Camera Lab 5 Manufacturing & Materials Sheet Metal Blanking

advertisement

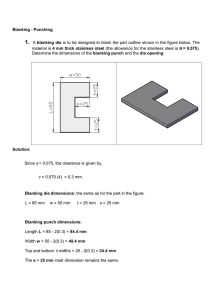

Camera Lab 5 Manufacturing & Materials Sheet Metal Blanking Introduction: Several camera components are manufactured from sheet metal, including the shutter (steel) and the copper strip that connects the shutter to the circuit board. The purpose of this demonstration is to illustrate the type of equipment (mechanical press) and tooling (blanking die) used to manufacture sheet metal components. The first step in sheet metal component manufacture is to cut out the shape of the part from the raw sheet material. This process is called blanking. Activity: In this demonstration, a blanking die has been set up on a mechanically actuated press that is capable of generating about 30 tons of force on the punch. The die is designed to cut out the shape of the State of Ohio all at once. The force required for this blanking operation depends on the strength of the sheet material, the thickness of the sheet material, and the overall length of the cut (perimeter of the punch). The press has been instrumented with strain gages on its columns and when the press is actuated, the tonnage applied to the punch to blank out the part will be recorded. Analysis: Using the formulation below, estimate the punch load required to blank out the State of Ohio. The 0.7 is a multiplier that in essence converts the UTS of the sheet into the equivalent shear strength. P = 0.7(UTS)(t)(L) Where: P UTS t L = punch load = ultimate tensile strength of material = material thickness = perimeter of punch Discussion Question: Calculate and explain the % difference between the calculated and measured mean punch loads for your group. What do you think accounts for the variation in measurement? Camera Lab 5 Sheet Metal Blanking 1