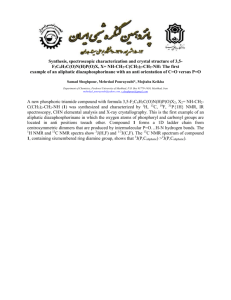

SYNTHESIS OF CHARGED RECEPTORS WITH A BIS PHENOLIC ETHER SCAFFOLD,

advertisement