Application of Central Composite Design (CCD) and Response Surface

advertisement

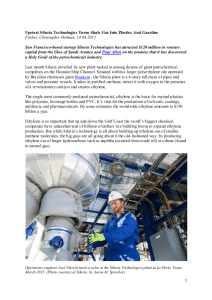

Application of Central Composite Design (CCD) and Response Surface Methodology (RSM) in the Catalytic Conversion of Methane and Ethylene into Liquid Fuel Products 1,2 Kusmiyati 1 , Nor Aishah Saidina Amin 1 Department of Chemical Engineering, Faculty of Chemical and Natural Resources Engineering, Universiti Teknologi Malaysia, 81310 UTM Skudai, Johor, Malaysia 2 Permanent address : Department of Chemical Engineering, Muhammadiyah University of Surakarta, Pabelan Surakarta 57102 , Indonesia Corresponding author email address: r-naishah@utm.my Abstract The effect of operating conditions i.e. temperature, feed composition, and catalyst loading on the reaction of a mixture of methane and ethylene to produce C5+ hydrocarbons was investigated by employing the design of experiment. A central composite design combined with response surface methodology was used to determine the optimum operating condition on the production of C5+ hydrocarbons from a mixture of methane and ethylene. A mathematical model that is able to predict the effect of independent variables towards the responses i.e. the selectivity to C5+ hydrocarbons product was established by multiple regression analysis. The reaction of a mixture of methane and ethylene into higher molecular hydrocarbons products was carried out in a fixed bed micro-reactor over W/HZSM-5 catalyst. Analysis of variance was used to determine the adequacy between the model and experimental value. Keywords: Central Composite Design, methane, Liquid Fuels Products, C5+ hydrocarbons. Introduction With the increasing of energy demand throughout the world and the depletion reserve of petroleum oil, studies on the conversion of natural gas into useful chemical and fuel products have attracted considerable attention by many researchers. Methane, the main component of natural gas can be converted to higher hydrocarbons product. However, the direct conversion of methane has been limited so far due to its very stable molecule. Previously, it has been reported that the addition of ethylene or ethane into methane feed could produce higher molecular weight hydrocarbons products. It has been found that non-oxidative activation of methane to higher hydrocarbons and aromatics with high conversion at lower temperature could be achieved by hydrogen transfer reactions between methane and alkene over H-galloaluminosilicate (MFI) zeolite [1]. Baba and Abe [2] investigated the activation of methane in the presence ethylene over metal action-acidic proton bifunctional catalyst. 13 They found that CH4 reacts with ethylene over metal cations such as indium cations-loaded H-ZSM-5 13 13 12 to form singly C-labeled propylene ( C C2H6) and hydrogen at 673 K. The heterolytic dissociation of C-H bond in methane presumly proceeds by the reaction of methane with metal cations for the formation of CH3+ and metal hydride species, thus allowing the reaction of CH 3+ with ethylene to form propylene and acidic protons. Metal cations are regenerated by the reaction of silver-hydride species with acidic protons, and hydrogen is simultaneously formed. Thus, bifunctionality of metal cations and acidic protons are essential for the activation of methane. Alkhawaldeh, et al. [3] reported the reaction of mixtures of methane and ethylene into higher molecular weight hydrocarbons over metal-loaded and unloaded HZSM-5 catalysts. The reaction produced higher molecular weight hydrocarbons + consisting of heavy products (C5 to C8 ) as well as lighter products (C2 to C4). As a consequence of environmental concerns, there is an increasing interest in the production of aromatics and sulfur-free transportation fuels via lower olefins oligomerization [4]. In order to get an + optimum higher hydrocarbons (C5 ) products, study on the relationships between process variables + and the C5 selectivity is desirable. It is difficult to find the most important factors and to optimize some variables by conventional optimization as it ignores possible interactions between the variables. The 257 aims of the present paper are to optimize the process variables such as temperature, feed + composition, and catalyst loading on the reaction of a mixture of methane and ethylene to form C5 selectivity over W/HZSM-5 catalysts. Central composite design coupled with response surface + methodology is applied for seeking the optimum conditions in the production of liquid fuel (C5 hydrocarbons) from the reaction of a feed containing methane and ethylene. Materials and Methods Catalyst preparation W/HZSM-5 catalyst (2.0 wt.% of W) was prepared by impregnation of HZSM-5 zeolite with calculated amount of ammonium tungsten hydrate ((NH4)6W12O40.H2O) solution. After impregnation, the catalyst was dried overnight and calcined at 823 K for 4h. Catalytic test The catalytic tests were carried out in a fixed bed continuous-flow quartz reactor with 9 mm i.d and operated at atmospheric pressure. Before reaction, the catalyst was pretreated in situ by using oxygen flow at 500 C for one hour. The reactants (methane and ethylene) and nitrogen were fed into the reactor through flow meters. Nitrogen is used not only as carrier gas, but also as an internal standard to determine the amounts of hydrocarbons. The reaction products were analyzed by gas chromatograph where a TCD was used to determine the gaseous product and a FID for liquid product. Experimental Design The study was performed with the use of an experimental design method. According to the central 3 composite design (CCD) a total of 16 experiments was generated including a 2 of the two-level factorial design, central points, and star points [5]. The number 3 is the independent variables used in this study consist of temperature, ethylene (methane) composition in the feed, and catalyst loading. These 16 experiments were performed with different combinations of the three independent variables : nc= 8 : (1, 1,1), na= 6 : (,0,0), no= 2 : (0,0,0) where the value of ( star point )= 1.287 to make the design orthogonal. Table 1: The levels of variables chosen for trials o Temperature ( C) (X1) Ethylene (methane) composition (X2) Catalyst Weight (X3) - 336 -1 350 0 400 +1 450 + 464 3.6 5 10 15 16.4 0.1 0.2 0.3 0.4 0.49 + The response chosen was C5 selectivity. The levels of independent variables and experimental plan based on CCD are shown in Tables 1 and 2. + Table 2 : An experimental plan based on CCD and the response selectivity of C5 hydrocarbons Run Coded Variables X1 258 X2 X3 Y, SC5+ 1 350 5 0.2 62.5 2 350 5 0.5 67.8 3 350 15 0.2 77.6 4 350 15 0.5 73.4 5 450 5 0.2 58.6 6 450 5 0.5 52.6 7 450 15 0.2 58.9 8 450 15 0.5 51.3 9 336 10 0.3 78.7 10 464 10 0.3 66.9 11 400 3.6 0.3 64.2 12 400 16.4 0.3 70.2 13 400 10 0.1 62.2 14 400 10 0.49 74.4 15 400 10 0.3 86.1 16 400 10 0.3 85.7 The response surface methodology (RSM) was used to analyze the experimental design. The response variable was fitted by a second order model in order to correlate the response variable to the independent variables. The general form of the second-degree polynomial equation is : Yi o 3 jx j j 1 i j ij xi x j 3 b jj x (1) 2 j j 1 Where Yi is the predicted response, , xixj are input variables which influence the response variable Y; o is the offset term;i is the ith linier coefficient;ii the ith quadratic coefficient and ij is the ijth interaction coefficient. xi is the dimensionless value of an independent variable defined as : x i X i X o / X i (2) X i is the real value of an independent variable X o is the real value of an independent variable at the center point X i is the step change Analysis of variance (ANOVA) is the statistical analysis used to check the significance of the equation with the experimental data. This analysis included the Fisher’ s F-test (overall model significance), its 2 associated probability p(F), correlation coefficient R, determination coefficient R which measures the goodness of fit of regression model. Its also includes the Student’ s t-value for the estimated coefficient and associated probabilities p(t). For each variable, the quadratic models were represented as contour plots (2D). The optimal combination was determined from contour plot. The statistica software (statsoft) was used to generate design, regression analysis, and plot abstention. Results and Discussion + The experimental design and the results of C5 hydrocarbons selectivity from the reaction of a mixture + of methane and ethylene are presented in Table 2. The mathematical model relating the C5 selectivity with the independent process variables, X1, X2, X3 is given in the second order polynomial, eq. (3) : Y 366 . 726 1 . 749 X 1 12 . 293 X 2 366 . 848 X 0 . 011 X 1 X 2 0 . 274 X 1 X 3 1 . 755 X 2 X 3 3 0 . 0002 2 X 1 0 . 346 X 2 2 366 . 848 X 2 3 (3) 259 + Where Y is the response variable, selectivity of C5 hydrocarbons and X1, X2, and X3 the values of independent variables, temperature, ethylene (methane) composition in the feed and catalyst loading, respectively. For testing the goodness of fit of the regression equation, the multiple correlation 2 2 coefficient R and the determination coefficient R were evaluated. The coefficient of determination (R ) and the value (R) are found to be 96.31 % and 98 %, respectively. This result indicates the secondorder polynomial model (eq 3) was highly significant and adequate to represent the actual relationship between the response and the independent variables [6], [7], [8]. + Table 3: ANOVA for C5 Selectivity Sum of Degree of Mean F Value squares freedom square SS regression S.S. error S.S. total 1626.32 62.23 1688.55 9 6 180.67 10.37 17.42 F Value 0.05 4.10 2 R 0.9631 The corresponding analysis of variance (ANOVA) is presented in Table 3. The F value is a measure of variation of the data about the mean. Generally, the calculated F value should be several times greater than the tabulated value if the model is a good prediction of the experimental results and the calculated value effects are real [6], [7]. Here, the computed F-value is greater than the tabulated F value , F9,6 = 4.10 at =0.05 level so that the null hypothesis (H0) is rejected. Having rejected the null hypothesis, it can be inferred that differences operating variables are highly significant. Also, the high F-value indicates that the present model is in good prediction of the experimental results. + Table 4: Multiple regression result and significance of regression coefficient for the selectivity of C5 Parameter Term Coefficient t-value p-value bo -366.726 44.00 B1 X1 1.749 -7.06 0.0004 B2 X2 12.293 2.40 0.0530 B3 X3 -366.848 -0.76 0.4744 B12 X1 X2 -0.011 -2.36 0.0561 B13 X1 X3 -0.274 -1.83 0.1165 B23 X2 X3 -1.755 -1.17 0.2847 2 B11 X1 -0.002 -3.80 0.0089 2 B 22 X2 -0.346 -6.24 0.0008 2 B 33 X3 -366.848 -6.42 0.0007 2 R 0.9631 R 0.9814 The student t-distribution and the corresponding p-values along with the second order polynomial coefficients are presented in Table 4. The p-value serves as a tool for checking the significance of each of the coefficients. The variables with low probability levels contribute to the model, whereas the others can be neglected and eliminated from the model. The p-values for the linier, quadratic, and interactive terms were as follows: 0.0004, 0.0530, 0.4744, 0.0089, 0.0008, 0.0007, 0.0561, 0.1165, 2 2 2 and 0.2847 for X1, X2, X3, X1 , X2 ,X3 , X1X2 ,X1X3, and X2X3, respectively. The p-values suggest that coefficient for linier effect of temperature (X1), with a value of 0.0004, is most significant. The 2 2 coefficient for quadratic effects of ethylene composition in the feed (X2 ) and catalyst loading (X3 ) may be significant to some extent. Linier effect of catalyst loading (X3) had the highest value of the coefficient probability (0.4744), indicating that only 52.56 % of the model is affected by this variable. It means that catalyst loading, at least in the range of 0.1 – 0.49 g did not significantly affect the + production of C5 hydrocarbons from a mixture of methane and ethylene. However, the coefficients of interactive effect of catalyst loading and temperature (X1X3) had a value of 0.1165 and the coefficients of interactive effect of catalyst loading and ethylene (methane) composition in the feed (X2X3) had a value of 0.2847 which may be significant. 260 0,55 18 16 0,45 Catalyst loading ,g Ethylene ,ml/min 60 70 14 50 0,50 50 60 80 12 10 8 70 0,40 80 0,35 0,30 0,25 0,20 6 0,15 4 2 320 0,10 340 360 380 400 420 440 460 480 0,05 320 340 360 380 Temperature o,C 400 420 440 460 480 Temperature o,C (a) (b) 0,55 50 0,50 60 Catalyst loading, g 0,45 70 0,40 80 0,35 0,30 0,25 0,20 0,15 0,10 0,05 2 4 6 8 10 12 14 16 18 Ethylene, ml/min (c) + Figure 1: Contour plot of the relationship: C5 hydrocarbons and (a) temperature and ethylene at fixed catalyst loading (b) temperature and catalyst loading at fixed ethylene concentration, (c) ethylene and catalyst loading at fixed temperature. Figs. 1 (a)-(c) show the contour plots obtained from the calculated response surface plots. The contour plots are the most useful approach in terms of visualization of the results of the statistical model and mathematical analysis. This is a reconfirmation that the fitted surface has a maximum point o which is T (X1) of 364.4 C, ethylene (methane) concentration of 11.2 ml/min (X2) and catalyst loading (X3) of 0.35 g. The model predicted a maximum response of 86.8313 for this point. Conclusion In this study, central composite design has been applied to optimize the conversion of methane and + ethylene into C5 hydrocarbons. Central composite coupled with response surface methodology generate a mathematical model to determine the correlation between the response factor and independent variables. ANOVA analysis is used to check the adequacy of the model predicted and the + experimental results. C5 hydrocarbons obtained from experiment can be explained by the second order polynomial model and the ANOVA result reveal that model predicts the experimental range + studied adequately. The results of this study revealed that the production of C5 hydrocarbons from a mixed methane and ethylene are influenced by the process variables i.e temperature, ethylene (methane) composition, and catalyst loading. According to the contour plots obtained from response surface methodology the fitted surface has a maximum point at the experimental range studied. Acknowledgements The authors would like to express their sincere gratitude to the Ministry of Science, Technology and Environment, Malaysia for providing funds to support this research under the Strategic Research project (project no: 09-02-06-0057 or SR 0005/09-07). 261 References 1. 2. 3. 4. 5. 6. 7. 8. 9. 262 B. Liu, Y. Yang, A. Sayari, Applied Catalysis A: General 214 (2001) 95. T. Baba, and Y. Abe, Applied Catalysis A: General 250, (2003) 265. A. Alkhawaldeh, X. Wu, and R.G. Anthony, Catalysis Today 84, (2003) 43. V. Hulea .and F.Fajula, Journal of Catalysis 225, (2004) 213. D.C. Montgomery, Design And Analysis of Experiments, Fifth edition, John Wiley and Sons, Inc.Arizona. Q.H. Chen, G.D. He, M.A.M. Ali, Enzyme and Microbial Technology 30, (2002) 667. S.H. Krishna, B. Manohar, S. Divakar, S.G. Prapulla, N.G.Karanth, Enzyme and Microbial Technology 26, (2000) 131. N.Garcia, Sanchez, M. Martinez,J. Aracil, Enzyme and Microbial Technology 25, (1999) 59. G. Calleja, A .Lucas and R. Grieken, Fuel 74 ,(1995) 445.