vii i TABLE OF CONTENTS

advertisement

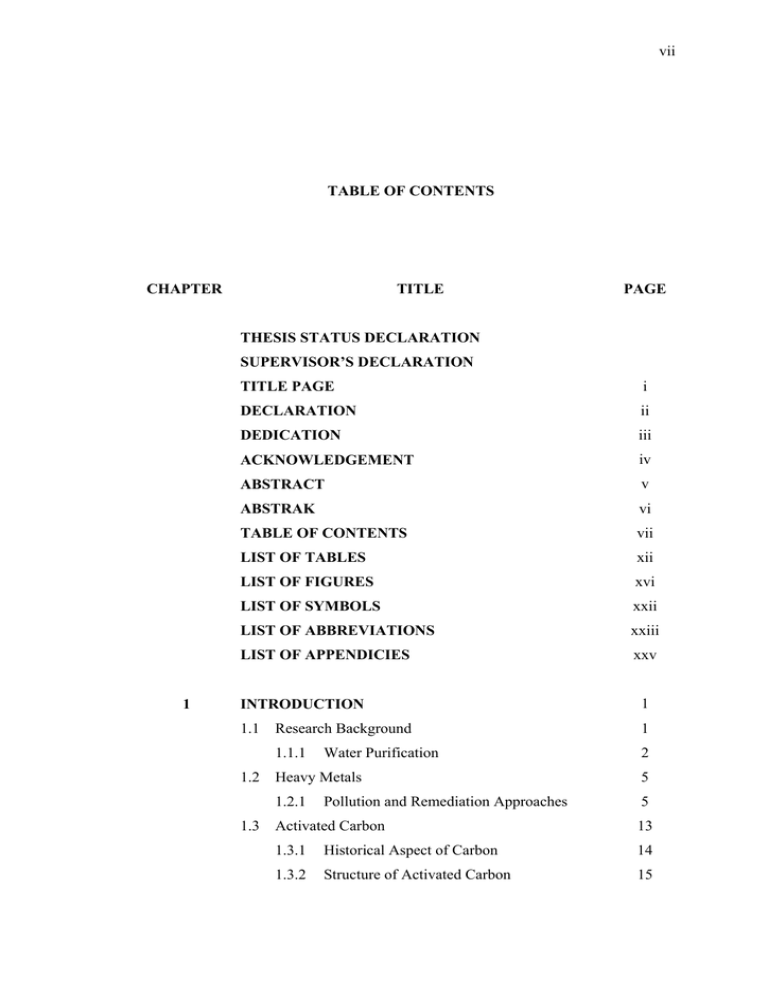

vii TABLE OF CONTENTS CHAPTER TITLE PAGE THESIS STATUS DECLARATION SUPERVISOR’S DECLARATION 1 TITLE PAGE i DECLARATION ii DEDICATION iii ACKNOWLEDGEMENT iv ABSTRACT v ABSTRAK vi TABLE OF CONTENTS vii LIST OF TABLES xii LIST OF FIGURES xvi LIST OF SYMBOLS xxii LIST OF ABBREVIATIONS xxiii LIST OF APPENDICIES xxv INTRODUCTION 1 1.1 Research Background 1 1.1.1 2 1.2 1.3 Water Purification Heavy Metals 5 1.2.1 5 Pollution and Remediation Approaches Activated Carbon 13 1.3.1 Historical Aspect of Carbon 14 1.3.2 Structure of Activated Carbon 15 viii 1.3.2.1 1.3.3 Surface Functional Groups 16 Preparation 20 1.3.3.1 23 Processing of Lignocellulosic Materials 1.3.3.2 Utilization of Oil Palm and 27 Coconut Shells as Carbon Precursor 1.4 Adsorption of Metal Ions onto Activated Carbon 30 1.5 Adsorption Equilibrium Models 41 1.5.1 Langmuir Adsorption Model 42 1.5.2 Freundlich Adsorption Model 43 1.6 1.7 2 Aims and Objectives 45 1.6.1 46 Objectives Scope and Limitations 46 MATERIALS AND METHODS 47 2.1 Chemicals and Reagents 47 2.2 Instruments 48 2.3 Preparation of Activated Carbon 48 2.3.1 Raw Material Preparation 49 2.3.2 Activation and Washing 50 2.4 Modification of Activated Carbon 51 2.5 Characterization of Activated and Composite 53 Carbon 2.5.1 Yield Determination 54 2.5.2 Surface Porosity Characterization (N2 54 Adsorption-Desorption) 2.5.3 Surface Morphology (SEM and EDX) 55 2.5.4 Fourier Transform Infrared Spectroscopy 55 (FTIR) 2.5.5 Boehm’s Titration 55 2.5.6 Determination of pH at Point of Zero 56 Charge (pHZPC) ix 2.6 2.5.7 Thermogravimetric Analysis (TGA) 57 2.5.8 Leaching Test of Fe 57 Adsorption Studies 58 2.6.1 Test and Standard Metal Ion Solutions 58 2.6.2 Adsorption Equilibrium Studies: Metal 60 Cations 2.6.2.1 Selection of Prepared Activated 60 Carbons for Metal Cations 2.6.2.2 Single Solute Adsorption 61 2.6.2.3 Binary Solute Adsorption 62 2.6.2.4 Ternary Solute Adsorption 62 2.6.2.5 Reuse of Cation-Exhausted 62 Activated Carbon 2.6.3 Adsorption Equilibrium Studies: Cr(VI) 63 2.6.4 Adsorption Equilibrium Studies: As(III) and 64 As(V) 2.6.5 Adsorption Dynamics: Cu(II), Ni(II), Pb(II) 64 and Cr(VI) 2.6.6 Determination and Uptake of Species of 65 Metal/Metalloid 3 RESULTS AND DISCUSSION: ADSORBENT 67 DEVELOPMENT 3.1 Preparation 67 3.1.1 Activated Carbon 67 3.1.2 Carbon-Hydrated Iron Oxide (C-HFO) 68 Composite 3.2 Characterization of Prepared Activated Carbon 3.2.1 69 Surface Porosity and Morphology 70 3.2.1.1 Effect of Precursor Type 72 3.2.1.2 Effect of Pretreatment 72 3.2.1.3 Effect of Impregnation Condition 76 3.2.1.4 Effect of Precursor Size 78 x 3.2.1.5 3.2.2 Effect of Activation Temperature 80 Surface Functional Groups 82 3.2.2.1 83 Fourier Transform Infrared (FTIR) Spectroscopy 3.2.2.2 Boehm’s Titration 84 3.2.2.3 Determination of pHZPC of 86 activated carbon (pH Drift Method) 3.2.3 Thermogravimetric Analysis (TGA) of 87 activated carbon 4 3.3 Characterization of C-HFO Composites 87 3.4 Leaching Test of Fe from C-HFO Composites 92 RESULTS AND DISCUSSION: APPLICATION OF 94 ADSORBENTS 4.1 4.2 Application of Prepared Adsorbents 94 4.1.1 95 Selection of Prepared Activated Carbon Adsorption Equilibria 97 4.2.1 98 Single Solute Adsorption Equilibria: Metal Cations 4.2.1.1 Single Solute Adsorption 98 Equilibria: Cu(II) 4.2.1.2 Single Solute Adsorption 103 Equilibria: Ni(II) 4.2.1.3 Single Solute Adsorption 107 Equilibria: Zn(II) 4.2.1.4 Single Solute Adsorption 110 Equilibria: Pb(II) 4.2.2 Binary Solute Adsorption Equilibria: 115 Competitive Adsorption of Cu(II) and Ca(II) (Cu-Ca) and Evaluation of Mechanism 4.2.3 Ternary Solute Adsorption Equilibria: 122 xi Competitive Adsorption of Cu(II), Ni(II) and Pb(II) (Cu-Ni-Pb) 4.2.4 Reuse of Cation-Exhausted Activated 128 Carbon 4.2.5 Adsorption Studies: Cr(VI) 130 4.2.5.1 Selection of Prepared Adsorbents 130 4.2.5.2 The Effect of pH 132 4.2.5.3 Effect of Initial Concentration and 134 Data Fitting to Models 4.2.6 4.3 Adsorption Studies: Arsenic 137 Adsorption Dynamics 142 4.3.1 144 Adsorption Dynamics of Cu(II) on PSW-Pad-500 4.3.2 Adsorption Dynamics of Ni(II), Pb(II) and 146 Cr(VI) on PSW-P-ad-500 4.4 5 Summary of Thesis 150 CONCLUSIONS AND SUGGESTIONS FOR 152 FUTURE STUDY 5.1 Conclusions 152 5.2 Problems Encountered in Present Study 155 5.3 Recommendations for Further Studies 156 REFERENCES 157 APPENDICES A - L 166 xii LIST OF TABLES TABLE NO. 1.1 TITLE A survey of recent literatures on the production of PAGE 23 activated carbons from various lignocellulosic precursors 1.2 Proximate analysis of solid oil palm residues (Husain, 29 Zainac and Abdullah, 2002) 1.3 Ultimate analysis of solid oil palm residues (Mahila et al., 30 2001) 1.4 Proximate and ultimate analyses of coconut shell 30 (Banerjee, et al.,1976) 2.1 Preparation variables of various activated carbons activated 51 either in a muffle (M) or in a tube furnace (T) 2.2 The operating parameters of FAAS in the determination of 66 metal cations 3.1 The contents of Fe, oxygen, Na/Ca and C in the prepared 69 composites and in their parent activated carbons 3.2 Yield, BET surface area, average pore width, total pore 71 volume and pore-types of various activated carbons 3.3 Contents of phosphorous (P) in some of the selected 71 activated carbons as determined by EDX 3.4 Base neutralization capacity and quantification of acidic 85 groups on surfaces of some of the prepared activated carbons by Boehm’s titration method 3.5 The pHZPC of some activated carbons obtained from pH 86 drift method 3.6 The proximate analysis of activated carbons using TGA 87 xiii technique 3.7 The BET surface area, average pore width, total pore 88 volume and pore-types of C-HFO composites and their parent activated carbons 3.8 Properties of Virgin GAC and Fe-GAC obtained from 92 Norit Americas Inc. (Reed, Vaughan and Jiang, 2000) 4.1 Cu(II) uptake capacity of various activated carbons in a 96 single solute solution while initial solution (adsorbate) concentration and pH were kept constant at 292 ± 6 mg.L-1 and 6 respectively with a constant adsorbent concentration of 2 g.L-1 4.2 Langmuir and Freundlich model parameters for the 101 adsorption of Cu(II) in single-solute solution while initial concentrations were varied, < 5 - < 120 mg.L-1 4.3 Langmuir and Freundlich model parameters for the 105 adsorption of Ni(II) by various activated carbons at initial pH 5 while initial concentrations were varied from 6 to 227 mg.L-1 and adsorbent concentration was kept constant at 2 g.L-1 4.4 The initial and equilibrium concentrations, and fractions 107 removal of Ni(II) by various activated carbons in the low concentration solution at a constant initial pH 5 4.5 Langmuir model parameters for the adsorption of Zn(II) by 110 various activated carbons at initial pH 5 while initial concentrations were varied from 19 to 310 mg.L-1 and adsorbent concentration was kept constant at 2 g.L-1 4.6 Langmuir and Freundlich model parameters for the 112 adsorption of Pb(II) at initial pH 5 and at varying concentrations, < 50 - < 600 mg.L-1 4.7 The initial and equilibrium concentrations, and fractions removal of Pb(II) by various activated carbons in the low concentration range at pH 5 113 xiv 4.8 Langmuir and Freundlich parameters for the adsorption of 115 Pb(II) on PSW-P-ad-500 for initial pH 3 at varying concentrations, 50.6 ± 0.6-583 ± 2 mg.L-1 4.9 The Langmuir model parameters of Cu(II) and Ca(II) for 117 the adsorption in binary solution at an initial pH 5, while initial concentrations of Cu(II) and Ca(II) were varied as 23.6 ± 0.1 to 117.5 ± 0.7 and 23.8 ± 0.2 to 120 ± 1 mg.L-1 respectively 4.10 Langmuir and Freundlich parameters for the adsorption of 120 Cu(II) on PSW-P-ad-500 at a constant initial pH 4.5 while initial solution concentrations were varied from < 25 to < 700 mg.L-1 keeping adsorbent concentration 2 g.L-1 4.11 The Langmuir model parameters of Cu(II) and Ca(II) for 122 the adsorption in binary solution at initial pH 3 while initial concentrations of Cu(II) and Ca(II) were varied as 26-151 and 20-109 mg.L-1 mg.L-1 respectively 4.12 Langmuir and Freundlich model parameters for the 124 isotherms of Ni(II), Pb(II) in ternary and Cu(II) in single and ternary solutes solutions at initial pH 5 4.13 The initial and equilibrium concentrations, adsorption 125 capacities and fractions removal of Cu(II), Ni(II), Pb(II) in the single and ternary solutes solutions by the best-selected carbon, PSW-P-ad-500 at initial pH 5 and at adsorbent concentration of 2 g.L-1 4.14 Langmuir model parameters for the adsorption-desorption 130 of Cu(II) 4.15 The adsorption capacities of various adsorbents in the 132 removal of Cr(VI) while initial pH was obtained without adjustment as 4.79 and adsorbent concentration was maintained as 2 g.L-1 4.16 Langmuir and Freundlich model parameters for the adsorption of Cr(VI) on PSW-P-ad-500 while initial concentrations were varied from 40 - < 200 mg.L-1 at an 136 xv optimum pH 3, keeping adsorbent concentration constant at 2 g.L-1 4.17 The initial and equilibrium concentrations, and fractions 136 removal of Cr(VI) by various activated carbons in the low concentration at an optimum pH 3 4.18 Aqueous and solid phase equilibrium concentration of 139 adsorbents (adsorption capacity) while adsorbate concentration was 1 mg.L-1, pH 7 and adsorbent concentration 0.2 g.L-1 (Reed, Vaughan and Jiang, 2000) 4.19 Experimental adsorption equilibrium capacity, qe and 146 kinetic model parameters for the adsorption of Cu(II) at constant initial concentration, < 50 mg.L-1 and at pH 5, while contact time was varied from 0.5 to 72 h 4.20 Experimental adsorption equilibrium capacity, qe and kinetic model parameters for the adsorption of Ni(II), Pb(II) and Cr(VI) 147 xvi LIST OF FIGURES FIGURE NO. 1.1 TITLE The periodic table showing classification of metals based PAGE 11 on Lewis acidity as: Class A-hard metals (black), Class B-soft metals (light grey), Class AB-borderline (dark grey) (IUPAC, 2002) 1.2 Structures of carboxyl, phenolic hydroxyl and quinone 18 type carbonyl groups 1.3 Structures of lactones, acid anhydrides and cyclic 18 peroxide 1.4 A cross section of masocarp of oil palm fruit bunch 28 showing fibre, shell, kernel and pericarp 1.5 Process flow diagram of palm oil extraction showing the 29 production of crude oil and wastages such as shells, kernel and fibres 2.1 A flow diagram of activated carbon preparation 49 2.2 A flow diagram of modification of activated carbons 52 3.1 N2 adsorption-desorption isotherms of various activated 70 carbons prepared from oil palm and coconut shell precursors under various process conditions 3.2 N2 adsorption-desorption isotherms of activated carbons 73 derived from oil palm (A) and coconut shell (B) precursors 3.3 Yield of various activated carbons as a function of precursor pretreatment such as non-pretreated (NP), 74 xvii H2SO4 pretreated (SAP) and H3PO4 pretreated (PAP) conditions 3.4 BET surface area of various activated carbons as a 75 function of precursor pretreatment such as non-pretreated (NP), H2SO4 pretreated (SAP) and H3PO4 pretreated (PAP) conditions 3.5 BET surface areas of various activated carbons derived 77 from different charge states such as wet (PSW-P-500), apparently/semi-dried (PSW-P-ad-500) and completely dried (PSW-P-ed-450) 3.6 Total pore volumes of activated carbons derived from 77 different charge states, as wet (PSW-P-500), semi-dried (PSW-P-ad-500) and dried (PSW-P-ed-450) 3.7 SEM micrograph of an activated carbon obtained from 78 semi-dried feedstock of oil palm shell precursor, namely PSW-P-ad-500 3.8 N2 adsorption-desorption isotherms of two activated 79 carbons, derived from smaller (1.18-0.6 mm) and larger (2.36-1.18 mm) particle sizes, namely PSWfg-P-450 and PSW-P-ed-450 3.9 The development of surface areas of various activated 80 carbons prepared under different activation temperatures 3.10 FTIR spectrums of some of the prepared activated 83 carbons, namely, PSW-P-500, CPW-P-500 and PSW-Pad-500 3.11 Graphs of equilibrated pH (pHf) vs. initial pH (pHi) by 86 some of the prepared activated carbons for determining the pHZPC from the crossover point 3.12 SEM micrographs of composites of C-HFO-1 (A) and C- 89 HFOCa-1 (B) obtained from parent activated carbon PSW-P-500 using different bases, such as NaOH and Ca(OH)2 3.13 SEM micrographs of a composite, C-HFO-2 obtained 90 xviii from parent activated carbon CPW-P-500 while magnification factor is different as 200X (A) and 800X (B) 3.14 SEM micrographs of C-HFO-3 obtained from parent 91 activated carbon PSW-P-ad-500 while magnification factor is different as 250X (A) and 1200X (B) 4.1 Langmuir adsorption isotherms of Cu(II) at initial pH 3 99 (A) and pH 5 (B) by various activated carbons while initial solution concentrations were varied from < 5 to <120 mg.L-1 4.2 Langmuir adsorption isotherms of Cu(II) by prepared 100 activated carbons for initial pH 3 (A) and pH 5 (B) and by a commercial activated carbon for initial pH 3 and pH 5 (C) while initial concentrations were varied, < 5 - < 120 mg.L-1 4.3 Freundlich adsorption isotherms of Cu(II) at pH 3 (A) 101 and at pH 5 (B) while initial solution concentrations of Cu(II) were varied, < 5 - < 120 mg.L-1 4.4 Langmuir (A, B, C) and Freundlich (D) adsorption 104 isotherms of Ni(II) at initial pH 5 by various activated carbons while initial solution concentrations were varied as 6 - 227 mg.L-1 4.5 Langmuir non-linear (A) and linear (B) isotherms of 108 Zn(II) by CAC at initial pH 5 while solution concentrations were varied, 19 - 250 mg.L-1 4.6 Langmuir non-linear isotherms of Zn(II) at initial pH 5 by 109 prepared activated carbons, PSW-P-500 (A), CPW-P-500 (B) and PSW-P-ad-500 (C) while initial solution concentrations were varied, 19 – 310 mg.L-1 4.7 Langmuir linear isotherms of Zn(II) at initial pH 5 by various prepared activated carbons while initial solution concentrations were varied from 19 to 310 mg.L-1 110 xix 4.8 Langmuir non-linear (A) and linear (B and C) adsorption 111 isotherms of Pb(II) at initial pH 5 by various activated carbons while initial concentrations were varied as < 50 < 600 mg.L-1 4.9 Freundlich adsorption isotherms of Pb(II) at initial pH 5 112 by various activated carbons while initial concentrations were varied as < 50 - < 600 mg.L-1 4.10 Langmuir non-linear (A) and linear (B) adsorption 114 isotherms of Pb(II) at initial pH 3 by the best-selected activated carbon, PSW-P-ad-500 while initial solution concentrations were varied from 50.6 ± 0.6 to 583 ± 2 mg.L-1 4.11 Freundlich adsorption isotherms of Pb(II) at initial pH 3 115 by activated carbon, PSW-P-ad-500 while initial solution concentrations were varied from 50.6 ± 0.6 to 583 ± 2 mg.L-1 4.12 Langmuir non-linear and linear isotherms of Cu(II) (A 116 and B) and Ca(II) (A and C) while Cu(II) ions were adsorbed from single (Cu), binary (Ca-Cu) and ternary (Cu-Ni-Pb) solutions and Ca(II) from binary solution (Ca-Cu) by PSW-P-ad-500 at initial pH 5 and at varying initial concentrations, < 25 - ≤ 120.mg.L-1 4.13 The proposed interactions of Cu(II) and Ca(II) cations 118 (Lewis acids) onto the surfaces of activated carbon where SO− and SOH (Lewis bases) represent the deprotonated surface functional groups on activated carbon. The vertical bars are depicted as solution-solid interface 4.14 Langmuir non-linear (A), linear (B) and Freundlich (C) 119 isotherms of Cu(II) by the carbon PSW-P-ad-500 at constant initial pH 4.5 while initial solution concentrations were varied from < 25 to < 700 mg.L-1 keeping adsorbent concentration constant at 2 g.L-1 4.15 Langmuir non-linear (A) and linear (B and C) isotherms 121 xx of Cu(II) and Ca(II) for the adsorption in binary solute solution while concentration of Cu(II) and Ca(II) were varied as 26-151 and 20-109 mg.L-1 respectively keeping initial pH and adsorbent concentration constant, at pH 3 and 2 g.L-1 respectively 4.16 Langmuir non-linear (A), linear (B) and Freundlich (C) 123 isotherms of ternary solute, Cu(II), Ni(II) and Pb(II), by the best selected carbon, PSW-P-ad-500 at initial pH 5, while their initial concentrations were varied as < 25 ≤ 600 mg.L-1. (Ni samples were analysed for initial concentration range, < 25 to 305 ± 2 mg.L-1) 4.17 Langmuir non-linear and linear adsorption-desorption 129 isotherms of Cu(II), while adsorbed at varying concentration, < 25 to < 700 mg.L-1 4.18 Adsorption capacity of Cr(VI) by various selected 133 adsorbents while pH were varied from 3 to 8 keeping initial concentration constant at about 40 mg.L-1 4.19 Langmuir non-linear (A), Linear (B) and Freundlich (C) 135 adsorption isotherms of Cr(VI) by activated carbons, CAC and PSW-P-ad-500, at initial pH 3 while initial concentrations were varied from 40 - < 200 mg.L-1 4.20 Adsorption equilibrium capacities of a HFO composite 138 and its counter activated carbon for the species of As(V) and As(III), while adsorptions were carried out in the solutions of As(V) and As(III) with constant initial concentrations, 1.641 and 2.170 mg.L-1 and with constant initial pH, at 5.5 and 7.6 respectively 4.21 An illustration of selective bond formation of dispersed 141 hydrated iron oxide with As(V) and As(III) species in aqueous phase predominantly through Lewis acid-base interaction 4.22 Graph to check kinetics data of Cu(II) with first order kinetic model 144 xxi 4.23 Graph of pseudo-second order kinetic model for the 145 adsorption of Cu(II) at constant initial concentration, < 50 mg.L-1 and at pH 5 4.24 A graph of adsorption capacity vs. contact time for the 145 adsorption of Cu(II) at constant initial concentration, < 50 mg.L-1 and at pH 5 4.25 Graphs of pseudo-second order kinetic model for the 147 adsorptions of Ni(II), Pb(II) and Cr(VI) at constant initial concentrations, < 45, 95 ± 1 and 77 ± 1 mg.L-1 respectively, while the initial pH of solutions of Ni(II) and Pb(II) were adjusted to 5 and that of Cr(VI) to 3 4.26 Graphs of adsorption capacities vs. contact time for the 148 adsorption of Ni(II) (A), Pb(II) (B) and Cr(VI) (C) 4.27 A comparison in the rate constants of various metal ions 149 for the adsorption onto acid activated carbon, PSW-P-ad500 4.28 A comparison in adsorption capacities (qe) of various metal ions while qe obtained from adsorption equilibrium data for kinetics studies for the adsorption onto acid activated carbon, PSW-P-ad-500 150 xxii LIST OF SYMBOLS °C - Degree Celsius C0 - Initial concentration Ce - Equilibrium concentration cm - Centi meter dm - Deci meter g - Gram L - Liter m - Meter M - Molar mA - Mili ampere meq - Mili equivalent mg - Mili gram min - Minute mL - Mili Liter mm - Mili meter mM - Mili Molar nm - Nano meter q or qt - Metal uptake at any time, t qe - Metal uptake at equilibrium t - Tonne y - year Å - Angstrom µg - Micro gram µm - Micro meter µmol - Micro mole xxiii LIST OF ABBREVIATIONS AAS - Atomic absorption spectrophotometer Av - Average B.C. - Before Christ BET - Brunauer, Emmett and Teller CAC - Commercial activated carbon DDW - Distilled deionized water Dia - Diameter DPC - 1,5-Diphenylcarbazide EDL - Electric double layer EDX - Energy dispersive X-ray analysis EFB - Empty fruit bunches EPA - Environment Protection Agency Et - Ethyl FAAS - Flame atomic absorption spectroscopy FTIR - Fourier transform infrared spectrophotometer GAC - Granular activated carbon h - hour HFO - Hydrated iron oxide HSAB - Hard and Soft Acids and Bases ICP-MS - Inducedly coupled plasma mass spectrophotometer IUPAC - International Union of Pure and Applied Chemistry Max - Maximum MOX - Malaysian Oxygen NOM - Naturally occurring organic matter PAC - Powered activated carbon xxiv QC - Quality control rpm - Revolution per minute RSD - Relative standard deviation SCF - Surface complex formation SD - Standard deviation SEM - Scanning electron microscope SOC - Synthetic organic chemicals SOCs - Synthetic organic compounds TGA - Thermogravimetric analysis USA - United States of America USEPA - United States Environment Protection Agency UV - Ultra violet VOCs - Volatile organic compounds WHO - World Health Organization xxv LIST OF APPENDICES APPENDIX A TITLE National Drinking Water Quality PAGE 166 Standards, 2000 of Malaysia for some species of metals and metalloids B EDX Spectrums of Some Selected 167 Activated and Modified Carbons C Summary Report of N2 Adsorption- 170 Desorption Data and BJH Pore size distribution Graph D FTIR Spectrums of Some of the Selected 174 Activated Carbons E Quantification of Acidic Groups on the 175 Surface of Some Selected Activated Carbons as meq Base per Gram Carbon F TGA Thermograms of Some of the 176 Selected Activated Carbons G FAAS Determined Fe Content in Samples 186 of Leached Water Contacted with C-HFO-1 Composite Adsorbent at pH 4.5 H FAAS Determined Adsorption Equilibrium Data of Various Metal Cations in Single, Binary and Ternary Solutes Solutions by Various Activated Carbons at Varying Initial Concentration and pH 187 xxvi I UV-Vis Spectrophotometer Determined 203 Adsorption Equilibrium Data of Cr(VI) in Single Solute Solution By Various Activated Carbons and C-HFO Composite Adsorbents J ICP-MS Determined Adsorption 208 Equilibrium Data of As(III) and As(V) for the Adsorption in a Single Point Initial Concentration By a Typical Prepared Activated Carbon and its modified ones, namely, PSW-P-500 and C-HFO-1 respectively K Adsorption Kinetics Data of Cu(II), Ni(II), 209 Pb(II) and Cr(VI) L Presented Papers and Expected Publications from This Study 212