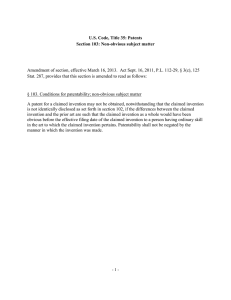

Comparative Study on Hypothetical/Real Cases: Inventive Step/Non-obviousness November 2008

advertisement