SYNTHESIS, CHARACTERIZATION AND CATALYTIC PROPERTIES OF TITANIUM CONTAINING SILICA AEROGEL

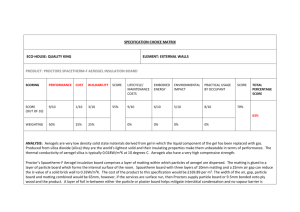

advertisement