CIFE CIFE Seed Proposal Summary Page 2007-2008 Projects

advertisement

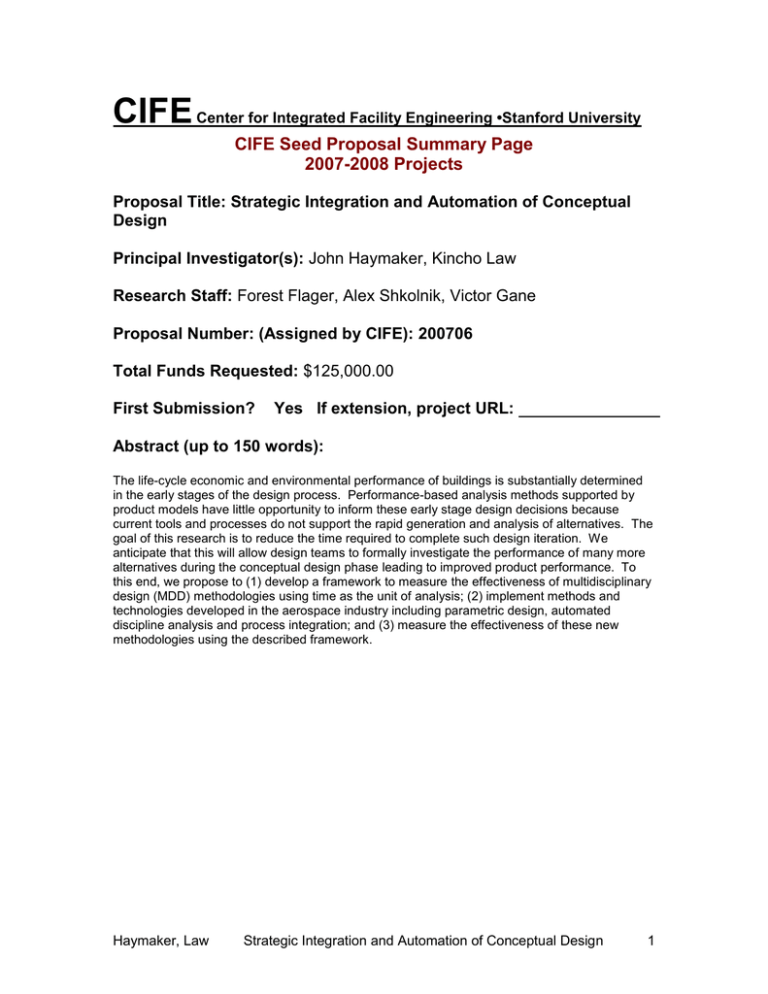

CIFE Center for Integrated Facility Engineering •Stanford University CIFE Seed Proposal Summary Page 2007-2008 Projects Proposal Title: Strategic Integration and Automation of Conceptual Design Principal Investigator(s): John Haymaker, Kincho Law Research Staff: Forest Flager, Alex Shkolnik, Victor Gane Proposal Number: (Assigned by CIFE): 200706 Total Funds Requested: $125,000.00 First Submission? Yes If extension, project URL: Abstract (up to 150 words): The life-cycle economic and environmental performance of buildings is substantially determined in the early stages of the design process. Performance-based analysis methods supported by product models have little opportunity to inform these early stage design decisions because current tools and processes do not support the rapid generation and analysis of alternatives. The goal of this research is to reduce the time required to complete such design iteration. We anticipate that this will allow design teams to formally investigate the performance of many more alternatives during the conceptual design phase leading to improved product performance. To this end, we propose to (1) develop a framework to measure the effectiveness of multidisciplinary design (MDD) methodologies using time as the unit of analysis; (2) implement methods and technologies developed in the aerospace industry including parametric design, automated discipline analysis and process integration; and (3) measure the effectiveness of these new methodologies using the described framework. Haymaker, Law Strategic Integration and Automation of Conceptual Design 1 1 Observed Problem Advancements in computer-based Building Information Modeling (BIM) and analysis methods now allow architects and engineers to simulate building performance in a virtual environment. The number of performance criteria which can be analyzed from product models now includes to some extent architectural, structural, mechanical (energy), acoustical, lighting and an expanding list of other concerns [Fischer 2006]. Consequently, performance-based design supported by product models is becoming state-of-the-art practice [Hänninen 2006]. However, the potential of this technology to inform the early stages of the design process has not been fully realized because current tools and processes do not support the rapid generation and evaluation of alternatives. The amount of time required to generate and evaluate a design option using model-based methods means that very few, if any, options can be adequately studied during the conceptual design phase before a decision must be taken. Often engineers resort to only using model-based methods to validate a chosen design option, rather than to rigorously explore alternatives. The inability to quickly generate multiple options and to rigorously analyze them from the perspective of multiple disciplines invariably leaves unexplored a broad area of the design space. The unexplored regions of the design space - different building orientations, massing, internal layouts and combinations of systems (i.e. structural and mechanical) - potentially may contain better performing building solutions than anything previously considered [Shea et. al. 2005]. The goal of this research is to identify and test methods that reduce the time required for architects and multidisciplinary engineers to complete a design iteration, which involves the generation and evaluation of a given design option using model-based methods. The current AEC process requires a significant amount of professionals’ time and the duplication of effort to integrate, communicate, and coordinate information in order to complete design iteration. Following is our diagnosis of the problem to be addressed by this research. 1.1 Benchmarking the Current AEC Process Process Description The conceptual design process can be characterized by four iterative steps (Fig. 1): (A) the architect creates a design option based on perceived stakeholder requirements and, depending on the project, engineering heuristics. (B) The architectural team represents the option in the form of sketches, 2-D drawing and/or a 3-D CAD model to communicate with the project team. (C) The engineering them then spends a significant amount of time integrating this information in order to construct discipline-specific analysis models to simulate the behavior of a particular building system. The analytic results are then used by the engineering team to complete the initial design of their respective building systems which are each, in turn, communicated to the rest of the design team in the form of sketches, 2-D architectural drawing and/or a 3-D CAD model. (D) Finally, the design team conducts meetings to ensure that the building systems are coordinated and are consistent with the architectural concept. The coordination process is also labor intensive and typically focuses on resolving conflicts so as to reach a feasible design option rather than optimizing the performance of the building as a whole. Haymaker, Law Strategic Integration and Automation of Conceptual Design 2 Figure 1: Diagram of the current building design process Process Metrics To assess the effectiveness of the current process and provide a baseline for future research using time as the unit of analysis, we conducted a survey of architects and multidisciplinary engineers at a leading practice1. The goal of the survey was to determine (1) approximately how many design iterations are possible within a standard project timeline and how long iteration customarily takes as well as (2) the relative amount of time spent on key process tasks defined in Figure 2. To provide a framework for analysis, these tasks were then classified into three basic categories – strategy and specification, execution, and management. The following working definitions were given to those surveyed: Design option: A particular configuration of the following variables: building orientation, massing and system types (e.g. structural – steel framing, mechanical – radiant floor system). Changes to one of more of these variables constitute a distinct design option. Design iteration: The generation and analysis of a single design option using model-based methods (Figure 1: steps A-D). The level of information required to demonstrate the feasibility of an option was set to a common industry milestone known as “25% Design Development (DD)”, which includes the preparation of architectural drawings, the selection of building systems and the preliminary positioning and sizing of system component The results of the survey are shown in Figure 3. These results suggest that architects and engineers spend the majority of their time managing design information (58%) and relatively less time executing (36%) and specifying (6%) this information. 1 Survey results were obtained in February, 2007 from 50 design professionals (5 architects, 45 multidisciplinary engineers) working at Ove Arup and Partners (www.arup.com) in San Francisco, USA and London, England. Haymaker, Law Strategic Integration and Automation of Conceptual Design 3 Strategy and Specification Multidisciplinary Design Tasks Tasks (Processes) Establishing an overall design strategy by determining the required tasks, deliverables and responsible personnel. Schemas (Information) Establishing the overall implementation strategy by determining what tools will be used to accomplish each task and the content and format of information to be exchanged Execute Integrate Management Definition Communicate Coordinate The activities directly pertaining to generating and analyzing design options and performing analyses (e.g. creating new geometric features, performing analyses and interpreting results). The activities pertaining to the exchange of information between tasks (e.g. converting and ensuring accuracy of input and output information to/from a specified format). The activities pertaining to exchange of information between persons responsible for the tasks (e.g. communicating the nature of your task and local schema). The activities pertaining to detection and resolution of conflicts and management of changes (e.g. detecting space conflicts between systems, propagating a local change throughout the entire design). Figure 2: Framework for measuring process effectiveness Relative time spent on design tasks by category Management (8%) 6% Specification (6%) Number and duration of design iterations 58% Initial Subsequent (avg.) 7 weeks 5 weeks Average Number of Iterations Per Project 36% Management Specification Execution Duration of Design Iterations 2.8 Execution (36%) Figure 3: AEC design process metrics Haymaker, Law Strategic Integration and Automation of Conceptual Design 4 1.2 Problem Summary and Intuition Conceptual design decisions have a significant impact of the life-cycle economic and environmental performance of buildings. Performance based analysis methods supported by product models have little opportunity to influence these early stage design decisions due to schedule limitations. According to our initial survey it takes architects and engineers over one month to generate and analyze a design option using product models and, typically, less than three such iterations are completed during the conceptual design phase. This appears to be due to a collection of tool and process limitations. Part of the problem is that designers’ tools are intended to generate static design options rather than help them define and explore solution spaces. Another problem is that when information is produced, little consideration is given as to how to represent that information to facilitate multidisciplinary analysis. Many have written about the difficulties of tools used by different disciplines to share data effectively [i.e., Gallaher 2004]. As a result, design professionals appear to be spending less than half of their time doing work directly related to design and analysis. The majority of this time is spent managing design information, including manually integrating and representing this information in their task-specific format, and coordinating their solutions (Fig. 2). These limitations prevent a more complete and systematic exploration of the design space based on multidisciplinary model-based performance analysis. The aerospace industry is in the process of overcoming a similar set of limitations by adopting a suite of technologies and methodologies to support multidisciplinary analysis (MDA) using product models, among them parametric geometry definition, integrated design schemas, automated discipline analysis and multidisciplinary optimization leading to improved process and product performance [Flager and Haymaker, 2007]. Our intuition is that these methods and technologies can be adopted by AEC design teams to significantly reduce the time required to generate and analyze a design option using model-based methods. Reducing the design iteration time will allow architects and engineers to formally investigate the performance of many more design alternatives within the current project timeline than is currently possible. This work has the potential to improve building performance in terms of initial cost, energy performance and overall quality. Figure 5: Results of an MDO process in which Boeing optimized the shape of a hypersonic vehicle. Each point in the graph represents a unique design. The desirable designs have a relatively low take off gross weight (TOGW) ratio and a positive excess propellant fraction 2 2 Image courtesy of Geojoe Kuruvila, Associate Technical Fellow, The Boeing Company Haymaker, Law Strategic Integration and Automation of Conceptual Design 5 2 Theoretical Points of Departure In this section we first describe the fundamental points of departure and their limitations which we propose to build upon with our research. We then describe some relationships of our research to other emerging methodologies which this proposal will contribute to in the future. 2.1 Fundamental Points of Departure Parametric computer-aided design (CAD) is a design methodology used to create and manage geometric dependencies within a model. The use of parametric tools can enable designers to shift from creators of single designs to designers of systems of inputs and outputs that generate design spaces. Parametric tools are beginning to be actively used in academia and industry [i.e., Burry 2000]; however, the extent to which parametric tools have been used to support modelbased MDA processes for conceptual design has been limited by a lack of integration with analysis processes. Further work is needed to determine if the appropriate geometric dependencies can be identified and captured within a parametric model, and if the necessary analysis representations can be defined in advance for a range of options. BPEL, XML and IFC are task and schema specifications that provide standard ways to define processes and information. Business Process Execution Language (BPEL) is an engine for specifying processes, coordinating communication between services and parties, implementing parallel processing of activities, manipulating data between partner interactions and providing consistent exception handling [Cobban, M. 2004]. EXtensible Markup Language (XML), is a set of rules for designing text formats to structure information. Several industry-specific sets of rules of XML-based schemas are currently being developed (i.e. aecXML, gbXML, ecoXML) but none have emerged to gain wide industry acceptance. Industry Foundation Classes (IFC) is an object oriented data model used to describe the relationships, and properties of building specific objects. To date its industry implementation is limited due to gaps in capturing the entire extent of AEC information and the lack of software systems that support it. In summary, a wide variety of data specific formats are available to enable interoperability which can be customized to process specific needs, but more research is needed to establish how to apply these standards to conceptual building design Process Integration and Design Optimization (PIDO), an emerging line of software products that aims to give users the ability to integrate processes that utilize multiple digital design and analysis tools. These products allow software tools to be “wrapped” and published on a computing network. This allows disciplines to keep ownership of their codes, maintain and upgrade them, and serve them from their preferred computing platform. PIDO tools also provide a graphical environment which permits users to select published components and graphically link their inputs and outputs as required to create an integrated MDA model. Among limitations of PIDO tools are the lack of support of various process components and a narrow problem focus that does not explicitly address communication and coordination issues. Very little work has been done to date to test the effectiveness of these frameworks in the AEC domain. Narratives [Haymaker, J. et. al. 2004] provide a means to describe and communicate the design process using an acyclic graph structure. Each node in the graph corresponds to a defined reasoning process which operates on designated inputs and outputs. Narratives help AEC professionals communicate multidisciplinary design processes and the information models used in these processes. However, Narratives do not explicitly facilitate the exchange or coordination of information for the described process. Haymaker, Law Strategic Integration and Automation of Conceptual Design 6 2.2 Relationship to other Methodologies Product Lifecycle Management (PLM) is an approach within systems engineering that takes a product from early conceptual stages all the way through manufacturing, maintenance and disposal. In industry PLM solutions allow collaborative creation, secure management and use of product definition information, support customers and supply partners as well as integrate people, processes, business systems and information [CIMdata, 2007]. The complicated nature of product design, manufacturing and supply within an evolving global market has forced PLM systems to develop technologies to help define, execute, measure, and manage key productrelated business processes and workflows. PLM has begun including Business Process Management (BPM) solutions, [McClellan, M., Harrison-Broninski, K. 2006]. As the nature of PLM is adapting to fast changing and dispersed product development practices its solutions come closer to addressing problems that characterize the AEC industry. Semantic Information Exchange. While BPM does offer solutions to organization and workflow management, an alternate, semantic vision persists in academia and includes KIF, the knowledge interchange format, PIF, the process interchange format and PSL, the process specification language. These logic based approaches see machine interpretation and reasoning as being an integral part of process control and management. One application of such an approach within AEC is detailed in a PhD thesis entitled “A Distributed Problem Solving Approach to Collaborative Facility Engineering Through Agent-Based Software Integration” [Khedro, T., 1994]. The dissertation presents a framework for integration of facility design and engineering software applications based on the Agent-Based Software Engineering approach [Genesereth, M. R., 1992]. The framework offers a distributed and automated exchange of design information, knowledge and constraints based on KIF and organizational structuring of designers with conflict negotiation strategies. This approach, however, has not been validated in real world AEC projects and was developed with mostly theoretical considerations in mind. The meeting of PLM and BPM worlds and the semantic vision of information exchange can prove to be a foundation for emergence of new ideas which can be mapped to AEC practice. Our research, which includes understanding current AEC practice and developing an analysis framework to evaluate how methodologies impact multi-disciplinary design, serves as the first step to establishing which of these ideas are applicable to AEC. 3 Research Questions 4 How to measure the effectiveness of conceptual MDA processes? What is the current conceptual MDA process and how well does it perform? How can model-based design and analysis information be constructed more effectively? How can model-based design and analysis information be exchanged more effectively? How can model-based design and analysis information be managed more effectively? Research Methods Our research methods can be broken down into two concurrent parts, one dealing with strategy and problem exploration and the second dealing with implementation and testing. Part one consists of three stages: (1a) evaluation of two current MDA processes, (1b) development of a framework to measure methodology effectiveness and (1c) exploration of data schema interoperability. Part two, the implementation and testing, consists of two stages: (2a) incorporation of parametric modeling into current MDA processes and (2b) process integration and automation. We also will measure the effectiveness of each of our proposed interventions to Haymaker, Law Strategic Integration and Automation of Conceptual Design 7 current practice and document detailed comparison studies. We describe all of the stages in detail below. 1a. Evaluate current MDA processes: We will evaluate the MDA processes of two leading AE firms: SOM and Arup. Each firm has multiple offices in North America, Europe and Asia. These firms represent a reasonable diversity in terms of organization structure and domain of focus. Arup is an Engineering firm that is usually a consultant for an architect, whereas SOM hires engineering consultants, and sometimes uses their own multidisciplinary practice. At SOM, we will document the San Francisco Trans Bay or similar high-rise project. At Arup, we will observe the Stanford Graduate School of Business project. Our evaluation will be conducted through direct interviews of project architects, engineers and managers. 1b. Development of our framework: Relying on work done within the areas of systems engineering, workflow management and AEC we will continue to expand our framework to measure methodology effectiveness (see Figure 2) to precisely characterize the challenges faced by teams of multidisciplinary professionals on AEC projects. In addition to using this framework to assess the methodologies we will implement as part of this proposal, Methodologies found within AE and parallel industry and academia will be speculatively evaluated within our framework. These speculative predictions will be used to propose future work and formulate specific problems that address challenges faced within AE design. 1c. Explore data schema interoperability: The directed interviews described above will also be used to identify the existing structure and format of model-based information that is exchanged on the selected projects. This research will be coupled with literature review of data schemas currently researched in the AEC and parallel industries. This information will be studied to recommend an existing or infer a new data schema to facilitate interoperability. We will then specify the format and structure of information to be exchanged for the selected project. This process will resolve the information transfer protocols between parametric tools such as Digital Project or CATIA and analysis tools (i.e. ETABS - structural, ECOTECT - Incident solar radiation, Flovent - CFD, etc). 2a. Incorporate parametric modeling into MDA processes: We will formalize geometric dependencies between design and analysis representations and automate this reasoning using parametric tools. This model is intended to test if geometric dependencies can be defined to generate a feasible solution space, and if the necessary analysis representations can be defined in advance and the dependencies captured in the model such that engineering analysis geometry can be created in parallel with the architectural model. We will implement the described parametric models and compare the results to current practice. 2b. Process Integration and Automation: Two phases will be considered. Both will rely on our study of data schema interoperability (see above) as we will select the data schema most appropriate to our modeled process. The first phase entails automating the data extraction from the created parametric models for use within analysis software and other tools. The second involves using commercial PIDO software (Phoenix Integration, ESTECO, Engineous software) to implement the modeling and analyses portions of the evaluated MDA processes. An exploration of the design space will be conducted with resulting design performance improvements documented. Haymaker, Law Strategic Integration and Automation of Conceptual Design 8 5 Research Impact 5.1 Contribution to Research The proposed research will document the implementation of methodologies and technologies developed in the aerospace industry to support multidisciplinary design processes on AEC projects, among them parametric geometry definition, automated discipline analysis and multidisciplinary optimization (MDO). We will provide a framework to scientifically assess the proposed methodologies compared to current AEC practice using time as the unit of analysis. We anticipate that this research will lead to an improved understanding of both the current AEC design process as well as the potential benefits of the proposed methodologies to AEC. 5.2 Contribution to Professional Practice The goal of this research is to reduce the amount of time required to generate and evaluate a design option using model-based methods. Reducing the simulation cycle time will allow architects and engineers to formally investigate the performance of many more design alternatives within the current project timeline than is currently possible. This work has the potential to improve building performance in terms of initial cost, sustainability and overall quality. 6 Funding, Schedule and Deliverables 6.1 Funding We seek funding for 2 - 50 % Research Assistantships for 3 quarters and for one programmer for this period of time for a total of $125,000. Forest Flager’s participation in this research is covered by Stanford Graduate Fellowship (SGF) funding. We will use this work to formulate a proposal to the National Science Foundation (NSF) and to seek additional funding from our industry partners, Arup and SOM, who have agreed to dedicate their time and provide access to current projects which will serve as case studies for our research. 6.2 Schedule and Deliverables Quarter 1: (1) Evaluate current design AEC processes based on directed interviews with Arup and SOM staff. Forest Flager has already worked for Arup (London and San Francisco) for approximately three years, and Victor Gane has worked for SOM (Chicago and San Francisco) for over two years. Both are ideally situated to collect data on ongoing projects. Alex Shkolnik will formalize the framework categories along with task-specific metrics and provide evaluation representations. The deliverables are: Narrative (process diagram): We will develop detailed Narratives to document the people, tools, reasoning, information used, and information constructed at each step in the process. Measure of current MDA practice: Documented initial framework together with data representing our findings of challenges within current MDA practice. (2) Explore data schema interoperability to identify and document the most compatible methodology to exchange information between design generation and design analyses type processes (tasks) which were identified in the evaluation of current MDA. Alex Shkolnik will perform this study with input from Forest Flager and Victor Gane. The deliverables include a survey of effective approaches for interoperability compatible with considered processes. The survey will document advantages and disadvantages of the approaches reviewed. Haymaker, Law Strategic Integration and Automation of Conceptual Design 9 (3) Implement a design space exploration study using Process Integration and Design Optimization (PIDO) software for a small subset of one of our AEC projects. Quarter 2: (1) Complete all parametric modeling required for the SOM and Arup processes. Victor Gane will lead this effort with Forest Flager and Alex Shkolnik participating. Each contributor has an extensive parametric modeling background. (2) Implement the data schema selected during Quarter 1 ensuring information flow at each node (process) within the Narrative developed during Quarter 1. Forest Flager will head this effort with technical aspects implemented by Alex Shkolnik. Victor Gane will also provide his expertise with node (process) specific requirements. The deliverables for this step are two non-automated but integrated processes simulating SOM and Arup design generation and analysis tasks with the intervention of parametric technology and our chosen data schema approach. (3) Use our framework to evaluate the impact of parametric techniques and our chosen data schema. The deliverables are the documentation of the two evaluations and a discussion of the advantages and disadvantages of both. Quarter 3: (1) The final quarter will be spent implementing the two processes in a PIDO software. The deliverables are two integrated and automated processes simulating SOM and Arup design generation and analysis tasks. Forest Flager and Alex Shkolnik will head this effort with Forest Flager providing engineering expertise and Alex Shkonik providing technical assistance and optimization expertise. (2) Arrive at a fully developed framework for evaluating methodology effectiveness and go through an evaluation the impact of PIDO methodologies within MDA practice. (3) During this quarter the final framework will be used to collect evaluation of methodologies from AEC and parallel industry and academia (see Points of Departure: Relationship to other Methodologies Section). Alex Shkonik will conduct this study delivering documented evaluations and a discussion of the mapping of specific methodologies from AEC and parallel industry and academia. References Burry, M.C. (2003) “Between Intuition and Process: Parametric Design and Rapid Prototyping”. In Branko Koarevic (Ed.). Architecture in the Digital Age, Spon Press, London. Cobban, M. (2004). “What is BPEL and why is it so important to my business?”. SoftCare EC, Inc CIMdata, Inc. provides worldwide strategic Product Lifecycle Management (PLM) consulting and program support, indepth research, and education for both industrial organizations and suppliers of technologies and services seeking competitive advantage in the global economy. Gallaher, M. P., et. al. (2004). “Cost Analysis of Inadequate Interoperability in the U.S. Capital Facilities Industry”. Technical Report GRC 04-867, National Institute of Standards and Technology (NIST), Gaithersburg, MD. Genesereth, M. R., (1992). “An Agent-Based Framework for Software Interoperability”. Proceedings of DARPA Software Technology Conference, Pages 359-366. Fischer, M. (2006). “Formalizing Construction Knowledge for Concurrent Performance-Based Design”. In Smith, I. (Ed.). Intelligent Computing in Engineering and Architecture. Springer, New York, NY, pp. 186-205 Flager, F., Haymaker, J. (2007). “A Comparison of Multidisciplinary Design, Analysis and Optimization Processes in the Building Construction and Aerospace Industries”. EG-ICE conference in Maribor, Slovenia, June 27-29. Hänninen, R. (2006). “Building Lifecycle Performance Management and Integrated Design Processes: How to Benefit from Building Information Models and Interoperability in Performance Management”. Invited presentation, Watson Seminar Series, Stanford University. Haymaker, J., et. al. (2004). “Engineering test cases to motivate the formalization of an AEC project model as a directed acyclic graph of views and dependencies,” ITcon Vol. 9. Khedro, T., (1994). “A Distributed Problem Solving Approach To Collaborative Facility Engineering Through Agent-Based Software Integration”. PhD Thesis, Stanford University. McClellan, M., Harrison-Broninski, K. (2006). “Product Meets Process”. CPM Media LLC. Shea, K., Aish, R., and Gourtovaia, M. (2005). “Towards Integrated Performance-driven Generative Design Tools.” In Automation in Construction 14(2), pp. 253-264 Haymaker, Law Strategic Integration and Automation of Conceptual Design 10 6.3 Itemized Budget Project: CEE-FY07-481 Assessment of MDA - CIFE proposal for 2007-2008 Department: Civil Engineering Principal Investigator: HAYMAKER, JOHN (Asst Prof) - CE Administrator: L. Unerdem Period 1 All Periods 10/01/07 - 9/30/2008 10/01/07 - 09/30/08 % Amount Total Amount Senior Personnel Haymaker, John (Asst Prof) Law, Kincho Prof) Graduate Students 2007, RA - Post Quals, Grad (Res Asst) 2007, RA - Post Quals, Grad (Res Asst) Contingent Staff CEE-for Prof. Haymaker, Programmer (Programmer) Total Salaries Benefits Faculty Graduate Contingent Total Salaries and Benefits Tuition Tuition for 2 50% PhD Students (3 quarters) Total Direct Costs Modified Total Direct Costs University IDC Costs Total IDC Costs Annual Amount Requested acad smmr acad smmr 1 1 1 1 1,082 360 2,000 677 1,082 360 2,000 677 acad smmr acad smmr 50 0 50 0 22,248 0 22,248 0 22,248 0 22,248 0 99.7 40,000 85,938 40,000 85,938 428 1,691 3,360 91,417 428 1,691 3,360 91,417 30,906 122,323 91,417 30,906 122,323 91,417 125,000 125,000 cal Rates Used in Budget Calculations Benefit Rates Faculty: UFY08 29.70%; UFY09 29.70% Graduate: UFY08 03.80%; UFY09 03.80% Contingent: UFY08 08.40%; UFY09 08.40% Indirect Cost Rate Special Rate: UFY08 00.00%; UFY09 00.00% The budgeted salary amount is comprised of the direct effort for the project plus 8.65% vacation accrual/disability sick leave (DSL) for exempt employees and 7.35% for non-exempt employees. These amounts do not exceed total salary. The vacation accrual/DSL rates will be charged at the time of the salary expenditure. No net salary will be charged when the employee is on vacation, disability or worker’s compensation. Haymaker, Law Strategic Integration and Automation of Conceptual Design 11