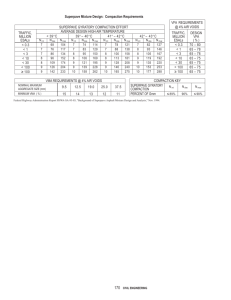

COMPARISON BETWEEN SUPERPAVE GYRATORY AND MARSHALL LABORATORY COMPACTION METHODS

advertisement