Document 14670934

advertisement

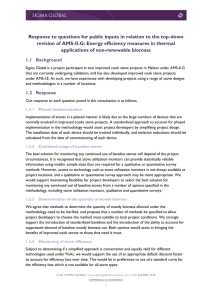

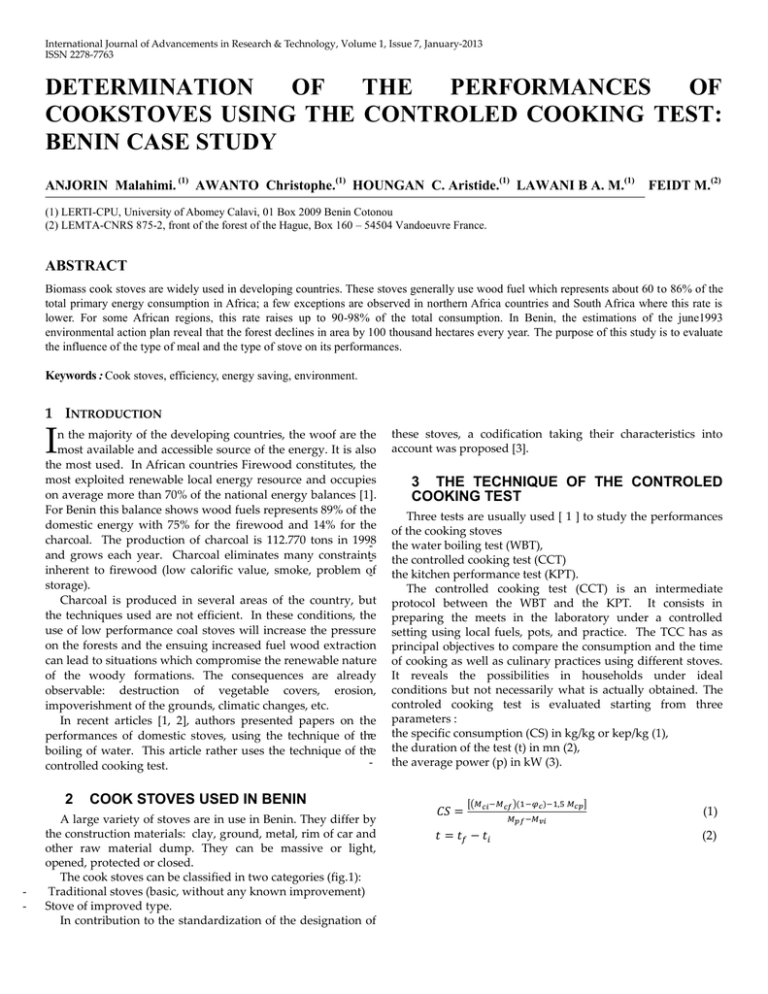

International Journal of Advancements in Research & Technology, Volume 1, Issue 7, January-2013 ISSN 2278-7763 DETERMINATION OF THE PERFORMANCES OF COOKSTOVES USING THE CONTROLED COOKING TEST: BENIN CASE STUDY ANJORIN Malahimi. (1) AWANTO Christophe.(1) HOUNGAN C. Aristide.(1) LAWANI B A. M.(1) FEIDT M.(2) (1) LERTI-CPU, University of Abomey Calavi, 01 Box 2009 Benin Cotonou (2) LEMTA-CNRS 875-2, front of the forest of the Hague, Box 160 – 54504 Vandoeuvre France. ABSTRACT Biomass cook stoves are widely used in developing countries. These stoves generally use wood fuel which represents about 60 to 86% of the total primary energy consumption in Africa; a few exceptions are observed in northern Africa countries and South Africa where this rate is lower. For some African regions, this rate raises up to 90-98% of the total consumption. In Benin, the estimations of the june1993 environmental action plan reveal that the forest declines in area by 100 thousand hectares every year. The purpose of this study is to evaluate the influence of the type of meal and the type of stove on its performances. Keywords : Cook stoves, efficiency, energy saving, environment. 1 INTRODUCTION I n the majority of the developing countries, the woof are the most available and accessible source of the energy. It is also the most used. In African countries Firewood constitutes, the most exploited renewable local energy resource and occupies on average more than 70% of the national energy balances *1+. For Benin this balance shows wood fuels represents 89% of the domestic energy with 75% for the firewood and 14% for the charcoal. The production of charcoal is 112.770 tons in 1998 and grows each year. Charcoal eliminates many constraints inherent to firewood (low calorific value, smoke, problem of storage). Charcoal is produced in several areas of the country, but the techniques used are not efficient. In these conditions, the use of low performance coal stoves will increase the pressure on the forests and the ensuing increased fuel wood extraction can lead to situations which compromise the renewable nature of the woody formations. The consequences are already observable: destruction of vegetable covers, erosion, impoverishment of the grounds, climatic changes, etc. In recent articles *1, 2+, authors presented papers on the performances of domestic stoves, using the technique of the boiling of water. This article rather uses the technique of the controlled cooking test. 2 - COOK STOVES USED IN BENIN A large variety of stoves are in use in Benin. They differ by the construction materials: clay, ground, metal, rim of car and other raw material dump. They can be massive or light, opened, protected or closed. The cook stoves can be classified in two categories (fig.1): Traditional stoves (basic, without any known improvement) Stove of improved type. In contribution to the standardization of the designation of these stoves, a codification taking their characteristics into account was proposed *3+. 3 THE TECHNIQUE OF THE CONTROLED COOKING TEST Three tests are usually used * 1 + to study the performances of the cooking stoves the water boiling test (WBT), the controlled cooking test (CCT) the kitchen performance test (KPT). The controlled cooking test (CCT) is an intermediate protocol between the WBT and the KPT. It consists in preparing the meets in the laboratory under a controlled setting using local fuels, pots, and practice. The TCC has as principal objectives to compare the consumption and the time of cooking as well as culinary practices using different stoves. It reveals the possibilities in households under ideal conditions but not necessarily what is actually obtained. The controled cooking test is evaluated starting from three parameters : the specific consumption (CS) in kg/kg or kep/kg (1), the duration of the test (t) in mn (2), the average power (p) in kW (3). [( )( ) ] (1) (2) International Journal of Advancements in Research & Technology, Volume 1, Issue 7, January-2013 ISSN 2278-7763 Double fuel Stove 3 stones rural (terracotta) Metallic " Adopké " 1 pot " improved "3 stones" 1 pot and chimney" improved "3 stones" "2 pots and chimney" improved "3 stones" stove " Adopké " sawdust stove square coal pot Rim made coal pot clay made coal pot Modified double fuels stove "Nansu" imitation stove "Nansu" stove kerosene stove Gas stove Fig.1. Modified Double fuels stove Oryx" Gas cooker Electric stove Hearths of domestic use used with the Benin one. Table n°1 Average characteristics of the pots. Type or the Shape of the pots Spherical Cylindrical Characteristic Pots Weight kg external Diameter cm 1 2 3 4 5 6 7 8 9 10 11 12 13 2,13 2,12 2,12 2,21 2,19 2,08 2,06 2,21 2,03 2,23 1,59 1,73 2,73 25 25 25 25 25 25 25 25 25 25 25 25 29 Height compared to the ground cm 20,3 20,3 20,3 20,3 20,3 20,3 20,3 20,3 20,3 20,3 12 12 13,8 International Journal of Advancements in Research & Technology, Volume 1, Issue 7, January-2013 ISSN 2278-7763 Table n°2 Characteristics of the hearths used N0 Characteristics of the stoves Code of the stoves Diameter of the pots (cm) Height from the ground (cm) Number of holes on the grid Holes diameter (cm) Variable - - 22 25 - 1,6 - 1 "3 stones" Osp0b Variable 2 Rural (terracotta) Placb 25 3 4 5 Metallic "Adokpe" double fuel stove "2 pots and chimney" improved "3 stones" stove "1 pot and chimney" "3 stones" Plmcb Plmcbc Pstcb 30 31,5 30 Pshtcb 30 34 - - "2 pots and chimney" improved "3 stones" " Adopké " sawdust stove P2shtcb 30 30 - - Plmcd Plmpc Pljcc Plmccb Flmccb* Plasc Plmcc P2acc Plm0k Psm0g Plm0g Plm0e 31,5 34 36 31,5 32,3 23 30 24,5 37,7 - 8 12 25 54 23 16 18 Multitude Multitude Multitude - 1,6 1,4 2,2 2 1,8 0,4 0,1 0,1 - 6 7 8 9 10 11 12 13 14 15 16 17 18 19 square coal pot Rim made coal pot Double fuel stoves Modified double fuels stove clay made coal pot "Nansu" imitation stove "Nansu" stove kerosene stove Gas cooker "Oryx" Gas cooker Electric stove 18,8 30,5 30 25,7 26,4 47 30,5 40 23,5 23 26,5 23 79,5 66 79,5 *( ) )( ( + ) (3) In these relations, M ci is the initial mass of fuel in kg; M cf is the final mass of fuel in kg; M vi is the mass of the pot empties in kg; M Pf stands for the final mass of the pot and its contents cooked in kg; M cp is the charcoal mass recovered in kg; t I is the initial moment of the mn test; t F represents the final moment of the mn test; c stand for the moisture content of fuel in % And PCI: the lower calorific value in kJ/kg. 4 THE EXPERIMENTAL SET The measuring instruments used for the tests are: A thermo-anemometer for the wind velocity measurement, A probe thermo-hygrometer " HUMICOR " H1100 for the temperature of and the moisture measurement of the environment air, A digital balance " SARTORIUS " 3100 of range 3,1kg, sensitive with a margin of 0,01 gr, Two mechanical scales (20 -30 kg) with sensitivity - 100 gr A digital wattmeter "VOLTCRAFT" M-3860 m, with sensitivity - 0,01W. The pots having been used for the tests are made of aluminum. They are of two types (tab.1): Spherical form convex bottom); there is ten of them and they are numbered from 1 to 10. They are used with wood and charcoal stoves, Cylindrical form (flat bottom), they are three and numbered from eleven to thirteen, they are used with fossile fuels and electric stoves. Table 2 shows the average characteristics of the hearths used for the test. The CCT was carried out for nineteen (19) types of stoves used in Benin. Three identical stoves are tested at the same time. This operation is repeated three times. All the tests were carried out with one kg of food and at the end of the test, the meal was weighed then tasted by six (06) housewives. For a better appreciation of the performances, three kings of food for which cooking duration is classified in (short, average and long were prepared: rice imported from Thailand, local bean called ‚Tofin‛', dry International Journal of Advancements in Research & Technology, Volume 1, Issue 7, January-2013 ISSN 2278-7763 corn 5 RESULTS AND ANALYSES The results of experimentation are gathered in table 3. The various losses on the stoves were compared with the stoves presenting the best performance. The cost of 1 kg or the kWh of fuel are those of May 2012, namely: 46, 20, 100, 713, 670 and 110 francs respectively for wood, sawdust, charcoal, kerosene, butane gas and electricity. Table 3 presents the consumptions, the costs of the cooking process, the time of cooking and the power of the stoves for the three prepared meals. For the meals with short cooking duration (rice), the stove with fossile fuels and electric have the best performances with respectively in kep/kg: 0.028; 0.029; 0.030 and 0.038 for the gas stove, the electric stove, the " Oryx " gas cooker and the kerosene fueled stove. The worst stoves are respectively: the " 3 stones " (0.186), the rim made coal pot (0.249), the improved ‛3 stone‛ – 1 pot stove, (0.253) and the hearth " 3 stones " improved, 1 pot (0.406). When one looks at the cost of fuels, it is noted that the cost of cooking process becomes higher for fuel wood; the following values in franc/kg are obtained : 9.41 for the double fuels stove, 11.40 for the Adokpe sawdust stove, 14.07 for the Adokpe metallic stove and 15.69 for the ‛2 pots and chimney‛ improved ‚3 stones‛ stove. Higher costs are observed for the kerosene stove (28.12), the rim made coal pot (34,80), the Oryx gas cooker (37,10) and the ‛1 pot‛ improved ‚3 stones‛ stove (42,66). Basing on the cooking process duration, the fastest stoves are: the Nansu stove (38.50), The double fuel stove, tested with charcoal (40.75), the rim made coal pot (41.00), the square coal pot (41.50). The slowest are: Adopke sawdust stove (63.25), the rural stove (terracotta) (65.00), the "1 pot and chimney" improved "3 stones" stove (67.75), the "1 pot" improved "3 stones" stove (148.5). It is observed, that this last stove presents the worst performances, considering the three parameters. Adopting a multicriterion analysis which consists in adding the different ranks, , one finds in first position the mixed hearth (cumulated rank: 14) and in last position, "1 pot" improved "3 stones" stove (cumulated rank: 57). For the meal with medium cooking process duration (bean), the stoves using fossil fuels and electric still have the best performances as in the preceding case with respectively 0.080; 0.089; 0.098 and 0.117 for the gas cooker, the " Oryx " gas cooker, the electric stove, and the kerosene stove. The stoves which occupied the last positions are respectively: the "3 stones" stove, (0.540), the rim made stove (0.545), the "1 pot and chimney" improved "3 stones" stove (0.549) and the "1 pot" improved "3 stones" stove (0,781). The behavior of the stove is identical to the preceding rice case. By taking account of the cost of the fuels, the cost of the cooking process is weaker for fuel wood with a score of: 23.04, the for the sawdust Adokpe stove, 26.93 for the metallic Adokpe, 32.62 for the double fuel stove and 39.71 for the "2 pots and chimney" improved "3 stones" stove. The highest costs are observed for the rim made stove (76.29), the "1 pot" improved "3 stones" stove (82.02), the kerosene (85.50) and the electric stove (126.12). Regarding the duration of the cooking process expressed in minutes, the fastest stoves are: the rim made (72.25), the double fuelled tested with firewood (76.50), the "Oryx" gas cooker (77.50), the modified double fuels stove tested with coal (78.25). The slowest stoves are: the electric stove (122.75), the gas cooker (123.50), the "3 stones" stove (128.50), the "1 pot" improved "3 stones" stove (180.25). It is observed for the three parameters that the latter stove presents the worst performances. The multicriterion analysis shows that the double fuel stove tested with firewood (cumulated renk: 11) stands in the first position and the "1 pot" improved "3 stones" stove (cumulated rank: 55) stands in the last rank. For the meal with the long duration cooking process (dry corn), the fossil fuel and the electric stoves present once again the best performances with the scores : 0.099, 0.124, 0.204 and 0.235 respectively for the electric stove, the gas cooker, the Oryx gas cooker and the kerosene stove. The worst stoves are respectively: the « 2 pots and chimney » improved "3 stones" (0.920), the "1 pot and chimney" "3 stones" (1.040), the « 1 pot » improved « 3 stones » stove (1.147) and the rim made coal pot (1.193). On the basis of the cost of fuels, the cost of the cooking process becomes weaker for wood fuels with 32.96 F/kg for the " Adopké " sawdust stove and the double fuel stove, 68.26 for the Nansu imitation stove. 68.39 for the metallic Adokpe and 76.00 for the rural stove (terracotta). The highest costs are observed for the Oryx gas cooker (125.41), the electric stove (127.53), rim made coal pot (166.99) and the kerosene stove (172.04). The fastest stoves are the rim made coal pot (94.50), Nansu stove (130,25), the double fuel stove tested with coal (145,25), the modified double fuels stove tested with coal (145,75). The slowest are the gas cooker (191.75), the "2 pots and chimney" improved "3 stones" stove(211,50), the "1 pot and chimney" improved "3 stones" (232) and the « 2 pots and chimney » improved "3 stones" (340,00). It is observed, for the three parameters that this latter stove presents bad performances. The multicriterion analysis shows that the first position is occupied by the "Nansu" imitation stove (cumulated rank 14) and the last is the "2 pots and chimney" improved "3 stones" (cumulated rank 52). Extending the multicriterion globally to the 3 types of meal, the most interesting stove is the double fuel one tested with fire wood (cumulated rank 53); the worst is the "1 pot" improved "3 stones" (cumulated rank 164). The most economic stoves in energy consumption are the those with fossil fuels namely the kerosene stove, the gas cooker, the Oryx gas cookers and electric stove. This consumption depends on the nature of the cooked meal. The analysis of the cooking process duration shows that the rim made and the " Nansu" stoves present the best performances. One can accuse their height under the pot * 2 + Figure 2 presents the normalized loss taking the most economical stove, the gas cooker (Psm0G) as reference. The stoves are x-axis is arranged as following: firewood, sawdust, charcoal, kerosene, gas and electricity. The losses are weaker for fuels located on the right (fossil and electric) for the three International Journal of Advancements in Research & Technology, Volume 1, Issue 7, January-2013 ISSN 2278-7763 types of meal. For more of stoves, the losses are lower for the meal of short cooking. The "2 pots and chimney" improved "3 stones" stove Pstcb and the rim made Pljcc present the highest losses in fuel consumption. For the former, this result raise questions about its past popularization. As for the latter, its lack of performance comes from its inadequate volume of its combustion chamber and of the effect of the wind. The losses of the rim made stove increases with the duration of cooking process. Among the stoves tested with charcoal, the "Nansu" presents the best performances for the three durations of cooking. Figure 3 shows the normalized waste in time the fastest stove, the rim made as reference for the three prepared meals. The rim made Pljcc was the quickest for the three types of meal. For the time of cooking of short duration, the "Nansu" stove was fast. The "2 pots and chimney" improved "3 stones" stove Pstcb having showed the greatest loss in consumption of energy appears to be the worst once again. The normalized monetary losses are represented on figure 4. It is especially this criterion which directs the households in the choice of the stoves. An inversion of the situation is observed. The more elaborated fuels are costly. Moreover, generally in the developing countries, the cost of the wood fuels does not integrate environmental concerns. The stoves with fossil fuels which showed very good performances concerning consumption become worse compared to the wood fuels stoves. Such a situation has been observed *2+ in spite of the subsidy granted in the 2002 year on fossil fuels. The sawdust stove appears to be more interesting for the three types of meal. After cooking using sawdust, the fuel remaining is not used anymore; this causes significant losses in consumption. This aspect, combined with the current cost of the sawdust encourages seeking means to add value to this fuel so that its calorific value increases towards that of the wood. If these conditions are met, the best of the stoves could be the sawdust one. The massive "2 pots and chimney" improved "3 stones" stove Pstcb is one of those showing the highest losses in cooking of short duration (rice). This fact may be due to the moisture accumulated in the mass of the stove. After cooking the short duration meal (rice), the performances obtained were worse than those concerning the following medium and long durations cooking processes. The rim made stove also presents high losses primarily due to the volume of its combustion chamber and to its high power which negatively serve the cooking of short duration meal (rice). In cooking of bean, a medium cooking time meal, the losses are less. The kerosene stove Plm0k used for these tests is not indicated for the cooking of a long cooking duration meal. It is noted that several stoves, even improved have presented longer cooking time than the "3 stones" stove. 6 CONCLUSION This study conducted on the stoves used in Benin showed that the criteria of performances targeted depend on the type of stove, the type of meal and the delivery price of the fuel. It also made it possible to detect the modifications needed in order to improve the performances of certain stoves; this constitutes one of the goals of this study. The research continues, with the objective to define a global criterion of appreciation of the stoves, also including the cost of the stoves. It has been also pointed out that the improved "3 stones" stoves are not economic. Further studies to improve their technology and a possible government intervention in the form of tax reduction on fossil fuels and electricity could arouse interests to the kerosene, the gas and the electric cookers with the target to decrease the pressure on the vegetal formations and to stop the advancing desert. BIBLIOGRAPHY *1+ *2+ *3+ *4+ *5+ *6+ *7+ *8+ ANJORIN M., AWANTO C., HOUNGAN C. A., FEIDT M., ‘’Détermination des performances techniques des foyers utilisés au Bénin par la technique d'ébullition de l'eau,’’ 2010. (SFT) ANJORIN M., AWANTO C., HOUNGAN C. A., FEIDT M., ’’Détermination des performances économiques des foyers utilisés au Bénin par la technique d'ébullition de l'eau. To be published’’, ANJORIN M., AWANTO C., HOUNGAN C. A., FEIDT M., ‘’Codification des foyers utilisés au Bénin par la technique d'ébullition de l'eau’’, 2010. (CIFEM Sénégal) LAWANI B. ABOU Mouftaou., ‘’Détermination des performances des fourneaux à usage domestique au Bénin par la technique de la cuisine contrôlée’’, Octobre 2002. (Mémoire de fin de cycle, CPU, UAC, Abomey-Calavi) De LEPLEIRE et al.,’’Guide technique des fourneaux à bois’’, (Edisud, Bois de feu, ENDA-SKAT 375p) MICUTA W., ‘’Des fourneaux modernes pour tous’’, 61p, 1984. (Edisud, ABF, Fondation de Bellerive) WESTHOFF Béatrice, GERMANN Dorci., ‘‘Foyers en images. Commission des Communautés Européennes, Bruxelles, 180 p. Bulletins d'information trimestrielle de la fondation pour la diffusion des foyers améliorés, Région Afrique de l'Ouest : Foyers améliorés n° 5 Avril 1992, Foyers améliorés n° 9 Avril 1993. International Journal of Advancements in Research & Technology, Volume 1, Issue 7, January-2013 ISSN 2278-7763 Table 3 Results of the tests with rice, bean and dry corn CS1: specific consumption (kg/kg, kWh/kg ; CS2: specific consumption (kep/kg ; Rg: row; Rgi: intermediate row; Rgf: final row; T: duration of cooking (mn ; Ct: cost (F/kg); P: power N0 Stoves "3 stones" 2 Rural (terracotta) 1 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 Metallic "Adokpé" double fuel stove "2 pots and chimney" improved "3 stones" stove "1 pot and chimney" "3 stones" "2 pots and chimney" improved "3 stones" " Adopké " sawdust stove square coal pot Rim made coal pot Double fuel stoves Modified double fuels stove clay made coal pot "Nansu" imitation stove "Nansu" stove kerosene stove Gas cooker "Oryx" Gas cooker Electric stove Code Rice results CS1 CS2 Rg Ct Rg T Bean results Rg Rgi P CS1 CS2 Rg Ct Rg T Dry corn results Rg Rgi P CS1 CS2 Rg Ct Rg T Rg Rgi P Rgf Osp0b 0,424 0,186 16 19,50 11 54,50 14 41 7,28 1,233 0,540 16 56,71 12 128,50 18 46 7,22 1,881 0,824 15 86,54 7 170,75 14 36 6,89 123 Placb 0,384 0,168 14 17,66 6 65,00 17 37 5,86 0,953 0,418 13 43,85 5 105,50 14 32 6,11 1,652 0,724 11 76,00 4 153,50 8 23 6,71 92 Plmcb 0,306 0,134 9 14,07 3 46,75 10 22 6,26 0,586 0,257 5 26,93 2 103,25 13 20 4,35 1,487 0,651 8 68,39 3 150,00 6 17 5,64 59 Plmcbc 0,205 0,090 5 43,80 4,44 0,709 0,311 6 32,62 3 6,88 1,853 0,812 13 85,23 6 154,75 9 28 7,56 53 Pstcb 9,41 1 8 14 0,927 0,406 19 42,66 19 148,50 19 57 76,50 2 11 5,97 1,783 0,781 19 82,02 17 180,25 19 55 7,64 2,617 1,147 18 120,40 15 340,00 19 52 8,14 164 Pshtcb 0,578 0,253 18 26,57 15 67,75 18 51 7,62 1,253 0,549 18 57,65 13 93,75 9 40 9,36 2,374 1,040 17 109,21 12 232,00 18 47 8,00 138 P2shtcb 0,341 0,149 10 15,69 4 59,50 15 29 5,90 0,863 0,378 12 39,71 4 5 21 9,76 2,099 0,920 16 96,56 10 211,50 17 43 8,79 93 Plmcd 0,570 0,170 15 11,40 2 63,25 16 33 6,28 1,152 0,344 10 23,04 1 115,75 15 26 4,59 1,648 0,492 6 32,96 1 165,75 12 19 5,66 78 6,96 0,648 0,463 14 64,82 14 95,75 11 39 6,40 0,938 0,670 9 93,79 9 146,25 5 6,20 91 Plmpc 0,220 0,157 12 22,04 13 41,50 81,75 4 29 0,348 0,249 17 34,80 17 41,00 3 37 11,76 0,763 0,545 17 76,29 16 72,25 Plmccb 0,216 0,154 11 21,63 12 40,75 2 25 7,56 0,665 0,475 15 66,54 15 98,00 12 42 7,79 1,138 0,813 14 113,77 14 145,25 3 31 7,20 98 Flmccb* 0,177 0,126 6 17,70 7 7 20 6,43 0,461 0,329 8 Pljcc Plasc 42,85 0,233 0,167 13 23,34 14 48,50 11 38 Plmcc 0,180 0,129 7 18,02 8 1 34 11,51 1,670 1,193 19 166,99 18 94,50 1 23 38 12,02 109 46,09 7 78,25 4 19 5,99 0,999 0,714 10 99,94 11 145,75 4 25 5,83 64 7,02 0,495 0,354 11 49,53 9 85,50 6 26 7,02 1,112 0,794 12 111,16 13 154,75 9 34 6,54 98 44,50 9 24 6,08 0,468 0,334 9 46,80 8 94,00 10 27 5,79 0,683 0,488 5 68,26 2 152,50 7 14 4,88 65 P2acc 0,184 0,131 8 18,41 10 38,50 1 19 6,99 0,446 0,319 7 44,61 6 86,00 7 20 5,74 0,905 0,647 7 90,51 8 130,25 2 17 6,33 56 Plm0k 0,039 0,038 4 28,12 16 42,00 6 26 1,94 0,120 0,117 4 85,50 18 88,50 8 30 2,19 0,241 0,235 4 172,04 19 167,25 13 36 2,01 92 Psm0g 0,026 0,028 1 17,37 5 48,50 11 17 1,32 0,074 0,080 1 49,53 1,20 0,114 0,124 2 Plm0g 0,027 0,030 3 18,28 9 41,75 1,56 0,082 0,089 2 54,78 11 77,50 5 17 Plm0e 0,337 0,029 2 37,10 18 51,75 13 33 9 123,50 17 27 5 191,75 16 23 1,23 67 16 1,89 0,187 0,204 3 125,41 16 158,50 11 30 1,73 63 1,27 1,147 0,098 3 126,12 19 122,75 16 38 1,31 1,160 0,099 1 127,53 17 181,75 15 33 1,02 104 3 76,19 International Journal of Advancements in Research & Technology, Volume 1, Issue 7, January-2013 ISSN 2278-7763 RizRice 90,0 Bean Haricot 80,0 Maïs dry sec corn 70,0 60,0 50,0 40,0 30,0 20,0 10,0 0,0 Stoves Code Fig. 2. Loss in consumption of energy for rice, bean and dry corn 100,0 Loss in reduced variable Time of cooking in % Loss in reduced variable Consumption in % 100,0 90,0 RizRice 80,0 Bean Haricot 70,0 Maïs sec dry corn 60,0 50,0 40,0 30,0 20,0 10,0 0,0 Stoves code International Journal of Advancements in Research & Technology, Volume 1, Issue 7, January-2013 ISSN 2278-7763 Fig. 3 Waste of time of cooking for rice, bean and dry corn Monetary loss in variable reduced in % 100,0 Riz Rice 90,0 Bean Haricot 80,0 Maïs sec dry corn 70,0 60,0 50,0 40,0 30,0 20,0 10,0 0,0 STOVES CODE Fig. 4. Monetary loss for rice, bean and dry corn