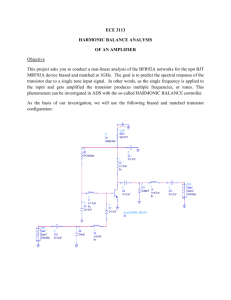

2010_3_march_gomac_rodwell_slides.ppt

advertisement

GOMAC, March 25, 2010, Reno, NV.

THz Bipolar Transistors:

Design and Process Technologies

Mark Rodwell

University of California, Santa Barbara

E. Lobisser, V. Jain, A. Baraskar, M. Seo, B. J. Thibeault,

University of California, Santa Barbara

M. Seo, Z. Griffith, J. Hacker, M. Urteaga, Richard Pierson, B. Brar

Teledyne Scientific Company

rodwell@ece.ucsb.edu 805-893-3244, 805-893-5705 fax

Why

THz Transistors ?

Why Build THz Transistors ?

500 GHz digital logic

→ fiber optics

THz amplifiers→ THz radios

→ imaging, sensing,

communications

precision analog design

at microwave frequencies

→ high-performance receivers

Higher-Resolution

Microwave ADCs, DACs,

DDSs

Why Bipolars for Fast Analog Applications ?

digital frequency synthesis

mm-wave

phased arrays

high resolution ADCs and DACs for 2-20, 38 GHz

CMOS does not serve all ICs

low analog gain

low analog precision

low breakdown voltage

high Cds /Cgs , high Cgd /Cgs

→ less bandwidth

than ft suggests

0.35 fF

0.7 fF

0.7 fF

jammer on chip

BJTs, particularly InP,

have high breakdown

How to Make

THz Transistors

Changes required to double transistor bandwidth

We

emitter

length LE

HBT parameter

emitter & collector junction widths

current density (mA/mm2)

current density (mA/mm)

collector depletion thickness

base thickness

emitter & base contact resistivities

change

decrease 4:1

increase 4:1

constant

decrease 2:1

decrease 1.4:1

decrease 4:1

nearly constant junction temperature → linewidths vary as (1 / bandwidth)2

LG

gate width WG

constant voltage, constant velocity scaling

FET parameter

gate length

current density (mA/mm), gm (mS/mm)

channel 2DEG electron density

gate-channel capacitance density

dielectric equivalent thickness

channel thickness

channel density of states

source & drain contact resistivities

change

decrease 2:1

increase 2:1

increase 2:1

increase 2:1

decrease 2:1

decrease 2:1

increase 2:1

decrease 4:1

fringing capacitance does not scale → linewidths scale as (1 / bandwidth )

40

Z. Griffith

340 GHz dynamic frequency divider

H

mA/mm2

10

30

dB

256 nm Generation

InP HBT

150 nm thick collector

U

21

20

fmax = 780 GHz

10

M. Seo, UCSB/TSC

t

10

10

10

11

10

Vtune

max

2

3

4

5

12

11

10

20

21

U

f

1

V

2

E. Lind

mA/mm

M. Seo, UCSB/TSC

dB

340 GHz VCO

0

12

10

ce

10

10

10

9

10

H

20

4

0

Hz

70 nm thick collector

30

6

2

f = 424 GHz

0

9

10

8

= 560 GHz

15

10

5

f = 560 GHz

t

0

0

9

10

VBB

VEE

10

10

11

10

0

12

10

1

2

V

Hz

Vout

3

4

ce

60 nm thick collector

40

30

H

U

Z. Griffith

2

dB

30

mA/mm

324 GHz amplifier J. Hacker, TSC

21

20

10 fmax = 218 GHz

20

10

f = 660 GHz

t

0

9

10

10

10

11

10

Hz

10

12

0

0

1

2

V

ce

3

InP Bipolar Transistor Scaling Roadmap

emitter 512

16

256

8

128

4

64

2

32 nm width

1 mm2 access r

base

300

20

175

10

120

5

60

2.5

30 nm contact width,

1.25 mm2 contact r

collector 150

4.5

4.9

106

9

4

75

18

3.3

53

36

2.75

37.5 nm thick,

72 mA/mm2 current density

2-2.5 V, breakdown

520

850

430

240

730

1300

660

330

1000

2000

1000

480

1400 GHz

2800 GHz

1400 GHz

660 GHz

ft

fmax

power amplifiers

digital 2:1 divider

370

490

245

150

We

Tb

Wbc

Tc

Conventional ex-situ contacts are a mess

THz transistor bandwidths: very low-resistivity contacts are required

textbook contact

with surface oxide

with metal penetration

Interface barrier → resistance

Further intermixing during high-current operation → degradation

In-Situ Refractory Ohmics on Regrown N-InGaAs

5

8

In-situ Mo on n-InAs

Resistance ()

Resistance ()

4

3

2

ρc = 0.6 ± 0.4 Ω·µm2

1

In-situ Mo on n-InGaAs

6

4

ρc = 1.0 ± 0.6 Ω·µm2

2

n = 5×1019 cm-3

n = 1×1020 cm-3

0

0

0.5

1

1.5

2

2.5

3

Gap Spacing (mm)

In-situ emitter contacts good

enough for 64 nm node

3.5

00

0.5

1

1.5

2

2.5

3

3.5

Gap Spacing (mm)

HAADF-STEM*

InGaAs

regrowth

Interface

InGaAs

2 nm

TEM by Dr. J. Cagnon, Stemmer Group, UCSB

A. Baraskar

Process Must Change Greatly for 128 / 64 / 32 nm Nodes

control undercut

→ thinner emitter

thinner emitter

→ thinner base metal

Undercutting of emitter ends

{101}A planes: fast

{111}A planes: slow

thinner base metal

→ excess base metal resistance

128 / 64 nm process: Dry-Etched Emitter Metal

In-situ MBE emitter contacts:

refractory→ high J

low contact r: ~0.7 -mm2

Refractory emitter contact

dry-etched→ nm resolution

refractory→ high current

Wet/dry etched emitter

dry-etched→ nm resolution

conventional base liftoff

high penetration→ thick bases

moderate contact r ~4-mm2

yield issues ?

V. Jain

E. Lobisser

Dry-Etched W/TiW Emitter Contact Process

Sputtered

W/ Ti0.1W0.9

process

Vertical ICP

etch profile

Low-stress film

Good adhesion

between layers

Refractory

Metals

W/TiW bilayer:

stress and

etch bias

compensation

V. Jain

E. Lobisser

Sub-100 nm devices: lifted-off base metal

V. Jain

E. Lobisser

After Sidewall Etch

Base Contact, Post and Mesa Etch

Device Isolation Etch

HBT before BCB processing

Sub-100 nm devices: lifted-off base metal

V. Jain

E. Lobisser

Sub-100 nm devices: lifted-off base metal

15 MAG/MSG

A = 0.11mm x 3.5mm

je

U

I = 9.1mA; V = 1.75V

c

ce

40

30

A = 0.11mm x 3.5mm

je

f = 400 GHz

U

H

20

t

f

max

= 660 GHz

21

Gain (dB)

2

J = 23.6mA/mm ; V

10

e

H

10 I = 8.9mA; V = 1.74V

c

ce

2

J = 23.1mA/mm ; V

e

0

9

10

10

cb

11

50 mW/mm

50

0

11

10

2

t

:V

:V

I

b,step

= 0.2 mA

cb

cb

=0V

20

V

cb

10

=0V

I = 0.01 mA

b

0

1

2

V

ce

(V)

3

Peak f /f

t max

12

750

= 0.7 V

600

600

450

450

300

300

max

30

(GHz)

A = 0.11mm x 3.5mm

10

freq (Hz)

750

je

0

= 660 GHz

t

e

2

10

40

max

= 0.7V

f (GHz)

J (mA/um )

12

10

freq (Hz)

60 40 mW/mm2

f

cb

f = 465 GHz

= 0.7V

10

21

5

f

Gain (dB)

MAG/MSG

V. Jain

E. Lobisser

150

0

5

150

10 15 20 25 30 35

2

J (mA/mm )

e

128 / 64 nm process: Sputtered Refractory Base

In-situ MBE emitter contacts:

refractory→ high J

low contact r: ~0.7 -mm2

Refractory emitter contact

dry-etched→ nm resolution

refractory→ high current

Wet/dry etched emitter

dry-etched→ nm resolution

Refractory base contacts

low penetration→ thin bases

low contact r ~2.5 -mm2

self-aligned/ liftoff-free

V. Jain

E. Lobisser

In-Situ Refractory Ohmics on P-InGaAs

Metal Contact

ρc (Ω-µm2)

ρh (Ω-µm)

In-situ Ir

1.0 ± 0.7

11.5 ± 3.3

Resistance ()

20

Iridium

15

10

5

0

2 rC RSh

2 RC

W

0

1

2

3

Gap Spacing (mm)

In-situ base contacts good enough for 32 nm node

Remaining work: contacts on processed surfaces

contact thermal stability & reliability

4

A. Baraskar

Benefits of refractory base contacts

15 nm Pd/Ti diffusion

100 nm InGaAs grown in MBE

30 nm Mo

After 250°C anneal, Pd/Ti/Pd/Au diffuses 15nm into semiconductor

deposited Pd thickness: 2.5nm

base now 30 nm thick: observed to degrade with thinner bases

Refractory Mo contacts do not diffuse measurably

Refractory, non-diffusive metal contacts for thin base semiconductor

A.. Baraskar

Sputtered Process for in-situ base contacts

20

• Planarization and etch back

• Low contact resistivity

• Lift-off free and Au free base process

• Self-aligned process for thin emitters

• Enables refractory, in-situ base contacts

Resistance ()

• Blanket ex-situ Pd/W contacts

Iridium

15

10

5

0

ρc =1.0 ± 0.7 Ω-µm2

0

1

2

3

Gap Spacing (mm)

4

Planarization boundary

SiNx Sidewall

V. Jain

E. Lobisser

Sub-100 nm HBTs : planarized base contact

Emitter projecting from PR for

planarization

Base Contact, Post and Mesa Etch

Planarized Emitter

Contact Via Etch

V. Jain

E. Lobisser

670 GHz Transceiver Simulations in 128 nm InP HBT

transmitter exciter

Simulations @ 670 GHz (128 nm HBT)

LNA: 9.5 dB Fmin at 670 GHz

30

PA: 9.1 dBm Pout at 670 GHz

35

35

20

30

20

30

620

receiver

640

660

680

SP.freq, GHz

freq, GHz

(a)

700

10

0

0

720

800

820

64nm

-10

840 -10

-8860 -6

-4880 -2

(b)

VCO:

-50 dBc (1 Hz)

@ 100 Hz offset

at 620 GHz (phase 1)

128nm

4 0.986

(c)

free-running

VCO

0

Total PLL

phase noise

-50

closed-loop

VCO noise

-100

multiplied

reference noise

-150

1

10

2

3

4

10

6

10

7

950 GHz Input

-0.9

-0.95

-0.95

Vout, Vout_bar

Vout , Vout_bar

5

10

10

10

offset from carrier, Hz

-1

-1.05

-1.1

-1.15

-1

-1.05

-1.1

-1.15

197.5 10

-12

200 10

-1.2

-12

195 10

-12

Noise Figure, Conversion Gain (dB)

197.5 10

-12

time, seconds

time, seconds

Mixer:

10.4 dB noise figure

11.9 dB gain

-8

50

-0.9

-1.2

-12

195 10

1.04

-10

SP.freq, THz

freq, THz

690 GHz Input

Dynamic divider:

novel design,

simulates to 950 GHz

3

-10

1.02 -12

8 1.0010

(a)

10

3-layer thin-film THz interconnects

thick-substrate--> high-Q TMIC

thin -> high-density digital

0

-5

Pin

SP.freq, GHz

freq, GHz

5

10

0

0900 2

10

20

Gain

Pout

5

-5

128nm

0

nf(2)

dB(S(2,1))

10

15

10

20

PLL single-sideband

phase noise spectral density, dBc (1 Hz)

20

Gain

Pout

nf(2)

dB(S(2,1))

nf(2)

dB(S(2,1))

15

30

25

20

15

10

5

0

-5

-15.00

-10.00

-5.000

0.0000 5.000

LO Power

10.00

200 10

-12

1.-

InP HBT Fundamental Oscillators to > 340 GHz

M. Seo UCSB

M. Rodwell UCSB

M. Urteaga TSC

TSC HBT Technology

Differential Topology, Cascode output buffer, ECL outputs

Fixed frequency and voltage controlled designs

R1

Lout2

Vtune

VOUT

R3

Lout1

Q5

Q3

Q4

LC3

R2

LC2

R4

LC1

VBB

VEE

Q6

LB

Q1

LE1

CVar

Q2

CVar

LE2

Vout

RE

C1

C2

VEE VTUNE

C3

VBB

InP HBT 331 GHz Dynamic Frequency Dividers

Topology: Double-balanced mixer with emitter

follower feedback and resonant loading

M. Seo UCSB

M. Rodwell UCSB

M. Urteaga TSC

Z. Griffith TSC

TSC HBT Technology

Circuit Schematic

Modified version of modern dynamic divider (H.M. Rein)

Inverted microstrip wiring

Design variations with input for external clock

source and with integrated fixed frequency and

voltage controlled oscillators for testing.

Output spectrum with 331.2 GHz clock input

“Signal Identification” test at fIN= 331.2 GHz

Chip photograph

THz 240 GHz PA Design

Teledyne InP HBTs We=256nm, Tc=150nm

Two-finger design achieves S21 = 4.9dB @ 238GHz

T. Reed UCSB

M. Urteaga TSC

Z. Griffith TSC

TSC HBT Technology

THz Transistors

THz Integrated Circuits

Device scaling (Moore's Law) is not yet over.

Scaling→ multi-THz transistors.

Challenges in scaling:

contacts, dielectrics, heat

Multi-THz transistors:

for systems at very high frequencies

for better performance at moderate frequencies

Vast #s of THz transistors

complex systems

new applications.... imaging, radio, and more

end

On-Wafer TRL Calibration Envirnoment

Ref Plane for TRL

Ref Plane for TRL

0.5-67GHz Data: Lumped Pads, Off Wafer LRRM Cal.

m7

freq=1.103GHz

dB(h21d)=26.624

Fmax_fit = 660GHz

Ft_fit = 400GHz

m7

Standard Off Wafer OSLT

Open & Short Pad Cap Extraction

Open

Short

THz

Bipolar Transistors

Sub-100 nm devices: lifted-off base metal

15 MAG/MSG

A = 0.11mm x 3.5mm

je

U

I = 9.1mA; V = 1.75V

c

ce

40

A = 0.11mm x 3.5mm

je

f = 400 GHz

U

H

20

t

f

max

= 660 GHz

21

Gain (dB)

30

2

J = 23.6mA/mm ; V

10

e

H

2

J = 23.1mA/mm ; V

e

10

10

11

12

10

freq (Hz)

f

max

cb

= 0.7V

= 660 GHz

f = 465 GHz

= 0.7V

10

0

11

10

t

S21/5

:V

:V

cb

cb

=0V

750

= 0.7 V

600

600

450

450

300

300

max

t

--- : Measured

x : Simulated

S11

S22

150

0

5

150

10 15 20 25 30 35

2

J (mA/mm )

freq (1.000GHz to 67.00GHz)

freq (100.0MHz to 67.00GHz)

12

f (GHz)

(GHz)

S12x5

10

freq (Hz)

750

f

0

9

10

cb

21

5

10 I = 8.9mA; V = 1.74V

c

ce

S_parameter_Deembed_PNA..S21d/5

S_parameter_Deembed_PNA..S12d*5

S(2,1)/5

S(1,2)*5

S(2,2)

S_parameter_Deembed_PNA..S22d

S_parameter_Deembed_PNA..S11d

S(1,1)

Gain (dB)

MAG/MSG

V. Jain

E. Lobisser

e

Sub-100 nm devices: lifted-off base metal

-2

60 40 mW/mm2

Dashed Line: V

cb

b

-6

n = 3.04

b

10

10

A = 0.11mm x 3.5mm

je

I

b,step

20

V

c

cb

10

-10

0

0.4

V

be

0.6

(V)

0.8

1

=0V

I = 0.01 mA

b

0

1

2

V

ce

(V)

3

Peak f /f

t max

8

V

7

cb

0.2

(fF)

0

= 0.2 mA

30

C

10

n = 1.41

2

40

e

b

-8

50 mW/mm

50

= 0.7 V Ic

I

c

I , I (A)

10

-4

cb

=0V

2

Solid Line: V

J (mA/um )

10

V. Jain

E. Lobisser

cb

=0V

6

5

V

cb

= 0.4 V

4

V

3

0

cb

5

= 0.7 V

10 15 20

2

J (mA/mm )

e

25

30

2008 UCSB Dry-Etched Ti/TiW Emitter Process

a

b

Litho

Cr

pattern

metal

c

SF6/Ar ICP

SiNsidewall

x sidewall

d

dry/N

etch

Cl

2 2 ICP

SiO2

e

Wetetch

Etch

wet

HCl:H3PO4

BHF

TiW

Ti

InGaAs n++

InP n

InP n

InP n

InGaAs p++ Base

InGaAs p++ Base

InGaAs p++ Base

InGaAs p++ Base

H

10

10

10

9

10

30

Worked well @ 200 nm

21

U

20

dB

base contact

by liftoff

f

10

max

InGaAs p++ Base

12

InP n

11

InGaAs n++

10

InGaAs n++

Low yield @ 128 nm:

stress→ poor adhesion

= 560 GHz

f = 560 GHz

t

0

9

10

10

10

11

10

Hz

12

10

Substantial revision

required