Document 14780620

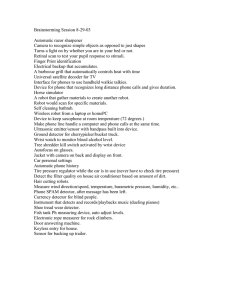

advertisement