Press work

advertisement

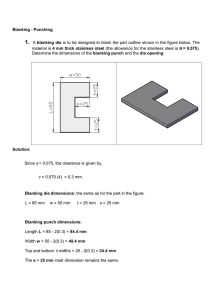

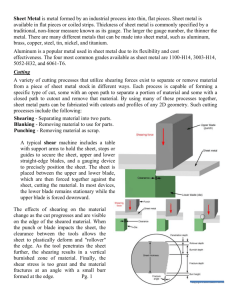

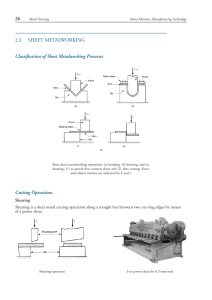

Submitted to Puneet kamboj Press working processes make use of large forces by press tools for a short interval of time which result in cutting or shaping the sheet metal Press working process does not involve heating of the part and high surface finish can be obtain. Press worked part do not require any machining process. A press working operation involves application of large forces by press tool to cut or shape the sheet metal The press working operation is generally completed in one stroke of the press and often result in the production of a finished part in less than one second Shearing Blanking Piercing Trimming Punching Notching Shaving Embossing stamping Shearing:-Separating material into two parts Blanking:- Removing material to use for parts. Punching:-Removing material as scrap Blanking is a cutting process in which a piece of sheet metal is removed from a larger piece of stock by applying a great shearing force. the piece removed, called the blank, is not scrap The blanking process requires a blanking press, sheet metal stock, blanking punch, and blanking die. The sheet metal stock is placed over the die in the blanking press. The die, instead of having a cavity, has a cut out in the shape of the desired part and must be custom made unless a standard shape is being formed. The hydraulic press drives the punch downward at high speed into the sheet. A small clearance, typically 10-20% of the material thickness, exists between the punch and die. When the punch impacts the sheet, the metal in this clearance quickly bends and then fractures. The blank which has been sheared from the stock now falls freely into the gap in the die. This process is extremely fast, with some blanking presses capable of performing over 1000 strokes per minute. Punching is a the cutting of a slug from the metal to produce a hole by applying a great enough shearing force. Punching is very similar to blanking except that the removed material, called the slug, is scrap and leaves behind the desired internal feature in the sheet, such as a hole or slot. Punching can be used to produce holes and cut outs of various shapes and sizes. The punching process requires a punch press, sheet metal stock, punch, and die. The sheet metal stock is positioned between the punch and die inside the punch press. The die, located underneath the sheet, The punch press drives the punch downward at high speed through the sheet and into the die below. There is a small clearance between the edge of the punch and the die, causing the material to quickly bend and fracture. The slug that is punched out of the sheet falls freely through the tapered opening in the die. During any working process in which the part in place by the press, the outer edge of the part which is the area usually gripped, become marked and scored . Trimming is the cutting off of this excess of metal edge. Trimming may be performed horizontally or vertically, depending upon the configuration of the part. Piercing is punching process. It is use to make hole. In piercing a pointed bullet shaped punch is forced through the sheet metal to produce hole. Notching is the cutting of relatively small indention in the edge of a strip or part Shaving is a secondary searing or cutting operation in which the surface of a previously cut edge is finished or smooth.