Partnership for Innovations for Laser-Based Manufacturing and Material Processing

advertisement

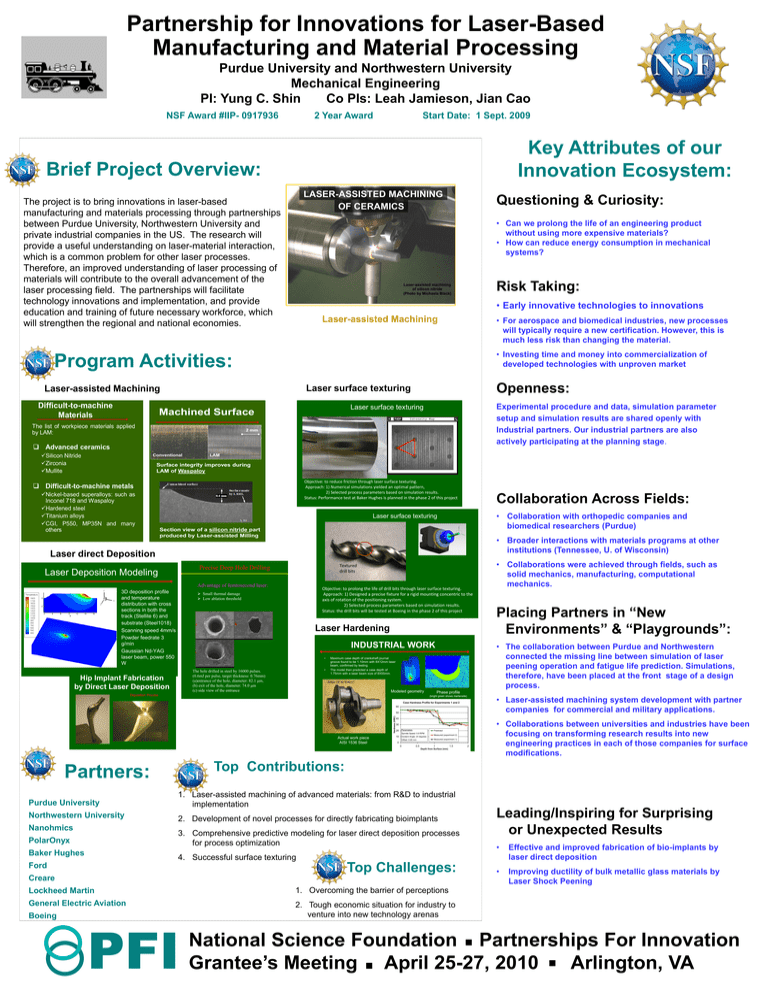

Partnership for Innovations for Laser-Based Manufacturing and Material Processing Purdue University and Northwestern University Mechanical Engineering PI: Yung C. Shin Co PIs: Leah Jamieson, Jian Cao NSF Award #IIP- 0917936 2 Year Award Start Date: 1 Sept. 2009 Key Attributes of our Innovation Ecosystem: Brief Project Overview: LASER-ASSISTED MACHINING OF CERAMICS The project is to bring innovations in laser-based manufacturing and materials processing through partnerships between Purdue University, Northwestern University and private industrial companies in the US. The research will provide a useful understanding on laser-material interaction, which is a common problem for other laser processes. Therefore, an improved understanding of laser processing of materials will contribute to the overall advancement of the laser processing field. The partnerships will facilitate technology innovations and implementation, and provide education and training of future necessary workforce, which will strengthen the regional and national economies. Questioning & Curiosity: Picture or Logo from your project here • Can we prolong the life of an engineering product without using more expensive materials? • How can reduce energy consumption in mechanical systems? Risk Taking: Laser-assisted machining of silicon nitride (Photo by Michaela Black) • Early innovative technologies to innovations Laser-assisted Machining • For aerospace and biomedical industries, new processes will typically require a new certification. However, this is much less risk than changing the material. • Investing time and money into commercialization of developed technologies with unproven market Program Activities: Difficult-to-machine Materials Openness: Laser surface texturing Laser-assisted Machining Machined Surface The list of workpiece materials applied by LAM: Experimental procedure and data, simulation parameter setup and simulation results are shared openly with Industrial partners. Our industrial partners are also actively participating at the planning stage. Laser surface texturing 2 mm Advanced ceramics Silicon Nitride Zirconia Mullite Conventional LAM Surface integrity improves during LAM of Waspaloy Objective: to reduce friction through laser surface texturing. Approach: 1) Numerical simulations yielded an optimal pattern, 2) Selected process parameters based on simulation results. Status: Performance test at Baker Hughes is planned in the phase 2 of this project Difficult-to-machine metals Nickel-based superalloys: such as Inconel 718 and Waspaloy Hardened steel Titanium alloys CGI, P550, MP35N and many others Collaboration Across Fields: • Collaboration with orthopedic companies and biomedical researchers (Purdue) Laser surface texturing Section view of a silicon nitride part produced by Laser-assisted Milling • Broader interactions with materials programs at other institutions (Tennessee, U. of Wisconsin) Laser direct Deposition Textured drill bits Precise Deep Hole Drilling Laser Deposition Modeling Advantage of femtosecond laser: • 3D deposition profile and temperature distribution with cross sections in both the track (Stellite 6) and substrate (Steel1018) • Scanning speed 4mm/s • Powder feedrate 3 g/min • Gaussian Nd-YAG laser beam, power 550 W Objective: to prolong the life of drill bits through laser surface texturing. Approach: 1) Designed a precise fixture for a rigid mounting concentric to the axis of rotation of the positioning system. 2) Selected process parameters based on simulation results. Status: the drill bits will be tested at Boeing in the phase 2 of this project Small thermal damage Low ablation threshold a b Laser Hardening INDUSTRIAL WORK • The hole drilled in steel by 16000 pulses. (0.6mJ per pulse, target thickness: 0.76mm) (a)entrance of the hole, diameter: 82.1 μm, (b) exit of the hole, diameter: 74.0 μm (c) side view of the entrance Hip Implant Fabrication by Direct Laser Deposition Maximum case depth of crankshaft journal groove found to be 1.10mm with 8X12mm laser beam, confirmed by testing. The model then predicted a case depth of 1.75mm with a laser beam size of 8X55mm. Modeled geometry Deposition Process Phase profile (bright green shows martensite) • Laser-assisted machining system development with partner companies for commercial and military applications. Case Hardness Profile for Experiments 1 and 2 60 Hardness (HRC) 50 Actual work piece AISI 1536 Steel 40 30 Parameters 20 Predicted Spindle Speed: 0.8 RPM 10 Incident Angle: 20 degrees Offset: 0.65 mm Measured (experiment 2) Measured (experiment 1) 0 0 0.5 1 1.5 2 Depth from Surface (mm) Northwestern University Nanohmics 1. Laser-assisted machining of advanced materials: from R&D to industrial implementation Leading/Inspiring for Surprising or Unexpected Results 2. Development of novel processes for directly fabricating bioimplants 3. Comprehensive predictive modeling for laser direct deposition processes for process optimization PolarOnyx Baker Hughes • Effective and improved fabrication of bio-implants by laser direct deposition • Improving ductility of bulk metallic glass materials by Laser Shock Peening 4. Successful surface texturing Top Challenges: Ford Creare Lockheed Martin 1. Overcoming the barrier of perceptions General Electric Aviation 2. Tough economic situation for industry to venture into new technology arenas Boeing • Collaborations between universities and industries have been focusing on transforming research results into new engineering practices in each of those companies for surface modifications. Top Contributions: Partners: Purdue University Placing Partners in “New Environments” & “Playgrounds”: • The collaboration between Purdue and Northwestern connected the missing line between simulation of laser peening operation and fatigue life prediction. Simulations, therefore, have been placed at the front stage of a design process. c • • Collaborations were achieved through fields, such as solid mechanics, manufacturing, computational mechanics. PFI . National Science Foundation Partnerships For Innovation Grantee’s Meeting April 25-27, 2010 Arlington, VA . .