ERP - Notes of OAS, KBS, MRP, BRP, SCM, CRM, Information Communication Technology

advertisement

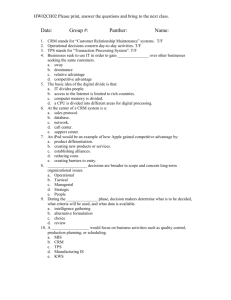

Notes of OAS, KBS, MRP, BRP, SCM, CRM, Information Communication Technology Option-adjusted spread Option adjusted spread (OAS) is the flat spread over the treasury yield curve required to discount a security payment to match its market price. This concept can be applied to mortgage-backed security (MBS), Options, Bonds and any other interest-rate Derivative. Definition In contrast to the simple "yield curve spread" measurement of bond premium over a predetermined cash-flow model, the OAS describes the market premium over a model including two types of volatility: Variable interest rates Variable prepayment rates. Designing such models in the first place is complicated because prepayment variations are a behavioural function of the stochastic interest rate. (They tend to go up as interest rates come down.) OAS is an emerging term with fluid use across MBS finance. The definition here is based on Lakhbir Hayre's Mortgage Backed Securities text book. Other definitions are rough analogs: Take the expected value (mean NPV) across the range of all possible rate scenarios when discounting each scenario's actual cash flows with the treasury yield curve plus a spread, X. The OAS is defined as the value of X equating the market price of the MBS to its value in this theoretical framework. Treasury bonds may not be available with maturities exactly matching likely cash flow payments so some interpolation may be necessary to make this calculation. Knowledge-based systems Knowledge-based systems are systems based on the methods and techniques of Artificial Intelligence. Their core components are the knowledge base and the inference mechanisms. While for some authors expert systems, case-based reasoning systems and nueral networks are all particular types of knowledge-based systems, there are others who consider that neural networks are different, and exclude it from this category. KBS is a frequently used abbreviation for knowledge-based system. Material Requirements Planning Material Requirements Planning (MRP) is a software based production planning and inventory control system used to manage manufacturing processes. Although it is not common nowadays, it is possible to conduct MRP by hand as well. An MRP system is intended to simultaneously meet three objectives: Ensure materials and products are available for production and delivery to customers. Maintain the lowest possible level of inventory. Plan manufacturing activities, delivery schedules and purchasing activities. The scope of MRP in manufacturing Manufacturing organizations, whatever their products, face the same daily practical problem - that customers want products to be available in a shorter time than it takes to make them. This means that some level of planning is required. Companies need to control the types and quantities of materials they purchase, plan which products are to be produced and in what quantities and ensure that they are able to meet current and future customer demand, all at the lowest possible cost. Making a bad decision in any of these areas will make the company lose money. A few examples are given below: If a company purchases insufficient quantities of an item used in manufacturing, or the wrong item, they may be unable to meet contracts to supply products by the agreed date. If a company purchases excessive quantities of an item, money is being wasted the excess quantity ties up cash while it remains as stock and may never even be used at all. However, some purchased items will have a minimum quantity that must be met, therefore, purchasing excess is necessary. Beginning production of an order at the wrong time can cause customer deadlines to be missed. MRP is a tool to deal with these problems. It provides answers for several questions: What items are required? How many are required? When are they required? MRP can be applied both to items that are purchased from outside suppliers and to subassemblies, produced internally, that are components of more complex items. The data that must be considered include: The end item (or items) being created. This is sometimes called Independent Demand, or Level "0" on BOM (Bill of materials). How much is required at a time. When the quantities are required to meet demand. Shelf life of stored materials. Inventory status records. Records of net materials available for use already in stock (on hand) and materials on order from suppliers. Bills of materials. Details of the materials, components and subassemblies required to make each product. Planning Data. This includes all the restraints and directions to produce the end items. This includes such items as: Routings, Labor and Machine Standards, Quality and Testing Standards, Pull/Work Cell and Push commands, Lot sizing techniques (i.e. Fixed Lot Size, Lot-For-Lot, Economic Order Quantity), Scrap Percentages, and other inputs. Outputs There are two outputs and a variety of messages/reports: Output 1 is the "Recommended Production Schedule" which lays out a detailed schedule of the required minimum start and completion dates, with quantities, for each step of the Routing and Bill Of Material required to satisfy the demand from the Master Production Schedule (MPS). Output 2 is the "Recommended Purchasing Schedule". This lays out both the dates that the purchased items should be received into the facility AND the dates that the Purchase orders, or Blanket Order Release should occur to match the production schedules. Messages and Reports: Purchase orders. An order to a supplier to provide materials. Reschedule notices. These recommend cancelling, increasing, delaying or speeding up existing orders. Note that the outputs are recommended. Due to a variety of changing conditions in companies, since the last MRP / ERP system Re-Generation, the recommended outputs need to be reviewed by trained people to group orders for benefits in set-up or freight savings. These actions are beyond the linear calculations of the MRP computer software. The Barely Repeatable Process (BRP) Typically exceptions to the ERPs, anything that involves people in non-rigid flows through education, health, support, government, consulting or the daily unplanned issues that happens in every organisation. The activities that employees spend most of their time on every day. Processes that often starts with an e-mail or a call. A process volume, measured by time and resource spent at organisations, probably larger than for the Easily Repeatable Processes. These are mostly handled and organised - frameworked - by systems like paper based rules and policies, e-mail, meetings, calls and now in more modern organisations by wikis and other collaboration systems and methods. Known by extensive loss of information (e-mails residing on HDDs), little knowledge acquired and reused (typical research says 70% of problems solved before without being known) and most of all, untrustworthy processes (oops, forgot to send that mail). In other words not an iota (well almost) of business process thinking or methodology applied to this huge untapped area of business processes. Supply chain management Supply chain management (SCM) is the management of a network of interconnected businesses involved in the ultimate provision of product and service packages required by end customers (Harland, 1996). Supply Chain Management spans all movement and storage of raw materials, work-in-process inventory, and finished goods from point-oforigin to point-of-consumption (supply chain). Supply chain management Organizations increasingly find that they must rely on effective supply chains, or networks, to successfully compete in the global market and networked economy. In Peter Drucker's (1998) new management paradigms, this concept of business relationships extends beyond traditional enterprise boundaries and seeks to organize entire business processes throughout a value chain of multiple companies. During the past decades, globalization, outsourcing and information technology have enabled many organizations, such as Dell and Hewlett Packard, to successfully operate solid collaborative supply networks in which each specialized business partner focuses on only a few key strategic activities (Scott, 1993). This inter-organizational supply network can be acknowledged as a new form of organization. However, with the complicated interactions among the players, the network structure fits neither "market" nor "hierarchy" categories (Powell, 1990). It is not clear what kind of performance impacts different supply network structures could have on firms, and little is known about the coordination conditions and trade-offs that may exist among the players. From a systems perspective, a complex network structure can be decomposed into individual component firms (Zhang and Dilts, 2004). Traditionally, companies in a supply network concentrate on the inputs and outputs of the processes, with little concern for the internal management working of other individual players. Therefore, the choice of an internal management control structure is known to impact local firm performance (Mintzberg, 1979). In the 21st century, changes in the business environment have contributed to the development of supply chain networks. First, as an outcome of globalization and the proliferation of multinational companies, joint ventures, strategic alliances and business partnerships, there were found to be significant success factors, following the earlier "Just-In-Time", "Lean Manufacturing" and "Agile Manufacturing" practices. Second, technological changes, particularly the dramatic fall in information communication costs, which are a significant component of transaction costs, have led to changes in coordination among the members of the supply chain network (Coase, 1998). Many researchers have recognized these kinds of supply network structures as a new organization form, using terms such as "Keiretsu", "Extended Enterprise", "Virtual Corporation", "Global Production Network", and "Next Generation Manufacturing System". In general, such a structure can be defined as "a group of semi-independent organizations, each with their capabilities, which collaborate in ever-changing constellations to serve one or more markets in order to achieve some business goal specific to that collaboration" (Akkermans, 2001). The security management system for supply chain is described in ISO/IEC 28000 and ISO/IEC 28001 and related standards published jointly by ISO and IEC. Supply chain business process integration Successful SCM requires a change from managing individual functions to integrating activities into key supply chain processes. An example scenario: the purchasing department places orders as requirements become appropriate. Marketing, responding to customer demand, communicates with several distributors and retailers as it attempts to satisfy this demand. Shared information between supply chain partners can only be fully leveraged through process integration. Supply chain business process integration involves collaborative work between buyers and suppliers, joint product development, common systems and shared information. According to Lambert and Cooper (2000) operating an integrated supply chain requires continuous information flow. However, in many companies, management has reached the conclusion that optimizing the product flows cannot be accomplished without implementing a process approach to the business. The key supply chain processes stated by Lambert (2004) are: Customer relationship management Customer service management Demand management Order fulfillment Manufacturing flow management Supplier relationship management Product development and commercialization Returns management Much has been written about demand management. Best in Class companies have similar characteristics. They include the following: a) Internal and external collaboration b) Lead time reduction initiatives c) Tighter feedback from customer and market demand d) Customer level forecasting One could suggest other key critical supply business processes combining these processes stated by Lambert such as: a. b. c. d. e. f. g. Customer service management Procurement Product development and commercialization Manufacturing flow management/support Physical distribution Outsourcing/partnerships Performance measurement a) Customer service management process Customer Relationship Management concerns the relationship between the organization and its customers. Customer service provides the source of customer information. It also provides the customer with real-time information on promising dates and product availability through interfaces with the company's production and distribution operations. Successful organizations use following steps to build customer relationships: determine mutually satisfying goals between organization and customers establish and maintain customer rapport produce positive feelings in the organization and the customers b) Procurement process Strategic plans are developed with suppliers to support the manufacturing flow management process and development of new products. In firms where operations extend globally, sourcing should be managed on a global basis. The desired outcome is a winwin relationship, where both parties benefit, and reduction times in the design cycle and product development are achieved. Also, the purchasing function develops rapid communication systems, such as electronic data interchange (EDI) and Internet linkages to transfer possible requirements more rapidly. Activities related to obtaining products and materials from outside suppliers requires performing resource planning, supply sourcing, negotiation, order placement, inbound transportation, storage, handling and quality assurance, many of which include the responsibility to coordinate with suppliers in scheduling, supply continuity, hedging, and research into new sources or programs. c) Product development and commercialization Here, customers and suppliers must be united into the product development process, thus to reduce time to market. As product life cycles shorten, the appropriate products must be developed and successfully launched in ever shorter time-schedules to remain competitive. According to Lambert and Cooper (2000), managers of the product development and commercialization process must: 1. coordinate with customer relationship management to identify customerarticulated needs; 2. select materials and suppliers in conjunction with procurement, and 3. develop production technology in manufacturing flow to manufacture and integrate into the best supply chain flow for the product/market combination. d) Manufacturing flow management process The manufacturing process is produced and supplies products to the distribution channels based on past forecasts. Manufacturing processes must be flexible to respond to market changes, and must accommodate mass customization. Orders are processes operating on a just-in-time (JIT) basis in minimum lot sizes. Also, changes in the manufacturing flow process lead to shorter cycle times, meaning improved responsiveness and efficiency of demand to customers. Activities related to planning, scheduling and supporting manufacturing operations, such as work-in-process storage, handling, transportation, and time phasing of components, inventory at manufacturing sites and maximum flexibility in the coordination of geographic and final assemblies postponement of physical distribution operations. e) Physical distribution This concerns movement of a finished product/service to customers. In physical distribution, the customer is the final destination of a marketing channel, and the availability of the product/service is a vital part of each channel participant's marketing effort. It is also through the physical distribution process that the time and space of customer service become an integral part of marketing, thus it links a marketing channel with its customers (e.g. links manufacturers, wholesalers, retailers). f) Outsourcing/partnerships This is not just outsourcing the procurement of materials and components, but also outsourcing of services that traditionally have been provided in-house. The logic of this trend is that the company will increasingly focus on those activities in the value chain where it has a distinctive advantage and everything else it will outsource. This movement has been particularly evident in logistics where the provision of transport, warehousing and inventory control is increasingly subcontracted to specialists or logistics partners. Also, to manage and control this network of partners and suppliers requires a blend of both central and local involvement. Hence, strategic decisions need to be taken centrally with the monitoring and control of supplier performance and day-to-day liaison with logistics partners being best managed at a local level. g) Performance measurement Experts found a strong relationship from the largest arcs of supplier and customer integration to market share and profitability. By taking advantage of supplier capabilities and emphasizing a long-term supply chain perspective in customer relationships can be both correlated with firm performance. As logistics competency becomes a more critical factor in creating and maintaining competitive advantage, logistics measurement becomes increasingly important because the difference between profitable and unprofitable operations becomes more narrow. A.T. Kearney Consultants (1985) noted that firms engaging in comprehensive performance measurement realized improvements in overall productivity. According to experts internal measures are generally collected and analyzed by the firm including 1. 2. 3. 4. 5. Cost Customer Service Productivity measures Asset measurement, and Quality. External performance measurement is examined through customer perception measures and "best practice" benchmarking, and includes 1) customer perception measurement, and 2) best practice benchmarking. Components of Supply Chain Management are 1. Standardization 2. Postponement 3. Customization Customer relationship management Customer relationship management (CRM) consists of the processes a company uses to track and organize its contacts with its current and prospective customers. CRM software is used to support these processes; information about customers and customer interactions can be entered, stored and accessed by employees in different company departments. Typical CRM goals are to improve services provided to customers, and to use customer contact information for targeted marketing. While the term CRM generally refers to a software-based approach to handling customer relationships, most CRM software vendors stress that a successful CRM effort requires a holistic approach. CRM initiatives often fail because implementation was limited to software installation, without providing the context, support and understanding for employees to learn, and take full advantage of the information systems. CRM can be implemented without major investments in software, but software is often necessary to explore the full benefits of a CRM strategy. Other problems occur when failing to think of sales as the output of a process that itself needs to be studied and taken into account when planning automation. Overview From the outside, customers interacting with a company perceive the business as a single entity, despite often interacting with a number of employees in different roles and departments. CRM is a combination of policies, processes, and strategies implemented by an organization to unify its customer interactions and provide a means to track customer information. It involves the use of technology in attracting new and profitable customers, while forming tighter bonds with existing ones. CRM includes many aspects which relate directly to one another: Front office operations — Direct interaction with customers, e.g. face to face meetings, phone calls, e-mail, online services etc. Back office operations — Operations that ultimately affect the activities of the front office (e.g., billing, maintenance, planning, marketing, advertising, finance, manufacturing, etc.) Business relationships — Interaction with other companies and partners, such as suppliers/vendors and retail outlets/distributors, industry networks (lobbying groups, trade associations). This external network supports front and back office activities. Analysis — Key CRM data can be analyzed in order to plan target-marketing campaigns, conceive business strategies, and judge the success of CRM activities (e.g., market share, number and types of customers, revenue, profitability). Perhaps it is important to note that while most consumers of CRM view it as a software "solution", there is a growing realization in the corporate world that CRM is really a customer-centric strategy for doing business; supported by software. Along these lines, CRM thought leaders like Dick Lee of High Yield Methods define CRM as "CRM adds value to customers in ways that add value back to the company" Types/variations of CRM There are several different approaches to CRM, with different software packages focusing on different aspects. In general, Customer Service, Campaign Management and Sales Force Automation form the core of the system (with SFA being the most popular). Operational CRM Operational CRM provides support to "front office" business processes, e.g. to sales, marketing and service staff. Interactions with customers are generally stored in customers' contact histories, and staff can retrieve customer information as necessary. The contact history provides staff members with immediate access to important information on the customer (products owned, prior support calls etc.), eliminating the need to individually obtain this information directly from the customer. Reaching to the customer at right time at right place is preferable. Operational CRM processes customer data for a variety of purposes: Managing campaigns Enterprise Marketing Automation Sales Force Automation Sales Management System Analytical CRM Analytical CRM analyzes customer data for a variety of purposes: Designing and executing targeted marketing campaigns Designing and executing campaigns, e.g. customer acquisition, cross-selling, upselling Analysing customer behavior in order to make decisions relating to products and services (e.g. pricing, product development) Management information system (e.g. financial forecasting and customer profitability analysis) Analytical CRM generally makes heavy use of data mining and other techniques to produce useful results for decision-making Sales Intelligence CRM Sales Intelligence CRM is similar to Analytical CRM, but is intended as a more direct sales tool. Features include alerts sent to sales staff regarding: Cross-selling/Up-selling/Switch-selling opportunities Customer drift Sales performance Customer trends Customer margins Customer alignment Campaign Management Campaign management combines elements of Operational and Analytical CRM. Campaign management functions include: Target groups formed from the client base according to selected criteria Sending campaign-related material (e.g. on special offers) to selected recipients using various channels (e.g. e-mail, telephone, SMS, post) Tracking, storing, and analyzing campaign statistics, including tracking responses and analyzing trends Collaborative CRM Collaborative CRM covers aspects of a company's dealings with customers that are handled by various departments within a company, such as sales, technical support and marketing. Staff members from different departments can share information collected when interacting with customers. For example, feedback received by customer support agents can provide other staff members with information on the services and features requested by customers. Collaborative CRM's ultimate goal is to use information collected by all departments to improve the quality of services provided by the company. Consumer Relationship CRM Consumer Relationship System (CRS) covers aspects of a company's dealing with customers handled by the Consumer Affairs and Customer Relations contact centers within a company. Representatives handle in-bound contact from anonymous consumers and customers. Early warnings can be issued regarding product issues (e.g. item recalls) and current consumer sentiment can be tracked (voice of the customer). Information and communication technologies Information and Communications Technology - or technologies (ICT) is an umbrella term that includes all technologies for the manipulation and communication of information. The term is sometimes used in preference to Information Technology (IT), particularly in two communities: education and government. In the common usage it is often assumed that ICT is synonymous with IT; ICT in fact encompasses any medium to record information (magnetic disk/tape, optical disks (CD/DVD), flash memory etc. and arguably also paper records); technology for broadcasting information - radio, television; and technology for communicating through voice and sound or images - microphone, camera, loudspeaker, telephone to cellular phones. It includes the wide variety of computing hardware (PCs, servers, mainframes, networked storage), the rapidly developing personal hardware market comprising mobile phones, personal devices, MP3 players, and much more; the full gamut of application software from the smallest homedeveloped spreadsheet to the largest enterprise packages and online software services; and the hardware and software needed to operate networks for transmission of information, again ranging from a home network to the largest global private networks operated by major commercial enterprises and, of course, the Internet. Thus, "ICT" makes more explicit that technologies such as broadcasting and wireless mobile telecommunications are included. It should be noted that "ICT" by this English definition is different in nuance and scope than under "ICT" in Japanese, which is more technical and narrow in scope. ICT capabilities vary widely from the sophistication of major western economies to lesser provision in the developing world. But the latter are catching up fast, often leapfrogging older generations of technology and developing new solutions that match their specific needs. Transaction processing In computer science, transaction processing is information processing that is divided into individual, indivisible operations, called transactions. Each transaction must succeed or fail as a complete unit; it cannot remain in an intermediate state. Transaction processing is designed to maintain a computer system (typically, but not limited to, a database or some modern filesystems) in a known, consistent state, by ensuring that any operations carried out on the system that are interdependent are either all completed successfully or all canceled successfully. For example, consider a typical banking transaction that involves moving £500 from a customer's savings account to a customer's checking account. This transaction is a single operation in the eyes of the bank, but it involves at least two separate operations in computer terms: debiting the savings account by £500, and crediting the checking account by £500. If the debit operation succeeds but the credit does not (or vice versa), the books of the bank will not balance at the end of the day. There must therefore be a way to ensure that either both operations succeed or both fail, so that there is never any inconsistency in the bank's database as a whole. Transaction processing is designed to provide this. Transaction processing allows multiple individual operations to be linked together automatically as a single, indivisible transaction. The transaction-processing system ensures that either all operations in a transaction are completed without error, or none of them are. If some of the operations are completed but errors occur when the others are attempted, the transaction-processing system “rolls back” all of the operations of the transaction (including the successful ones), thereby erasing all traces of the transaction and restoring the system to the consistent, known state that it was in before processing of the transaction began. If all operations of a transaction are completed successfully, the transaction is committed by the system, and all changes to the database are made permanent; the transaction cannot be rolled back once this is done. Transaction processing guards against hardware and software errors that might leave a transaction partially completed, with the system left in an unknown, inconsistent state. If the computer system crashes in the middle of a transaction, the transaction processing system guarantees that all operations in any uncommitted (i.e., not completely processed) transactions are cancelled. Transactions are processed in a strict chronological order. If transaction n+1 intends to touch the same portion of the database as transaction n, transaction n+1 does not begin until transaction n is committed. Before any transaction is committed, all other transactions affecting the same part of the system must also be committed; there can be no “holes” in the sequence of preceding transactions. Methodology The basic principles of all transaction-processing systems are the same. However, the terminology may vary from one transaction-processing system to another, and the terms used below are not necessarily universal. Rollback Transaction-processing systems ensure database integrity by recording intermediate states of the database as it is modified, then using these records to restore the database to a known state if a transaction cannot be committed. For example, copies of information on the database prior to its modification by a transaction are set aside by the system before the transaction can make any modifications (this is sometimes called a before image). If any part of the transaction fails before it is committed, these copies are used to restore the database to the state it was in before the transaction began (rollback). Rollforward It is also possible to keep a separate journal of all modifications to a database (sometimes called after images); this is not required for rollback of failed transactions, but it is useful for updating the database in the event of a database failure, so some transactionprocessing systems provide it. If the database fails entirely, it must be restored from the most recent back-up. The back-up will not reflect transactions committed since the backup was made. However, once the database is restored, the journal of after images can be applied to the database (rollforward) to bring the database up to date. Any transactions in progress at the time of the failure can then be rolled back. The result is a database in a consistent, known state that includes the results of all transactions committed up to the moment of failure. Deadlocks In some cases, two transactions may, in the course of their processing, attempt to access the same portion of a database at the same time, in a way that prevents them from proceeding. For example, transaction A may access portion X of the database, and transaction B may access portion Y of the database. If, at that point, transaction A then tries to access portion Y of the database while transaction B tries to access portion X, a deadlock occurs, and neither transaction can move forward. Transaction-processing systems are designed to detect these deadlocks when they occur. Typically both transactions will be cancelled and rolled back, and then they will be started again in a different order, automatically, so that the deadlock doesn't occur again. Or sometimes, just one of the deadlocked transactions will be cancelled, rolled back, and automatically re-started after a short delay. Deadlocks can also occur between three or more transactions. The more transactions involved, the more difficult they are to detect, to the point that transaction processing systems find there is a practical limit to the deadlocks they can detect. ACID criteria (Atomicity, Consistency, Isolation, Durability) Main article: ACID Transaction processing has these benefits: It allows sharing of computer resources among many users It shifts the time of job processing to when the computing resources are less busy It avoids idling the computing resources without minute-by-minute human interaction and supervision It is used on expensive classes of computers to help amortize the cost by keeping high rates of utilization of those expensive resources A transaction is an atomic unit of processing.