in the pores of electrode materials and the corresponding utilized cylindrical pore surface. Tightly stacked (a) IL and (b) solvated organic & aqueous electrolyte ions with complete matching between the EID of the electrolyte ions and the pore size, (c) not tightly stacked together due to mismatching. The d value is equal to the radius of the solvated ion. The black regions of the pore circumference in (c) represent the unused or wasted cylindrical pore surface. 7 Figure S2 Relationship between the experimental and theoretical specific capacitances of various carbon materials in (a) EMIMBF4, (b) BMIMBF4, (c) TEABF4/AN and (d) KOH. In each pair of the columns, the left is Cex and the right is Cth. 8 Table S1 Preparation of various bulk sp2 carbon materials and the corresponding BET SSA Weight ratio of sp2 carbon Activation activation agent to agent hydrothermal Carbon source materials Activation BET temperature SSA / / °C m2 g-1 product RP20 - - - - 1677 HXAC - - - - 1820 GAC - - - - 2654 GA GO KOH 4:1 900 1810 PA PFa) KOH 4:1 900 2074 BA bitumen KOH 4:1 900 2470 P@8GA PF/GO = 8:1b) KOH 4:1 900 2356 L@24GA Lignin/GO = 24:1 KOH 4:1 900 3026 C@24GA cellulose/GO = 24:1 KOH 4:1 900 3117 V@20GA PVA/GO = 20:1 KOH 4:1 900 3192 S@24GA sucrose/GO = 24:1 KOH 4:1 900 3271 P@16GA PF/GO = 16:1 KOH 4:1 900 3523 P@16GA-8R PF/GO = 16:1 KOH 8:1 900 2078 P@16GA-1100 PF/GO = 16:1 KOH 4:1 1100 1136 P@24GA- PF/GO = 24:1 NaOH 4:1 900 2119 P@24GANaOH P@24GAK2CO3 PF/GO = 24:1 K2CO3 4:1 900 1426 PF/GO = 24:1 ZnCl2 4:1 900 989 P@24GAZnCl2 P@24GAH3PO4 PF/GO = 24:1 H3PO4 4:1 900 651 PF/GO = 24:1 CaO 4:1 900 557 P@24GA-2R CaO P@24GA-3R PF/GO = 24:1 KOH 2:1 900 1366 PF/GO = 24:1 KOH 3:1 900 2216 P@24GA PF/GO = 24:1 KOH 4:1 900 3394 P@24GA-5R PF/GO = 24:1 KOH 5:1 900 2613 P@24GA-6R PF/GO = 24:1 KOH 6:1 900 2341 P@24GA-7R PF/GO = 24:1 KOH 7:1 900 1700 P@24GA-8R PF/GO = 24:1 KOH 8:1 900 1466 P@24GA-600 PF/GO = 24:1 KOH 4:1 600 1587 P@24GA-700 PF/GO = 24:1 KOH 4:1 700 2200 9 P@24GA-800 PF/GO = 24:1 KOH 4:1 800 2536 P@24GA-1000 PF/GO = 24:1 KOH 4:1 1000 2218 a) PF = phenol and formaldehyde b) weight ratio 10 Table S2 The height (Lc) and lateral size (La) of the graphene domains XRD results Raman results Lc / nm La / nm P@16GA 0.81 6.5 C@24GA 0.84 4.8 L@24GA 0.83 5.9 S@24GA 0.75 6.5 V@20GA 0.88 4.8 P@24GA 0.85 6.7 P@8GA 0.88 6.9 Products 11 Table S3 Detailed data for the calculation of E-SSA and the specific capacitance of (Cp) for all the pores for the GAC electrode material in EMIMBF4 electrolyte. The cumulative specific capacitance (Cc) is 320 F g-1. DFT SSA / Db) / E-SSA / Wa) / nm UE-SSAe) ηd) nc) 2 m g -1 nm m2 g-1 Cpg) / Cch) / F g-1 F g-1 df) / nm 2 -1 /m g 0.500 685 0.752 0 0 0 0 0.536 0 0.752 0 0 0 0 0.590 0 0.752 0 0 0 0 0.643 0 0.752 0 0 0 0 0.679 0 0.752 0 0 0 0 0.733 97 0.752 0 0 0 0 0.804 149 0.752 149 1 0.935 139 0.376 48 48 0.858 7 0.752 7 1 0.877 6 0.376 2 50 0.929 0 0.752 0 1 0.809 0 0.376 0 50 1.001 0 0.752 0 1 0.751 0 0.376 0 50 1.090 120 0.752 120 1 0.690 82 0.376 29 79 1.179 154 0.752 154 1 0.638 98 0.376 34 113 1.269 73 0.752 73 1 0.593 43 0.376 15 128 1.358 36 0.752 36 1 0.554 20 0.376 7 135 1.483 61 0.752 61 1 0.507 31 0.376 11 146 1.591 60 0.752 60 2 0.709 42 0.376 15 161 1.716 38 0.752 38 3 0.855 33 0.376 11 172 1.859 45 0.752 45 4 0.952 43 0.376 15 187 2.002 54 0.752 54 4 0.823 45 0.376 16 203 2.162 64 0.752 64 5 0.895 57 0.376 20 223 2.341 58 0.752 58 6 0.942 54 0.376 19 242 2.520 55 0.752 55 7 0.980 54 0.376 19 261 2.734 56 0.752 56 8 0.991 56 0.376 19 280 12 2.949 37 0.752 37 8 0.890 33 0.376 12 292 3.181 27 0.752 27 9 0.902 25 0.376 9 300 3.431 24 0.752 24 11 0.997 23 0.376 8 308 3.699 13 0.752 13 12 0.986 12 0.376 4 313 4.003 8 0.752 8 13 0.966 7 0.376 3 315 4.325 5 0.752 5 14 0.946 5 0.376 2 317 4.664 3 0.752 3 16 0.986 3 0.376 1 318 5.040 2 0.752 2 17 0.954 2 0.376 1 319 5.433 1 0.752 1 19 0.976 1 0.376 0 319 5.880 1 0.752 1 21 0.984 1 0.376 0 319 6.344 1 0.752 1 23 0.988 1 0.376 0 320 6.845 0 0.752 0 25 0.985 0 0.376 0 320 7.399 0 0.752 0 27 0.975 0 0.376 0 320 7.988 0 0.752 0 30 0.995 0 0.376 0 320 8.632 0 0.752 0 32 0.974 0 0.376 0 320 9.311 0 0.752 0 35 0.981 0 0.376 0 320 10.061 0 0.752 0 38 0.979 0 0.376 0 320 10.866 0 0.752 0 42 0.995 0 0.376 0 320 11.723 0 0.752 0 45 0.983 0 0.376 0 320 12.653 0 0.752 0 49 0.987 0 0.376 0 320 13.671 0 0.752 0 53 0.983 0 0.376 0 320 14.761 0 0.752 0 58 0.992 0 0.376 0 320 15.941 0 0.752 0 63 0.994 0 0.376 0 320 17.210 0 0.752 0 68 0.990 0 0.376 0 320 18.586 0 0.752 0 74 0.994 0 0.376 0 320 20.069 0 0.752 0 80 0.992 0 0.376 0 320 21.660 0 0.752 0 87 0.997 0 0.376 0 320 23.393 0 0.752 0 94 0.994 0 0.376 0 320 25.252 0 0.752 0 102 0.997 0 0.376 0 320 13 27.271 0 0.752 0 110 0.994 0 0.376 0 320 29.451 0 0.752 0 119 0.993 0 0.376 0 320 31.792 0 0.752 0 129 0.995 0 0.376 0 320 34.330 0 0.752 0 140 0.999 0 0.376 0 320 37.064 0 0.752 0 151 0.996 0 0.376 0 320 40.031 0 0.752 0 164 1.000 0 0.376 0 320 43.230 0 0.752 0 177 0.998 0 0.376 0 320 46.679 0 0.752 0 191 0.996 0 0.376 0 320 50.396 0 0.752 0 207 0.999 0 0.376 0 320 54.417 0 0.752 0 224 1.000 0 0.376 0 320 58.760 0 0.752 0 242 0.999 0 0.376 0 320 63.442 0 0.752 0 261 0.997 0 0.376 0 320 68.499 0 0.752 0 282 0.997 0 0.376 0 320 73.968 0 0.752 0 305 0.998 0 0.376 0 320 79.865 0 0.752 0 330 0.999 0 0.376 0 320 86.245 0 0.752 0 356 0.997 0 0.376 0 320 93.126 0 0.752 0 385 0.998 0 0.376 0 320 100.560 0 0.752 0 416 0.998 0 0.376 0 320 108.566 0 0.752 0 450 1.000 0 0.376 0 320 117.233 0 0.752 0 486 0.999 0 0.376 0 320 126.580 0 0.752 0 525 0.999 0 0.376 0 320 136.677 0 0.752 0 567 0.999 0 0.376 0 320 147.596 0 0.752 0 613 1.000 0 0.376 0 320 159.355 0 0.752 0 662 1.000 0 0.376 0 320 172.079 0 0.752 0 715 0.999 0 0.376 0 320 185.804 0 0.752 0 772 0.999 0 0.376 0 320 200.619 0 0.752 0 834 0.999 0 0.376 0 320 216.632 0 0.752 0 901 1.000 0 0.376 0 320 233.913 0 0.752 0 973 0.999 0 0.376 0 320 14 a) W: pore width b) D: diameter of EID of electrolyte ions c) n: number of electrolyte ions in one cylindrical pore η: proportion of true E-SSA d) e) UE-SSA: utilized E-SSA f) d: thickness of electric double layer g) Cp: specific capacitance contributed by the pores at the given pore size h) Cc: cumulative specific capacitance of all the pores below the given pore size 15 Table S4 Detailed data for the calculation of E-SSA and the specific capacitance of (Cp) for all the pores for the GAC electrode material in BMIMBF4 electrolyte. The cumulative specific capacitance (Cc) is 143 F g-1. Cp / Cc / F g-1 F g-1 0 0 0 0 0 0 0 1.107 0 0 0 0 0 1.107 0 0 0 0 0.679 0 1.107 0 0 0 0 0.733 97 1.107 0 0 0 0 0.804 149 1.107 0 0 0 0 0.858 7 1.107 0 0 0 0 0.929 0 1.107 0 0 0 0 1.001 0 1.107 0 0 0 0 1.090 120 1.107 0 0 0 0 1.179 154 1.107 154 1 0.939 144 0.554 30 30 1.269 73 1.107 73 1 0.872 64 0.554 13 43 1.358 36 1.107 36 1 0.815 30 0.554 6 49 1.483 61 1.107 61 1 0.746 46 0.554 9 58 1.591 60 1.107 60 1 0.696 42 0.554 9 67 1.716 38 1.107 38 1 0.645 25 0.554 5 72 1.859 45 1.107 45 1 0.596 27 0.554 6 78 2.002 54 1.107 54 1 0.553 30 0.554 6 84 2.162 64 1.107 64 1 0.512 33 0.554 7 91 2.341 58 1.107 58 2 0.709 41 0.554 8 99 2.520 55 1.107 55 3 0.860 47 0.554 10 109 2.734 56 1.107 56 4 0.953 53 0.554 11 120 E-SSA / DFT SSA / D/ m2 g-1 nm m g 0.500 685 1.107 0 0.536 0 1.107 0.590 0 0.643 W / nm UE-SSA / η n 2 d / nm m2 g-1 -1 16 2.949 37 1.107 37 4 0.821 31 0.554 6 126 3.181 27 1.107 27 5 0.897 24 0.554 5 131 3.431 24 1.107 24 6 0.949 22 0.554 5 136 3.699 13 1.107 13 7 0.984 12 0.554 3 138 4.003 8 1.107 8 8 0.999 8 0.554 2 140 4.325 5 1.107 5 8 0.895 5 0.554 1 141 4.664 3 1.107 3 9 0.907 3 0.554 1 142 5.040 2 1.107 2 11 1.000 2 0.554 0 142 5.433 1 1.107 1 12 0.989 1 0.554 0 142 5.880 1 1.107 1 13 0.969 1 0.554 0 142 6.344 1 1.107 1 14 0.950 1 0.554 0 142 6.845 0 1.107 0 16 0.989 0 0.554 0 143 7.399 0 1.107 0 17 0.958 0 0.554 0 143 7.988 0 1.107 0 19 0.978 0 0.554 0 143 8.632 0 1.107 0 21 0.987 0 0.554 0 143 9.311 0 1.107 0 23 0.991 0 0.554 0 143 10.061 0 1.107 0 25 0.987 0 0.554 0 143 10.866 0 1.107 0 27 0.978 0 0.554 0 143 11.723 0 1.107 0 30 0.998 0 0.554 0 143 12.653 0 1.107 0 32 0.979 0 0.554 0 143 13.671 0 1.107 0 35 0.983 0 0.554 0 143 14.761 0 1.107 0 38 0.982 0 0.554 0 143 15.941 0 1.107 0 42 0.999 0 0.554 0 143 17.210 0 1.107 0 45 0.986 0 0.554 0 143 18.586 0 1.107 0 49 0.989 0 0.554 0 143 20.069 0 1.107 0 53 0.986 0 0.554 0 143 21.660 0 1.107 0 58 0.995 0 0.554 0 143 23.393 0 1.107 0 63 0.997 0 0.554 0 143 25.252 0 1.107 0 68 0.993 0 0.554 0 143 17 27.271 0 1.107 0 74 0.997 0 0.554 0 143 29.451 0 1.107 0 80 0.995 0 0.554 0 143 31.792 0 1.107 0 87 1.000 0 0.554 0 143 34.330 0 1.107 0 94 0.998 0 0.554 0 143 37.064 0 1.107 0 101 0.990 0 0.554 0 143 40.031 0 1.107 0 110 0.996 0 0.554 0 143 43.230 0 1.107 0 119 0.996 0 0.554 0 143 46.679 0 1.107 0 129 0.998 0 0.554 0 143 50.396 0 1.107 0 139 0.994 0 0.554 0 143 54.417 0 1.107 0 151 0.999 0 0.554 0 143 58.760 0 1.107 0 163 0.997 0 0.554 0 143 63.442 0 1.107 0 176 0.995 0 0.554 0 143 68.499 0 1.107 0 191 0.999 0 0.554 0 143 73.968 0 1.107 0 206 0.997 0 0.554 0 143 79.865 0 1.107 0 223 0.998 0 0.554 0 143 86.245 0 1.107 0 241 0.998 0 0.554 0 143 93.126 0 1.107 0 261 1.000 0 0.554 0 143 100.560 0 1.107 0 282 1.000 0 0.554 0 143 108.566 0 1.107 0 304 0.997 0 0.554 0 143 117.233 0 1.107 0 329 0.999 0 0.554 0 143 126.580 0 1.107 0 355 0.997 0 0.554 0 143 136.677 0 1.107 0 384 0.999 0 0.554 0 143 147.596 0 1.107 0 415 0.999 0 0.554 0 143 159.355 0 1.107 0 448 0.998 0 0.554 0 143 172.079 0 1.107 0 484 0.998 0 0.554 0 143 185.804 0 1.107 0 523 0.998 0 0.554 0 143 200.619 0 1.107 0 565 0.998 0 0.554 0 143 216.632 0 1.107 0 611 0.999 0 0.554 0 143 233.913 0 1.107 0 660 0.999 0 0.554 0 143 18 Table S5 Detailed data for the calculation of E-SSA and the specific capacitance of (Cp) for all the pores for the GAC electrode material in 1M TEABF4/AN electrolyte. The cumulative specific capacitance (Cc) is 169 F g-1. E-SSA / Cp / D/ m2 g-1 nm m g 0.500 685 0.684a) 0 0 0 0 0.536 0 0.684 0 0 0 0 0.590 0 0.684 0 0 0 0 0.643 0 0.684 0 0 0 0 0.679 0 0.684 0 0 0 0 0.733 97 0.684 97 1 0.934 90 0.342 23 23 0.804 149 0.684 149 1 0.851 126 0.342 32 54 0.858 7 0.684 7 1 0.797 5 0.342 1 55 0.929 0 0.684 0 1 0.736 0 0.342 0 55 1.001 0 0.684 0 1 0.683 0 0.342 0 55 1.090 120 0.684 120 1 0.627 75 0.342 19 74 1.179 154 0.684 154 1 0.580 89 0.342 22 96 1.269 73 0.684 73 1 0.539 39 0.342 10 106 1.358 36 1.320b) 36 1 0.972 35 0.660 5 111 1.483 61 1.320 61 1 0.890 55 0.660 7 118 1.591 60 1.320 60 1 0.830 50 0.660 6 124 1.716 38 1.320 38 1 0.769 30 0.660 4 128 1.859 45 1.320 45 1 0.710 32 0.660 4 132 2.002 54 1.320 54 1 0.659 36 0.660 5 137 2.162 64 1.320 64 1 0.610 39 0.660 5 142 2.341 58 1.320 58 1 0.564 32 0.660 4 146 2.520 55 1.320 55 1 0.524 29 0.660 4 150 2.734 56 1.320 56 2 0.767 43 0.660 6 156 W / nm UE-SSA / Cc / DFT SSA / η n 2 d / nm m2 g-1 -1 19 F g-1 F g-1 2.949 37 1.320 37 3 0.903 34 0.660 4 160 3.181 27 1.320 27 3 0.753 21 0.660 3 163 3.431 24 1.320 24 4 0.860 20 0.660 3 165 3.699 13 1.320 13 5 0.936 12 0.660 2 167 4.003 8 1.320 8 6 0.983 8 0.660 1 168 4.325 5 1.320 5 6 0.869 4 0.660 1 168 4.664 3 1.320 3 7 0.905 3 0.660 0 169 5.040 2 1.320 2 8 0.924 2 0.660 0 169 5.433 1 1.320 1 9 0.936 1 0.660 0 169 5.880 1 1.320 1 10 0.935 1 0.660 0 169 6.344 1 1.320 1 11 0.931 0 0.660 0 169 6.845 0 1.320 0 13 0.999 0 0.660 0 169 7.399 0 1.320 0 14 0.976 0 0.660 0 169 7.988 0 1.320 0 15 0.952 0 0.660 0 169 8.632 0 1.320 0 17 0.983 0 0.660 0 169 9.311 0 1.320 0 18 0.951 0 0.660 0 169 10.061 0 1.320 0 20 0.966 0 0.660 0 169 10.866 0 1.320 0 22 0.972 0 0.660 0 169 11.723 0 1.320 0 24 0.972 0 0.660 0 169 12.653 0 1.320 0 26 0.967 0 0.660 0 169 13.671 0 1.320 0 29 0.989 0 0.660 0 169 14.761 0 1.320 0 31 0.971 0 0.660 0 169 15.941 0 1.320 0 34 0.979 0 0.660 0 169 17.210 0 1.320 0 37 0.980 0 0.660 0 169 18.586 0 1.320 0 41 0.999 0 0.660 0 169 20.069 0 1.320 0 44 0.987 0 0.660 0 169 21.660 0 1.320 0 48 0.993 0 0.660 0 169 23.393 0 1.320 0 52 0.991 0 0.660 0 169 25.252 0 1.320 0 56 0.984 0 0.660 0 169 20 27.271 0 1.320 0 61 0.989 0 0.660 0 169 29.451 0 1.320 0 66 0.987 0 0.660 0 169 31.792 0 1.320 0 72 0.994 0 0.660 0 169 34.330 0 1.320 0 78 0.994 0 0.660 0 169 37.064 0 1.320 0 85 1.000 0 0.660 0 169 40.031 0 1.320 0 92 0.999 0 0.660 0 169 43.230 0 1.320 0 99 0.993 0 0.660 0 169 46.679 0 1.320 0 107 0.992 0 0.660 0 169 50.396 0 1.320 0 116 0.994 0 0.660 0 169 54.417 0 1.320 0 126 0.998 0 0.660 0 169 58.760 0 1.320 0 136 0.995 0 0.660 0 169 63.442 0 1.320 0 147 0.995 0 0.660 0 169 68.499 0 1.320 0 159 0.995 0 0.660 0 169 73.968 0 1.320 0 172 0.995 0 0.660 0 169 79.865 0 1.320 0 186 0.996 0 0.660 0 169 86.245 0 1.320 0 202 1.000 0 0.660 0 169 93.126 0 1.320 0 218 0.998 0 0.660 0 169 100.560 0 1.320 0 236 1.000 0 0.660 0 169 108.566 0 1.320 0 255 1.000 0 0.660 0 169 117.233 0 1.320 0 275 0.997 0 0.660 0 169 126.580 0 1.320 0 297 0.997 0 0.660 0 169 136.677 0 1.320 0 321 0.997 0 0.660 0 169 147.596 0 1.320 0 347 0.997 0 0.660 0 169 159.355 0 1.320 0 375 0.998 0 0.660 0 169 172.079 0 1.320 0 406 1.000 0 0.660 0 169 185.804 0 1.320 0 438 0.998 0 0.660 0 169 200.619 0 1.320 0 474 1.000 0 0.660 0 169 216.632 0 1.320 0 512 1.000 0 0.660 0 169 233.913 0 1.320 0 553 0.999 0 0.660 0 169 21 the diameter of bare TEA+ a) the diameter of solvated TEA+ in AN system[5] b) 22 Table S6 Detailed data for the calculation of E-SSA and the specific capacitance of (Cp) for all the pores for the GAC electrode material in KOH electrolyte. The cumulative specific capacitance (Cc) is 683 F g-1. E-SSA / Cp / D/ m2 g-1 nm m g 0.500 685 0.266a) 685 1 0.532 364 0.133 325 325 0.536 0 0.266 0 1 0.496 0 0.133 0 325 0.590 0 0.266 0 1 0.451 0 0.133 0 325 0.643 0 0.266 0 1 0.413 0 0.133 0 325 0.679 0 0.662b) 0 1 0.975 0 0.331 0 325 0.733 97 0.662 97 1 0.903 87 0.331 31 356 0.804 149 0.662 149 1 0.823 122 0.331 44 400 0.858 7 0.662 7 1 0.772 5 0.331 2 402 0.929 0 0.662 0 1 0.712 0 0.331 0 402 1.001 0 0.662 0 1 0.661 0 0.331 0 402 1.090 120 0.662 120 1 0.607 73 0.331 26 428 1.179 154 0.662 154 1 0.561 86 0.331 31 459 1.269 73 0.662 73 1 0.522 38 0.331 14 472 1.358 36 0.662 36 2 0.800 29 0.331 10 483 1.483 61 0.662 61 3 0.896 55 0.331 20 502 1.591 60 0.662 60 3 0.758 45 0.331 16 519 1.716 38 0.662 38 4 0.865 33 0.331 12 531 1.859 45 0.662 45 5 0.934 42 0.331 15 546 2.002 54 0.662 54 6 0.988 54 0.331 19 565 2.162 64 0.662 64 6 0.873 56 0.331 20 585 2.341 58 0.662 58 7 0.903 52 0.331 19 604 2.520 55 0.662 55 8 0.928 51 0.331 18 622 2.734 56 0.662 56 9 0.932 52 0.331 19 641 W / nm UE-SSA / Cc / DFT SSA / η n 2 d / nm m2 g-1 -1 23 F g-1 F g-1 2.949 37 0.662 37 10 0.935 35 0.331 13 653 3.181 27 0.662 27 11 0.932 25 0.331 9 662 3.431 24 0.662 24 13 0.999 24 0.331 8 671 3.699 13 0.662 13 14 0.980 12 0.331 4 675 4.003 8 0.662 8 15 0.953 7 0.331 3 678 4.325 5 0.662 5 17 0.984 5 0.331 2 680 4.664 3 0.662 3 18 0.953 3 0.331 1 681 5.040 2 0.662 2 20 0.967 2 0.331 1 681 5.433 1 0.662 1 22 0.975 1 0.331 0 682 5.880 1 0.662 1 24 0.972 1 0.331 0 682 6.344 1 0.662 1 26 0.967 1 0.331 0 682 6.845 0 0.662 0 29 0.991 0 0.331 0 682 7.399 0 0.662 0 31 0.972 0 0.331 0 682 7.988 0 0.662 0 34 0.980 0 0.331 0 682 8.632 0 0.662 0 37 0.980 0 0.331 0 683 9.311 0 0.662 0 40 0.976 0 0.331 0 683 10.061 0 0.662 0 44 0.988 0 0.331 0 683 10.866 0 0.662 0 48 0.992 0 0.331 0 683 11.723 0 0.662 0 52 0.992 0 0.331 0 683 12.653 0 0.662 0 56 0.985 0 0.331 0 683 13.671 0 0.662 0 61 0.989 0 0.331 0 683 14.761 0 0.662 0 66 0.987 0 0.331 0 683 15.941 0 0.662 0 72 0.994 0 0.331 0 683 17.210 0 0.662 0 78 0.994 0 0.331 0 683 18.586 0 0.662 0 84 0.988 0 0.331 0 683 20.069 0 0.662 0 92 1.000 0 0.331 0 683 21.660 0 0.662 0 99 0.994 0 0.331 0 683 23.393 0 0.662 0 107 0.993 0 0.331 0 683 25.252 0 0.662 0 116 0.995 0 0.331 0 683 24 27.271 0 0.662 0 126 0.998 0 0.331 0 683 29.451 0 0.662 0 136 0.996 0 0.331 0 683 31.792 0 0.662 0 147 0.996 0 0.331 0 683 34.330 0 0.662 0 159 0.996 0 0.331 0 683 37.064 0 0.662 0 172 0.996 0 0.331 0 683 40.031 0 0.662 0 186 0.996 0 0.331 0 683 43.230 0 0.662 0 201 0.996 0 0.331 0 683 46.679 0 0.662 0 218 0.999 0 0.331 0 683 50.396 0 0.662 0 235 0.996 0 0.331 0 683 54.417 0 0.662 0 254 0.996 0 0.331 0 683 58.760 0 0.662 0 275 0.998 0 0.331 0 683 63.442 0 0.662 0 297 0.997 0 0.331 0 683 68.499 0 0.662 0 321 0.998 0 0.331 0 683 73.968 0 0.662 0 347 0.998 0 0.331 0 683 79.865 0 0.662 0 375 0.998 0 0.331 0 683 86.245 0 0.662 0 405 0.998 0 0.331 0 683 93.126 0 0.662 0 438 0.999 0 0.331 0 683 100.560 0 0.662 0 473 0.998 0 0.331 0 683 108.566 0 0.662 0 511 0.998 0 0.331 0 683 117.233 0 0.662 0 552 0.998 0 0.331 0 683 126.580 0 0.662 0 597 1.000 0 0.331 0 683 136.677 0 0.662 0 645 1.000 0 0.331 0 683 147.596 0 0.662 0 696 0.999 0 0.331 0 683 159.355 0 0.662 0 752 0.999 0 0.331 0 683 172.079 0 0.662 0 813 1.000 0 0.331 0 683 185.804 0 0.662 0 878 1.000 0 0.331 0 683 200.619 0 0.662 0 948 1.000 0 0.331 0 683 216.632 0 0.662 0 1024 1.000 0 0.331 0 683 233.913 0 0.662 0 1106 1.000 0 0.331 0 683 25 the diameter of bare K+ [6] a) the diameter of solvated K+ in aqueous system [7] b) 26 Table S7 DFT SSA, E-SSA and the corresponding Cth of various sp2 carbon materials in different electrolyte systems for several of the representative bulk sp2 materials prepared in this work. DFT KOH EMIMBF4 BMIMBF4 TEABF4/AN 2 bulk sp carbon SSA E-SSA Cth E-SSA Cth E-SSA Cth E-SSA Cth m2 g-1 m2 g-1 F g-1 m2 g-1 F g-1 m2 g-1 F g-1 m2 g-1 F g-1 P@16GA-1100 760 760 101 582 75 422 54 614 73 RP20 1255 1255 160 739 96 415 46 817 112 GA 1361 1361 179 748 98 544 70 781 92 HXAC 1035 1035 119 846 101 483 53 935 124 PA 1486 1486 191 956 116 390 44 1009 129 P@8GA 1571 1571 195 1058 129 654 74 1088 132 BA 1508 1508 195 1230 163 1034 134 1305 146 GAC 1934 1934 273 1153 139 878 102 1250 147 P@24GA 1779 1779 234 1439 196 1125 143 1509 182 L@24GA 1952 1952 254 1558 215 1347 179 1636 184 S@24GA 2105 2105 278 1631 209 1402 179 1738 195 P@16GA 2224 2224 290 1686 216 1391 176 1759 192 materials 27 Table S8 The Cex of various sp2 carbon materials in different electrolyte systems 6 M KOH EMIMBF4 Cex materials BMIMBF4 Cex materials F g-1 P@16GA- P@16GA- 1100 P@16GA- R 53 1100 P@16GA171 Cex materials F g-1 71 1100 P@16GA- Cex materials F g-1 92 1 M TEABF4/AN F g-1 P@16GA1100 53 P@16GA125 8R 102 GA 92 8R RP20 143 RP20 91 RP20 45 RP20 94 P@8GA 209 P@8GA 136 P@8GA 80 P@8GA 119 GAC 244 GAC 139 GAC 108 GAC 140 P@24GA 212 PA 120 PA 38 PA 112 S@24GA 281 S@24GA 216 GA 75 S@24GA 197 P@16GA 296 P@16GA 231 P@24GA 144 P@16GA 202 BA 183 L@24GA 213 BA 133 V@20GA 174 28 Table S9 Reaction Gibbs free energy change ΔrG per carbon atom of different aromatic/polyaromatic compounds. Aromatic/polyaromatic Number of carbon atoms ΔrG/n / kcal mol-1 compound (n) benzene 6 -2.08 naphathlene 10 -1.14 anthracene 14 -0.79 phenanthrene 14 -0.90 pyrene 16 -0.77 graphene0505 20 -0.58 Coronene 24 -0.48 graphene1010 54 -0.21 graphene1515 104 -0.14 graphene2020 170 -0.09 graphene2525 252 -0.06 29 Table S10 The corresponding best capacitance in different electrolyte systems for the E-SSA limit of about 3500–3700 m2 g-1 based on the linear relationship between capacitance and ESSA. Electrolyte system Linear relationship Capacitance / F g-1 EMIMBF4 Y = 0.144 X - 19.2 484.8–513.6 KOH Y = 0.141 X - 24.4 469.1–497.3 BMIMBF4 Y = 0.137 X - 8.96 470.5–497.9 TEABF4/AN Y = 0.122 X - 11.5 415.5–439.9 30 References 1 Zhang L, Zhang F, Yang X, et al. Porous 3d graphene-based bulk materials with exceptional high surface area and excellent conductivity for supercapacitors. Sci Rep, 2013, 3. 2 Zhang L, Yang X, Zhang F, et al. Controlling the effective surface area and pore size distribution of sp2 carbon materials and their impact on the capacitance performance of these materials. J Am Chem Soc, 2013, 135(15): 5921-5929 3 Becke AD. Density‐functional thermochemistry. Iii. The role of exact exchange. J Chem Phys, 1993, 98(7): 5648-5652 4 Lee C, Yang W, Parr RG. Development of the colle-salvetti correlation-energy formula into a functional of the electron density. Phys Rev B, 1988, 37(2): 785-789 5 Huang J, Sumpter BG, Meunier V. A universal model for nanoporous carbon supercapacitors applicable to diverse pore regimes, carbon materials, and electrolytes. Chem-Eur J, 2008, 14(22): 6614-6626 6 Israelachvili JN. Intermolecular and surface forces, third edition, USA: Academic Press, 2011. 79 7 Volkov AG, Paula S, Deamer DW. Two mechanisms of permeation of small neutral molecules and hydrated ions across phospholipid bilayers. Bioelectrochem Bioenerg, 1997, 42(2): 153-160 8 Simon P, Gogotsi Y. Materials for electrochemical capacitors. Nat Mater, 2008, 7(11): 845854 9 Singh T, Kumar A. Static dielectric constant of room temperature ionic liquids: Internal pressure and cohesive energy density approach. J Phys Chem B, 2008, 112(41): 1296812972 10 Chmiola J, Yushin G, Gogotsi Y, et al. Anomalous increase in carbon capacitance at pore sizes less than 1 nanometer. Science, 2006, 313(5794): 1760-1763 11 Ania CO, Pernak J, Stefaniak F, et al. Polarization-induced distortion of ions in the pores of carbon electrodes for electrochemical capacitors. Carbon, 2009, 47(14): 3158-3166 12 Lin R, Taberna PL, Chmiola J, et al. Microelectrode study of pore size, ion size, and solvent effects on the charge/discharge behavior of microporous carbons for electrical double-layer capacitors. J Electrochem Soc, 2009, 156(1): A7-A12 13 Dueren T, Millange F, Ferey G, et al. Calculating geometric surface areas as a characterization tool for metal-organic frameworks. J Phys Chem C, 2007, 111(42): 1535015356 31 14 Connolly ML. Solvent-accessible surfaces of proteins and nucleic acids. Science, 1983, 221(4612): 709-713 32