EFFICIENCY OF AERATION SYSTEM IN WASTEWATER TREATMENT PLANTS. SRI RUTHIRA KUMAR

advertisement

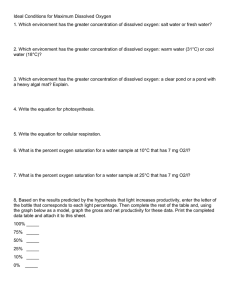

EFFICIENCY OF AERATION SYSTEM IN WASTEWATER TREATMENT PLANTS. SRI RUTHIRA KUMAR UNIVERSITY TEKNOLOGI MALAYSIA ii DEDICATION I would like to dedicate this project report to my parents (V. Amirthalingam and S.Sarojini Thevi), wife ( Lily) and my beloved daughter (Sanjana Sri) for their constant love and encouragement iii APPRECIATION The author would like to extend his most sincere appreciation and gratitude to Associate Professor Dr. Fadil Othman for his guidance and encouragement throughout the course. Special gratitude also goes to Indah Water Konsortium Sdn. Bhd for without its financial sponsorship and the releasing of its professional staffs as lecturers, my colleagues and my-self would not have completed this post-graduate course in Wastewater Engineering. Last but not least, I would like to record my most sincere gratitude to my colleague Miss Monica who had taken a lot of her own time to type and proof read this project report for me. iv ABSTRACT The most important factor in selecting aeration equipment for a specific application is the oxygen transfer rate. Other factors that are equally important are reliability, serviceability, capital cost, system appurtenances and cost of operation and maintenance. Although there are many systems designed to aerate and mix the waste water, they vary in their effectiveness in providing uniform oxygen dispersion. It is the intention of the study to evaluate the performance of different types of aeration devices based on dissolved oxygen (DO) readings and costing. To achieve this objective, experimental work were carried out on five different aeration devices namely brush aerator, tornado, surface aerator, aspirator and diffusers on five different sewerage treatment plant with average PE of 2000. Through the experiment it was found that aspirator was able to achieve 1 to 2 mg/l dissolved level while meeting the regulators requirement on biochemical oxygen demand level. In the terms of electricity, aspirator needed the lowest consumption compared to the other type of device system. A detailed study on costing was done for the last 6 months in term of operating and maintenance on the aeration device and was found that aspirator was the cheapest to maintain compared to the others. While meeting the biochemical oxygen demand standard as require by the regulators, this outcome of the study would be a crucial factor when selecting a suitable aeration device in sewerage industry in future. v ABSTRAK Kadar resapan oksigen merupakan faktor yang paling penting semasa pemilihan peralatan untuk pengudaraan Faktor-faktor lain termasuk realiabiliti, servisabiliti, kos pembelian, kos peralatan sampingan serta kos operasi dan penyelenggaran. Walaupun terdapat berbagai-bagai sistem direkabentuk untuk mengudarakan serta mengadunkan kumbahan, ia berbeza dari segi kecekapan dalam menghasilkan oksigen yang setara. Tujuan projek ini adalah untuk menilai kecekapan pelbagai jenis peralatan pengudaraan melalui bacaan oksigen terlarut serta perbelanjaan penyelenggaraan dan operasi setiap loji kumbahan. Untuk mencapai objektif ini satu kajian telah dijalankan terhadap lima jenis peralatan aeration yang berbeza iaitu “brush aerator”, “tornado”, “surface aerator”, “aspirator” serta diffusers yang terdapat pada lima loji kumbahan tersebut yang mempunyai penduduk setara sekitar 2500. Melalui kajian ini, telah terbukti bahawa aspirator mampu mencapai oksigen terlarut “dissolved oksigen” sebanyak antara 1 mg/L hingga 2 mg/L. Aspirator juga menggunakan kadar elektrik yang rendah berbanding dengan peralatan pengudaraan yang lain. Satu kajian perbelanjaan terperinci telah dijalankan selama enam bulan untuk penyelenggaran peralatan pengudaraan dan terbukti bahawa aspirator merupakan peralatan yang paling murah untuk diselenggarakan. Keputusan dari kajian ini merupakan faktor terpenting dalam pemilihan peralatan pengudara “aeration” yang sesuai dalam industri pembetungan pada masa hadapan. vi TABLE OF CONTENTS CHAPTER TITLE DECLARATION DEDICATION APPRECIATION ABSTRACT ABSTRAK TABLE OF CONTENTS LIST OF TABLES LIST OF FIGURES LIST OF APPENDICES PAGE i ii iii iv v vi vii viii ix CHAPTER 1 - INTRODUCTION 1.1. 1.2. 1.3. 1.4. 1.5. 1.6. 1.7. 1.8. 1.9. MALAYSIAN SEWERAGE SYSTEM IMPORTANCE OF A SEWERAGE SYSTEM SEWERAGE SYSTEM UNCONNECTED SEWERAGE SYSTEMS (TRADITIONAL TOILET) CONNECTED SEWERAGE SYSTEMS MECHANICAL PLANTS MONITORING EFFLUENT OBJECTIVE SCOPE OF STUDY 1 1 2 4 4 4 4 6 6 CHAPTER II - LITERATURE REVIEW 2.1. 2.2. 2.3. 2.4. INTRODUCTION OXYGEN TRANSFER FACTORS AFFECTING OXYGEN REQUIREMENTS AERATION 2.4.1. DIFFUSED-AIR AERATION DIFFUSES POROUS DIFFUSES NON-POROUS DIFFUSES OTHER AIR-DIFFUSION DIFFUSER PERFORMANCE BLOWERS AIR PIPING 2.4.2. MECHANICAL AERATORS AERATOR PERFORMANCE MECHANICAL AERATION 2.5. OXYGEN DIPERSION EFFICIENCY AND MIXING 7 7 9 10 13 13 15 16 17 17 20 22 22 23 23 24 CHAPTER III - METHODOLOGY 3.1. INTRODUCTION 3.2. MEASURING AERATION DISSOLVED OXYGEN 3.2.1 WINKLER TITRATION METHOD 3.2.2 MEMBRANE ELECTRODE METHOD 3.3. AERATION BASIN DISSOLVED OXYGEN PROFILES 26 27 28 CHAPTER IV - RESULTS & DISCUSSION 4.1. DISSOLVED OXYGEN 4.2. COSTING OPERATIONAL AND MAINTENANCE COSTING / CAPITAL COST 4.3. ELECTRICITY CONSUMTPTION CHAPTER V - 29 34 36 37 CONCLUSION AND SUGGESTION 5.1. CONCLUSION 5.2. SUGGESTION 40 41 REFERENCES 42 APPENDICES 43 vii LIST OF TABLES TABLES TITLES PAGES 1.1. EFFLUENT STANDARD BY ENVIRONMENT QUALITY ACT (1974) 5 2.1. EFFICIENCY OF VARIOUS AERATION SYSTEM IN KWH/KG 11 2.2. DESCRIPTION OF COMMONLY USED DEVICES FOR WASTEWATER AERATION 12 2.3. DESCRIPTION OF COMMONLY USED AIR DIFFUSION DEVICES 14 3.1. TYPE OF AERATION 26 4.1. DISSOLVED OXYGEN READINGS AT TAMAN GERMUDA 31 4.2. DISSOLVED OXYGEN READINGS AT TAMAN PAKATAN JAYA 31 4.3. DISSOLVED OXYGEN READINGS AT TAMAN ANDA 31 4.4. DISSOLVED OXYGEN READINGS AT TAMAN DESA KEBUDAYAAN 32 4.5. DISSOLVED OXYGEN READINGS AT TAMAN MEDAN PENGKALAN IMPIAN 32 4.6. CHART & SUMMARY OF AVERAGE DISSOLVED OXYGEN FOR DIFFERENT PLANTS 33 4.7. CAPITAL COST OF DIFFERENT TYPE OF AERATION DEVICES 35 4.8. SUMMARY OF OPERATIONAL AND MAINTENANCE COSTING FROM NOV’06-APRIL’06 36 4.9. SUMMARY OF ELECTRICITY CONSUMPTION FROM NOV’06-APRIL’06 38 viii LIST OF FIGURES FIGURES TITLES PAGES 1.1. WHAT ENTERS THE SEWERAGE SYSTEM FROM HOUSEHOLDS 3 1.2. MECHANICAL PLANTS 4 2.1. PICTURES OF BLOWERS 19 4.1. GRAPH DISSOLVED OXYGEN AT EACH TAMAN 33 4.2. GRAPH CAPITAL COST OF AERATION DEVICE 35 GRAPH SUMMARY OF OPERATIONAL AND MAINTENANCE COSTING 36 4.4 GRAPH SUMMARY OF ELECTRICITY CONSUMPTION 38 4.5 RESULTS OF MIXING CAPABILITIES AND FLOW PATTERN 39 ix LIST OF APPENDICES APPENDICES TITLES A. SUMMARY OF SAMPLING RESULTS FOR SEWERAGE PLANTS 43 PHOTOGRAPH OF VARIOUS AERATION DEVICE 44 B. PAGES 1 CHAPTER 1 INTRODUCTION 1.1 MALAYSIAN SEWERAGE SYSTEM An effective sewerage system ensures sewage being treated and disposed in a safe manner. Sewage includes human waste, urine and wastewater from kitchens, bathrooms and laundries. Sewerage systems are designed to collect, transfer, treat and dispose of human waste and wastewater. The system serves government, domestic, commercial and industrial properties in economical and environmentally responsible manner. In some countries the sewerage systems are designed to treat commercial and industrial sewage, toxic waste and manufacturing waste. However Malaysia’s sewerage system treats only human waste and household wastewater. Industrial and trade waste is treated separately by on site industrial waste treatment plant. None of the industrial waste or trade effluent is allowed to be discharged into existing sewerage system. 1.2 IMPORTANCE OF A SEWERAGE SYSTEM In certain places in Malaysia, where there are no sewerage systems, sewage ends up in waterways. This is usually due to toilets discharging straight into the waterways or sewer pipes discharging into the sea. Irrespective of the manner, in which the sewage ends up in our waterways, it can have detrimental effects on public health and the environment. Untreated human waste may carry infectious pathogenic organisms into our rivers. Such polluted rivers cause the spread of diseases like cholera, typhoid and hepatitis A. polluted rivers will contaminate sea life, particularly fish, cockles and prawns. People who eat this contaminated seafood can become seriously ill. Incidents of waterborne diseases such as these are not uncommon in Malaysia and have often been traced to sewage contaminated waters. 2 Other than the tremendous public health risk that untreated sewage poses, it also pollutes our environment. This is because sewage is able to consume oxygen normally found dissolved in river water, for example, will mean that eventually the river will lack sufficient oxygen to allow aquatic life and plants to survive. As a result of this, there will be drop in supply of seafood and aquatic plants. Aquatic plants produce oxygen, which keep the river alive. This vicious cycle will eventually result in the river being “dead”. A dead river emits an unpleasant odor, is unsightly, poses a health risk and does not support any plant or animal life. Sadly enough, today 72% of the rivers in Malaysia are polluted and 65% of all pollution loads has been identified as raw sewage. A step towards keeping our rivers clean is to treat all the sewage that is generated by the community. 1.3 SEWERAGE SYSTEM A modern and efficient sewerage system is vital of a developing nation such as ours if we are to successfully move towards Vision 2020. A reliable system will not only ensure that our increasing population is kept away from unnecessary health risks but also that our water resources are preserved for future generations. Sewage comprises of various pollutants that enter the sewerage system from domestic, commercial and industrial premises. It is more than just what goes down a toilet as it also includes wastewater from kitchen, bathrooms and laundries. Many of our activities at home generate pollutants that find their way into the sewerage system. Unless treated at a sewage treatment plant, raw sewage and pollutants can end up in our drains, rivers and coastal water. It risks public health, contaminating water resources and polluting the environment. In Malaysia, sewerage systems range from simple toilets providing little or no treatment to sewage to modern sewage treatment plants that employ mechanical means to treat large volumes of sewage to acceptable environmental standards. 3 WHAT ENTERS THE SEWERAGE SYSTEM FROM HOUSEHOLDS TOILET BATHROOM Faeces, toilet paper, Urine, Sanitary goods, medicine, Bacteria + viruses Disposable nappies, Toys Shower/ bath water Soap Hair Nail Clippings Toothpaste tubes Toothbrushes Blood SEWERAGE LINE KITCHEN LAUNDRY Sink Water Leftover food Fat + grease Cutlery + Glass Tea leaves Coffee Grinds Clothes Washing Detergents Lint Household Cleaning bleach Figure : 1.1: - Source : Indah Water Konsortium 1998 There are various sewerage systems that produce effluent of different standards. There are simple toilets, where sewage undergoes no treatment causing it to be highly damaging to our environment, to the more modern mechanical plants that are able to produce Standard “A” effluent. Sewerage systems can be categorized into two board categories that are unconnected sewerage systems and connected sewerage system. 4 1.4. UNCONNECTED SEWERAGE SYSTEMS (TRADITIONAL TOILETS) Simple toilets come under this category. These toilets were very popular before the modern day toilets came into the scene. Depending on its make, there are two types of traditional toilets. Firstly, toilets that do not treat the sewerage and secondly, toilets that partially treat the sewage. 1.5. CONNECTED SEWERAGE SYSTEMS In connected sewerage systems, sewage outlets from a number of premises are connected to a sewage treatment plant via a network of underground sewer pipes. Modern and efficient sewage treatment plants are the best way to treat sewage. Connected sewerage system generally comprise of a network of underground sewer pipes, pump stations, sewage treatment plants and sludge treatment facilities. Connected sewerage system generally operates by gravity so sewage treatment plants should be located at the outlet of drainage catchments to capture all the sewage from the catchments without the need for costly pumping. 1.6. MECHANICAL PLANTS In Malaysia, 11% of treatment plants are made up of various types of mechanical plants. These plants run on mechanical equipment that accelerates the breakdown of sewage. In the long term it is hoped that Malaysia’s sewerage system will be made more efficient by standardising the types of plants used. The diagram below shows an extended aeration plant where air is bubbled through sewage to accelerate the breakdown of sewage by bacteria. Figure : 1.2.: - Source : Indah Water Konsortium 1998 5 1.7. MONITORING EFFLUENT Various pollutants in sewage are analyzed in order to understand how sewage should be treated and to examine the effect of treated sewage (effluent) on the environment. Effluent from all sewage treatment plants is sampled at regular intervals and analyzed in modern laboratories to ensure it complys the required standards. These tests are carried out as part of a monitoring programmed to ensure that Indah Water meets its operational license conditions and that its’ treatment processes are operating efficiently. This provides for a cleaner and safer environment that improves the living conditions of Malaysia. The two most important parameters measured are biological oxygen demand (BOD) and suspended solids (SS). BOD is a measurement of the amount of oxygen sewage will consume over a given time. High BOD means that sewage will rapidly consume all the oxygen naturally dissolved in streams, rivers and lakes killing all aquatic life and turn the water septic and smelly. SS is a measurement of the undissolved material in sewage. High SS leads to sludge deposit in the waterways causing significant environmental degradation. Table 1.1.: – Effluent Standard by Environmental Quality Act (1974) Biochemical Suspended Oxygen Solids (SS) Demand (BOD) Oil & COD Grease STANDARD A 20 mg/L 50 mg/L 0 mg/L 50 mg/L STANDARD B 50 mg/L 100 mg/L 10 mg/L 100 mg/L If the effluent is discharged upstream of a water supply intake point, it should meet Standard A. For effluent that is discharged downstream, it should meet Standard B. These standards are set by the Environmental Quality Act (1974). 6 1.8. OBJECTIVE The objective of this study is to determine the most effective aeration device in wastewater industry by monitoring their oxygen transfer and costing which includes operational and maintenance cost, the capital cost and electricity consumption of each and every aeration device. 1.9. SCOPE OF STUDY The study consists of a thorough experimental work at five sewerage treatment plants using five sewerage treatment plants with five different aeration devices. The five sewerage treatment plants were observed based on their oxygen transfer level. It was carried out by using dissolved oxygen meter on a daily basis for one week. During the experiment, five sewerage treatment plants sampling were carried out in order to monitor the BOD level. These would enable to verify the most efficient aeration device while meeting the Standard as required by the regulators. There was also a study on the energy saving of different type of aeration device. It was carried out by monitoring the electricity consumption of aeration device for a period of six months. Capital cost and the operation and maintenance cost were also taken into consideration as factors before deciding the most effective aeration device. 7 CHAPTER II LITERATURE REVIEW 2.1. INTRODUCTION In the treatment of wastewater, an aeration system is ineffective in providing a completed and uniform transfer of oxygen without the capability to disperse oxygen throughout the entire process/basin. Although many systems are designed to aerate wastewater, they vary in their effectiveness in providing uniform oxygen dispersion. In this literature review, the importance of oxygen transfer and types of aeration system that normally being practiced in Malaysian sewerage system were discussed. 2.2. OXYGEN TRANSFER Oxygen is supplied to the mixed liquor in an aeration tank by dispersing air bubbles through sub-merged diffusers or by entraining air into the liquid by mechanical means. Air diffusers are porous plates, tubes or nozzles attached either to air piping on the bottom of the tank or to pipe headers that can be lifted out of the tank. Centrifugal blowers provide compressed air to the diffusers. Coarse-bubble devices are orifices or nozzles designed so that the discharged air is broken up into bubbles and dispersed in the surrounding liquid. Fine-bubble devices are porous materials that release air as fine bubble. Although each kind of diffuser has individual features, coarse-bubble nozzles are noted for maintenance-free operation, but finebubble diffusers have been the advantage of higher oxygen-transfer efficiency. Mechanical aerators are horizontal paddle, vertical turbine, and vertical-turbine draft tube. A horizontal rotor rotates partially submerged in an aeration channel. A vertical turbine may be surface unit or completely submerged with compressed air supplied under the rotating blade. For deep mixing, a vertical turbine may be in a draft tube so that liquid from the bottom of the tank is drawn up through the tube and discharged at the surface. 8 Oxygen transfer is a two-phase process. First, gaseous oxygen is dissolved in the wastewater by diffused or mechanical aeration. Then the dissolved oxygen is taken up by the microorganisms in metabolism of the waste organic matter. If the rate of oxygen utilization exceeds the rate of dissolution, the dissolved oxygen in the mixed liquor is depleted. The oxygen transfer from the air bubbles into solution. The K-factor depends on wastewater characteristics and more important on the physical features of knowledge of the basic concepts of oxygen transfer and uptake, is helpful in understanding operational problems generally associated with aeration processes. An oxygen deficiency in an aerating basin is possible if the rate of biological utilization exceeds the capabilities of the equipment. For example, organic overloading of an extended aeration system that is equipped with coarse-bubble diffusers set a shallow depth can result in a dissolved oxygen level of less than 0.5 mg/l even though the tank contents are being vigorously mixed by air bubbles emitting form diffusers. Perhaps a situation that occurs more frequently in practice is uneconomical operation from over aeration, producing a dissolved oxygen level greater than is necessary in the mixed liquor. Since biological activity is just as great at low levels and the transfer rate from air to dissolved oxygen increases with decreasing concentration, it is logical to operate a system as close to critical minimum dissolved oxygen as possible. Operation of the air compressors at reduced capacity, or even turning off one blower on weekends may be feasible to conserve electrical energy with no adverse effects to the biological process. Automatic control of blowers using dissolved oxygen probes has increased with improvements in control systems and the reliability of dissolved oxygen meters. (Metcalf and Eddy. 1991) 9 2.2. FACTORS AFFECTING OXYGEN REQUIREMENTS There are many factors that affect oxygen requirements of the bacteria in the aeration basin. But in this chapter, the discussion or explanation is only on two factors. The first factor is the direct relationship between the influent BOD concentration and the aeration basin dissolved oxygen. As the concentration of BOD entering the aeration basin rises, the amount of oxygen required to maintain DO levels rises also. If you don’t respond to increase influent BOD levels by increasing aeration rates, the level of dissolved oxygen in the aeration basin will drop. Some operators mistakenly assume that if dissolved oxygen drops, a toxic material has entered the aeration basin and killed or inhibited the bacteria. Actually, the opposite happens. Healthy bacteria are the agents that use the oxygen in the mixed liquor. If you kill or slow them down, the aeration basin dissolved oxygen will increase (Tim Hobson. 1992) There is another relationship concerning dissolved oxygen and the amount of bacteria in the aeration basin that you should be aware of. The amount of aeration required to maintain a given level of dissolved oxygen is directly proportional to the amount of bacteria you have in the aeration basin. As the concentration of bacteria in the basin goes up, aeration rates must be increased to maintain a given level of dissolved oxygen. If you are having trouble-maintaining dissolved oxygen and your solids level in the aeration basin is high, you can increase dissolved oxygen by washing more sludge to bring solids levels down. (Tim Hobson. 1992). 10 2.4. AERATION Aeration is the process by which the area of contact between water and air is increased, either by natural or mechanical means, resulting in air being suspended in air. Aeration is the most important operation in the treatment process, to provide oxygenation and mixing. The aeration facilities are designed to meet the calculated oxygen demand of the process while maintaining in the aeration tank minimum Dissolved oxygen of about 1-2 mg/l which is necessary for proper development of biological sludge. In addition to supplying dissolved oxygen, the aeration devices have also to provide adequate mixing ad agitation so that the mixed liquor suspended solids do not settle down. This way aeration increases the contact opportunity between the floc and sewerage. To summarize aeration serves the following three functions: (i) Oxygenation of the mixed liquor (ii) Flocculation of the colloids in sewage influent and (iii) Suspension of activated sludge floc. Following are the three methods, which are usually employed for the purpose of aeration in activated sludge process: (i) Diffused air aeration (ii) Mechanical aeration (iii) Combined diffused air and mechanical aeration One of the pollutants of water is organic matters. The reason why organic matters are considered water pollutants is that microorganism feed on them and in the process used up the dissolved oxygen needed for aquatic life. If the organic matters are in sufficient quantity, this can lead to nearly all the dissolved oxygen being used up, aquatic life killed, and to anaerobic conditions in which anaerobic microorganism produces hydrogen sulfite and other odorous constituents are produced. 11 The purpose of aeration is to improve their physical and chemical characteristics, to remove or reduction of objectionable taste and odor and to precipitate inorganic contaminants such as iron and manganese. In wastewater treatment, the purpose of aeration is to ensure continued aerobic conditions for the microorganism to degrade the organic matters. The efficiency of aeration systems can be measured in different ways. Different aeration systems have different efficiency. (Metcalf and Eddy. 2004) The exact efficiency of an aeration system is veries, depending on circumstances under which it is measured such as liquid depth, density of diffuser, energy level in the tank, etc.. The following Table 2.1 is a table of the efficiency of various aeration systems adapted to give values in kilowatt-hour per kilogram of oxygen. It is adapted from the table given by Environmental Dynamics. Table 2.1.: - Efficiency of various aeration system in kWH/kg Aeration system kWh/kg Mechanical aeration systems Brush aerators surface aeration Slow speed surface High speed splash surface aeration Induced surface aeration 0.47-0.66 0.47-0.55 0.51-0.66 1.10-1.64 Combination systems Submerged turbine Jets (pumps with compressors) 0.66-1.10 0.47-0.82 Diffused Aeration, Coarse Bubble Static tubes Wide band grid Misc. coarse bubble 0.47-0.82 0.47-0.66 0.47-0.82 Diffused Aeration, Fine Pore Ceramic disc or ceramic dome grid Flexible membrane disc Advanced technology membrane 0.23-0.33 0.23-0.41 0.14 12 Table 2.2.: - Description of commonly used devices for wastewater aeration Classification Submerged: Fine-bubble (fine-pore) system Description Use or application Bubbles generated with ceramic, plastic, or All types of activated-sludge flexible membranes (domes, tubes, disks, processes plates, or panel configuration) Coarse bubble Bubbles generated with orifices, injectors All types of activated-sludge and nozzles, or shear plates processes, channel and grit (nonporous) chamber aeration and aerobic system digestion Sparger turbine Low-speed turbine and compressed-air All types of activated-sludge injection processes and aerobic digestion Static tube mixer Short tubes with internal baffles designed Aerated lagoons and activatedto retain air injected at bottom of tube in sludge processes contact with liquid Jet Surface: Low-speed turbine aerator Compressed air injected into mixed liquid All types of activated-sludge as it pumped under pressure through jet processes, equalization tank mixing and aeration, and deep device tank aeration Large-diameter turbine used to expose Conventional activated-sludge processes, aeration lagoons, and liquid droplets to the atmosphere aerobic digestion High-speed floating aerator Small-diameter propeller used to expose Aerated lagoons and aerobic liquid droplets to the atmosphere digestion Aspirating Inclined propeller assembly Aerated lagoons ditch, channel Rotor-brush or Blades or disks mounted on a horizontal Oxidation central shaft are rotated through the liquid. aeration and aerated lagoons rotating-disk Oxygen is induced into the liquid by the assembly splashing action of the rotor and by exposure of liquid droplets to the atmosphere 13 2.4.1. DIFFUSED-AIR AERATION The two basic methods of aerating wastewater are (1) injection of air or pure oxygen into the wastewater with submerged diffusers or other aeration devices or (2) to agitation of the wastewater mechanically so as to promote solution of air from the atmosphere. A diffused-air system consists of diffuses that are submerged in the wastewater, header pipes, air mains and the blowers and appurtenances through which the air passes. The following discussion covers the selection of diffusers, the designs of blowers and air piping. Diffuses In the past, the various diffusion devices have been classified as either fine bubble or coarse bubble, with the connotation that fine bubbles were more efficient in transferring oxygen. The definition of terms and the demarcation between fine and coarse bubbles, however, have not been clear, but they continue to be used. The current preference is to categorize the diffused aeration systems by the physical characteristics of the equipment. 14 Three categories are defined: (1) porous or fine-pore diffusers, (2) nonporous diffusers, and (3) other diffusion devices such as jet aerators, aspirating aerators and U-tube aerators. The various types of diffused-air devices are described in Table 2.3 Table 2.3.: - Description of commonly used air diffusion devices Type of diffuser or device Transfer efficiency Description Porous Disk High Rigid ceramic disks mounted on airdistribution pipes near the tank floor. Dome High Dome-shaped ceramic diffusers mounted on air-distribution pipes near the tank floor. Membrane High Flexible porous membrane supported on disk mounted on air-distribution grid Panel Very High Rectangular panel with a flexible plastic perforated membrane Orifice Low Devices usually constructed of molded plastic and mounted in air-distribution pipes. Slotted tube Low Stainless-steel tubing containing perforations and slots to provide a wide band of diffused air Static Tube Low Stationary vertical tube mounted on basin bottom and functions like an air-lift pump NonPorous Fixed orifice 15 Porous Diffuses Porous diffuses are made in many shapes, the most common being domes, disks and membrane. Tubes are also used. Plates were once the most popular but are costly to install and difficult to maintain. Porous domes disks and membrane has largely supplanted plates in new installations. Domes, disks, or tube diffuses are mounted on or screwed into air manifold, which may run the length of the tank close to the bottom and along one or two sides, or short manifold headers may be mounted on movable drop pipes on one side of the tank. Dome and disk diffusers may also be installed in a grid pattern on the bottom of the aeration tank to provide uniform aeration throughout the tank. Numerous materials have been used in the manufacture of porous diffusers. These materials generally fall into the categories of rigid ceramic and plastic materials and flexible plastic, rubber or cloth sheaths. The ceramic materials consist of rounded passageways through which compressed air flows. As the air emerges from the surface pores, pore size, surface tension and air flow rate interact to produce the bubble size. Porous plastic materials are newer developments. Similar to the ceramic materials, the plastics contain a number of interconnecting channels or pores through which the compressed air can pass. Thin, flexible sheaths made from soft plastic or synthetic rubber have also been developed and adapted to disks and tubes. Air passages are created by punching minute holes in the sheath material. When the air is turned on, the sheath expands and each slot acts as variable aperture opening; the higher the air flow rate, the greater the opening. Rectangular panels that use a flexible polyurethane sheet are also used in activated-sludge aeration. The panels are constructed with a stainless steel frame and are placed on or close to the bottom of the tank and anchored. 16 Advantages cited for aeration panels are: (1) Ultra-fine bubbles are produced that significantly improve oxygen transfer and system energy efficiency (2) Large areas of the tank floor can be covered, which facilities mixing and oxygen transfer, and (3) Foul ants can be dislodged by “bumping”, i.e. increasing the airflow to flex the membrane. Disadvantages cited for aeration panels are: (1) The panel is a proprietary design and thus lacks competitive bidding, (2) The membrane has a higher head loss, which may affect blower performance in retrofit applications, and (3) Increased blower air filtration is required to prevent internal fouling. With all porous diffusers, it is essential that the air supplied be clean and free of dust particles that might clog the diffusers. Air filters, often consisting of viscous impingement and dry-barrier type, are commonly used. Precoated bag filters and electrostatic filters have also been used. The filters should be installed on the blower inlet. (S.K. Gang, 2004) Nonporous Diffuses Several types of nonporous diffusers are available. Nonporous diffusers produce larger bubbles than porous diffusers and consequently have lower aeration efficiency; but the advantages of lower cost, less maintenance and the absence of stringent air-purity requirements may offset the lower oxygen transfer efficiency and energy cost. Typical system layouts for orifice diffusers closely parallel the layouts for porous dome and disk diffusers; however single and dual roll spiral patterns using narrow or wide-band diffuser placement are the most common. Application for orifice and tube diffuser includes aerated grit chambers, channel aeration, flocculation basin mixing, aerobic digestion and industrial waste treatment. 17 In the static tube aerator air is introduced at the bottom of a circular tube that can vary in height from 0.5 to 1.25 m (1.5 to 4.0 ft). Internally, the tubes are fitted with alternately placed deflection plates to increase the contact of the air with the wastewater. Mixing is accomplished because the tube aerator acts as an airlift pump. Static tubes are normally installed in a grid-type floor coverage pattern. Other Air-Diffusion Devices Jet aeration combines liquid pumping with air diffusion. The pumping system re-circulates liquid in the aeration basin, ejecting it with compressed air through a nozzle assembly. This system is particularly suited for deep (>8 m) tanks. Aspirating aeration consists of a motor-driven aspirator pump. The pump draws air in through a hollow tube and injects it underwater where both high velocity and propeller action creates turbulence and diffuses the air bubbles. The aspirating device can be mounted on a fixed structure or on pontoons. U-tube aeration consists of a deep shaft that is divided into two zones. Air is added to the influent wastewater in the down comer under high pressure; the mixture travels to the bottom of the tube and then backs to the surface. The great depth to which the air-water mixture is subjected results in high oxygen transfer efficiencies because the high pressure forces all the oxygen into solution. U-tube aeration has particular application for high-strength wastes. Diffuser Performance The efficiency of oxygen transfer depends on many factors, including the type, size, and shape of the diffuser; the air flow rate; the depth of submersion; tank geometry including the header and diffuser location; and wastewater characteristics. Aeration devices are conventionally evaluated in clean water and the results adjusted to process operating conditions through widely used conversion factors. Typical clean water transfer efficiencies and air flow rates for various diffused-air devices. 18 Typically, the standard oxygen transfer efficiency (SOTE) increases with depth; the transfer efficiencies for the 4.5-m (15-ft) depth, the most common depth of submergence. Data on the variation of SOTE with water depth for various diffuser types can be found in WPCF (1988). The variation of oxygen transfer efficiencies with the type of diffuser and diffuser arrangements. Additional data on the effects of diffuser arrangement on transfer efficiency are reported in V.S. EPA (1989). Oxygen transfer efficiency (OTE) of porous diffusers may also decrease with use due to internal clogging or exterior fouling. Internal clogging may be due to impurities in the compressed air that have not been removed by the air filters. External fouling may be due to the formation of biological slimes or inorganic precipitants. The effect of fouling on OTE is described by the term F. The rate at which F decreases with time is designated ƒF which is expressed as the decimal fraction of OTE lost per unit time. The rate of foul will depend on the operating conditions, changes in wastewater characteristics, and the time in service. The fouling rates are important in determining the loss of OTE and the expected frequency of diffuser cleaning. Fouling and the rate of fouling can be estimated by (1) conducting full-scale OTE tests over a period of time, (2) monitoring aeration system efficiency and (3) conducting OTE tests of fouled and new diffusers. Factors commonly used to convert the oxygen transfer required for clean water to wastewater are the alpha, beta, and theta factors. The alpha factor, the ratio of the KLa of wastewater to the KLa of clean water, is especially important because alpha factor varies with the physical features of the diffuser system, the geometry of the reactor, and the characteristics of the wastewater. Wastewater-constituents may affect porous diffuser oxygen transfer efficiencies to a greater extent than other aeration devices, resulting in lower alpha factors. The presence of constituents such as detergents, dissolved solids, and suspended solids can affect the bubble shape and size and result in diminished oxygen transfer capability. 19 Values of alpha varying from 0.4 to 0.9 have been reported for fine-bubble diffuser systems (Hwang and Stenstrom, 1985). Therefore, considerable care must be exercised in the selection of the appropriate alpha factors. Another measure of the performance of porous diffusers is the combination of the alpha and fouling factors, designated by the term αF In a number of in-process studies, the values of ∂F have ranged widely, from 0.11 to 0.79 with a mean of < 0.5, and were significantly lower than anticipated (U.S. EPA, 1989). The variability of αF was found to be site-specific, and demonstrated the need for the designer to investigate and evaluate carefully the environmental factors that may affect porous diffuser performance in selecting an appropriate α or αF factor. Because the amount of air used per kilogram (pound) of BOD removed varies greatly from one plant to another, and there is risk in comparing the air use at different plants, not only because of the factors mentioned above but also because of different loading rates, control criteria, and operating procedures. Extra-high air flow rates applied along one side of a tank reduce the efficiency of oxygen transfer and may even reduce the net oxygen transfer by increasing circulating velocities. The result is a shorter residence time of air bubbles as well as larger bubbles with less transfer surface. (Metcalf and Eddy. 2004) Methods of cleaning porous diffusers may consist of refining of ceramic plates, high-pressure water sprays, brushing, or chemical treatment with acid or caustic baths. Additional details on cleaning methods may be found in U.S. EPA (1989). . Figure 2.1 - Picture of blowers 20 Blowers There are three types of blowers commonly used for aeration: centrifugal, rotary lobe positive displacement and inlet guide vane-variable diffuser. Centrifugal blowers (see Figure 2.1) are almost universally used where the unit capacity is greater than 425 m3/min (15,000 ft3/min) of free air. Rated discharge pressures range normally from 48 to 62 kN/m2. Centrifugal blowers have operating characteristics similar to a low-specific-speed centrifugal pump. The discharge pressure rises from shutoff to a maximum at about 50 percent of capacity and then drops off. The operating point of the blower is determined, similar to a centrifugal pump, by the intersection of the head-capacity curve and the system curve. In wastewater-treatment plants, the blowers must supply a wide range of airflows with a relatively narrow pressure range under varied environmental conditions. A blower usually can only meet one particular set of operating conditions efficiently. Because it is necessary to meet a wide range of airflows and pressures at a wastewater treatment plant, provisions have to be included in the blower system design to regulate or turn down the blowers. Methods to achieve regulation or turndown are: (1) Flow blow off or bypassing, (2) Inlet throttling (3) Adjustable discharge diffuser (4) Variable speed driver, and (5) Parallel operation of multiple units. Inlet throttling and an adjustable discharge diffuser are applicable only to centrifugal blowers; variable-speed drivers are more commonly used on positive-displacement blowers. Flow blow off and bypassing is also an effective method of controlling surging of a centrifugal blower, a phenomenon that occurs when the blower operates alternately at zero capacity and full capacity, resulting in vibration and overheating. Surging occurs when the blower operates in a low volumetric range. 21 For higher discharge pressure applications [> 55 kN/m2] and for capacities smaller than 425 m3/min (15,000 ft3/min) of free air per unit, rotary-lobe positive displacement blowers are commonly used. The positive-displacement blower is a machine of constant capacity with variable pressure. The units can throttle, but capacity control can be obtained by the use of multiple units or a variable speed drive. Rugged inlet and discharge silencers are essential. A relatively new blower design, the inlet guide vane-variable diffuser that developed in Europe, mitigates some of the problems and considerations associated with standard centrifugal and positive-displacement aeration blowers. The design based on a single-stage centrifugal operation that incorporates actuators to position inlet guide vane and variable diffusers to vary blower flow rate and optimize efficiency The blowers are especially well suited to applications with medium to high fluctuations in inlet temperature, discharge pressure, and flow rate. Blower capacities range from to 1700 m3/min (3000 to 60,000 ft3/min) at pressures up to 170 kN/m2. Turndown rates of up to 40 percent of maximum capacity are possible without significant reduction in operating efficiency over the range of operation. Principal disadvantages are high initial cost and a sophisticated computer control system to ensure efficient operation. The performance curve for a centrifugal blower is a plot of pressure versus inlet volume and resembles the performance curve for a centrifugal pump. The performance curve typically is a falling-head curve where the pressure decreases as the inlet volume increases. Blowers are rated at standard air conditions, defined as a temperature of 20°C (68°F), a pressure of 760 mm Hg, and a relative humidity of 36 pen Standard airs has a specific weight of 1.20 kg/m3. The air density aft the performance of a centrifugal blower; any change in the inlet air temperature barometric pressure will change the density of the compressed air. 22 The greater the density, the higher the pressure will rise. As a result, greater power is needed for compression process. Blowers must be selected to have adequate capacity for a hot summer day, and be provided with a driver with adequate power for the cold set winter weather. Air Piping Air piping consists of mains, valves, meters, and other fittings that port compressed air from the blowers to the air diffusers. Because the pressure [less than 70 kN/m2 J, lightweight piping can be used. The piping should be sized so that losses in air headers and diffuser manifolds small in comparison to the losses in the diffusers. Typically, if head losses in the air piping between the last flow-split device and the farthest diffuser are less than 10 percent of the head loss across the diffusers, good air distribution through the aeration basin can be maintained. Valves and control orifices are an important consideration in design (WEF, 1998b). 2.4.2. Mechanical Aerators Mechanical aerators are commonly divided into two groups based on major design and operating features: aerators with vertical axis and aerators with horizontal axis. Both groups are further subdivided into surface and submerged aerators. In surface aerators, oxygen is entrained from the atmosphere; in submerged aerators, oxygen is entrained from the atmosphere and, for some types, from air or pure oxygen introduced in the tank bottom. In either case, the pumping or agitating action of the aerators helps to keep the contents of the aeration tank or basin mixed. In the following discussion, the various types of aerators will be described, along with aerator performance and the energy requirement for mixing. (D.Lal. 2004) 23 Aerator Performance Mechanical aerators are rated in terms of their oxygen transfer rate expressed as kilograms of oxygen per kilowatt-hour (pounds of oxygen per horsepower-hour) at standard conditions. Standard conditions exist when the temperature is 20°C, the dissolved oxygen is 0.0 mg/L, and the test liquid is tap water. Testing and rating are normally done under non-steady-state conditions using fresh water, deaerated with sodium sulfite. Commercial-size surface aerators efficiency ranges from 1.20 to 2.4 kg 02kW·h. Oxygen transfer data for various types of mechanical aerators. Design engineer should accept efficiency claim for aerator performance only when they are supported by actual test date for actual model and size of aerator under consideration. Mechanical Aeration Two major types of mechanical aeration equipment are commonly used for post-aeration systems: low-speed surface aerators and submerged turbine aerators. Low-speed surface aerators are preferred because they are usually the most economical, except where high oxygen transfer rates are required. For high oxygen transfer rates, submerged turbine units are preferred. Most installations consist of two or more aerators in rectangular basins. Detention times for post-aeration using either mechanical or diffused-air aeration is usually 10 to 20 min at peak flow rates. 24 Aeration rates in mechanically aerated tanks center controlled in several ways: • Changing aerator speed • Changing the amount of “bite” that the aerator makes in the mixed liquor. This increases of decreases the amount of energy transferred to the water (and the amount of aeration) • Changing the numbers of aerators in services • Changing the amount of time the aerators are “ON” in a given period. When using this type of aeration control, be careful to keep “OFF” times under an hour in duration. An “OFF” time of 10 – 15 minutes is even better because it is not advisable for the bacteria to spend much time in an anaerobic environment and unaerated mixed liquor organisms or it will start to active aneraobically. 2.5. OXYGEN DISPERSION EFFICIENCY AND MIXING In the treatment of wastewater, an aeration system is ineffective in providing a complete and uniform transfer of oxygen throughout the entire basin. Although many systems are designed to aerate wastewater, they vary in their effectiveness in providing uniform oxygen dispersion. Typical aeration systems such as diffused air, surface splashers, and rotor have limited areas of influence, causing short-circuiting, dead zones, and only partial aeration. Because the Triton aeration/mixer technology procedures a horizontal and circular flow pattern, the equipment provides whole basin circulation. Conventional splashing type system, pump water upward and throws it into the air, creating a high aerosol environment. Overcoming gravity also consumes large amounts of energy. The area of influence is confined. Short-circuiting and dead spots may occur due to inadequate basin mixing. Sludge deposits typically accumulate at corners and between units in the basin, creating and even greater oxygen demand. 25 Blower/diffuser systems introduce compressed air through diffusers into the water from the bottom of the basin. More horsepower (higher energy consumption) is required to overcome the water head resistance. The mixing pattern is a limited vertical column as air rises from the diffuser heads to the water’s surface. Over time, the system’s diffuser heads clog as solids and biofilm accumulated. This reduces oxygen transfer efficiency. Rotor system proper water into the air creating an aerosol environment that releases offending odour into the air. These systems are expensive to operate both in electrical consumption and maintenance. Rotors are inefficient in suspending solids uniformly, having similar mixing constraints of splasher type aerator. The aspirator a horizontal circular flow pattern is created and controlled for maximum treatment efficiency. (Mark J. Hammer. 2004) 26 CHAPTER III METHODOLOGY 3.1. INTRODUCTION The study was carried out by choosing five different sewerage treatment plants (STP) with five different aeration devices. The STP and type of aeration specification is stated in Table 3.1. Table 3.1. – Type of Aeration STP Type PE Aeration Devices HP Taman Germuda Oxidation Ditch 1465 Brush aerator 2 nos x 5.5kw Taman Anda Aerated Lagoon 2300 Tornado 2 nos x 5.5kw Depa Kebudayaan Aerated Lagoon 1420 Surface aerator 2 nos x 5.5kw Taman PakatanJaya Oxidation Ditch 2465 Aspirator 2 nos x 3.7kw 1050 Diffusers 2 nos x 5.5kw Taman Idaman Pengkalan Extented Aeration (Blowers) All the above Sewerage Treatment Plants which are operating with different aeration device operates 16 hours daily except Taman Pakatan Jaya operates only 8 hours were monitored by using membrane electrode dissolved oxygen meter on a daily basis for a week to determine the device efficiency. Samplings were also done on each Sewerage Treatment Plant while the above study was being carried out. The samples were then sent to Taiping Indah Water Konsortium laboratory to determine the effluent results mainly on BOD. Subsequently the dissolved oxygen readings were compared with the sampling result to determine the most efficient aeration system. 27 3.2. MEASURING AERATION DISSOLVED OXYGEN There are two common methods for measuring aeration basin dissolved oxygen, the Winkler Titration Method and the Membrane Electrode Method. As for this study case I used the membrane electrode method at difficult Sewerage Treatment Plants 3.2.1. WINKLER TITRATION METHOD This method is commonly used when the Dissolved Oxygen meter cannot be obtained. If you use this method, be sure that you use the modification specifically designed for measurement of aeration basin of dissolved oxygen. In the standard Winkler procedure for measuring of dissolved oxygen, aerobic bacteria in the mixed liquor sample continue to remove dissolved oxygen from the sample even while you are preparing to run the test. This causes measured dissolved oxygen levels to be lower than true levels. In the dissolved oxygen procedure modified for measuring aeration basin dissolved oxygen, the technician adds a solution containing copper sulfate and sulfuric acid to the sample container before collecting the mixed liquor sample. As the sample is collected the copper sulfatesulfuric acid solution kills aerobic organisms and prevents them from using dissolved oxygen during the test. The procedure for the Winkler method is readily available in most texts and lab manuals for wastewater treatment plant operation. 3.2.2. MEMBRANE ELETRODE METHOD This is other common way of determining aeration basin dissolved oxygen. I used this method because of it reliability speed and also easier to handle. The equipment consists of a meter, probe and cable and is available at any major scientific equipment supplier. After calibration, I measured the dissolved oxygen in the aeration basin on all the five Sewerage Treatment Plants by directly placing the probe where I want a dissolved oxygen reading. I attached the probe to a light-weight pole so it can be positioned exactly where they want it. The probe is often attached to the pole upside down (membrane end up). 28 This prevents air bubbles from getting trapped against the membrane and causing high readings. After positioning the probe in the mixed liquor, switch the meter to get a temperature reading. I recorded the temperature of the mixed liquor for later reference. Now switch the meter and read the dissolved oxygen. It may take as much as a minute for the meter to stabilize around a specific dissolved oxygen reading. 3.3. AERATION BASIN DISSOLVED OXYGEN PROFILES Most aeration basins won’t have dissolved oxygen concentration that is the same all through the tank. Since the dissolved oxygen reading is high and low, I took few readings with a minimum of 0.5mg/l. The bacteria in the basin failed to perform properly when the dissolved oxygen drops below that level for more than a few minutes. Therefore, a reading at the location, of the lowest dissolved oxygen concentration is the most important factor. To find this location, you need to have a dissolved oxygen profile in the basin. To perform an aeration basin dissolved oxygen profile, you will need a dissolved oxygen meter with a 4.5m cord on the probe. Mark the probe cord in one meter intervals and attach to a long pole so I can position it precisely where I want it. Testing of Dissolved oxygen concentrations should be done at selected points across the length and width of the tank. Measure the Dissolved oxygen at designated depths (intervals of 2-3 meters) for each selected sampling point. Plot the cross sectional measurements along the length of the tank that results from plotting the Dissolved oxygen results. As you can see the Dissolved oxygen in the example tank, varied a great deal from one location to another. The location for taking regular Dissolved oxygen measurement, in this case, should be in the center, near the bottom of the tank where the region of lowest Dissolved oxygen is located. Adjust aeration rates to maintain dissolved oxygen of around 1.0 mg/L here and you can be reasonable certain there is enough Dissolved oxygen in the rest of the aeration basin. There was a comparison on costing in terms of energy saving of the aeration device while maintaining the required Dissolved oxygen level. Wastewater treatment facilities must meet strict effluent discharge permit standards to stay in compliance with government regulations. 29 CHAPTER IV RESULTS & DISCUSSION 4.1. DISSOLVED OXYGEN From the case study the below data were collected for further analysis in order to achieve the objective of this study. The date collected for all five sewerage treatment plants are attached as Table 4.1, Table 4.2, Table 4.3, Table 4.4 & Table 4.5. T a b le 4 .1 . D IS S O L V E D O X Y G E N R E A D IN G S A T T M N G E R M U D A L O C A T IO N TM N GERM UDA TYPE S A M P L IN G D A T E OD 8 .3 .0 7 D IS S O L V E D O X Y G E N IN M G /L A T G IV E N D IS T A N C E IN F R O N T O F A E R A T IO N D E V IC E (B R U S H A E R A T O R ) DEPTH O F 3M 8 .3 0 A M T IM E LENG TH 1 .0 0 P M 4 .3 0 P M 0 .5 m 1 .5 m 0 .5 m 1 .5 m 0 .5 m 1 .5 m 0 6 -0 3 -0 7 D O R E A D IN G 4 .6 4 .2 4 .5 4 .2 5 4 .3 0 7 -0 3 -0 7 D O R E A D IN G 4 .9 4 .4 3 .9 3 .7 5 .3 4 .5 0 8 -0 3 -0 7 D O R E A D IN G 3 .8 3 .5 3 .7 3 .1 4 .2 3 .8 0 9 -0 3 -0 7 D O R E A D IN G 5 .2 4 .8 5 .7 5 .1 4 .9 4 .6 1 0 -0 3 -0 7 D O R E A D IN G 5 4 .7 4 .8 4 .3 5 .2 4 .7 T a b le 4 .2 . D IS S O L V E D O X Y G E N R E A D IN G S A T T M N P A K A T A N J A Y A L O C A T IO N TAM AN PAKATAN JAYA TYPE OD S A M P L IN G D A T E 2 8 .2 .0 7 DEPTH O F 3M T IM E LENG TH 2 4 -0 2 -0 7 D O R E A D IN G D IS S O L V E D O X Y G E N IN M G /L A T G IV E N D IS T A N C E IN F R O N T O F A E R A T IO N D E V IC E (A S P IR A T O R ) 8 .3 0 A M 1 .0 0 P M 4 .3 0 P M 0 .5 m 1 .9 1 .5 m 1 .7 0 .5 m 2 .1 2 5 -0 2 -0 7 D O R E A D IN G 2 1 .8 1 .9 2 6 -0 2 -0 7 D O R E A D IN G 5 .1 1 .9 2 .3 6 2 7 -0 2 -0 7 D O R E A D IN G 2 .1 2 2 .3 2 8 -0 2 -0 7 D O R E A D IN G 1 .8 1 .6 2 1 .5 m 1 .9 0 .5 m 2 .1 1 .5 m 2 1 .8 1 .8 1 .6 2 .1 2 .3 2 2 .1 2 .3 2 .1 1 .8 2 .1 2 T a b le 4 .3 . D IS S O L V E D O X Y G E N R E A D IN G S A T T M N A N D A L O C A T IO N TM N ANDA TYPE AL S A M P L IN G D A T E 5 .3 .0 7 D IS S O L V E D O X Y G E N IN M G /L A T G IV E N D IS T A N C E IN F R O N T O F A E R A T IO N D E V IC E (T O R N A D O ) DEPTH O F 3M 8 .3 0 A M T IM E LENG TH 1 .0 0 P M 4 .3 0 P M 0 .5 m 1 .5 m 0 .5 m 1 .5 m 0 .5 m 1 .5 m 0 3 -0 3 -0 7 D O R E A D IN G 5 4 .6 5 .3 5 .1 5 .3 5 .2 0 4 -0 3 -0 7 D O R E A D IN G 4 .8 4 .4 5 4 .8 4 .9 4 .7 0 5 -0 3 -0 7 D O R E A D IN G 5 .4 5 .6 5 .1 4 .6 5 .3 5 .1 0 6 -0 3 -0 7 D O R E A D IN G 5 .3 5 4 .9 4 .4 5 4 .8 0 7 -0 3 -0 7 D O R E A D IN G 5 5 .1 4 .9 4 .6 4 .8 4 .6 30 Table 4.4. DISSOLVED OXYGEN READINGS AT TMN DESA KEBUDAYAAN LOCATION TMN DESA KEBUDAYAAN TYPE AL SAMPLING DATE 21.3.07 DISSOLVED OXYGEN IN MG/L AT GIVEN DISTANCE IN FRONT OF AERATION DEVICE (SURFACE AERATOR) DEPTH OF 3M 8.30AM TIME LENGTH 1.00PM 4.30PM 0.5m 1.5m 0.5m 1.5m 0.5m 1.5m 19-03-07 DO READING 5.6 5.1 5.8 5 5.9 5.1 20-03-07 DO READING 5.8 5 6.1 5.5 5.8 5 21-03-07 DO READING 4.6 4 5.2 4.6 6 5.1 22-03-07 DO READING 5.2 4.6 5.6 4.9 6.1 5.2 23-03-07 DO READING 4.9 4.4 5.9 5.2 6 5.3 Table 4.5. DISSOLVED OXYGEN READINGS AT MEDAN PENGKALAN IMPIAN LOCATION MEDAN PENGKALAN IMPIAN TYPE EA SAMPLING DATE DEPTH OF 3M TIME LENGTH DISSOLVED OXYGEN IN MG/L AT GIVEN DISTANCE IN FRONT OF AERATION DEVICE (DIFFUSER WITH BLOWERS) 8.30AM 1.00PM 4.30PM 0.5m 1.5m 0.5m 1.5m 0.5m 1.5m 19-03-07 DO READING 4.8 5.1 6.2 5 5.6 5.1 20-03-07 DO READING 5.2 4.7 5.6 5.5 5.8 5 21-03-07 DO READING 4.6 6 5.2 4 6 5.1 22-03-07 DO READING 5.2 4.6 4 4.9 5.9 5.6 23-03-07 DO READING 4.9 4.4 5.9 5 6.1 5.3 31 TABLE 4.6: CHART & SUMMARY OF AVERAGE DISSOLVED OXYGEN FOR 5 DIFFERENT PLANTS TMN GERMUDA TMN PAKATAN (BRUSH JAYA (ASPIRATOR) AERATOR) TMN AVE.DO (MG/L) 1.9 4.5 MEDAN PENGKALAN TMN ANDA IMPIANA (TORNADO) (DIFFUSER WITH BLOWER) TMN DESA KEBUDAYAAN (SURFACE AERATOR) 5.3 4.9 BCOD~25 MG/L (REFER TO SAMPLING DATA) DISSOLVED OXYGEN (MG/L) 6 5 4 3 2 1 0 TMN PAKATAN JAYA (ASPIRATOR) TMN GERMUDA (BRUSH AERATOR) AVE.DO (MG/L) TMN DESA KEBUDAYAAN (SURFACE AERATOR) TMN ANDA (TORNADO) TAMAN FIGURE 4.1 : GRAPH DISSOLVED OXYGEN AT EACH TAMAN MEDAN PENGKALAN IMPIANA (DIFFUSER WITH BLOWER) 5.3 32 Dissolved oxygen readings were collected for each and every STP on different week so it was easier on the sampling purpose. This is because it takes 3 to 4 days for the sampling results to be analysed. The sampling results from Indah Water Konsortium Sdn. Bhd. (IWK) were sent to Taiping laboratory so that a comparison can be done on each and every aeration device. In actual fact air was added to an aeration basin to keep the wastewater and activated sludge mixed. In these way bacteria was exposed to fresh food all the time. The other important reason for adding air to the aeration basin was to provide dissolved oxygen which is actually oxygen which has been dissolved in water. In real fact, oxygen is not very soluble in water. At 20 degrees Celsius only 9.2 mg/l of oxygen can be dissolved into water. We need to add to the aeration basin to provide an environment in the aeration basin that will encourage the growth of many bacteria. The Dissolved oxygen test was very crucial because it measures the amount of oxygen available to the facultative activated sludge organisms. In general aeration rates that provided dissolved oxygen of between 1.0 and 2.0 mg/l were adequate for maintaining efficient, healthy activated sludge organisms. 33 If the Dissolved oxygen drops below 1.0 and especially below 0.5 mg/l , the treatment efficiency was begin to suffer because the activated sludge organisms was starting to function anaerobically. On the other hand, if the dissolved oxygen was maintained above 2.0 mg/l, it would be wasting power (that power providing dissolved oxygen to the aeration basin) dissolved oxygen. Therefore, careful measurement and control of dissolved oxygen in the aeration basin were necessary to provide efficient treatment without wasted energy. This was evident with the sampling result that was done on all type of aeration devices that was discussed earlier. It was actually inter-related between sampling results, dissolved oxygen and electricity consumption. From the result it was evident that 2 numbers 3.7kw aspirator operating only 8 hours a day in Taman Pakatan Jaya could achieve dissolved oxygen of 1.9 mg/l compared to the other, achieving higher dissolved oxygen while operating on 16 hours daily. The brush aerator at Taman Germuda was recorded at 4.5 mg/l dissolved oxygen. The aerator at Taman Desa Kebudayaan was recorded at 5.3 mg/l dissolved oxygen while the tornado at Taman Anda and the diffusers with blowers at Medan Pengkalan Impiana were recorded at 4.9 mg/l and 5.3 mg/l respectively. 34 4.3. COSTING Capital cost and comparison of each and every aeration system in RM is shown in Table 4.7 and Figure 4.2. It may differ from time to time due to financial constraints. Only 5 models are captured that mainly being operated in the waste water industry:TABLE 4.7 : CAPITAL COST OF DIFFERENT TYPE OF AERATION DEVICE Model (kw) 3.7kw 5.5kw 7.0kw OBSELETE OBSELETE OBSELETE Tornado c/w set 30,000 43,000 50,000 Aspirator c/w set 25,000 40,000 45,000 Surface Aerator c/w set 15,000 20,000 25,000 Diffuser (blowers cost) 10,000 15,000 20,000 Type Brush Aerator CAPITAL COST OF AERATION DEVICE 60,000 50,000 TOTAL 40,000 30,000 20,000 10,000 0 Tornado c/w set Aspirator c/w set Surface Aerator c/w set Diffuser (blowers cost) 3.7kw 5.5kw TYPE OF AERATION DEVICE 7.0kw FIGURE 4.2 : GRAPH CAPITAL COST AERATION DEVICE 35 TABLE 4.8 : SUMMARY OF OPERATIONAL AND MAINTENANCE COSTING FROM NOV'06 - APRIL'07 MONTH NOV'06 DEC'06 JAN'07 FEB'07 MAC'07 APR'07 TOTAL (IN RM) TAMAN TMN PAKATAN JAYA (ASPIRATOR) 594 TMN GERMUDA (BRUSH AERATOR) 1,220 6,880 TMN DESA KEBUDAYAAN (SURFACE AERATOR) 1,260 1,500 TMN ANDA (TORNADO) 1,890 780 870 2,560 MEDAN PENGKALAN IMPIANA (DIFFUSER WITH BLOWER) 515 714 3,043 8,580 3,485 18,945 650 200 573 3,983 1,800 600 3,270 300 5,730 SUMMARY OF OPERATIONAL & MAINTENANCE COSTING 20,500 18,500 COSTING (RM) 16,500 14,500 12,500 10,500 8,500 6,500 4,500 2,500 500 TMN PAKATAN JAYA (ASPIRATOR) TMN GERMUDA (BRUSH AERATOR) TMN DESA KEBUDAYAAN (SURFACE AERATOR) TOTAL (IN RM) TMN ANDA (TORNADO) MEDAN PENGKALAN IMPIANA (DIFFUSER W ITH BLOW ER) TAMAN FIGURE 4.3 : GRAPH SUMMARY OF A OPERATIONAL & MAINTENANCE COSTING Long term expenditure that a wastewater treatment plant endures becomes extremely expensive for those choosing to select knockoff equipment. Original equipment was designed to operate with very little maintenance and few parts replacement for extended periods of time. Typical knockoff equipment is lucky if it ever reaches a five-year lifetime. Although the knockoff equipment might be as little as 50 per cent the cost of the original product and attractive to the customer/contractor during the bidding process, when factor in its failure ratio, frequent parts failure and its inability to perform, the decision is quite easy. 36 This high cost of operation endured by selecting the knockoffs ends up causing the client to pay sometimes over double the amount in operation expenditures over a 10 year period of time. The decision to choose the cheapest knockoff to save a small portion of investment usually ended up creating numerous headaches and costing them (and the public taxpayers) a heap of cash. Estimated capital cost of each and every aeration system in this study is stated in below table. It may vary from time to time due to financial stability. Although it appears that diffusers are the cheapest among the devices but this is only the cost of blower. The costing of diffusers is not included because each aeration tank that uses this device are different size thus making the costing vary. Each diffusers cost are around RM 100.00. Usually an aeration tank would be using around 50 numbers of diffusers. Surface aerators would be costing around RM 15,000.00 (3.7 kw) to RM 25,000.00 (7.0 kw). Aspirators will be costing slightly cheaper compare to tornado. Aspirators costing are from RM 25,000.00 (3.7 kw) to RM 45,000.00 (7.0 kw). Tornado costing are from RM 30,000.00 (3.7 kw) to RM 50,000.00 (7.0 kw).There are no costing on brush aerators because it is an obsolete product which is no more in the market. Even-though the costing varies, but in terms of operational and maintenance, diffusers is the most difficult to be maintained due to frequent choking. Aspirators are the cheapest and the easiest to maintain compared to others as shown in Table 4.7 and Table 4.8. This is due to aspirators are the latest product in the market. 37 4.3. ELECTRICITY CONSUMPTION Summary of TNB bill for each STP for a period of six months are stated in the table 4.9 and the comparison of electricity consumption in Figure 4.4. TABLE 4.9: SUMMARY OF ELECTRICITY CONSUMPTION FROM NOV'06 - APRIL'07 MONTH TAMAN NOV'06 DEC'06 JAN'07 FEB'07 MAC'07 APR'07 Average kw RM kw RM kw RM kw RM kw RM kw RM kw 2,338 678 2,050 594 2,066 599 1,736 503 1,003 290 na na 1,839 533 TMN GERMUDA (BRUSH AERATOR) 590 171 1,295 375 na na 728 211 1,505 436 437 126 911 264 TMN DESA KEBUDAYAAN (SURFACE AERATOR) 2,753 798 588 170 577 2,730 731 1,865 540 2,423 702 TMN ANDA (TORNADO) 4,808 1,394 4,060 1,177 3,302 850 3,465 1,004 3,306 958 3,646 1,056 MEDAN PENGKALAN IMPIANA (DIFFUSER WITH BLOWER) 3,884 1,126 3,980 1,154 4,870 1,412 4,948 1,434 4,364 1,265 3,872 1,122 TMN PAKATAN JAYA (ASPIRATOR) 4,612 1,337 1,990 957 2,932 COSTING (RM) SUMMARY OF ELECTRICITY CONSUMPTION 1,300 1,200 1,100 1,000 900 800 700 600 500 400 300 200 100 TMN PAKATAN TMN GERMUDA JAYA (ASPIRATOR) (BRUSH AERATOR) Average TMN DESA KEBUDAYAAN (SURFACE AERATOR) TMN ANDA (TORNADO) TAMAN FIGURE 4.4 : GRAPH SUMMARY OF ELECTRICAL CONSUMPTION MEDAN PENGKALAN IMPIANA (DIFFUSER WITH BLOWER) RM 4,320 1,252 38 The operational requirement for wastewater system differs according to variation flow and strength of wastewater. The peak energy demand usually occurred from midday to early evening hours when other peak demands for electricity occurs in the community. As the wastewater load changes during the course of the day the requirements for aeration, pumping and solid processing change accordingly. Some sewerage treatment plants modified schedules for equipment operation to meet the load condition while others operate their devices such as aeration devices continuously at full capacity regardless of the electricity consumption. Sewerage treatment plant that has biological treatment for nutrient removal used 30 to 50 percent more electricity for aeration, pumping and solid processing. With introduction of new technologies for wastewater treatment, the energy requirements will change. The impacts can either reduce in electricity or increase due to higher level of treatment. Refer to the electricity data collected for the five different aeration system if appears that Taman Pakatan Jaya (aspirator) needed an average of 1,839kw per month while meeting the biological oxygen demand of Standard B requirement. Although Taman Germuda (Brush Aerator) recorded a mere 911kw per month, it was found that the brush aerator was unable to function efficiently due some mechanical problem that continued for three months. Apparently this caused the electricity consumption to be very low compared to the others which recorded between 2423 kw till 4320 kw per month. 39 To further prove that aspirator performed well by providing effective aeration Auburn University in United Kingdom conducted an experiment on mixing capability and flow pattern. The results were as below:(1) (2) (3) Aspirator: Utilizing units, a circular horizontal flow pattern was created, covering the whole lagoon area, thus preventing short circuiting and maximizing lagoon volume. The results was a highly oxygenated flow pattern that provides complete mixing of the lagoon, keeps solids suspended in any climate and maintain optimum temperatures year round. Surface aerators: The area of influence for surface splashers was limited and has the additional negative affect of cooling the aeration basin through evaporation. Blower/Diffusers System: As seen in the photograph, the diameter of influence for a diffuser system was very limited, requiring a large quantity of diffusers to cover the area needed. Much of the area was still snow covered from lack of aeration and mixing, giving the lagoon a pincushion looks. FIGURE 4.5 : RESULTS OF MIXING CAPABILITIES 40 CHAPTER V CONCLUSION AND SUGGESTION 5.1. CONCLUSION When selecting aeration equipment to use for a specific application, issues it address include reliability, serviceability, capital cost, system appurtenances and cost of operation and maintenance. Another important consideration is oxygen transfer rate using equipment with high oxygen transfer rate values would obviously increase the electricity consumption. As conclusion an effective aeration system designed for wastewater treatment process must be adequate and comply with the biochemical oxygen demand (BOD) Standard required by the regulators satisfy the oxygen demand of nitrification, provide adequate mixing, maintain a minimum dissolved oxygen (1 to 3 mg/l) throughout the aeration basin and efficient in energy saving. Thus, from the experiment and evaluation conducted from this study case, aspirator performed extremely well in order to provide the most effective aeration in wastewater. It was also a very cost effective device compared to other aeration devices. 41 5.2. SUGGESTION Since this study only concentrated on an average Population Equivalent of 2500, further studies or experiments should be carried out on higher Population Equivalent with different kind of STP (sewerage treatment plants) such as sequence batch reactors, rotating biological contacted, activated sludge and others . This would be an indicator whether different population equivalent plants reacts differently in terms of oxygen transfer rate. It should concentrate on different age of plants because it may produce different results. New plants or aeration devices most probably would perform without any hiccups compared to the aged equipment or devices. Another factor that should be taken into consideration is the location of the sewerage treatment plant whether it is on highland or lowland such as Cameron Highland because low temperature would produce different results compared to high temperature. 42 REFERENCES Indah Water Konsortium. 2002. Operation and Maintenance . Kuala Lumpur, Tim Hobson. 1992. Activated sludge, Evaluating and Controlling Process, 2nd Ed. Mckenna Metcalf and Eddy. 1991. Wastewater Engineering. 3rd Ed. McGraw Hill, S.K.Gang. 2004. Sewage Disposal and Air Pollution Engineering. Khanna Publishers, Mark J.Hammer, Mark J.Hammer,Jr. 2004. Water and Waste Water Technology 5th Ed. Pearson Prentice Hall D.Lal.A.K. Upadhyay. 2004. Water Supply and Waste Water Engineering. Revised Edition. Sanjeer Kataria. Sewerage Services Department (1999). Guidelines for Developers, Sewerage Policy for New Developments. Malaysia, Volume I.. Sewerage Services Department (1998). Guidelines for Developers, Sewerage Treatment Plants. Malaysia, Volume IV. 43 APPENDIX A SUMMARY OF SAMPLING RESULTS FOR SEWERAGE PLANTS SAMPLING INDAH RESULTS LOCATION SAMPLING EFF. SPL PURPOSE BOD COD NH3 NO3 DATE STD TYPE CODE mg/l mg/l mg/l mg/l IPH240 TMN PAKATAN JAYA, FASA 1 28-Feb-07 B FE O 20 62 6 n.a 7.1 IPH052 TMN ANDA 5-Mac-07 B FE O 26 77 26 1 IPH145 TMN DESA KEBUDAYAAN 21-Mac-07 B FE O 57 155 3 IPH005 TMN GERMUDA 8-Mac-07 B FE O 21 66 IPH346 MEDAN PENGKALAN IMPIAN 23-Mac-07 B FE O 28 66 REF pH O&G SS mg/l mg/l 1 47 8.5 2 46 n.a 8.8 n.a 81 10 n.a 7.2 2 52 21 n.a 7.4 n.a 22 44 APPENDIX B PHOTOGRAPH OF VARIOUS AERATION DEVICE TAMAN ANDA ( TORNADO) TAMAN PAKATAN JAYA (ASPIRATOR) 45 MEDAN PENGKALAN IMPIAN (DIFFUSERS AND BLOWERS) TAMAN GERMUDA (BRUSH AERATOR) TAMAN DESA KEBUDAYAAN (SURFACE AERATOR)