Document 14650859

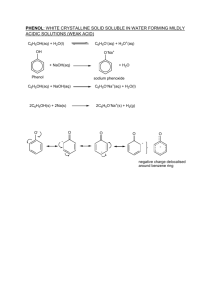

advertisement