REAL-TIME BARCODE READER USING PERSONAL DIGITAL ASSISTANCE (PDA) OSAMA SALEM ELSHERAIRI

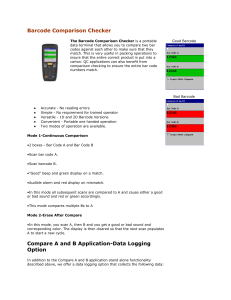

advertisement

REAL-TIME BARCODE READER USING PERSONAL DIGITAL

ASSISTANCE (PDA)

OSAMA SALEM ELSHERAIRI

A project report submitted in partial fulfillment

of the requirements for the award of the degree

of Master Engineering

(Electrical-Electronics & Telecommunication)

Faculty of Electrical Engineering

Universiti Teknologi Malaysia

MAY 2007

iii

In the name of Allah, Most Gracious, Most Merciful

All praise and thanks are due to Allah Almighty and peace and

blessings be upon His Messenger

The results of this effort are truly dedicated to my mother and father whose

example as devoted professionals, as well as, parents taught

me to be perseverant, responsible and loyal

to my belief.

To my brothers, and sisters, and my best friend my uncle for all their support,

encouragement, sacrifice, and especially for their love.

Thank you all and this work is for YOU.

iv

ACKNOWLEDGEMENTS

First and foremost, I thank Allah for giving me the strength to complete my

project. I would like to thank especially supervisor ASSOC. PROF. DR. SYED ABD

RAHMAN AL-ATTAS for his constant support and guidance during my graduate

studies at Universiti Teknologi Malaysia. I would also like to convey my deepest

gratitude to Mr. Usman Ullah Sheikh for his guidance to complete this research.

Thanks to all my colleagues and friends with whom I had the opportunity to

learn, and share a good time during my stay here. Finally, special and infinite thanks

goes to the most important people in my life; my parents, for their love, prayers,

sacrifice and support.

v

ABSTRACT

This project concerns the design and implementation of a system for real time

barcode reader using personal digital assistant (PDA) with built-in camera. A system

that reads and decodes (1D) linear barcodes based on images containing barcodes –

independent of the barcodes' orientation or rotation. Problems associated with images

taken by the PDA are limited depth of field, limited resolution, poor lighting

sensitively and camera shake. To accomplish this project with the above constraints

the following stages are undertaken; First the image from the camera is enhanced, the

camera will send continuous frame of images from the environment. These images

are converted to grayscale and some preprocesses are performed, image is filtered

(such as sharpening and noise reduction) and converted to binary. The image is then

scanned horizontally, vertically and diagonally for barcodes, thus enabling it to

detect rotated barcodes to suit the subsequent processing. Then the barcode is located

in the image using a method based on the evaluation of the correlation. To extract

relevant information from the located image the barcode is then isolated from the

image, after that it is used to gain a waveform that represents the information of the

barcode. Finally, the waveform will be wavered into a string of digits representing

the widths of each bars of the barcode. At this stage the processing has completely

decoded the barcode symbology. This project only considers European Article

Number 13, (EAN-13) barcodes. The system has been implemented in Windows

Mobile (windows CE) based software in Embedded Visual Studio 2005 C++ on

PDA, with a graphical user interface. Error correction and predictive decoding is

implemented to improve the capability accuracy and performance of the system.

vi

ABSTRAK

Projek ini berkenaan dengan reka-bentuk dan implementasi sistem kod-bar

maya nyata menggunakan pembantu peribadi digit (PDA) yang dilengkapi dengan

kamera terbina-dalam. Sistem ini mampu membaca dan menyahkod kod-bar satu

dimensi tanpa mengambil kira orientasi dan pusingan kod-bar. Kedalaman medan

yang terbatas, resolusi yang terhad, pencahayaan yang lemah dan goncangan kamera

adalah beberapa masalah yang berkaitan dengan imej-imej yang dihasilkan oleh

kamera PDA. Untuk melaksanakan projek yang mempunyai masalah diatas dengan

jayanya, proses-proses berikut perlu dilakukan. Pertama, kualiti imej ditingkatkan.

Imej-imej ini kemudiannya ditukar kepada imej aras kelabu dan beberapa peringkat

pra-pemprosesan dilakukan seperti penajaman dan pengurangan hingar, dan imej

ditukar ke nombor binary. Untuk mendapatkan kodbar, imej kemudiannya diimbas

secara menegak, melintang, dan pepenjuru untuk menentukan proses yang

selanjutnya. Dengan menggunakan kaedah penilaian korelasi, kodbar diletakkan

didalam imej. Untuk mengekstrak maklumat darapida imej. Kodbar kemudiannya

diasingkan daripada imej, dan digunakan untuk mendapat bentuk gelombang yang

mewakili kodbar. Akhir sekali, bentuk gelombang diliang-liuk menjadi rangkaian

digit yang mewakili lebar setiap buku kodbar. Pada peringkat ini, kodbar telah

dinnyahkod sama-sekali. Projek ini hanya mengambil kira kodbar jenis nombor

artikel Eropah (EAN-13). Sistem ini diatas diimplementasi di dalam persekitaran

Windows Mobile (Windows CE) dengan menggunakan Embedded Visual Studio

2005 C++ untuk PDA dengan antara muka grafik. Pembetulan kesalahan dann

penyahkid penjangkaan dilaksankan untuk meningkatkan ketepatan dan pencapaian

sistem.

vii

LIST OF CONTENTS

CHAPTERS

CHAPTER 1

TITAL

PAGE

DECLARATION

ii

DEDICATION

iii

ACKNOWLEDGEMENTS

iv

ABSTRACT

v

ABSTRAK

vi

TABLE OF CONTENTS

vii

LIST OF TABLES

xi

LIST OF FIGURES

xii

LIST OF ABBREVIATIONS

xv

LIST OF APPENDICES

xvii

INTRODUCTION

1

1.1

Overview

1

1.2

Personal Digital Assistant (PDA)

2

1.2.1 Pocket PC

3

1.3

Plam

4

1.4

Smartphones

4

1.5

Camera used with PDA

5

1.6

Windows Mobile

5

1.7

PDA using a camera

6

1.8

Limitation of conventional barcode readers

7

viii

CHAPTER 2

1.9

Objective of Project

8

1.10

Scope of Project

8

1.11

Project outline

8

LITERATURE REVIEW

10

2.1

Introduction

10

2.2

A bit of history

11

2.3

Types of Barcodes

11

2.3.1

One Dimensional barcodes

12

2.3.2

Two - Dimensional barcodes

13

2.4

2.5

2.6

CHAPTER 3

The Physical Reader

13

2.4.1

Input Device

14

2.4.2

Decoder

18

2.4.3

Barcode Reading

19

The Barcode Recognition System

21

2.5.1

EAN-13 Barcode Image Recognition

21

2.5.2

Barcode symbologies

21

2.5.3 Barcode Size and Color

22

Encoding Rule of Structure of an EAN barcode

23

2.6.1

The X-dimension

24

2.6.2

Quiet zone

24

2.6.3

Guard bars

25

2.6.4

Right & left hand side digits

26

2.6.5 How to calculate the checksum

27

2.6.6

Encoding

28

2.6.7

Decoding

31

METHODOLOGY

32

3.1

Introduction

32

3.2

Barcode Image Devices

33

ix

3.3

Image Capturing

33

3.4

Barcode processing in PDA

34

3.4.1

35

Searching for barcode image

automatically

3.4.2

Identification of the Bars and Spaces

36

3.4.3

Estimating How Correctly the Elements

36

Have Been Identified

3.4.4

3.5

Decoding the Barcode

37

Pre-Processing

38

3.5.1

39

The RGB color model

3.5.2 Gray scaling

40

3.5.3

41

Image Enhancement

3.6

Scanning Direction

42

3.7

Barcode Identification & Extraction

44

3.8

Program Architecture

45

3.8.1

45

Overview of Programming Languages

Used For PDA

3.8.2

3.9

CHAPTER 4

Program Build on PDA

46

Program screenshot

46

3.9.1

Program interface

47

3.9.2

Using the HP Photosmart Mobile Camera

48

RESULT

50

4.1

Introduction

50

4.2

Uneven Resolution, Shadow, Shake and

50

Illumination

4.3

Tests of Barcode Orientation

51

4.3.1

52

Computing the orientation of the barcode

4.4

Show scan diagonal read rotated barcode (offline)

53

4.5

Show scan horizontal read rotated (offline)

54

4.6

Show scan vertical read rotated barcode (offline)

54

x

4.7

Show scan horizontal read rotated barcode

55

(online)

4.8

Time Consumption

56

4.9

Performance Comparison

56

CHAPTER 5 CONCLUSION

58

5.1

Conclusion

58

5.2

Recommendations for Future Work

58

REFERENCE

59

APPENDIX

63

xi

LIST OF TABLES

TABLE

TITAL

PAGE

2.1

Specification for EAN-13 barcode

22

2.2

Total number of bars and modules for EAN-13 barcode

28

2.3

The list of oriented-modules on logic of 0-9 for A, B, C,

29

types

2.4

Result for example

30

3.1

Normal barcode (left to right)

37

3.2

Flipped or mirrored barcode

38

3.3

These are classes used in program

46

xii

LIST OF FIGURES

Figure

TITAL

PAGE

1.1

Symbol barcode

2

1.2

HP iPAQ hx4700 Pocket PC

3

1.3

Palm

4

1.4

Smartphone

4

1.5

Digital camera card (HP Photosmart mobile camera)

5

1.6

Different devices used windows CE

6

1.7

Interfaces for windows CE

6

1.8

PDA build-in camera

7

2.1

A scheme of a bar code reading system

10

2.2

Numeric barcode, 1D

12

2.3

Alphanumeric barcode, 1D

13

2.4

Some types of barcode, 2D

13

2.5

Reader (a), Laser scanner, (b) CCD scanner, (c) CCD

15

sensor by a lens.

2.6

Pen-Type readers

15

2.7

Some cameras can used to read barcode

16

2.8

These are some digital camera card (Photosmart mobile

16

camera)

2.9

The barcode reader with PDA in the shopping

17

2.10

Barcode EAN-13

21

2.11

(a) equivalent EAN-13 barcode, with the first character

22

set to zero, and (b) an EAN-13 with an additional digit

used, with the first character set to not zero

xiii

2.12

X-dimension barcode

23

2.13

Barcode Structure

24

2.14

Actual size of EAN-13

25

2.15

EAN-13, left and right hand

29

2.16

Barcode EAN-13 Parity Encoding

30

3.1

Architectural Overview: Our EAN-13 barcode and

33

resolution system consists of a PDA using camera and

load from file application for decodes barcode

3.2

There are some progress used to read barcode

33

3.3

Image processing in PDA

34

3.4

Some symbols barcode image

35

3.5

Schematic of the RGB color cube

39

3.6

Illustrating difference between a general RGB color

40

image and a general gray scale image.

3.7

Original gray-scale image

40

3.8

A 3x3 window, for use in a windowing function, where

42

the z-values corresponds to the gray-scale values of the

original image

3.9

Spatial filters (a) Gaussian Blur, (b) Laplacian (c)

42

Sharpen

(d) Unsharpen Mask

3.10

Scan 4 directions implemented

43

3.11

These are some direction of a barcode at different angles,

43

(a) Horizontal (b). Vertical (c) Diagonal (d) invest

horizontal

3.12

Illustrating how the barcode's angle µ is derived using the

44

vector displacement, k, the distance d between two

vectors, and basic trigonometry.

3.13

Steps to identify and extract the EAN-13 barcodes

44

3.14

program interface

47

3.15

Getting Acquainted

48

xiv

4.1

These are some samples for barcodes image are not clear,

51

all of them (uneven resolution and shake)

4.2

Some types of barcode all of them very clear

51

4.3

Some types of barcode all of them not clear

51

4.4

Shows the output from the localization algorithm. Angle

52

α is the angle of the bar code. The angle is also given by

90 - β

4.5

Rotation

53

4.6

Diagonal (+45, - 45), (a) scan consume operation

53

93ms,(b) scan consume 1482ms, (c) scan consume

operation 617ms

4.7

Horizontal, (a) scan consume operation 531ms,(b) scan

54

consume 492ms, (c) scan consume operation 462ms

4.8

Vertical, (a) scan consume operation 435ms,(b) scan

55

consume 336ms, (c) scan consume operation 515ms

4.9

some tests from camera (online), (a) scan consume

55

operation 203ms,(b) scan consume 270ms, (c) scan

consume operation 272ms

4.10

compare consume operation

57

xv

LIST OF ABREVIATIONS

PDA

-

Personal Digital Assistants

GPS

-

Global Positioning System

PC

-

Personal computer

MS

-

Microsoft

RAM

-

Random access memory

CPU

-

Central processing unit

GSM

-

Gold Standard Multimedia

GPRS

-

General Packet Radio Service

CDMA

-

Code division multiple access

WCDMA

-

Wideband Code Division Multiple Access

3G

-

3-Generation

SD

-

Secure Digital

MP

-

Micro Pixel

D

-

One- or Two- Dimensional

BMP

-

Windows Bitmap

EAN

-

European Article Number

UPC

-

Universal Product Code

CCD

-

Charge-Coupled Devices

PSA

-

Personal Shopping Assistant

PIM

-

personal information manager

JPEG

-

Joint Photographic Experts Group

RGB

-

Red, Green and Blue

SD

-

Secure Digital

SDIO

-

Secure Digital Input/Output

SDK

-

Software Development Kit

xvi

PCB

-

Printed Circuit Boards

CD

-

Compact Disc; conjugate directions

GSM

-

Groups :Special Mobile or Global System for Mobile

SMS

-

Simplex Minimization Search

xvii

LIST OF APPENDICES

APPENDIX

TITAL

PAGE

A

Camera SDIO SDK Specification

63

B

Visual Studio 2005 C++ CLASS DECLARATION

70

C

Some Types of digital camera card

75

D

SOME BARCODE IMAGE ARE VERY CLEAR

79

E

SCREENSHOTS OF COMMERCIAL TEST

80

PROGRAMS

F

Number System (number of countries)

82

CHAPTER 1

INTRODUCTION

1.1 Overview

Today barcodes are present all around us not only for use on groceries in the

super-market, but also in industries for example in a car assembly plant most the car

parts are marked with barcodes for identification purposes. Similarly, and for the

same reasons, most electronic circuits and microchips have barcodes on them.

Why is that? Why are barcodes used?

The main reason is the convenience and effectiveness barcodes provide since

they are designed for automated reading and interpretation. Leading to a

rationalization when a machine does the job instead of a human operator. Further, a

product can be given a fix barcode, only linking the barcode’s number to a database

containing attributes such as price, manufacturing date, adjacent bars and spaces

etcetera. Hence, attributes can easily be changed in the database, without actually relabeling the product.

Barcodes are standardized, as shown in figure 1.1, which leads to that they

are consistently shaped and used, and that they have a well defined structure

wherever they are found.

They provide unambiguous, and secure, identification. Some barcode

symbologies also offer a feature for tracing for example the origin of a product. As

2

barcodes are wide-spread over the world there has naturally evolved many different

ways to read them – using for example laser scanners, so called wands, CCDscanners, or digital cameras. If it could be possible to use personal digital assistant

(PDA) build in camera to read barcodes image much could be gained. Naturally, the

first advantage compared to, for example, a laser scanner is that the object with the

barcode is visible in the image, and thus that the operator can see whether the object

is for example intact or damaged, which means that the system easily could be

expanded with additional cameras. This is due to the fact that the PDA using a

camera downloads the images with ease could be connected to the network via the

internet such as the World Wide Web.

Figure 1.1: symbol barcode

1.2 Personal Digital Assistants (PDA)

A personal digital assistant (PDA) is a handheld device technology that can

implements various new kinds of applications such as telephone/fax, internet, GPS,

movie and network features. A typical PDA can function as a cellular phone, fax

sender, Web browser and personal organizer. Unlike portable computers, most

PDA’s began as pen-based, using a stylus rather than a keyboard for input. This

means that they are also integrated with handwriting recognition features. Some

PDA’s can also react to voice input by using voice recognition technologies. PDA’s

of today are available in either a stylus or keyboard version.

3

1.2.1 Pocket PC

This project will use Pocket PC (HP iPAQ hx4700 series as shown in Figure

1.3). The main reason for choosing Pocket PC rather than Palm is that Pocket PC is a

handheld computer with a subset of the capabilities of a PC and provides the basic

functionality those users need when they are traveling. Pocket PC also has a longer

battery life than a notebook PC, therefore, offers 320 x 240 color display or more,

moreover it can use touch screen for data entry. The pocket PC uses a cable serial &

USB sync port to connect with PC or other devices. It is an available compact flash

and/or Secure Digital (SD) Card for secondary storage. The pocket PC is better than

palm because the palm is just an organizer but the Pocket PC is a small computer that

uses a windows interface which is already user-friendly. The Pocket PCs are more

popular and used by many people because it can use Microsoft Word, Excel, and

Outlook. The Pocket PC uses high resolution color screens.

Pocket PCs come with mobile versions of office applications in addition to

Microsoft Outlook Mobile. Though there are different Pocket PCs, all of them can

compose e-mail messages and send them by synchronizing with desktop computer or

wirelessly.

Figure 1.2: HP iPAQ hx4700 Pocket PC

4

1.3 Palm

The palm has some applications with an easy to use interface, as shown in

figure 1.3

Figure 1.3: Palm

1.4 Smartphones

Mobile phones use Windows Mobile or Symbian as operating system

developed by the Palm Company. The smartphone is different with PDA’s, as shown

in figure 1.4.

Figure 1.4: Smartphone

5

Therefore, the smartphone has something like a PDA (storage on flash,

multimedia features, pocket outlook, pocket internet explorer, GSM/GPRS,

CDMA, WCDMA, 3G Radio, SD Card.

1.5 Camera used with PDA

There are many kinds of camera for PDA. They include; built–in camera,

wireless camera and digital card camera. The recent models of smartphone’s and

PDA’s have built-in camera, as shown in figure 1.5, which is digital camera card that

can be used in a PDA’s and other dives.

Figure 1.5: Digital camera card (HP Photosmart mobile camera)

1.6 Windows Mobile

Microsoft recently announced Windows Mobile operating system, which is a

handheld device powered by the Windows Mobile platform. It allows the user to

make phone calls, retrieve e-mails, browse the Internet, send and receive text

messages, read and compose Microsoft Word Mobile files, make Microsoft Excel

Mobile charts, and view Microsoft PowerPoint presentations. Windows Mobile

powered devices come in three types and includes: Pocket PC, Pocket PC Phone

Edition, and Smartphone, as Shown Figure 1.6

6

Figure 1.6: Different devices that use windows CE

Windows CE (WCE) is a Windows like operating system for various

handheld devices, including Personal Digital Assistants (PDA’s) and Mobile Phones.

While at the API level, many of the function calls and interfaces are the same as the

standard version of Windows as shown in figure 1.7, much of the internals have been

altered to accommodate many different types of CPUs and architectures.

Figure 1.7: Interfaces for windows CE

1.7 PDA using a camera

The system architecture of PDA using a camera is a recent generation of PDA

devices, as shown in figure 1.8

7

Figure 1.8: PDA build-in camera

This project can perform either in real-time (online) or load from a file

(offline). The application revolution has been made possible by the added extra

processor called an application processor into the newer PDA's. The software used is

Embedded Visual Studio 2005 C++ and the hardware system processing will be done

in real-time by PDA using camera. See figure 1.8, PDA with camera.

1.8 Limitations of Conventional Barcode Readers

In real time (online) phase, the capturing of barcodes image depends on the

following:

a) Resolution of the camera, for build-in camera in real time, the resolution

of the camera must be more than 3.0 MP.

b) Light intensity is very important to camera.

c) Camera stationary using a camera that is shaking will could the barcode

image to be blurred (that mean the bars are not clear.).

8

1.9 Objective of Project

The main objective of this project is to develop a system comprising of a

PDA using camera and software for the purpose of capturing 1-D barcodes and

decoding them in real-time (online) as well as offline (reading from a file). Suitable

image processing techniques must be implemented in the software to accommodate

inaccuracies or environmental changes during the acquiring process.

1.10 Scope of Project

The project is mainly to develop a Windows Mobile (windows CE) based

software in Embedded Visual Studio 2005 C++, which is to be run on HP Ipaq hx

4700 series PDA.

a. The program obtains images barcode from offline windows bitmap (BMP)

files or in real-time from a camera that is either attached or built in the PDA.

b. The image barcode is obtained from a camera that is either attached or built

in the PDA.

c. Barcode symbologies that will be considered in the project will be mainly the

EAN -13 (Very common in consumer products).

1.11 Project Outline

This project is organized into five chapters. The outline is as follows;

Chapter 1-Introduction

This chapter discusses the objectives and scope of the project and gives a

general introduction to barcode technology.

9

Chapter 2-Review of Literature Studies

This chapter reviews the relevant literature and previous work regarding PDA

using camera barcode readers. In addition to that, explain of EAN-13

symbologies are given.

Chapter 3- Methodology

This chapter elaborates on the principles behind good quality image

acquisition and the factors that must be taken into consideration to obtain

readable barcodes. This includes camera selection, determination of field of

view, resolution, light intensity and shake. The algorithms to initiate barcode

detection and decoding are also described and justified in this chapter.

Chapter 4-Result

The final results of this project are shown in this chapter.

Chapter 5-Conclusion

This chapter consists of the conclusion and future improvement.

CHAPTER 2

LITRATURE REVIEW

2.1 Introduction

There is quite a number of research works carried out on barcode reading and

localization using camera. Findings of these works are described in this chapter. This

chapter will also present an explanation of the barcode EAN-13 symbologies.

Barcodes are information carrying graphical patterns designed for easy and

reliable automatic retrieval. The most common barcodes are known as onedimensional barcodes. These graphical patterns in a single dimension (e.g.

horizontal), and are constant in the other (vertical) dimension and diagonal

dimension. In order to convey more information on the same surface area, the

constancy in the vertical dimension has to be abandoned for more intricate patterns,

known as two-dimensional barcodes.

Barcode reader is to extract the optical information in a symbol from bars and

spaces into computer-compatible data. The data can either be transmitted directly. A

general scheme for a bar code reading system is shown in figure 2.1.

Online or

Offline

Processor

Decoder

Figure 2.1: A scheme of a barcode reading system

Code

Barcode

11

2.2 A bit of history for Barcode

Beginning with 1932, when an ambitious project was conducted by a small

group of students headed by Wallace Flint at the Harvard University Graduate

School of Business Administration. The project proposed that customers select

desired merchandise from a catalog by removing corresponding punched cards from

the catalog.

Barcode was first used commercially in 1966, however, it was soon realized

that there would have to be some sort of industry standard set. [3] By 1970, the

Universal Grocery Products Identification Code or UGPIC was written by a company

called Logion Inc. The first company to produce barcode equipment for retail trade

use (using UGPIC) was the American company Monarch Marking in 1970, and for

industrial use, the British company Plessey Telecommunications was also first in

1970. UGPIC evolved into the U.P.C. symbol set or Universal Product Code, which

is still used in the United States. George J. Laurer is considered the inventor of

U.P.C. or Uniform Product Code, which was invented in 1973. In June of 1974, the

first U.P.C. scanner was installed at a Marsh's supermarket in Troy, Ohio. The first

product to have a barcode included was a packet of Wrigley's.

2.3 Types of Barcodes

To understand the contents of barcodes or be able to produce own barcodes

one has to understand the barcode symbology. The symbology is very much a like a

language defining how different combinations of various wide bars and spaces shall

be interpreted. There are many different barcode symbologies, one- dimensional or

two-dimensional, fixed-width or multi-width, each with various properties such as

data density or type of data stored, all designed to fulfill a specific purpose [1, 2].

The symbology also defines properties such as:

•

Quiet Zone, a quiet area around the barcode to avoid interference with

surrounding textures.

12

•

Start and Stop Patterns, speeds up the localization of the barcode.

•

Aspect Ratio, defines the relations between width and height of the whole

symbol and the different widths of bars and spaces.

•

Parity and Redundancy, ensures a low error rate and enables damaged

barcodes to be read.

Bar code systems can use several symbologies. A symbology is equivalent

to a language. Each symbology has strengths and weaknesses. Many symbologies are

around for historical or political reasons, while others have definite technical

advantages.

2.3.1

One Dimensional barcodes

It is employed in low information content applications like product index

registry (e.g. automatic price tagging and inventory management), or serial number

registry (e.g. test-tube tagging in automated medical tests). Two-dimensional

barcodes are used in applications that require more information contents like mail

addresses (for automated mail reading and distribution systems), or compressed

content of a printed page (to avoid the need for optical character recognition), as

shown in figure 2.2 and figure 2.3.

a. Numeric-only barcodes

EAN-13

EAN-8

UPC-A

Figure 2.2: Numeric barcode

UPC-E

13

b. Alphanumeric barcodes

Code-39

code-93

code-128

Figure 2.3: Alphanumeric barcode

2.3.2 Two - Dimensional barcodes

It is graphical patterns composed usually of dots. They are rendered using

two-toned dots (e.g. black dots on a white background), and occupy, usually a

rectangular area. Two-dimensional barcodes incorporate various registration and

fiducially marks, enabling automated identification, and accurate registration of the

barcode, which might be read-in in arbitrary orientations. In addition, two

dimensional barcode systems employ various error correcting codes for reliable

automated retrieval, as shown in figure 2.4.

PDF 417

DataMatrix

Maxicode

QR code

Figure 2.4: Some types of barcode, 2D

2.4 The Physical Reader

A physical barcode reader is considered to contain two separate elements: the

input device and the decoder [3]. These two elements can either be separated into

two different physical units or they can both be in one single unit. The input device

14

includes the electro-optical system and the camera system, while the decoder equals

the processor.

2.4.1 Input Device

There are different ways to read a barcode: by a scanner, using a wand or a

vision-based `device [2]. All these devices share a common structure in how the

reading process is performed. The user either holds the reader over the barcode or

holds the barcode image in front of the reader. All approaches scan a line across the

barcode and measure the intensity along the scan line. High intensity corresponds to

a bar and low intensity corresponds to a space. If the scan line does not cross the

entire bar code, the code will not be read. Then, another line must be scanned such

that the barcode is converted. The user has to ensure that the scan line is in the right

direction and that it covers the entire bar code [1].

a. Scanner

A scanner is usually a handheld device and is often used in the retail industry. In

some cases, the scanner is stationary and the user places the barcode in front of

the beam, like in the supermarket [1, 2], as shown in figure 2.5.

The scanner either moves the beam over the code by itself or the user has to

move the beam over the barcode. In the second case, the user has to be able to move

his hand with some skill.

The handheld device must stay at the same distance from the barcode while

the beam is moved over the code. A scanner does not have contact with the barcode.

A handheld, moving beam scanner has a large advantage over a fixed beam scanner.

It can scan with a much higher frequency, up to 40 scans per second, and almost no

operator skill is required. There is another type of handheld scanner that uses a raster

laser scan pattern to read 2D symbols.

15

(a)

(b)

(c)

Figure 2.5: Reader (a). Laser scanner, (b) CCD scanner, (c) CCD sensor by a lens.

b. Wand

A wand is a handheld device with a fixed beam that physically touches the

barcode is shown figure 2.6. The reading device of the wand is in the tip and the

wand looks like a pen that is moved over the barcode. The user has to provide the

moving motion of the beam, and therefore, some operator skill is required to use

a wand. The hardest thing is to move the wand at the right speed and to not make

too high accelerations [1, 3].

Figure 2.6: Pen-Type readers,

c. Vision-Based Scanning

Vision-based scanners use a camera to read the barcode, as shown figure 2.7. An

image is taken over the barcode area and is then analyzed so that the code can be

decoded. This technique has an advantage over the others when reading 2Dsymbols. It is not as fast but more accurate and thus better to use in some

applications, than the other two techniques. The performance and symbols

available for decoding have been evaluated [3].

16

Figure 2.7: Some cameras can used to read barcode

However, there are many kinds of a camera using with other devices. There

are built–in cameras, wireless camera and digital card camera, as shown Figure 2.8

The most of modern smartphone’s and PDA’s have built-in camera. This the camera

usually used with PDA to take a picture, video, etc.

Figure 2.8: These are some digital camera card (Photosmart mobile camera)

Wesley Chan [9], Project Voyager builds applications that link virtual

services to people, places, and things see figure 2.9. This is describes the design and

implementation of two such systems. The MIT Campus Guide application provides

services for specific points of interests. Campus visitors used the system to interact

with different sites, for example, a restaurant, a lecture hall, or a sculpture. The

Voyager Personal Shopping Assistant (PSA) connects shoppers in a supermarket to

17

virtual services, linked to specific products. Customers used handheld computers to

scan products. The system retrieved relevant information from the Internet about

each item, including recipes, nutritional information, and related product

recommendations. Project Voyager successfully deployed both systems and

conducted informal user trials.

Figure 2.9: The barcode reader with PDA in the shopping

Peter Sundström [3]. Barcode Reader for Surface Mounting Systems This is

describes a method for reading barcodes with a camera that has a field of view that is

smaller than the size of the barcode. The method analyzes partial barcode images.

From these images the barcode area is located and decoded. Using partial images

when reading barcodes is quite unique. The method reads the barcode EAN13 in two

steps. In the first step the partial barcode images are analyzed and a region of interest

is detected. The partial barcode images are then merged to one large image with one

region of interest. The barcode area is located by finding regions that have a high

concentration of mono-oriented gradients. In the second step, an average of lines is

scanned across the region of interest of the bar code. A waveform is produced that

has ridges and valleys. Ridges correspond to bars and valleys correspond to spaces in

the barcode. The width of the bars and spaces are classified and decoded so that the

bar code data can be extracted. Both code 128 and code 39 can be decoded. The

developed method has been tested on a set of bar code images. From a test set of 13

undamaged bar codes all were decoded correctly but from a test set of 11 damaged

18

bar codes 50 % were decoded correctly. The bar code area is correctly located in 90

% of all the partial bar code images.

2.4.2 Decoder

As mentioned before, the decoder analyzes the signal from the input device

and deciphers the information encoded in the barcode. The data is either transmitted

to an attached PDA, stored locally for later transfer, or forwarded to an application

program in the decoder itself. All decoders have a system that decodes the encoded

symbols information to understandable data. This system is usually implemented in

software on a microprocessor, but it might also be implemented in hardware. There

are some basic steps included in all decoders [2]:

1. Measure the width of each element or the edge-to-similar-edge distance,

depending on the symbol. Only for CCD input devices the actual distance is

measured. Instead, the decoder measures the time the signal spends in an

element.

2. Quantize the element widths to fit the symbol description. This is hard if the

input device does not have a moving beam.

3. Decode the quantized element characters to readable data. This is done via a

look-up table.

4. If necessary, reverse the order of the decoded data characters to accommodate

symbols that have been scanned in the wrong direction.

5. Perform additional checks to confirm the validity of the scan. Such as: quiet

zone size,check character...

6. Transmit the decoded data.

19

2.4.3 Barcode Reading

Usman Ullah Sheikh [1], real-time barcode reader using Active vision. This is

to decode the UPC-A and EAN-13 barcodes using an active vision system, consisting

of a camera and user-written software. The camera will feed the software with

continuous frames of images from the environment. These images are converted to

grayscale and some preprocessing is performed. Image is filtered (such as sharpening

and noise reduction) and converted to binary. An adaptive thresholding algorithm is

used to reduce the effects of uneven illumination. Image is then scanned horizontally,

vertically and diagonally for barcodes, thus enabling it to decode rotated

barcodes.Error correction and predictive decoding is implemented to improve the

speed and accuracy of the system. Overall system performance is benchmarked with

existing commercially available software.

Johan Bylund, Fredrik Jirhede [2],Visual Barcode Reading, the design and

implementation of a system for visual barcode reading, using a network camera A

system that reads and decodes linear barcodes based on images containing barcodes

– independently of the barcodes' orientation or rotation. To accomplish this method

based on various image and signal processing was developed, consisting of the

following main stages. First the image from the camera was enhanced, using Sobel

filters, to suit the succeeding processing. Then the barcode was located in the image

using a method based on the evaluation of the correlation between small parts of the

image. To extract relevant information from the located image the barcode was then

isolated in the image. After that the Hough transform was used to gain a waveform

representing the information of the barcode. The waveform was then subjected to

various processing resulting in a string of digits representing the width's of the

elements of the barcode. To this stage the processing has been completely barcode

symbology independent, which implicates that many symbologies could be included

parallelly in the succeeding stage. However, of practical reasons only EAN-13

barcodes were considered in the final decoding stage; where symbology specific

information was used to normalize the informa- tion, decode the information, and

validate the result using a checksum. The system was implemented in C on a PC

running Linux, with a graphical user interface written C++. The all over performance

was good, and all predefined objectives were met to full satisfaction. Key-words:

20

Barcode decoding, barcode symbologies, network camera, image processing, image

enhancement, Sobel operator, barcode localization, pattern recognition, feature

extraction, Hough transform.

Douglas Chai and Florian Hock [13], Locating and Decoding EAN-13

Barcodes from Images Captured. Digital Cameras by a vision-based technique to

locate and decode EAN-13 barcodes from images captured by digital cameras. The

ultimate aim of our approach is to enable electronic devices with cameras such as

mobile phones and Personal Digital Assistants (PDAs) to act as a barcode reader.

Yasser Ebrahim, Wegdan Abdelsalam, Maher Ahmed, Siu-Cheung Chau,

Proposed a Hybrid Tag-Camera-Based Identification and Navigation Aid for the

Visually Impaired, a barcode-based system to help the visually impaired to identify

objects in the environment and navigate through unknown territories is introduced.

The system is based on the idea of tagging the different objects with 2D barcodes,

with the aid of a portable camera and a computing device. The system can recognize

and relay the barcode content to the user. The advantages of the proposed system

compared to those of existing technologies. This paper addresses the self-localization

problem from a pragmatically point of view since it argues for using passive artificial

landmarks in order to support mobile robot localization in indoor environments. The

idea is to further improve already existing localization capabilities by providing

relevant environmental spots with semantic information. In order to facilitate the

detection of these landmarks the employment of bar codes is proposed. Experimental

results concerning the detection and identification of barcode labels by means of

vision have been presented [24]. The BCReader is a new product for smartphones

that gives possibility to decode barcodes from snapshots made by onboard camera.

Simply make photo of barcode on selected thing and save received data in phone’s

database for further processing. For each barcode BCReader can save title name,

price and description. The BCReader allows searching necessary goods and

comparing their prices in different stores to make best choice [27].

21

2.5 THE BARCODE RECOGNITION SYSTEM

2.5.1 EAN-13 Barcode Image Recognition

The European Article Numbering system (EAN) is by far the most popular

barcode used in the retail industry. It’s available on almost all consumer products.

While the EAN code format was adopted 3 years later. There are several versions

EAN-13 barcodes, such as EAN-13 (13 digits).While EAN-13 is the equivalent for

the European market. Thus, the structure and size are the same. The EAN-13 encodes

12 digits of numeric message and one check digit to form a 13 digit barcode. The

check digit is not a part of the data, but merely for error checking [3].

Figure 2.10: Barcode EAN-13

2.5.2 Barcode symbologies

Barcodes are like a printed version of the most code. Different bar and space

patterns are used to represent different characters. Sets of these patterns are grouped

together to form a "symbology". There are many types of barcode symbologies each

having their own special characteristics and features. Most symbologies were

designed to meet the needs of a specific application or industry. However, for the

EAN-13 symbology, the data is encoded differently, where the first two digits

represents the country of origin. The last digit is still the check digit, while the

remaining digits are composed of manufacturer’s number and product’s number.

There are differences between these two symbologies. The EAN-13 barcode

when the first character is set to 0. Visually looking at the bars of Figure 2.11.a and

Figure 2.11 b, both barcodes are identical. In other words, a digit EAN-13, if the first

22

digit is set to 0. EAN-13 “0-XXXXXX-XXXXXX”. Both barcodes are made of left

and right-hand character sets. The EAN-13 encodes a 13th digit into the parity pattern

of the left six digits symbol (EAN-13 = Data Structure + Symbology) [1].

(‘0’+11+1 Characters)

(12+1 Characters)

Symbology

L

R

L

R

Data Structure

(a)

(b)

Figure 2.11: (a) equivalent EAN-13 barcode, with the first character set to zero, and

(b) an EAN-13 with an additional digit used, with the first character set to not zero

2.5.3 Barcode Size and Color

The size in an EAN-13 barcode is at three different magnifications. Barcodes

can be a scaled to a minimum of 80% of the standard dimension, and up to 200% [1].

The complete specification is given in table 2.1.

Table 2.1: Specification for EAN-13 barcode

29.83 mm x 20.73 mm

Minimum size

74.58 mm x 51.82 mm

Maximum size

37.29 mm x 25.91 mm

Nominal dimensions

0.330 mm

X-dimension at normal size

80% to 200% from normal dimension

Magnification factor

Left 3.63 mm (11x), Right 2.31 mm

Quiet Zone

(7x) Top &Bottom 0.33 (1x)

22.85 mm at nominal size

Bar height

Rear lower right quadrant

Target location

23

2.6 Encoding Rule of Structure of an EAN barcode

The EAN-13 standard, consist of a number of printed bars with intervening

spaces. The characters within the symbology are encoded in a pattern with various

sizes of narrow and wide, bars and spaces. There are two different types of a barcode

depending on where it is marked. The first type is recognized as "source marking".

The barcode of this type is marked on the product during manufacturing process. The

second type is a recognized as "in-store marking". Products of this kind are only sold

in some particular stores. It is extensively used by most of the commercial products.

There are total of 13 digits in an EAN-13 code. The center pattern and the guard

pattern consist of auxiliary characters, see figure below.

Figure 2.12: Barcode Structure

In this standard, each digit is composed of 7 modules. The center pattern and

the guard pattern contain 5 modules and 3 modules, respectively. The first three

digits of an EAN-13 code are country prefix, see figure 2.12. They are used to

identify the nationality of the organization issuing the barcodes. Their four

successive digits represent the manufacturer number. Then, the five successive digits

represent the specific product item number. The last digit of an EAN-13 code is a

check digit. In this standard, a code consists of 7 modules. Different combinations of

011 will represent different numbers under this format. There are total of three

24

encoding rules for the so-called A, B, C types. Based on these encoding rules, we can

decode a bar code into its corresponding digits easily. In the EAN-13 standard, the

selection of encoding rule totally depends on the first digit of the country prefix. The

whole barcode is made of predefined standard elements [3].

2.6.1 The X-dimension

The X-dimension or module is the width of the narrowest bars or spaces in

the barcode [27-28]. The width of the other bars or spaces is two, three or four times

the size of X-dimension, see figure below. The X-dimension is 264μm, 330μm and

660μm for a barcode scaled at 80%, 100% and 200% respectively. The X-dimension

and the width of the thickest bar cannot be more than four times the width of Xdimension. Any barcode will be divided to a spatial, then, each spatial has two bars

(black is present (zero)) and two spaces (white is present (one)), after that, it will be

divided to 7-dimension, then, it will get a digital numbers from it [1].

Figure2.13 : X-dimension barcode

2.6.2 Quiet zone

Quiet zones are the areas to each side of the code that must be kept clear. The

blank areas are before/after the barcode [1, 3, 28]. It is measured in terms of “n”

times the narrowest bar size (X-dimension). The quiet zones for an EAN-13 barcode

25

are 11 modules on the left hand side (Figure 2.14(1)), 7 modules on the right hand

side (Figure 2.14(2)), and 1 module thickness each at the top and bottom of the

barcode (Figure 2.14(3), Figure 2.14(4)). The end of the barcode on the right hand

side is usually marked with an indicator ‘>’, indicating the end of quiet zone (Figure

2.14(11)).

2.6.3 Guard bars

A guard pattern is placed on the right, at the center and on the left of the

barcode. This pattern is required so that the reader can identify the starting point of a

particular barcode (Figure 2.14(5), Figure 2.14(7), Figure 2.14 shows) the starting

and ending guard bars in the order of Black-White-Black (3 bars, each 1 module

thick). A centre guard is placed in the middle of the barcode. The centre guard has

the same convention as the side guards. Figure 2.14(7), the center guard bars in the

order of White-Black- White-Black-White (5 bars, each 1 module thick).

Figure 2.14: Actual size of EAN-13

26

2.6.4 Right & left hand side digits

It consists of four areas; normally the number system digit is printed to the

left of the barcode, and the check digit to the right. The manufacturer and product

codes are printed just below the barcode, separated by the guard bar.

a. Number System

The number system consists of two digits (sometimes three digits) which identify

the country/region numbering authority which assigned the manufacturer code.

Any number system which starts with the digit 0 is a UPC-A barcode. The

number system list is maintained by EAN organization. Also, the number

systems for every country/region are listed (in last chapters).

b. The Manufacturer Code

The manufacturer code is a unique code assigned to each manufacturer by the

numbering authority indicated by the number system code. All products produced

by a given company will use the same manufacturer code. EAN uses what is

called "variable-length manufacturer codes." Assigning fixed-length 5-digit

manufacturer codes, means that each manufacturer can have up to 99,999 product

codes--and many manufacturers don't have that many products, which means

hundreds or even thousands of potential product codes are being wasted on

manufacturers that only have a few products. Thus if a potential manufacturer

knows that it is only going to produce a few products, EAN may issue it a longer

manufacturer code, leaving less - space for the product code.

This results in more efficient use of the available manufacturer and product

codes.

c. The Product Code

The product code is assigned by the manufacturer. The product code immediately

follows manufacturer code. The total length of manufacturer code plus product

code must be exact 10 digits.

27

d. The Check Digit

The check digit is used to verify that the barcode is generated or scanned

correctly. The check digit is calculated based on the rest of the barcode digits.

Since a scan can produce incorrect data due to inconsistent scanning speed, print

imperfections, or a host of other problems, it is useful to verify that the rest of the

data in the barcode has been correctly interpreted.

2.6.5 How to calculate the checksum

The check digit is a character included with the symbol to check on the validity

of a barcode’s data when decoding. In the previous section, the check digit was

assumed available. However, in the actual encoding process, the check digit is

calculated based on the data to be encoded. The process of calculating the check digit

is given below:

1. Multiply all odd digits with 3 (the first digit is even).

2. Add all the even digits with the multiplied odd digits.

3. Add a number X to the sum, so that it is evenly divisible by 10.

4. The number X is the check digit.

Example: Assume the data to be encoded is; data = 7-501031-31130C

(12 digits + 1 check digit) C is the check digit to be determined.

1. Multiply all odd digits with 3,

Barcode

7

5

0

1

0

3

1

3

1

1

3

0

Position

E

O

E

O

E

O

E

O

E

O

E

O

3

Multiplier

Result

7

15

3

0

3

3

0

9

3

1

9

3

1

2. Add all the even digits with the multiplied odd digits.

Total sum = 7+15+0+3+0+9+1+9+1+3+3+0 = 51

3

3

3

0

28

3. 51+9 = 60, evenly divisible by 10.

4. So check digit is 9.

5. Final barcode value is 7-501031-311309

2.6.6 Encoding

The process of encoding an EAN-13 barcode is relatively straight forward.

An EAN-13 requires 12-digits of data to be present for encoding while the 13th digit

(the check digit) will be calculated from the data.

a. Total number of bars and modules

An EAN-13 symbol can be divided into two halves, each consisting of six digits

separated by a center guard bar pattern. The whole symbol is surrounded by two

guard bar patterns. The same digit has different encoding depends whether it is in

the left halve or in the right halve. The encoding pattern for digits in the left halve

always starts with a space while the one for digits in the right halve always start

with a bar and ends with a space. An EAN-13 symbol has the following structure:

1. Start guard bars, always with a pattern (bar + space + bar (101)).

2. Left halve, six digits encoded using the encoding from main table A or B.

3. Center guard bars, with a pattern (space + bar + space + bar + space (01010)).

4. Right halve, six digits encoded using the encoding from main table C.

5. Stop guard bars, always with a pattern (bar + space + bar (101)).

Table 2.2: Total number of bars and modules for EAN-13 barcode

Left guards (start)

= 3 bars

= 3 modules

Left hand

= 24 bars

6 x 7 = 42 modules

Center guards

= 5 bars

= 5 modules

Right hand

= 24 bars

6 x 7 = 42 modules

Right guards (stop)

= 3 bars

= 3 modules

Total

= 59 bars

= 97 modules

29

a) Main table of barcode EAN-13 for encoding

This main table indicates how to encode each digit of the barcodes, see table2.3

depending on which half (left or right) of the barcode the digit is found.

Left-Hand

Sets A & B

Right-Hand

Set C

Figure 2.15: EAN-13, left and right hand

Table 2.3: The list of oriented-modules on logic of 0-9 for A, B, C, types

Digit

Left-Hand Encoding

Right-Hand Encoding

Odd Parity Even Parity

Set C

(Set A)

(Set B)

0

0001101

0100111

1110010

1

0011001

0110011

1100110

2

0010011

0011011

1101100

3

0111101

0100001

1000010

4

0100011

0011101

1011100

5

0110001

0111001

1001110

6

0101111

0000101

1010000

7

0111011

0010001

1000100

8

0110111

0001001

1001000

9

0001011

0010111

1110100

Each character has its own code and it is represented using 7 modules. The

corresponding modules are determined from Table 2.3 and Table 2.4. The first digit

will determines the parity encoding of the left hand side characters. Steps for

encoding are given below. Example of encoding an EAN-13 barcode (assume the

check digit is already calculated);

Example: EAN-13 Parity encoding from, see table 2.4, see figure below for barcode

EAN 13

30

Data = 7-612345-67890 (12 digits + 1 check digit), Number System 76, (number

of country), Manufacturer Code 12345, Product Code 67890, Check Digit is 0,

see example barcode divided below.

6 (Value)

= 7 X-dimension bars

= 0101111

= 2 black & 2 white bars

Figure 2.16: Encoding number

Table 2.4: Result for example

Digit name

Numeric Value Encoded with

Binary

-

-

101

2nd Number System

6

Odd

0101111

1st Manufacturer

1

Even

0110011

2nd Manufacturer

2

Odd

0011001

3rd Manufacturer

3

Even

0100001

4th Manufacturer

4

Odd

0100011

5th Manufacturer

5

Even

0111001

Central Guard

-

-

01010

1st Product Code

6

Set C

1010000

2nd Product Code

7

Set C

1000100

3rd Product Code

8

Set C

1001000

4th Product Code

9

Set C

1110100

5th Product Code

0

Set C

1110010

Check Digit

0

Set C

1110010

Right Guard

-

-

101

Left Guard

(always the same)

(always the same)

(always the same)

31

1.

parity digit is ‘7’, thus from Table 2.4, the parity encoding for the six right

hand characters are in the order of Odd-Even-Odd-Even-Odd-Even.

2.

The first of the left hand digits (the second digit of the 13 digit barcode) is 6,

because the parity is odd (obtained from step 1), by referring to Table 2.3,

the digit 6-odd will be encoded as 0101111, and is shown in Figure 2.63.

3.

The second digit is 1, and the parity is even. From Table 2.3, the code for 1 even is 0110011.

4.

The remaining left hand digits are encoded in the same manner.

5.

The right hand digits are encoded directly from Table 2.3.

6.

(Start guard) 101-> (Black, white, black).

7.

(Six left digits) 0101111-> (white, black white, black, black, black, black),

0110011 –> (White, black, black, white, white, black, black) etc, 0011001,

0100001, 0100011, 0111001.

8.

(center guard) -01010 -> (White, black, white, black, white).

9.

(six right digits) 1000010 ->(Black, white, white, white, white, black, white)

etc, 1100110, 1100110, 1000010, 1110010, 1110100

10.

(end guard) -101-> (Black, white, black).

2.6.7 Decoding

Decoding is just the reverse of the encoding process. By comparing the bars

with Table 2.3, the corresponding digit value and its parity can be determined. The

parity of the six left hand characters will decide the first character of the barcode.

When all the digits are obtained, the check digit can be calculated and then compared

with the check digit obtained from scanning. If the check digits do match, the

barcode is verified and assumed to be correct.

CHAPTER 3

METHODOLOGY

3.1 Introduction

This chapter describes the overall steps needed to decode an image barcode

with a camera built in the PDA system. Detailed information on how each step is

implemented is given, several methods are presented on each step.

3.2 Barcode Image Devices

The imaging barcode system should produce barcodes with high quality so

that the desired objects can be extracted successfully for processing.

The task of the system is to read EAN-13 barcode using a PDA with a buildin camera or reading from a file. In this case, a barcode image is captured using a

PDA and then decode it, see Figure 3.1, once captured the PDA will search for the

barcode area.

33

Figure 3.1: Architectural Overview: EAN-13 barcode and resolution system consists

of a PDA using camera and load from file application for decodes barcode.

3.3 Image Capturing

In this Project a SD camera is used (HP photosmart mobile camera). The

system can also read image from a file, see figure 2.3.

Press to

test to

load

from

file

barcode

Figure 3.2: There are some progresses used to read barcode

34

3.4 Barcode processing in PDA

There are some aspects that need to be mentioned when designing a barcode

reader. This design has two parts to a read barcode image. First-part, the capture

barcode image by camera built-in PDA (online). Second-part, load from file

(offline). This barcode image can contain whole a barcode or a partial barcode

depending on the field of view. See figure below.

Figure 3.3: Image processing in PDA

35

3.4.1 Searching for barcode image automatically

When the system wants to read a barcode it gives the coordinate of the

barcode to the barcode reader, see figure 3.4, some symbols barcode image. Then,

searching for the image barcode automatically (locate the area of interest), see figure

3.4. The barcode localization algorithm will then be applied to the barcode image.

Figure 3.4: Some symbols barcode image

To be able to identify the elements of a barcode with good result, the location

of interest of the barcode must be known. This area will be referred to as “the region

of interest” see figure above. There are scenarios after a barcode image has been

searched automatically. Thereby, it gets an accurate result when identifying the

elements. The localization algorithm will give information about the extent of the

barcode outside the image.

The system will be instructed to grab new a barcode images at the new

positions. Therefore, the localization algorithm must be able to locate the barcode

image area for any orientation of the barcode. Thus, to be able to identify where the

barcode is in an image one must be able to specify what is special about a barcode

area, either in the spatial domain. Linear barcodes have thin and narrow parallel lines

36

and these lines have high contrast. Two-dimensional symbols also have high

contrast, but they do not contain parallel lines.

In most barcode applications, the barcode occupies a small part of the

barcode image. In this application, the code will most likely occupy a large part of

the image, because the image size is small compared to the barcode. The direction of

the barcode is not known in most cases. The algorithm must therefore be able to

locate a barcode area in any orientation.

3.4.2 Identification of the Bars and Spaces

To be able to decode the barcode, the width of the elements must be

identified with high precision. One way to get a waveform for analysis is to use the

intensity in the barcode image in a similar way as the voltage from a laser scanner.

To accomplish this accurately the orientation of the barcode must be known.

Two adjacent edges in the waveform constitute the start and stop of an element. So,

the task is to detect the edges of the waveform. If the image barcode is damaged it

might have to be filtered to improve reading performance.

3.4.3 Estimating How Correctly the Elements Have Been Identified

All barcode symbols have a well defined set of valid element widths. For

EAN-13 (X-XXXXXX-XXXXXX), the set is {X, 2X, 3X, 4X, 5X, 6X}, X is the

smallest element size. If the output from the identification of the bars and spaces is

not within these sets or matches the elements in these sets poorly, an alternative

method should be used for identifying the bars and spaces.

37

3.4.4 Decoding the Barcode

The proposed decoding is as follows:

•

First, it obtains a sample row across the barcode image.

•

The signal is then converted into the binary form by simple thresholding

based on the mean value of the signal. The signal in a binary form, which is

essentially a binary sequence of 1’s and 0’s.

•

The run-length encoding is performed on the binary sequence so, that the

individual width of the alternating black and white bars can be determined.

•

The next step is to determine where the barcode begins by searching for the

left hand guard pattern.

•

Once the left hand guard pattern is found, the decoder will read the next 6

sets of 4 bars to determine the values of the 2nd, 3rd, 4th, 5th, 6th and 7th

barcode digits.

The center guard pattern should be detected before reading the next 6 sets of

4 bars, which specify the values of the 8th, 9th, 10th, 11th, 12th and 13th digits. The

lock-up tables for the EAN-13 symbologies are given in table 3.1 and table 3.2.

Table 3.1 is the lock-up table for a regular barcode and table 3.2 is for a flipped or

mirrored barcode. The decoding algorithms were used, namely the Predictive

decoding algorithm [1].

Digit

0

1

2

3

4

5

6

7

8

9

Table 3.1: Normal barcode (left to right)

Left

Right

Odd

Even

Odd

0001101

3211

0100111

1123

1110010

0011001

2221

0110011

1222

1100110

0010011

2122

0011011

2212

1101100

0111101

1411

0100001

1411

1000010

0100011

1132

0011101

2311

1011100

0110001

1231

0111001

1321

1001110

0101111

1114

0000101

4111

1010000

0111011

1312

0010001

2131

1000100

0110111

1213

0001001

3121

1001000

0001011

3112

0010111

2113

1110100

3211

2221

2122

1411

1132

1231

1114

1312

1213

3112

38

Table 3.2 Flipped or mirrored barcode

Digit Left (inverted)

Right (inverted)

Even

Even

Odd

0

1011000

1123

1110010

1123

0100111

1

1001100

1222

1100110

1222

0110011

2

1100100

2212

1101100

2212

0011011

3

1011110

1411

1000010

1411

0100001

4

1100010

2311

1001110

2311

0011101

5

1000110

1321

1001110

1321

0111001

6

1111010

4111

1010000

4111

0000101

7

1101110

2131

1000100

2131

0010001

8

1110110

3121

1001000

3121

0001001

9

1101000

2113

1110100

2113

0010111

3211

2221

2122

1411

1132

1231

1114

1312

1213

3112

a. Predictive Decoding

One of the major advantages of predictive decoding is that it handles noise

and inaccuracies very well. The predictive method basically predicts the outcome

without comparing all the bars. The basis of this method is that, certain

combinations of bars are unique and thus allowing some optimization to be

performed. In a worst case scenario, the predictive decoding method only

requires 3 out of 4 bars to be present for successful decoding.

3.5 Pre-Processing

As in all applications involving image acquisition followed by processing of

the images, the qualities of the images are of great importance. Many things do

influence the output of the camera built-in PDA, and as regarding all photography,

the lighting is the foremost important variable which affects it. Motion of the object,

and the distance between the camera and the object are other important issues.

Most of which depends on the actual location of the object and its light

conditions, or the chosen camera built-in PDA and its features and performance.

However, in many applications the sought image is not only an image that is

appealing to the human eye. Other features might be important to amplify or reduce

to enhance the relevant information of the image.

39

3.5.1 The RGB color model

In the RGB model, each color appears in its primary spectral components of

red, green and blue. This model is based on a Cartesian coordinate system. The color

subspace of interest is the cube shown in figure 3.5. In which RGB values are at

three corners, cyan, magnets and yellow are three other corners, black is at the origin,

and white is at the corner father from the origin. In this model, the gray scale (point

of equal RGB values) extends from black to white along the line joining these two

points. The different colors in this model are points on or inside the cube, and are

defined by vectors extending from the origin. For convenience, the assumption is that

all color values have been normalized so, that the cube shown in figure 3.5 is the unit

cube. That is, all values of R, G, and B are assumed to be in the range (0, 1).

Image represented in the RGB color model consist of three component

images, one for each primary color. When fed into an RGB monition, these three

images combine on the phosphor screen to produce a composite color image. The

number of bits used to represent each pixel in RGB space is called the pixel depth.

Consider an RGB image in which each of the red, green, and blue images is an 8-bit

image. Under these conditions each RGB color pixel (that is, a triplet number of bits

per plane). The full color image is used often to denote a 24-bit RGB color image.

B

Blue

0, 0, 1

Cyan

Magenta

White

Gray

scale

0, 1, 0

Green

Black

1, 0, 0

R

Red

Yellow

Figure 3.5: Schematic of the RGB color cube

G

40

3.5.2 Gray scaling

Gray scaling is done to remove the color values of the image. It is a very

common preprocessing step in most image processing applications where additional

color information is unnecessary. A color image is a composition of 3 separate layers

of Red, Green and Blue. Processing on a color image is 3 times slower as the

processing has to be performed on three different layers. Besides that, a color image

also requires three times the memory space compared to a gray level image (for an

uncompressed image). These drawbacks are definitely undesirable for real-time

application especially when the color information in not required. Grayscaling

converts a color image (a 24-bit RGB, 8-bit per channel in this case) to an 8-bit gray

level image, thus representing the light intensity of the image, see Figures below.

Thereby, the data is ready for further processing.

R

G

B

Figure 3.6: Illustrating difference between a general RGB color image and a general

gray scale image.

Figure 3.7: Original gray-scale image

41

3.5.3 Image Enhancement

To prepare the image for the next stage in the system, the Feature Extraction

stage, it has to be suitably enhanced. This process is a prelude to the Barcode

Localization phase, which is the first thing done in the Feature Extraction stage. In

this case barcodes are the region of interest, thus making the process of high- lighting

the patterns that are characteristic for barcodes the aim of this section. This means

that areas of high contrast containing many parallel lines are considered highly

interesting, and should thus be amplified. While oppositely, areas of uniform grayscale levels are considered as of low interest regarding barcodes.

The basic idea is to sharpen the image, thereby making details and edges

appear clearer, and at the same time to suppress areas of low interest, such as fields

of uniform gray-scale etcetera. Intuitively averaging of pixels in a region – which is

analogous to integrating over that region - does blur detail. Leading to the

expectation that differentiation yields the opposite effect, thus sharpening the image;

which is just the sought-for effect.

As a collective name these kinds of operators are called derivative filters, and

the most common method to achieve it is by using the gradient. The analytical

expression for the gradient, of the function f(x; y), this step is carried out to enhance

certain details in the image such as edges or to attenuate others such as noise.

Brightness and contrast of the image can also be adjusted here. Three filters can be

applied consecutively in a cascading manner to the image in addition to brightness

and contrast adjustment. Specifically, there are four spatial filters available for use,

mainly for sharpening and blurring. The filters are applied automatically. The filters

that are available and their respective kernels are shown in Figure 3.9

A convenient way of doing this kind of processing on images is by letting a

windowing function operate on the image. The windowing function exemplifed with

a window of 3 x 3 pixels works as follows: Consider Figure 3.7, where the z-values

represent the gray-level values of the original image. The values of all the nine

pixels, z1 through z9, are each multiplied with pre-defined factors. Then the sums of

all components are set as the new centre of the window, in this case position z5. [2]

42

The window is then moved on to the next pixel, and the same procedure is repeated,

see figure 3.8. By sliding the window in an overlapping fashion the whole image,

except the pixels in the margin of the image.

Figure 3.8: A 3x3 window, for use in a windowing function, where the z-values

corresponds to the gray-scale values of the original image.

Figure 3.9: Spatial filters (a) Gaussian Blur, (b)Laplacian (c) Sharpen

(d) Unsharpen Mask

3.6 Scanning Direction

The first step is to scan for a barcode or multiple barcodes in the scene or

image (a frame in the case of real-time acquiring). The method employed is similar

to that of a laser scanner. Image is scanned in 4 directions, horizontally (left to right),

vertically (top to bottom), 45 degrees diagonally (top left to bottom right) and -45

degrees (bottom left to top right), shown in Figure 3.10 Each of the direction is

known as a scan direction. The number of scan line depends on the scanning

resolution set by the user. Depending on the accuracy required, the number of scan

lines can be increased or decreased [1].

43

Figure 3.10: Scan 4 directions implemented

Each direction detects flipped and mirrored barcodes without a second pass.

This is because; flipped and mirrored barcodes are handled by the decoding

mechanism rather than the scanning mechanism. The scanning mechanism is merely

for obtaining a provisional location of a barcode.

(a)

(b)

(c)

(d)

Figure 3.11: These are some direction of a barcode at different angles, (a)

Horizontal (b). Vertical (c) Diagonal (d) invest horizontal

Four scan directions are implemented to allow detection of rotated barcodes

(rotation of barcodes also referred as skewing) which is a usual occurrence in reality.

By scanning horizontally (0), vertically (180) and diagonally (-45 and 45), the

barcode reader is capable of detecting barcodes throughout the 360o range. See

figure 3.11

44

Angular information of the barcode is acquired through knowledge of the

vector displacement, k, and the distance, d, between the correlated vectors, when the

correlation between two vectors is calculated. The barcode's angle is derived as (µ =

arctan( d k )), see Figure 3.12 Angles in the images are defined as increasing

counterclockwise from the x-axis, with 90 degrees on the y-axis, and 180 degrees on

the negative x-axis

Figure 3.12: Illustrating how the barcode's angle µ is derived using the vector

displacement, k, the distance d between two vectors, and basic trigonometry.

3.7 Barcode Identification & Extraction

One-dimensional barcodes are made of bars and spaces. This distinct feature

is what the scanning process is looking for. The identification and extraction of the

EAN-13 barcode consist of 4 main steps. Referring to Figure 3.12, the steps are;

Figure 3.13: Steps to identify and extract the EAN-13 barcodes

45

3.8 Program Architecture

3.8.1 Overview of Programming Languages Used For PDA Platform

There are many languages that can be used to program PDA's with Windows

CE, OS or Windows Mobile 2003 or 2005, but the most common and popular are:

a. Microsoft Visual Studio 2005 Professional Edition